System and method of disposing stale garbage in landfill

A landfill, obsolete technology, applied in combustion methods, regulating fuel supply, lighting and heating equipment, etc., can solve problems such as difficulty in achieving profitability, high water content, and incineration characteristics (low calorific value), and achieve stable working conditions. , handle efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

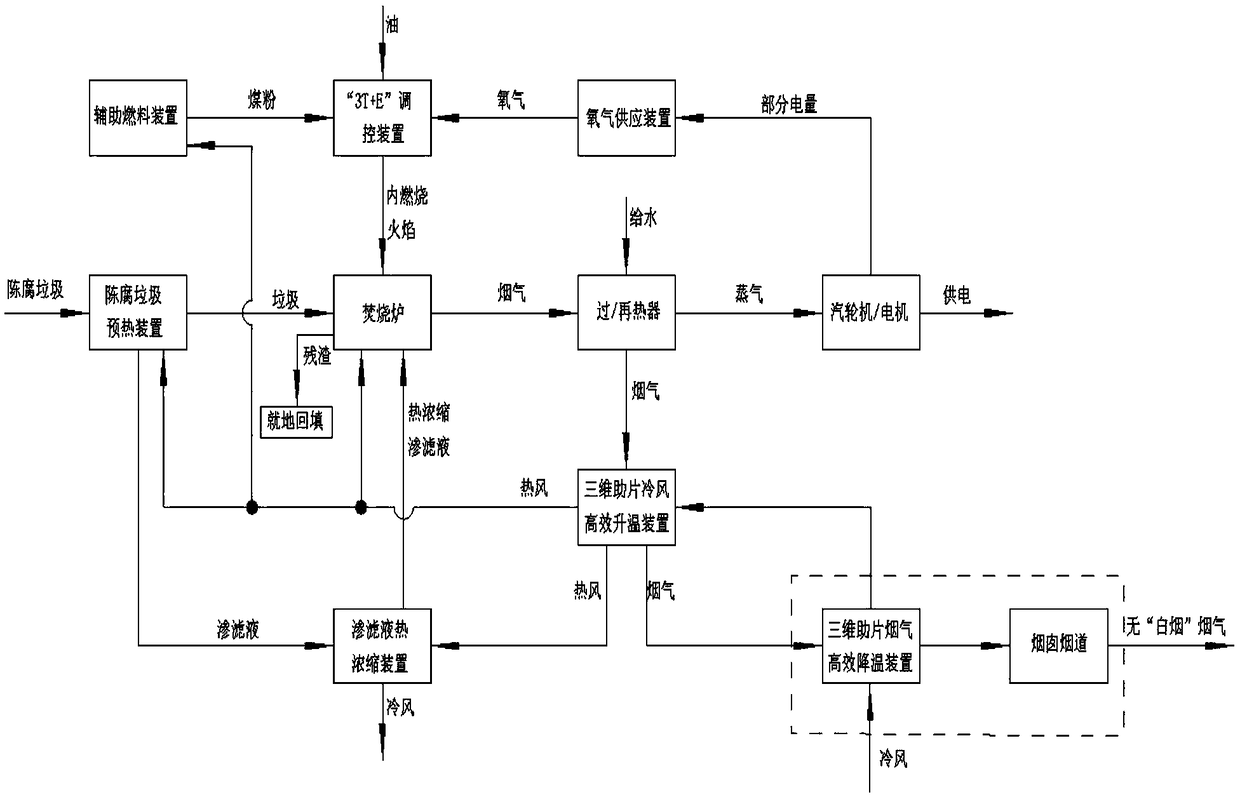

[0033] Such as figure 1 As shown, a system and method for treating obsolete waste in landfills includes an incinerator, a "3T+E" control device, an oxygen supply device, an auxiliary fuel device, a three-dimensional fin cold air high-efficiency heating device, and a three-dimensional fin high-efficiency flue gas Cooling device, stale waste preheating device, leachate thermal concentration device.

[0034] The incinerator is a reciprocating mechanical grate furnace, which is the main place for the incineration of stale waste in the landfill. The "3T+E" control device is the main place for the internal combustion of auxiliary fuel. The "3T+E" control device is installed On the furnace wall, the combination of the two is:

[0035] a. The "3T+E" control device directly enters the incinerator through the flame generated by internal combustion, and the flam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com