Flame-retardant plant fiber construction heat-insulation wall material and preparation method thereof

A plant fiber and building thermal insulation technology, applied in the field of building materials, can solve the problems of poor flame retardancy of thermal insulation materials, toxic smoke, aggravated consumption of petroleum resources, etc., and achieve the effect of solving economic development and pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

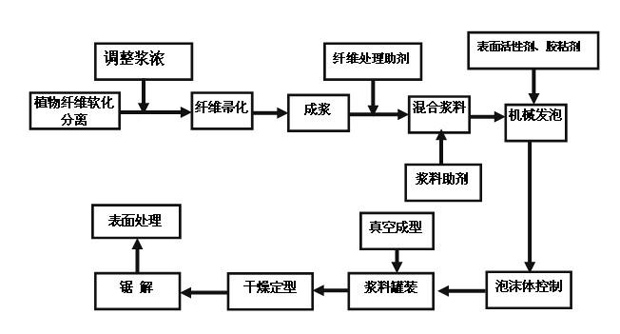

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: Chinese fir fiber building insulation wall material

[0023] The fast-growing Chinese fir thinning wood is cut into 3cm * 2cm * 0.2cm wood chip, boils and softens in 150 ℃ steamer with 2% NaOH solution for 6 hours. Put the cooked and softened wood chips (including all the treatment liquid) into the high-concentration disc mill to separate the fibers. Squeeze and filter (filter screen 30 mesh), extrude the treatment liquid in the fiber, and obtain the Chinese fir fiber with a concentration of 20%. The extruded treatment liquid is then used for chip treatment. Mix 70% of Chinese fir fiber pulp and 30% of chemical wood pulp (purchased in the market) into a beater (model: 6-2) for beating until the beating degree is 28°SR to achieve broomification treatment, and adjust the pulp concentration to 6%. Add carboxy-modified silicone oil 8mg / L, cationic corn starch 6mg / L, ASA 6mg / L and rosin water repellent 10mg / L to mix, then add FWR10mg / L, dicyandiamide...

Embodiment 2

[0025] Embodiment 2: bamboo fiber building insulation wall material

[0026]Cut the collected green bamboo into 3cm×1cm×0.2cm bamboo slices, cook and soften them in a steamer at 150° C. for 8 hours with 3% NaOH solution. Put the softened bamboo chips (including all the treatment liquid) into the high-concentration disc mill to separate the fibers. Squeeze and filter (filter screen 20 meshes) to squeeze out the treatment liquid in the fiber, and the concentration of the obtained bamboo fiber is 20%. The extruded treatment liquid is then used for bamboo chip treatment. 80% of bamboo fiber pulp and 20% of chemical wood pulp (purchased in the market) are mixed and put into a beater (model: 6-2) to beating to a degree of beating of 30°SR to achieve broomification treatment, and the pulp is adjusted to a concentration of 4%. Add carboxy-modified silicone oil 10mg / L, cationic corn starch 11mg / L, polyvinyl alcohol 75mg / L and rosin waterproofing agent 15mg / L and mix, then add silicon...

Embodiment 3

[0028] Embodiment 3: straw fiber building insulation wall material

[0029] The collected straw was cut into 3 cm long grass sections, and softened by steaming in a steamer at 110° C. for 5 hours with 1% NaOH solution. Put the cooked and softened grass section (including all the treatment liquid) into the high-concentration disc mill to separate the fibers. Squeeze and filter (filter screen 50 mesh), extrude the treatment liquid in the fiber, the straw fiber concentration that obtains is 20%. The extruded treatment liquid is then used for grass section treatment. Mix 60% of straw fiber pulp and 40% of chemical wood pulp (purchased in the market) into a beater (model: 6-2) for beating until the beating degree is 30°SR to achieve broomification treatment, and adjust the pulp concentration to 5%. Add cationic corn starch 20mg / L, polyvinyl alcohol 115mg / L and rosin water repellent 15mg / L to mix, then add silicon dioxide 3g / L and sodium silicate 20g / L to mix, and add alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com