Method used for producing biological organic fertilizer through conversion of straw and breeding industry manure with agricultural probiotics

A bio-organic fertilizer and probiotic technology, applied in the preparation of organic fertilizers, organic fertilizers, agriculture, etc., can solve the problems of breeding mosquitoes and flies, polluting the living environment, peculiar smell, etc., to stimulate the growth and development of crops, improve the nutritional level, reduce the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

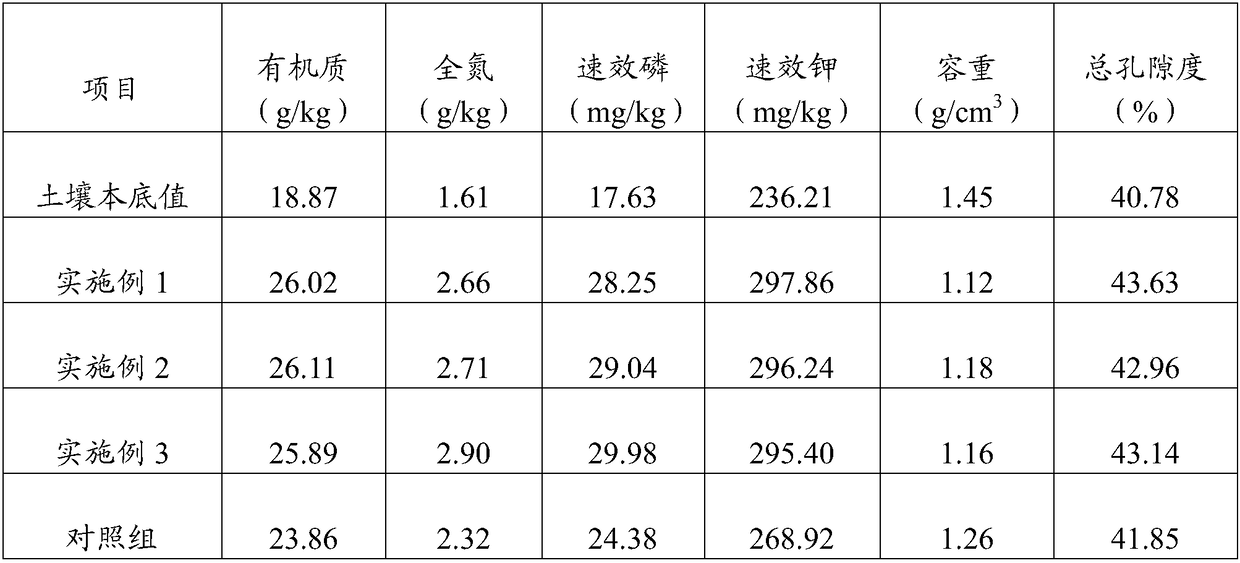

Examples

Embodiment 1

[0033] A method for producing bio-organic fertilizer by transforming straw and breeding manure with agricultural probiotics, specifically prepared according to the following steps:

[0034] Step 1, collecting straw after harvesting the crops, crushing the straw into 3 cm segments to obtain straw slag;

[0035] Step 2, add the compound enzyme equivalent to 1% of the quality of the cultured manure to it after the cultured manure is collected, then stir at a stirring speed of 100r / min, and feed hot air into the cultured manure while stirring, at the beginning, pass into Hot air at a temperature of 40°C for 8 hours, followed by hot air at a temperature of 50°C for 5 hours, and finally hot air at a temperature of 75°C for 3 hours, after the ventilation is completed, the pretreated aquaculture manure is obtained;

[0036] Among them, the compound enzyme is prepared by mixing protease, amylase and xylanase according to the mass ratio of 1:1:2; and the activity of protease is 6000U / mL...

Embodiment 2

[0045] A method for producing bio-organic fertilizer by transforming straw and breeding manure with agricultural probiotics, specifically prepared according to the following steps:

[0046] Step 1, collecting straw after harvesting the crops, crushing the straw into 4 cm segments to obtain straw slag;

[0047] Step 2, add the compound enzyme equivalent to 1% of the quality of the cultured manure to it after the cultured manure is collected, then stir at a stirring speed of 120r / min, and feed hot air into the cultured manure while stirring, at the beginning, pass into Hot air with a temperature of 45°C for 5 hours, followed by hot air with a temperature of 53°C for 4 hours, and finally hot air with a temperature of 80°C for 2 hours, after the ventilation is completed, the pretreated aquaculture manure is obtained;

[0048] Among them, the compound enzyme is prepared by mixing protease, amylase and xylanase according to the mass ratio of 1:1:2; and the activity of protease is 70...

Embodiment 3

[0057] A method for producing bio-organic fertilizer by transforming straw and breeding manure with agricultural probiotics, specifically prepared according to the following steps:

[0058] Step 1, collecting straw after the crops are harvested, crushing the straw into 5 cm segments to obtain straw slag;

[0059] Step 2, add the compound enzyme equivalent to 1% of the quality of the cultured manure to it after the cultured manure is collected, then stir at a stirring speed of 150r / min, and feed hot air into the cultured manure while stirring, at the beginning, pass into Hot air at a temperature of 35°C for 10 hours, followed by hot air at a temperature of 55°C for 3 hours, and finally hot air at a temperature of 78°C for 2.5 hours, and pretreated aquaculture manure after ventilation;

[0060] Among them, the compound enzyme is prepared by mixing protease, amylase and xylanase according to the mass ratio of 1:1:2; and the activity of protease is 6500U / mL, the activity of amylas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com