City sludge fluidized bed combustion device and method

A technology of incineration device and municipal sludge, which is applied in the directions of pyrolysis treatment of sludge, sludge treatment through temperature control, vaporization of by-products, etc. The effect of detoxification and recycling, ensuring complete incineration, and suppressing the generation and emission of NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

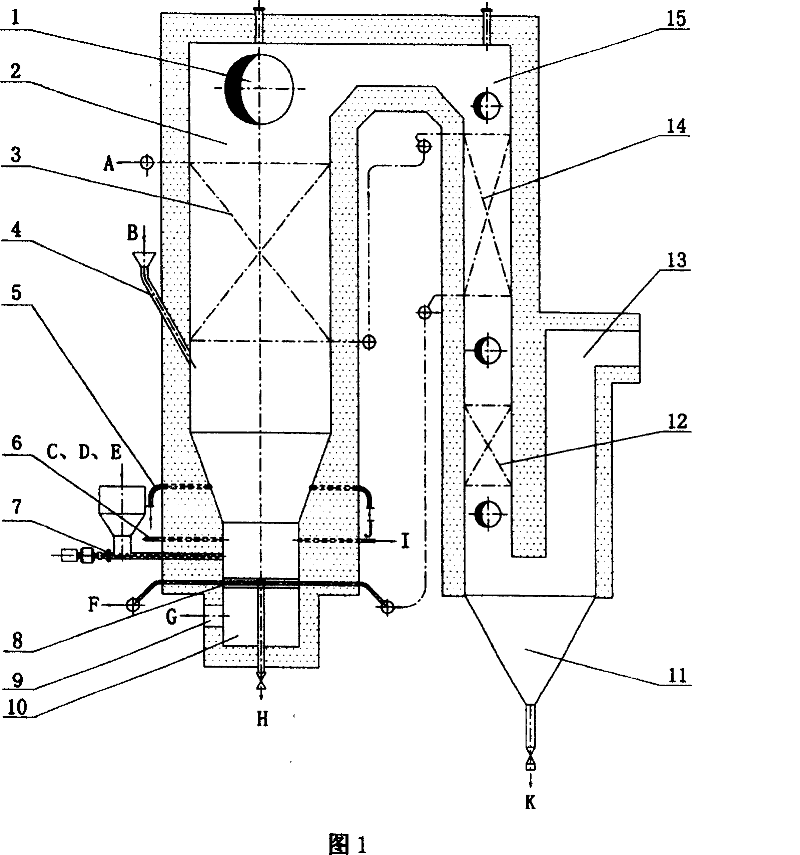

[0018] The urban sludge fluidized bed incineration device is composed of an incinerator body 2, an air distribution plate 8, an air chamber 10 and a tail flue 15. The tops of the incinerator body 2 and the tail flue 15 are connected; The bottom is provided with an air distribution plate 8, the lower part of the air distribution plate 8 is an air chamber 10, the lower part of the incinerator body 2 is a dense phase incineration area, and the upper part is a dilute phase incineration area; the explosion-proof door 1 is located on the upper part of the dilute phase incineration area. The secondary air pipe 5 is arranged in the lower part of the dilute phase incineration zone, the furnace radiation heating surface 3 and the quartz sand adding device 4 are set in the middle part of the dilute phase incineration zone; multiple sets of cooling water / wet sludge spray guns 6 are arranged in the upper part of the dense phase incineration zone, The screw feeder 7 is located in the middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com