Vacuum compression self-foaming thermal insulation system and construction method thereof

A technology of vacuum compression and heat preservation system, which is applied in the direction of heat preservation, construction, building components, etc. It can solve the problems of material compactness, quality assurance, construction convenience that cannot meet the growing demand, and the transportation of wall heat preservation system is inconvenient. Improving construction quality and convenience, improving convenience, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the accompanying drawings.

[0035] The embodiment of the present invention discloses a vacuum compression self-foaming thermal insulation system and a construction method thereof.

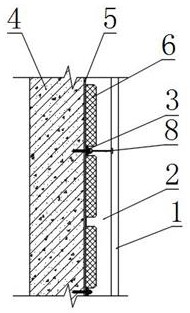

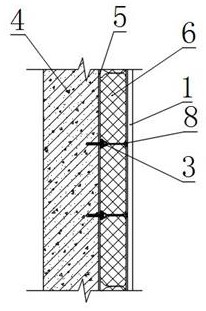

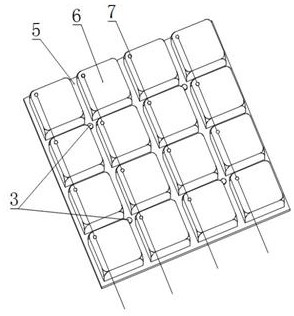

[0036] refer to figure 1 and figure 2 , including the thermal insulation assembly and the welded wire mesh 1, and the expansion gap 2 arranged between the thermal insulation assembly and the welded wire mesh, the thermal insulation assembly is arranged on the side of the wall 4 through the fastener 1 3, and the welded wire mesh 1 passes through the Fastener two 8 is connected with the fastener one 3, the number of the fastener one 3 and the fastener two 8 is several, the fastener one 3 and the fastener two 8 are both Insulation bolts. The head of the fastener one 3 is provided with an internal thread, the thread on the outer side of the bottom of the screw of the fastener two 8 is matched with the inner th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com