Kbac drink prepared by asynchronous fermentation technology and preparation method thereof

A technology of asynchronous fermentation and technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of difficult quality control and taste consistency of kvass, complicated processing technology, changeable flavor and other problems, so as to achieve easy quality and taste control, and equipment matching. Scientific and reasonable, pure taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A kind of kvass beverage prepared by asynchronous fermentation technology, every 100 kilograms is made from the following raw materials:

[0059] Malt extract 4.2kg, hop flower 3.1g, yeast powder 5g, lactic acid bacteria powder 4g, xylitol 390g, white sugar 4.6kg, citric acid 34g, sodium citrate 5.6g, pure water balance.

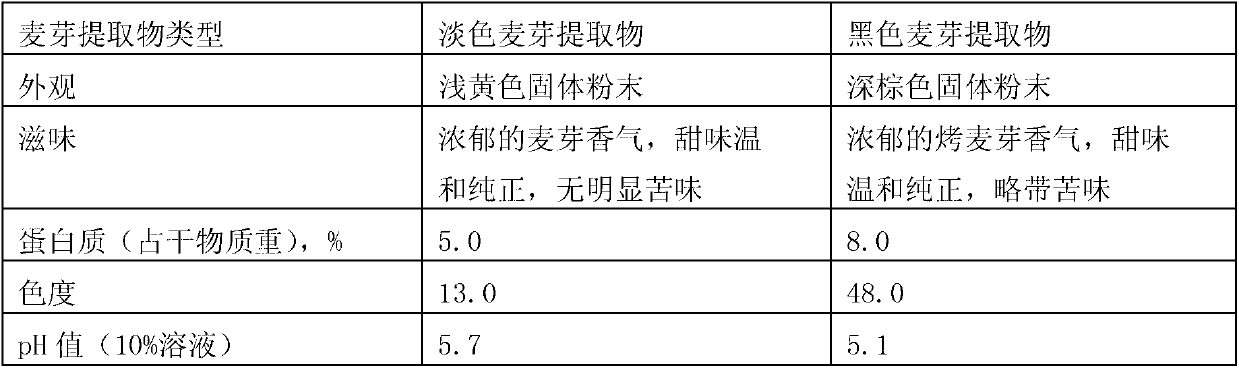

[0060] The above-mentioned malt extract is prepared by mixing 2.52 kg of light-colored malt extract and 1.68 kg of black malt extract.

[0061] The preparation method of above-mentioned kvass beverage, comprises the steps:

[0062] (1) Add 10 times the weight of malt extract to pure water at 55°C, add α-amylase to the water at the same time, stir evenly, and keep warm for 60 minutes to obtain saccharified wort;

[0063] (2) Heat the saccharified wort prepared in step (1) to boiling under the pressure of 0.12Mpa, continue heating for 100 minutes, then add pure water to dilute the wort in the boiling pot to 9°P wort, The protein precipitation was remo...

Embodiment 2

[0083] A kind of kvass beverage prepared by asynchronous fermentation technology, every 100 kilograms is made from the following raw materials:

[0084] Malt extract 4.4kg, hop flower 4.4g, yeast powder 5.5g, lactic acid bacteria powder 5g, xylitol 400g, white sugar 4.8kg, citric acid 35g, sodium citrate 6.0g, pure water balance.

[0085] The above-mentioned malt extract is prepared by mixing 1.76 kg of light-colored malt extract and 2.64 kg of black malt extract.

[0086] The preparation method of above-mentioned kvass beverage, comprises the steps:

[0087] (1) Add 9 times the weight of malt extract to pure water at 53°C, and at the same time add α-amylase to the water, stir evenly, and keep warm for 80 minutes to obtain saccharified wort;

[0088] (2) Heat the saccharified wort prepared in step (1) to boiling under the pressure of 0.14Mpa, continue heating for 110 minutes, then add pure water to dilute the wort in the boiling pot to 12°P wort, The protein precipitation wa...

Embodiment 3

[0103] The preparation method of kvass beverage as described in embodiment 2, the difference is that step (2) is:

[0104] After the saccharified wort prepared in step (1) is inactivated by enzymes; add lactic acid bacteria in an amount of 0.1 g of lactic acid bacteria per kilogram of saccharified wort, and carry out normal pressure fermentation at 41 ° C for 14 hours to obtain a primary fermentation liquid.

[0105] In this embodiment, because no high-intensity protein denaturation step is added, the clarity and brightness of the product is poor, the turbidity is relatively high, and light loss occurs, that is, the colloidal stability is poor; There is a protein odor and a bad smell of wheat skin and oxidation.

[0106] The sensory indicators of the prepared kvass beverage are shown in Table 8.

[0107] Table 8

[0108] project

Test results

color

brownish yellow, poor gloss

It has the inherent smell of fermented kvass, and also ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com