Grinding machines for superhard material products

A technology of superhard materials and grinding machines, which is applied in the direction of machine tools, grinding machines, and grinding feed movements suitable for grinding the edge of workpieces. It can solve the problems of high labor intensity, easy danger, and low grinding efficiency, and achieve dust Less pollution, less dust pollution, even grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

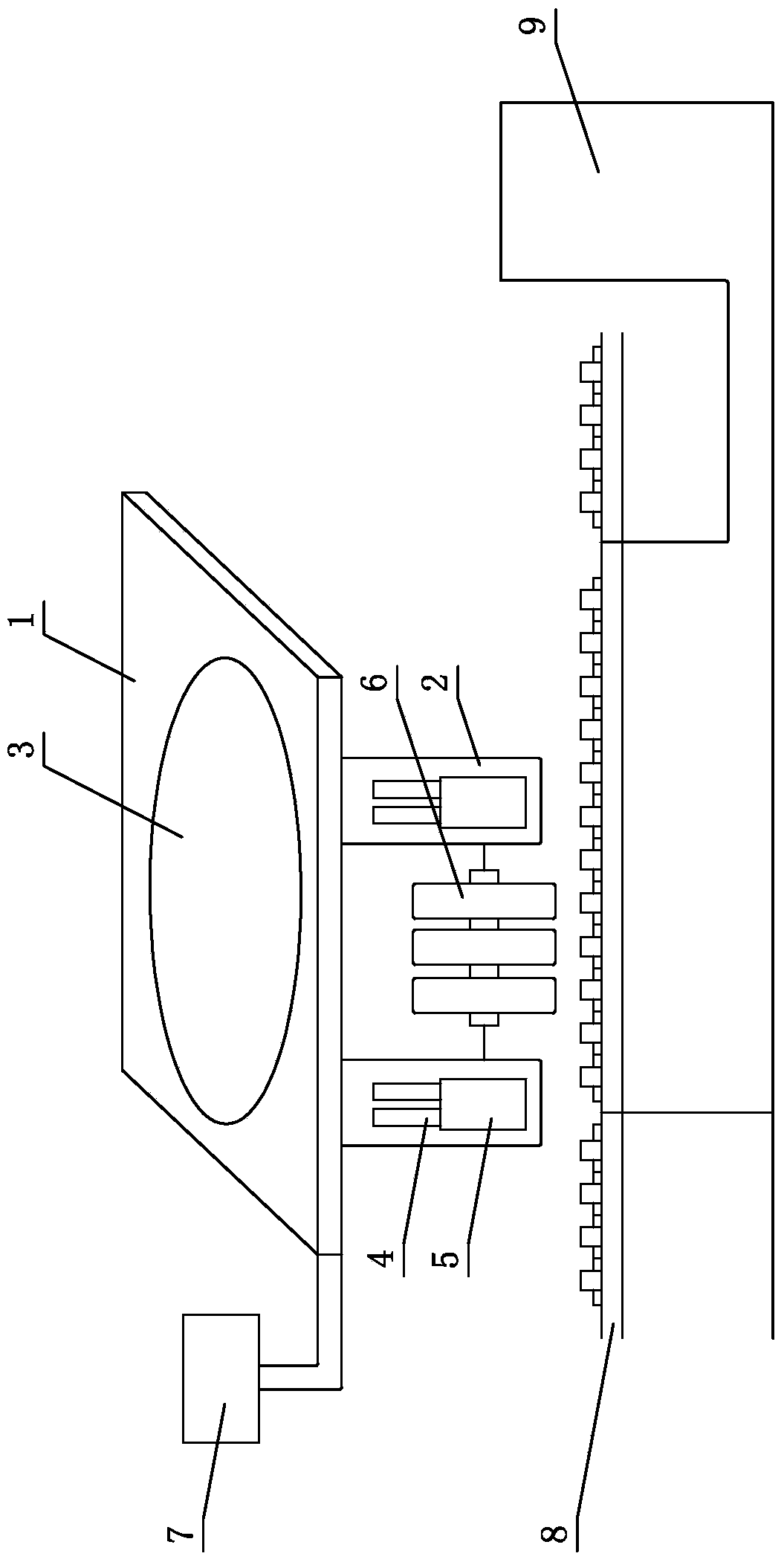

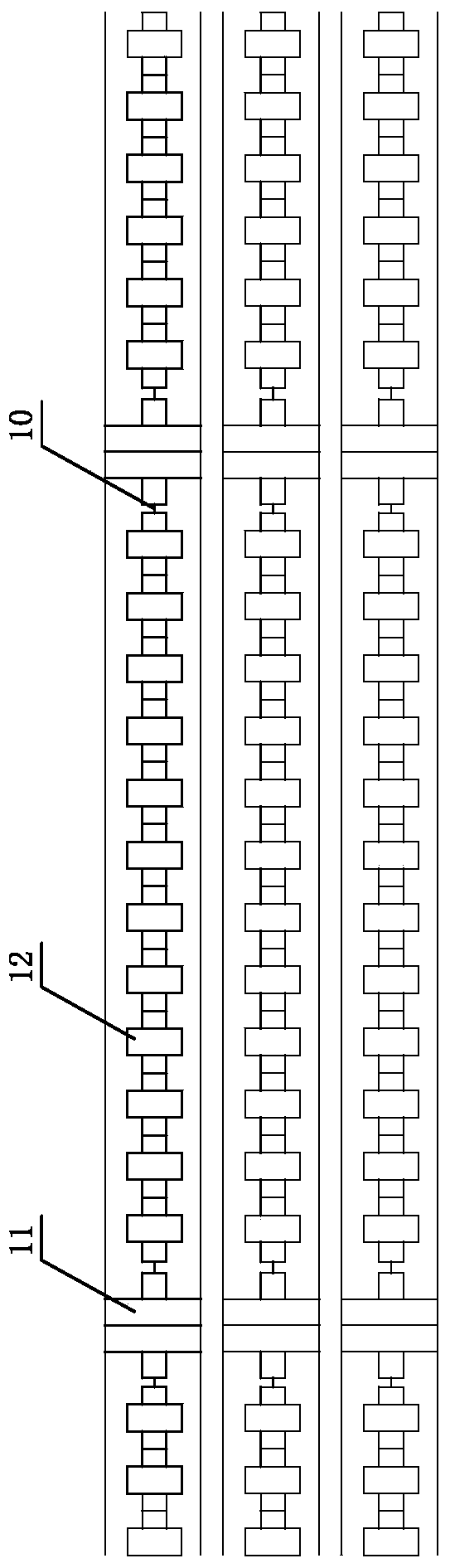

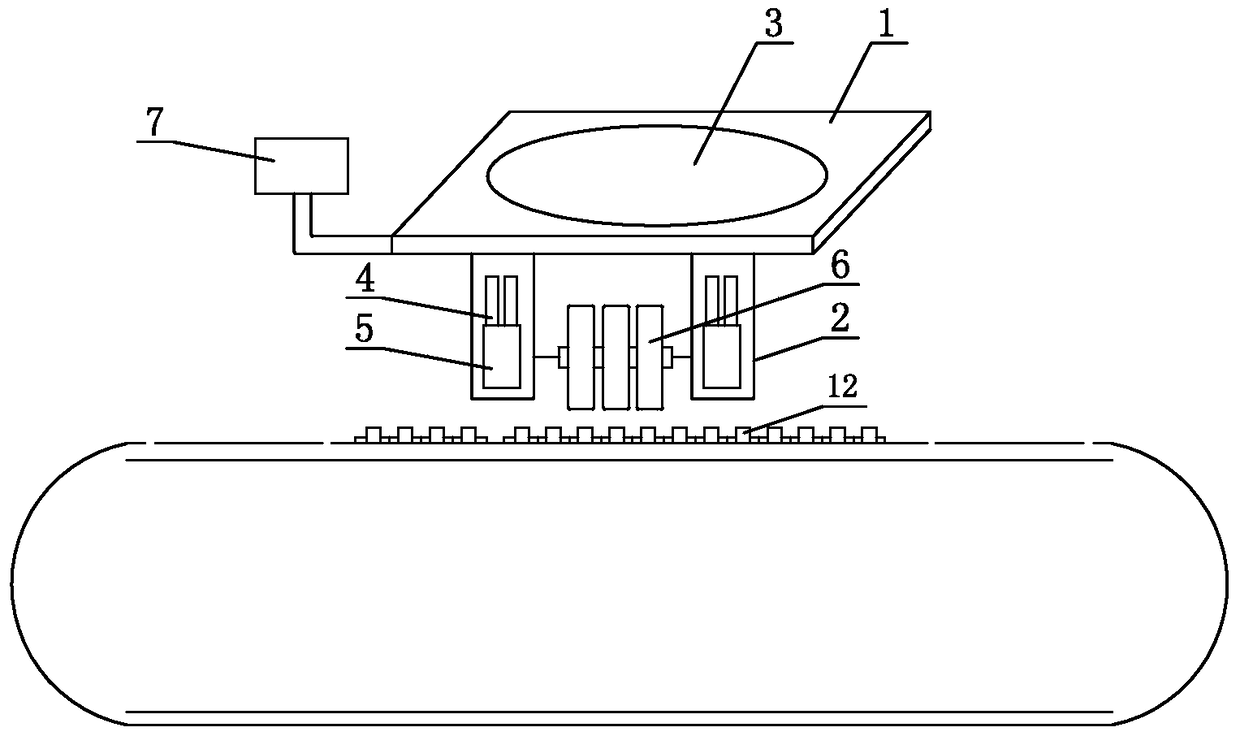

[0021] see Figure 1-Figure 3 , a grinding machine for superhard material products is used for grinding wire saw beads 12, including a bracket 1, a fixed frame 2, a rotating table 3, a sliding frame 4, a rotating motor 5 and a ceramic grinding wheel 6. Wherein, the rotary table 3 is arranged on the support 1, and is used to drive the vitrified grinding wheel 6 to rotate horizontally; two fixed frames 2 are fixed on the bottom of the rotary table 3, and the sliding frame 4 and the rotating motor 5 are assembled in the fixed frame respectively, and the vitrified grinding wheel 6 is placed in the fixed frame. Between the two fixed frames 2; the rotating motor 5 drives the ceramic grinding wheel 6 to rotate axially through the rotating shaft; the sliding frame 4 can drive the rotating motor 5 and the ceramic grinding wheel 6 to move up and down, and the sliding frame 4 and the rotating motor 5 are respectively connected with a controller 7, And be controlled by it; This grinder th...

no. 2 example

[0034] see Figure 4-Figure 5 , a grinding machine for superhard material products is used for grinding the edging wheel cutter head 13, and its specific structural composition and usage method are the same as those of the first embodiment. The rotation direction of the ceramic grinding wheel 6 is parallel to the transmission direction of the transmission track 8. The rotation of the ceramic grinding wheel 6 can be reasonably adjusted through the rotating table 3, and the edge grinding wheel cutter head 13 in the mold 10 can form a certain angle with the ceramic grinding wheel 6, so as to perform deep grinding. , to achieve sharpening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com