Method of accelerating decomposition of maize straw retention

A technology of corn stalks and corn stalk powder, which is applied in the field of accelerating the decomposition of corn stalks, which can solve the problems of difficulty in colonization, infecting the inside of straws, and insufficient contact with bacteria agents, so as to accelerate the process of returning to the field and promote decomposition , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The degrading bacteria were screened from the soil of rotten leaves in Zijin Mountain, Nanjing. The suspension of the soil samples diluted step by step was applied to the CMC-Congo red plate by the gradient dilution coating method, and cultured at 30°C to screen the cellulose-degrading bacteria. The formula of the above-mentioned CMC-Congo red medium is: sodium carboxymethylcellulose (CMC-Na) 10g, (NH 4 ) 2 SO 4 2g, KH 2 PO 4 1g, MgSO 4 ·7H 2 O0.5g, Congo red 0.2g, agar 20g, water 1000mL, autoclave at 121℃ for 20min.

[0029] Purify and isolate strains that produce larger transparent circles and grow faster on the CMC-Congo red plate, and then inoculate them into a rice straw powder medium with rice straw as the only carbon source (the formula of the rice straw powder medium is: Dry crushed rice straw powder 10g, KH 2 PO 4 3.0g; NaNO 3 3.0g; CaCl 2 0.5g; MgSO 4 ·7H 2 O0.5g, FeSO 4 ·7H 2 O0.0075g, MnSO 4 ·H 2 O0.0025g, ZnSO 4 0.002g, CoCl 2 0.003g, 20g...

Embodiment 2

[0031] Inoculate the strain NJGZ-2 into a conical flask containing 50 mL of spore-forming medium, culture it statically at 30°C for 7 days, then add 30 mL of sterile water and shake it on a shaker for 30 minutes, filter the culture with sterile gauze to get the spore suspension liquid, adjust the spore concentration in the spore suspension to 10 with sterile water 7 cfu / mL, the straw-degrading bacterial agent is obtained.

[0032] The preparation of the sporulation medium: 10.0 g of corn straw powder, 5.0 g of peptone, 2.0 g of yeast powder, 0.3 g of urea, 1000 mL of water, natural pH, autoclaving at 121° C. for 20 min.

[0033] The corn stalk powder is the corn stalk powder obtained by drying the corn stalks until the water content is below 1%, crushing and passing through a 30-mesh sieve.

