Film-coated slow release fertilizer as well as preparation method and device thereof

A technology of coated slow-release and slow-release fertilizers, which is applied in the direction of layered/coated fertilizers, nitrogen fertilizers, and potassium fertilizers. It can solve problems such as high fertilizer costs, secondary pollution, and the outer coating is not easy to degrade, and achieve improved soil quality. , saving energy and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Embodiment 1, the equipment that makes coated slow-release fertilizer

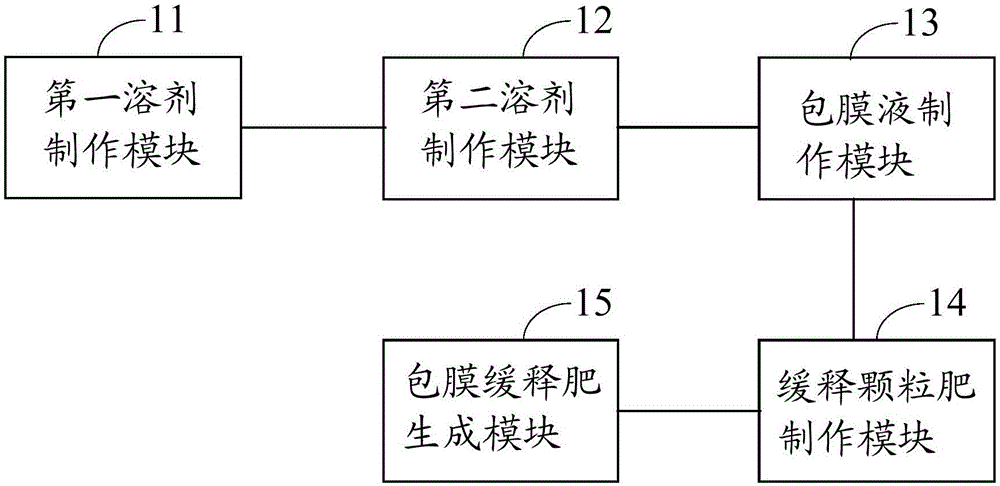

[0090] Such as figure 1 Shown is a schematic structural view of the equipment for making coated slow-release fertilizer according to the present invention.

[0091] Depend on figure 1 It can be seen that the equipment for making coated slow-release fertilizer in the present invention includes the first solvent making module 11, the second solvent making module 12, the coating liquid making module 13, the slow-release granular fertilizer making module 14 and the coated slow-release fertilizer. Release fertilizer generating module 15.

[0092] The first solvent making module 11 comprises a connected heating unit (not shown in the figure) and a gelatinization unit (not shown in the figure), wherein the heating unit is used to heat distilled water to 45 ° C, and the gelatinization unit is used to mix water with The starch mixture is gelatinized under stirring, and the first solvent is obtained after ...

Embodiment 2

[0117] Embodiment 2, making coated slow-release fertilizer

[0118] (1) Select wheat straw, and carry out the following treatment in the straw processing unit: air-dried, crushed through a 10-mesh sieve, and stored for future use.

[0119] (2) Add 2500kg of distilled water to the heating unit and heat to 45°C, stop heating, add 50kg of starch, and stir in the gelatinization unit for 30min until uniform, as the first solvent.

[0120] (3) Add 40 kg of polyethylene glycol (molecular weight: 800) to the first solvent, and stir evenly in the second solvent production unit 12 to increase moldability as the second solvent.

[0121] (4) Take by weighing 500kg pulverized wheat stalks, 15kg bentonite and 25kg tobacco scraps, mix uniformly together in coating solution making module 13, add 50kg second solvent, mix well quickly, as coating solution (i.e. outer coating material), wherein, the mass percentage of wheat straw in the outer coating material is 84.75%, the mass percentage of sta...

Embodiment 3

[0125] Embodiment 3, making coated slow-release fertilizer

[0126] (1) Select corn stalks, and carry out the following treatment in the straw processing unit: air-dry, crush through a 10-mesh sieve, and store for future use.

[0127] (2) Add 2500kg of distilled water to the heating unit and heat to 45°C, stop heating, add 20kg of starch, and stir in the gelatinization unit for 30min until uniform, as the first solvent.

[0128] (3) add 80kg konjac gum in the first solvent, stir in the second solvent production unit 12, to increase formability, as the second solvent.

[0129] (4) Take by weighing 500kg pulverized corn stalks, 10kg bentonite and 15kg tobacco scraps, mix uniformly together in coating solution making module 13, add 50kg second solvent, mix well quickly, as coating solution (i.e. outer coating material), wherein the mass percentage of corn stalks in the outer coating material is 86.96%, the mass percentage of starch is 0.07%, the mass percentage of bentonite is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com