Multi-angle punching device for round holes of collecting pipe

A manifold and multi-angle technology, applied in the field of multi-angle punching devices, can solve problems such as low production efficiency and high labor intensity of workers, and achieve the effects of improving production efficiency, reducing labor intensity, and reducing the number of times of loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

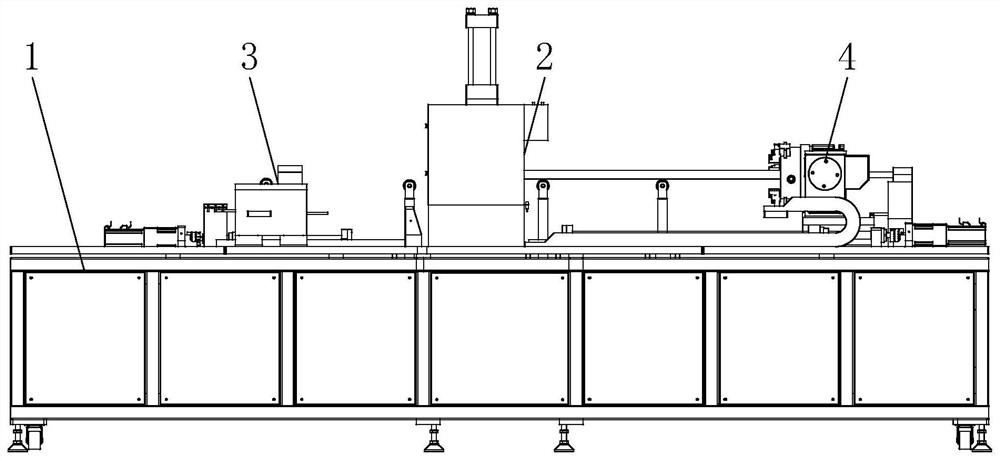

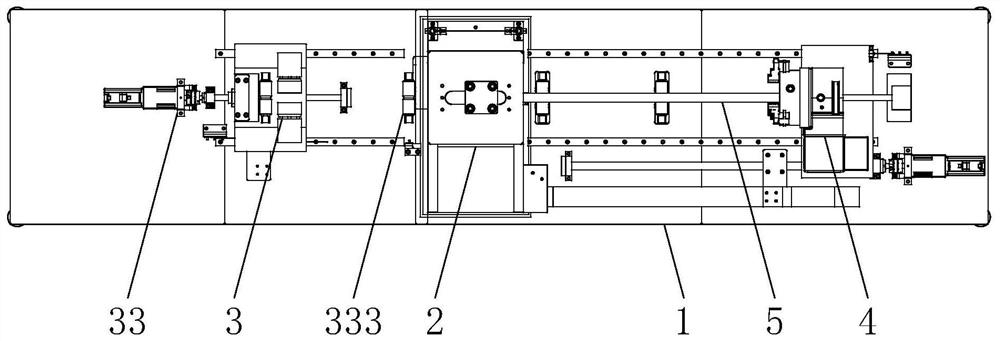

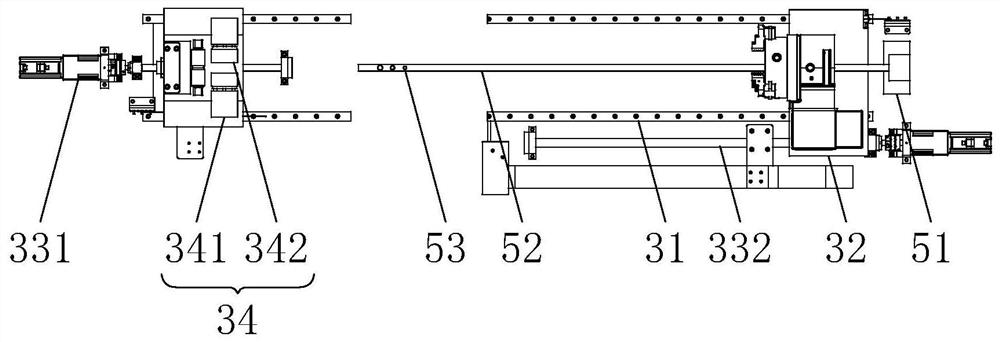

[0024] Figure 1 to Figure 5 It shows an embodiment of a multi-angle punching device of a collector pipe hole in the present invention, including a frame 1, which is equipped with a hole for positioning the collector pipe and making a round hole for the collector pipe. Punching punching mechanism 2, the frame 1 is equipped with an axial transfer mechanism 3 for adjusting the axial position of the collector at both ends of the punching mechanism 2 to realize the punching of round holes at different stations, the axial The transfer mechanism 3 is also equipped with a three-jaw chuck 4 for rotating the header to realize round hole punching from different angles. Through the cooperation between the punching mechanism 2 and the transfer mechanism 3, the manifold can move along the axis direction, thereby changing the axial punching statio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com