Self-propelled combined biomass carbonization system

A carbonization system and biomass technology, applied in the direction of biofuel, liquid hydrocarbon mixture preparation, special form of dry distillation, etc., can solve the problems of less than 10% effective utilization rate, air pollution, hazards, etc., and achieve the solution of straw burning and atmospheric pollution. The effect of pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

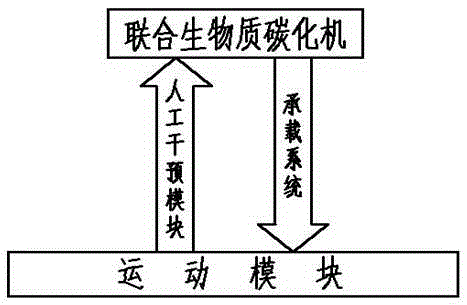

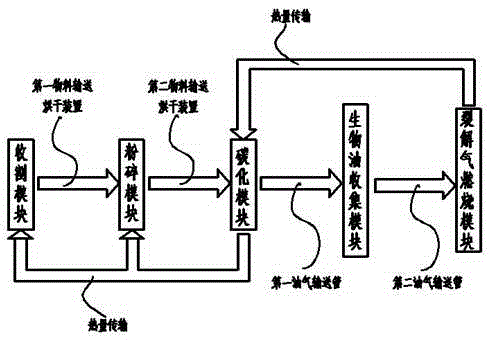

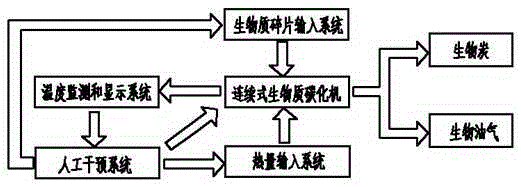

[0021] The self-propelled combined biomass carbonization system of the present invention includes a movement module, a harvesting module, a crushing module, a carbonization module, a bio-oil collection module, a cracking gas combustion module and a manual intervention module, wherein the movement module is used to carry the combined biomass carbonization machine, Choose general vehicle-mounted machinery; the harvesting module is used to harvest biomass raw materials, choose general straw harvesters, and choose different harvesting heads according to the type of straw and site conditions, such as corn straw standing on the ground. For cotton stalks on the land, choose the cotton stalk harvesting head; the crushing module is used to crush biomass raw materials, choos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com