Automatic multi-function rubber belt grinding and cutting assembly line

A transmission belt and multi-functional technology, which is applied in the field of vertical multi-functional rubber transmission belt automatic grinding and cutting production line, can solve the problems of low production efficiency of rubber belts, low production efficiency of rubber belts, and many production equipments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

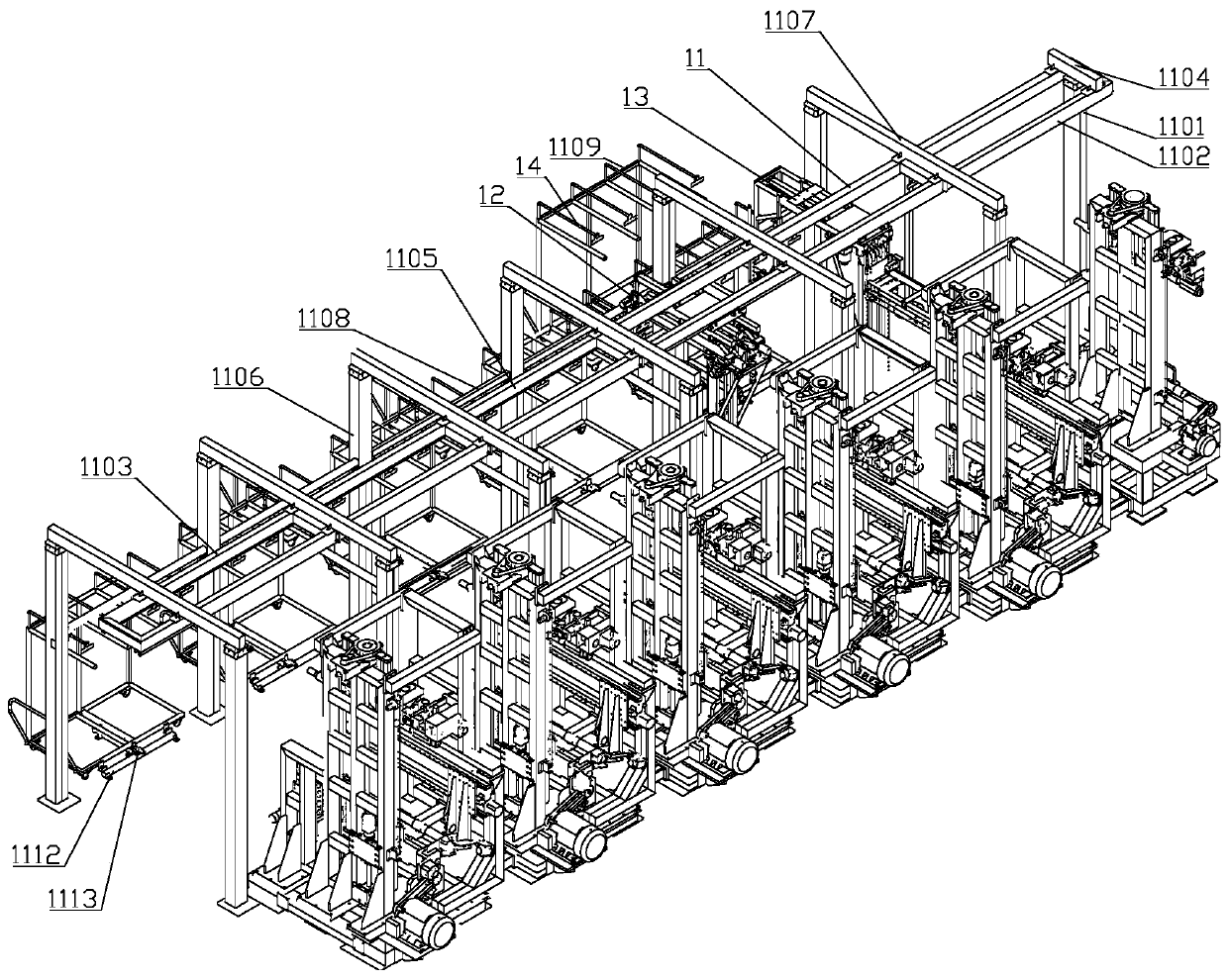

