Pesticide waste residue fluidized bed incinerating process and pesticide waste residue fluidized bed incinerating device

An incineration device and fluidized bed technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as melt flow, sticking and clogging, and achieve the effects of preventing secondary pollution, ensuring incineration, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

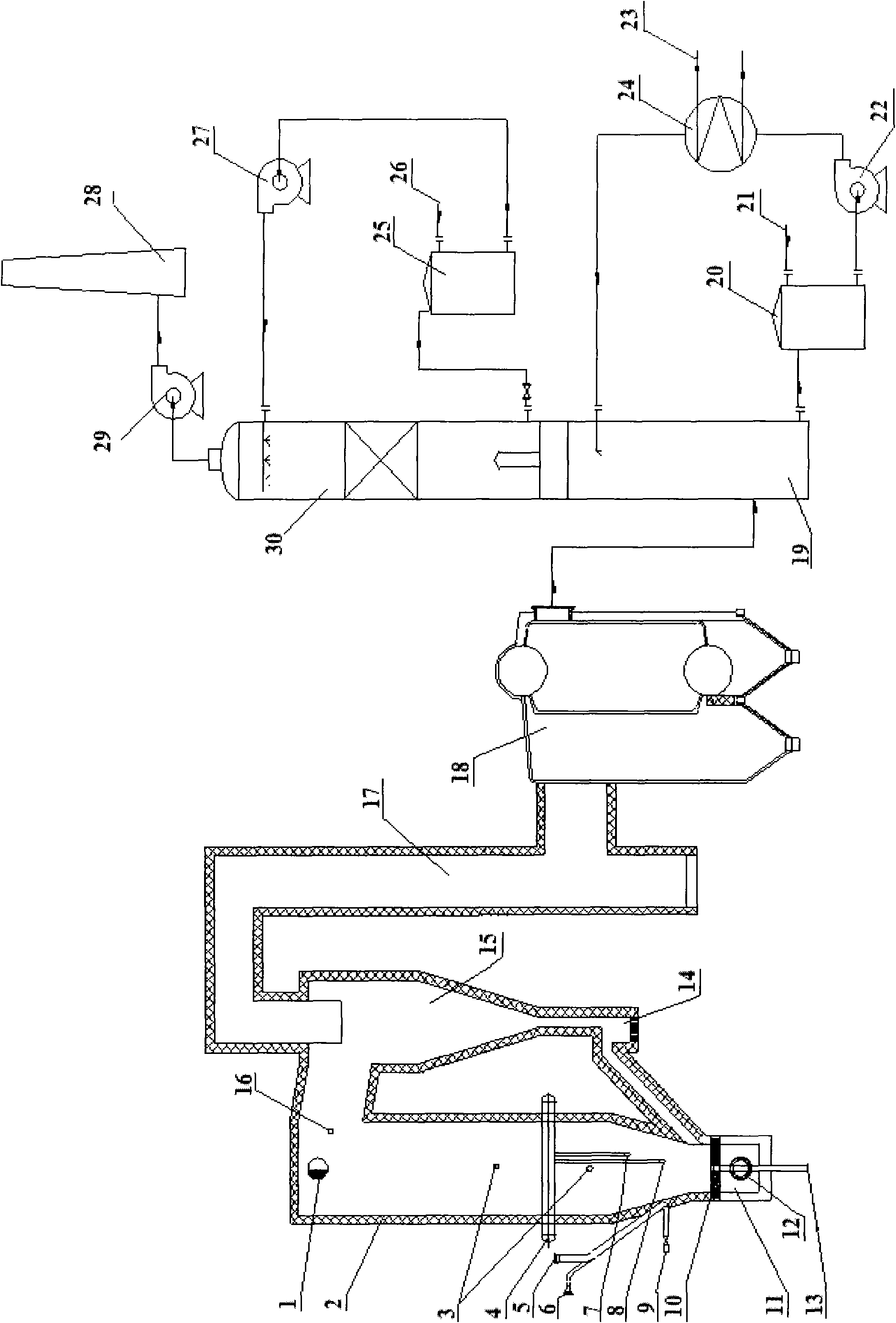

[0019] like figure 1 As shown, a kind of pesticide waste residue fluidized bed incineration device according to the present invention includes a fluidized bed incinerator body 2, the upper part of the incinerator body 2 is a dilute phase incineration area, and an explosion-proof door is arranged above the dilute phase incineration area 1, and ammonia spray gun 16. Ammonia water spray gun 16 sprays ammonia water into the incinerator to realize denitrification in the furnace and reduce the generation of NOx during incineration

[0020] The lower part of the incinerator body 2 is a dense-phase incineration zone, and the feed port pipeline 5 is located in the dense-phase incineration zone. A cooling tuyere 9 is also provided on the upper part of the feed port pipeline 5, and a sowing tuyere 6 is also provided at the bottom. An air distribution plate 10 is provided at the lower part of the dense phase incineration zone, and the lower part of the air distribution plate 10 is an air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com