Embodiment 3

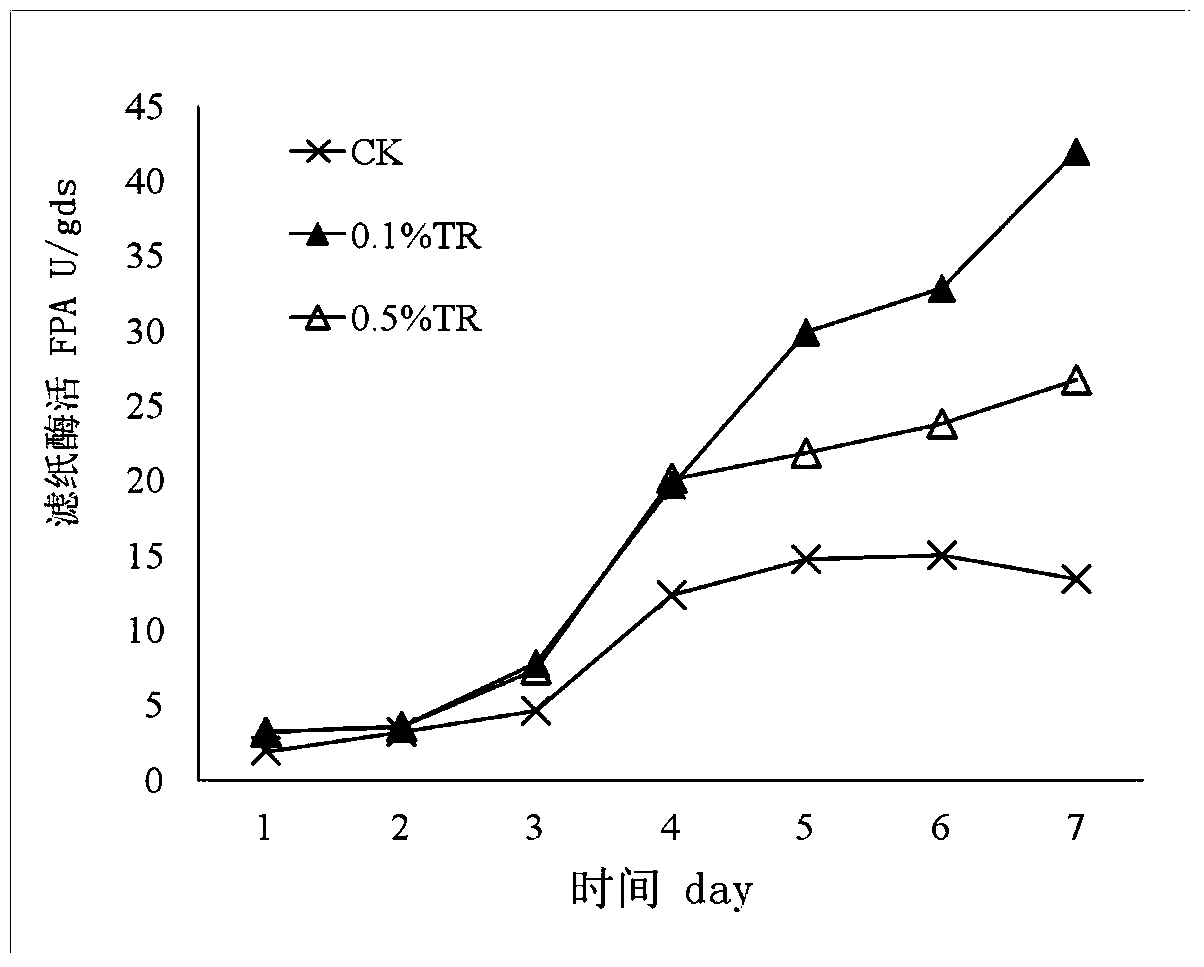

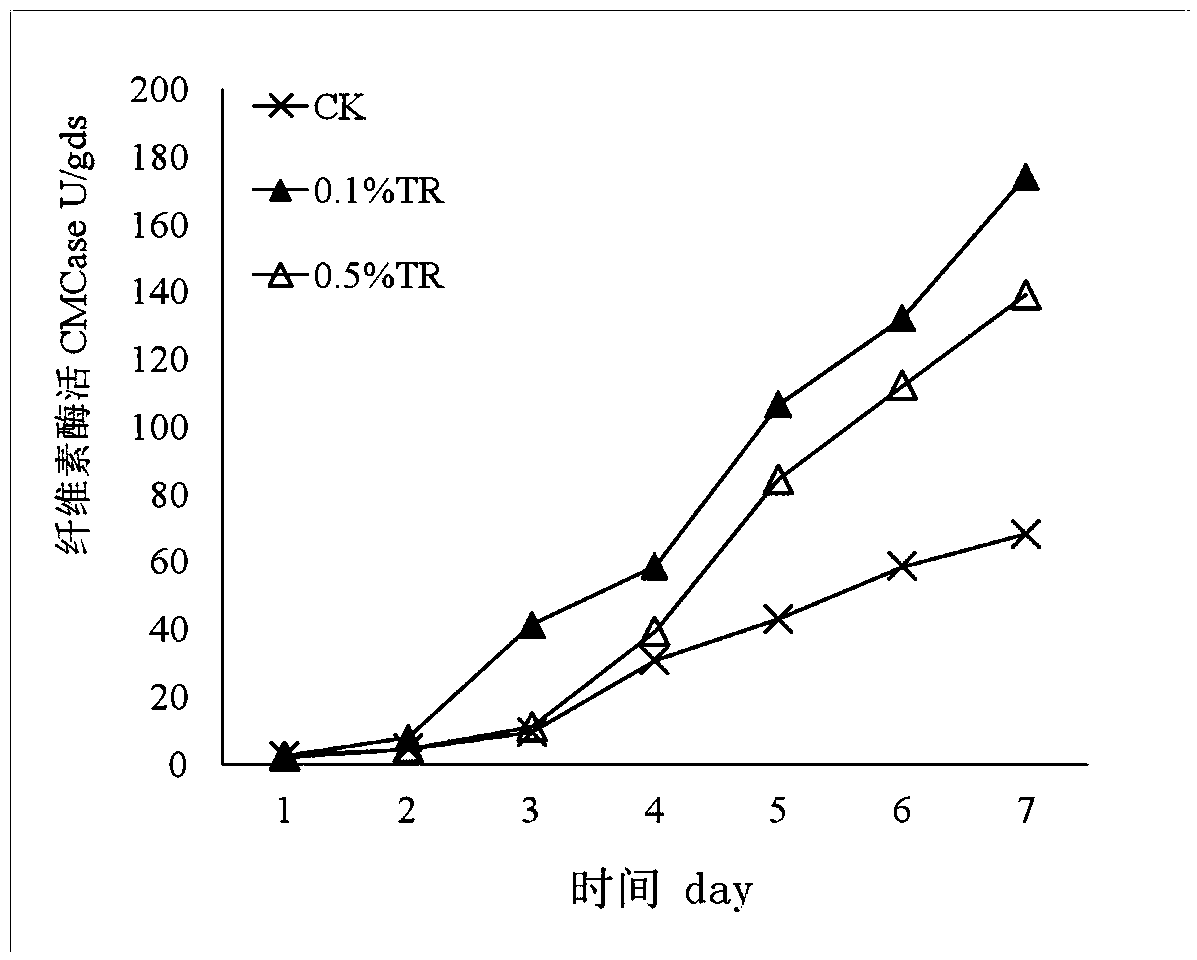

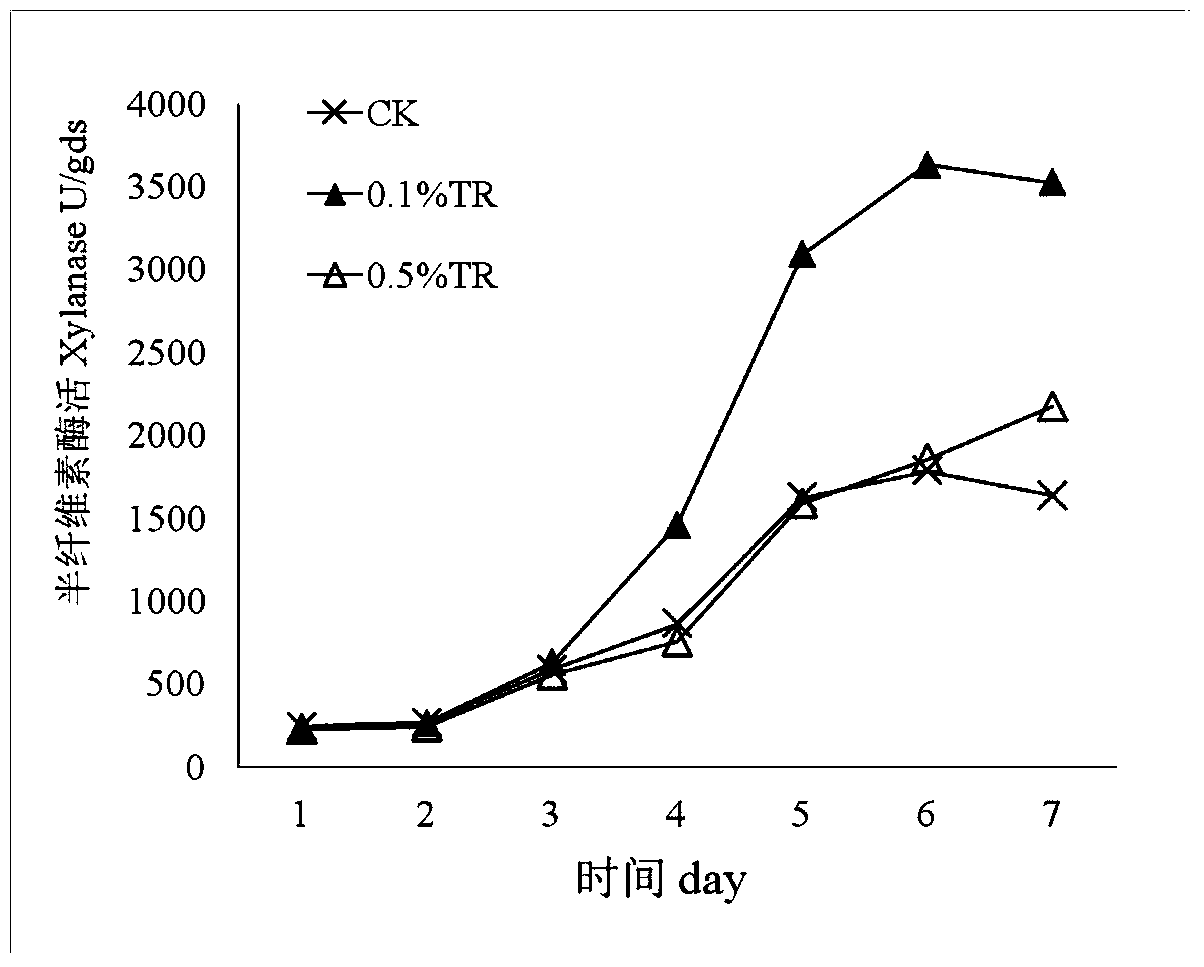

[0035] The effects of the method of the present invention and the method of directly returning straw to the field on the decomposition of corn straw were compared through a pot plant simulation test.

[0036]The auxiliary agent is polyethylene glycol p-isooctyl phenyl ether, take 1mL polyethylene glycol p-isooctyl phenyl ether, add water to prepare an auxiliary agent with a concentration of polyethylene glycol p-isooctyl phenyl ether of 0.1% solution.

[0037] Pot simulation test: cut corn stalks into 1-2cm corn stalks, take 10g of corn stalks and put them into a 100-mesh nylon mesh bag of 10cm×15cm. In a flowerpot filled with soil, 3cm deep from the soil surface, control the soil water content to 60%-80% of the field water holding capacity during the test (approximately add 25mL of water per 100g of soil), and cultivate it statically at 20-30°C for 30 Days later, the degradation rate of corn stalks was measured.

[0038] Determination of the degradation rate of corn stalks:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com