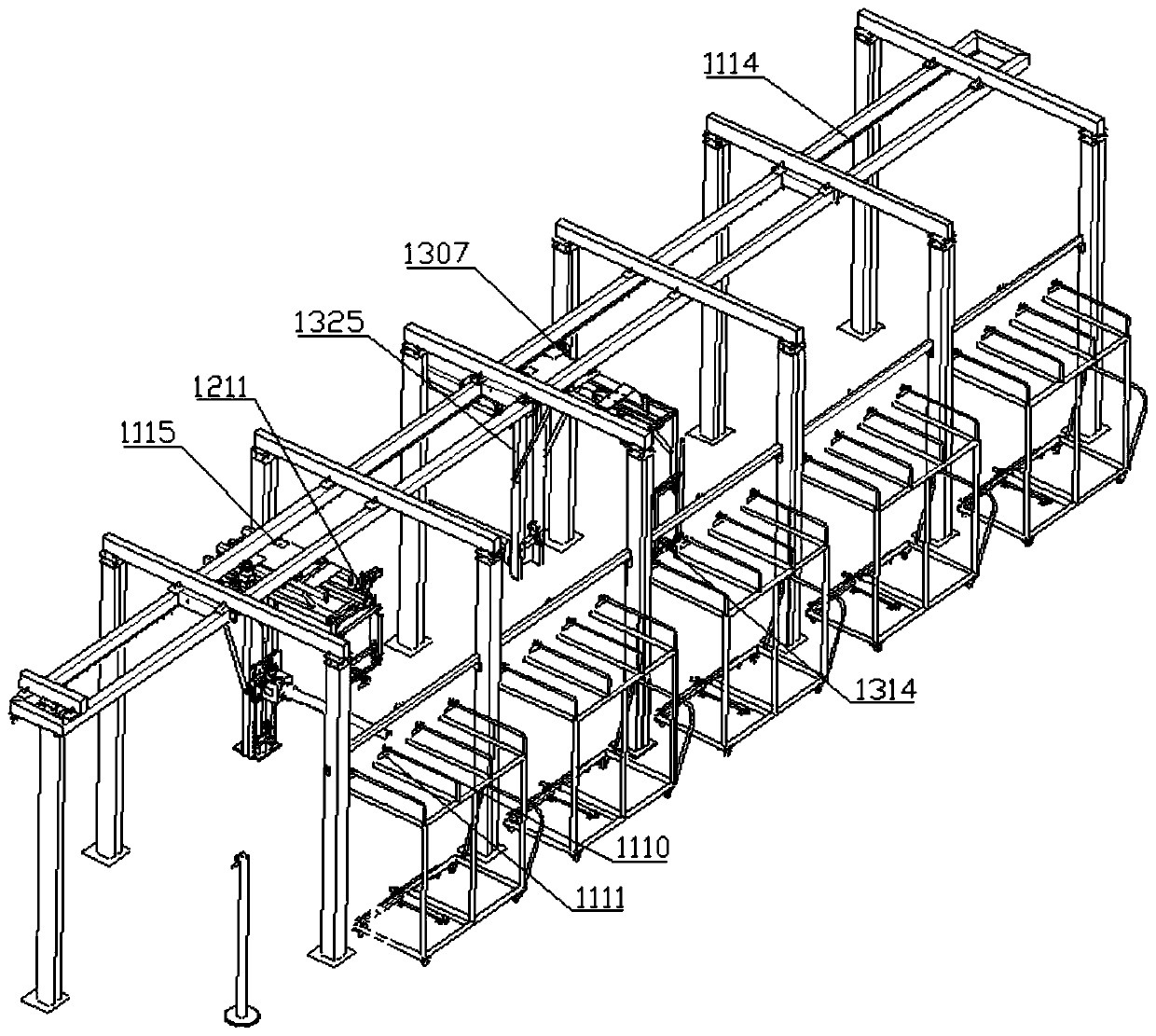

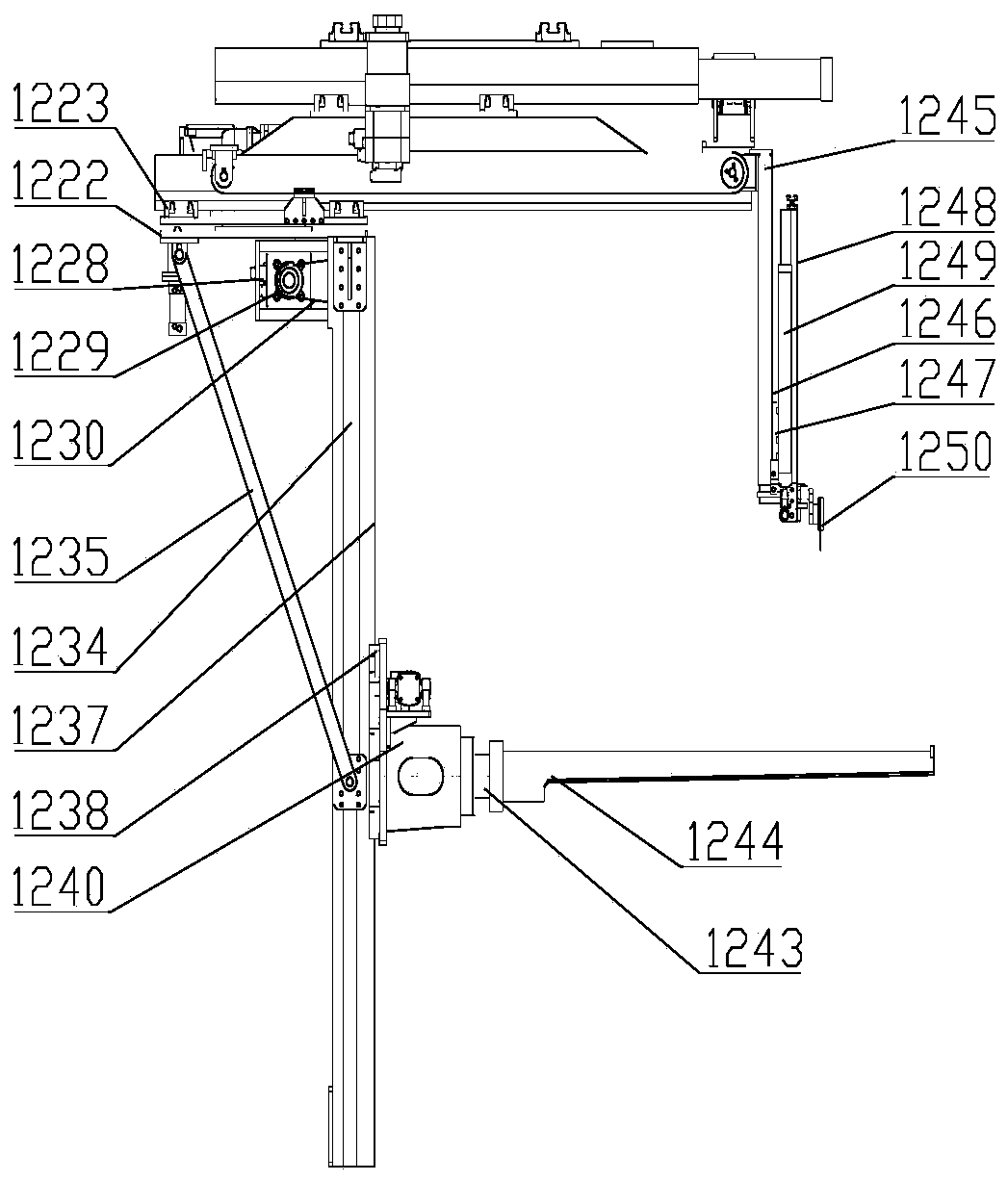

[0024]The device is mainly composed of a grinding device 1, a cutting device 2, a driving device 4, a dust suction device 3, a tensioning device 7, a speed measuring device 6, an auxiliary supporting device 5, a conveying device 14, a grinding auxiliary device 11, and a belt unloading device. 12. It consists of a tensioning mobile loading device 13, the grinding device 1 is set on the base 118 of the fuselage, the grinding roller 106 is movably connected with the base 118, and the dust suction device 3 is set at the lower end of the grinding device 1 , the cutting device 2 is installed under the tensioning device 7, the driving device 4 is arranged on the top of the tensioning base 301, the speed measuring device 6 is installed on the left side wall of the tensioning base 301, and the motor I101 is fixed On the base 118, the tape unlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com