Method for preparing starch gum used for straw fiber products

A technology of straw fiber and starch glue, applied in the direction of starch adhesive, adhesive type, etc., can solve the problems of harsh use process conditions, unsuitable for straw fiber, immature manufacturing process, etc., achieve low cost and benefit plants Effects of Growth, Strong Social Value, and Economic Value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

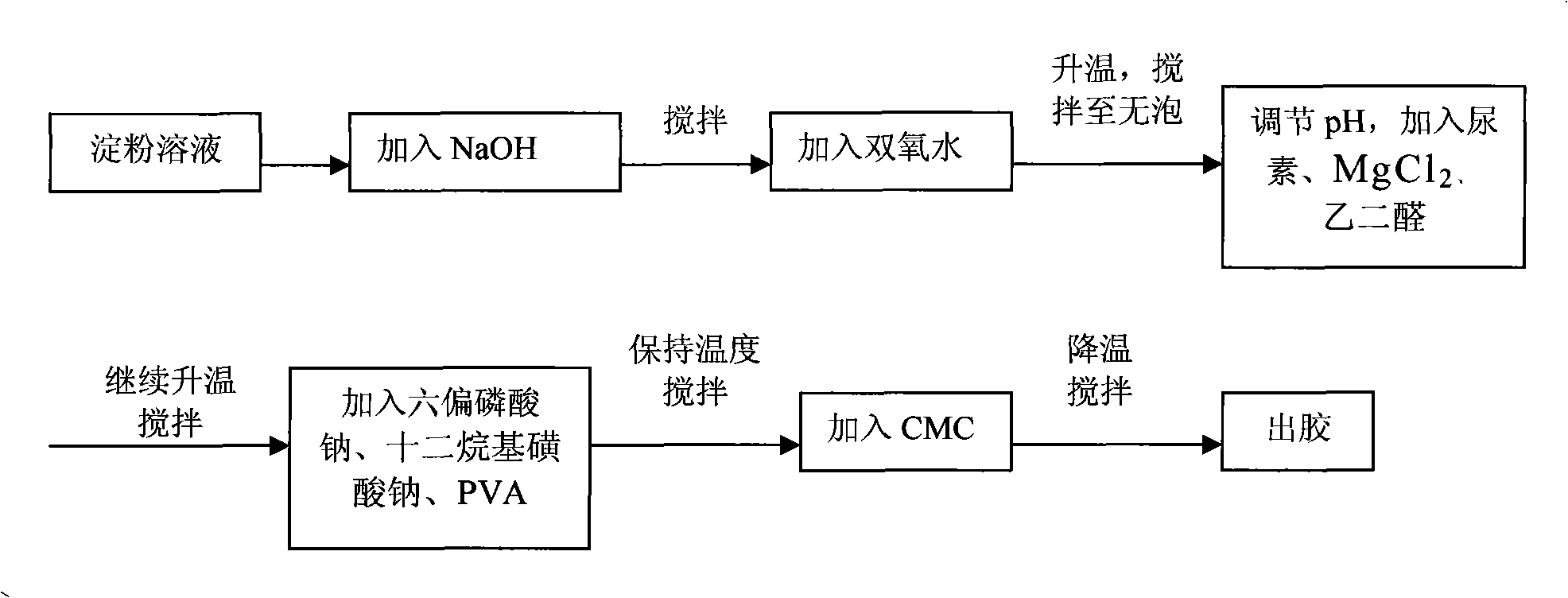

Embodiment 1

[0013] Take 1kg of starch and 4L of water, add 20g of NaOH, stir for about 15 minutes, add 100ml of hydrogen peroxide with a volume fraction of 30% (commercially available hydrogen peroxide is bottled hydrogen peroxide with a volume ratio of 30%), heat to 65°C in a water bath, stir fully, and wait until no Until obvious bubbles appear, adjust the pH to 6 with 5wt% sulfuric acid, add 150g urea, 30g MgCl 2 , 100ml of glyoxal, the temperature was raised to 90°C, stirred and heated for 30min, then added 20g of sodium hexametaphosphate, 50g of sodium dodecylsulfonate, 40g of PVA (dissolved in hot water in advance), kept the temperature and stirred for 30min, and finally Add 200g of dissolved CMC to the reaction solution, heat and stir at 65°C for 1 hour, add appropriate amount of water during the preparation process to ensure that the volume of the starch glue is about 5L, cool down, and the glue will come out. Using the finished product of this embodiment to bond straw fibers is s...

Embodiment 2

[0016] Add 0.1kg NaOH to the aqueous solution of 1kg starch at room temperature, stir for 15 minutes, then add 0.6kg hydrogen peroxide, stir the resulting mixed solution in a water bath at 50°C until no bubbles are generated, then use hydrochloric acid to adjust the pH of the mixed solution to 5, and then mix Add 1kg urea, 0.2kg MgCl to the solution 2 , 1kg glyoxal, heat the mixed solution to 90°C in a water bath, stir for 30min, then add 1kg sodium hexametaphosphate, 0.2kg polyvinyl alcohol PVA, 0.2kg sodium dodecylsulfonate, keep stirring at 90°C for 30min, and finally add 2kg of carboxymethyl fiber CMC that has been dissolved is cooled to 60°C, stirred for 1 hour, and an appropriate amount of water is added during the period to ensure that the pot is not dry. Finally, dehydration is performed to the required concentration, and the temperature is lowered to produce glue.

[0017] The finished product was dropped from a height of 3 meters without cracks; soaked in water for 1...

Embodiment 3

[0019] Add 0.2 kg NaOH to 1 kg starch aqueous solution at room temperature, stir for 15 minutes, then add 1.2 kg hydrogen peroxide, stir the resulting mixed solution in a water bath at 50°C until no bubbles are generated, then use phosphoric acid to adjust the pH of the mixed solution to 5.5, and then mix Add 2kg urea, 0.7kg MgCl to the solution 2 , 2kg glyoxal, heat the mixed solution to 90°C in a water bath, stir for 30min, then add 1.6kg sodium hexametaphosphate, 0.6kg polyvinyl alcohol PVA, 0.8kg sodium dodecylsulfonate, keep stirring at 90°C for 30min, and finally Add 4kg of dissolved carboxymethyl fiber CMC, cool down to 60°C, stir for 1 hour, add appropriate amount of water during this period to ensure that the pot is not dry, and finally perform dehydration to the required concentration, cool down, and glue out.

[0020] The finished product was dropped from a height of 1.8 meters without cracks; soaked in water for 22 days, it softened slightly but did not disperse. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com