PIN height automatic detecting equipment

An automatic detection and high-level technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of reducing the detection efficiency of testing equipment, increasing the labor intensity of workers, and the inability of the stage to step and shift, and reduce the number of loading and unloading. , The effect of reducing labor intensity and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

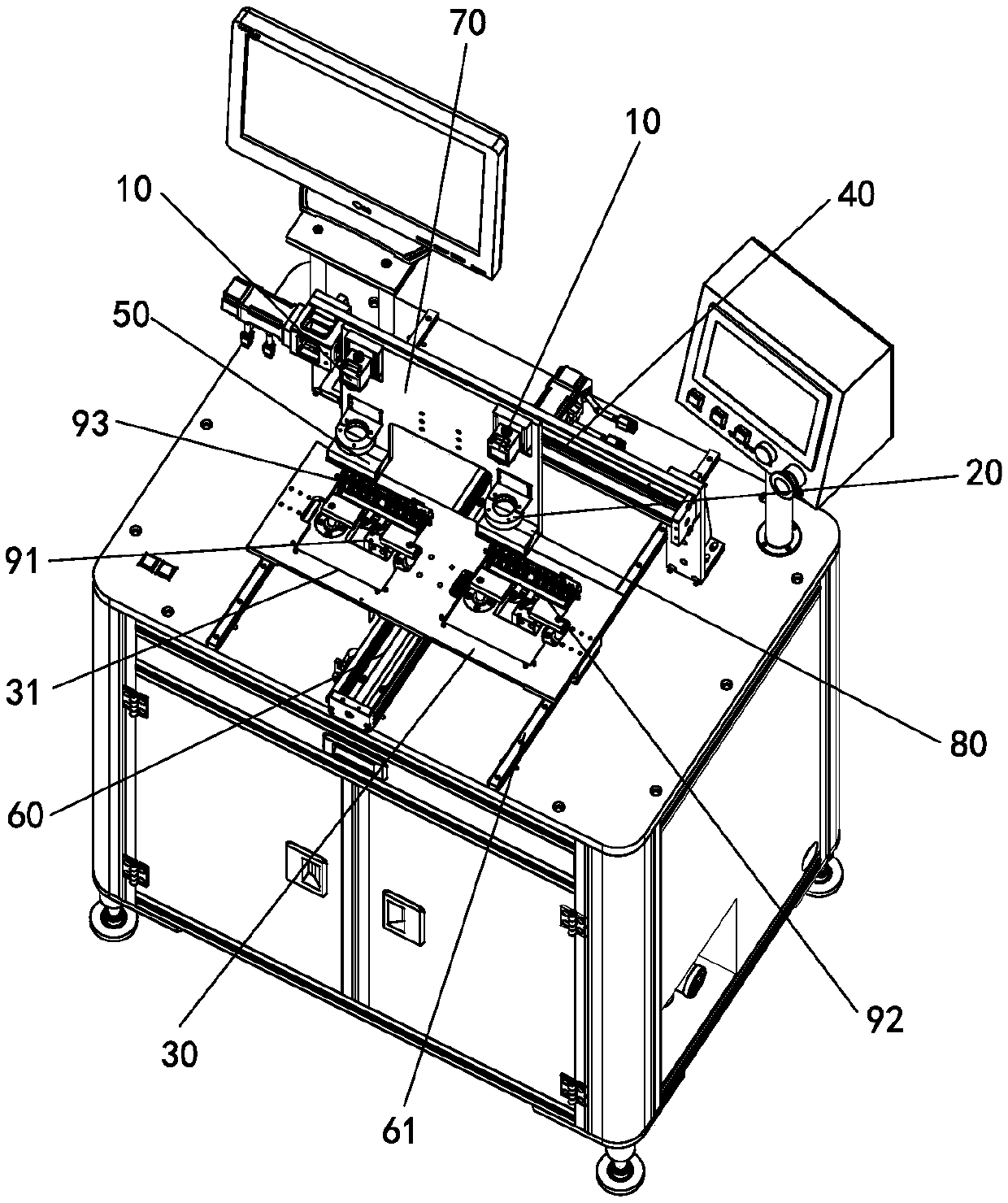

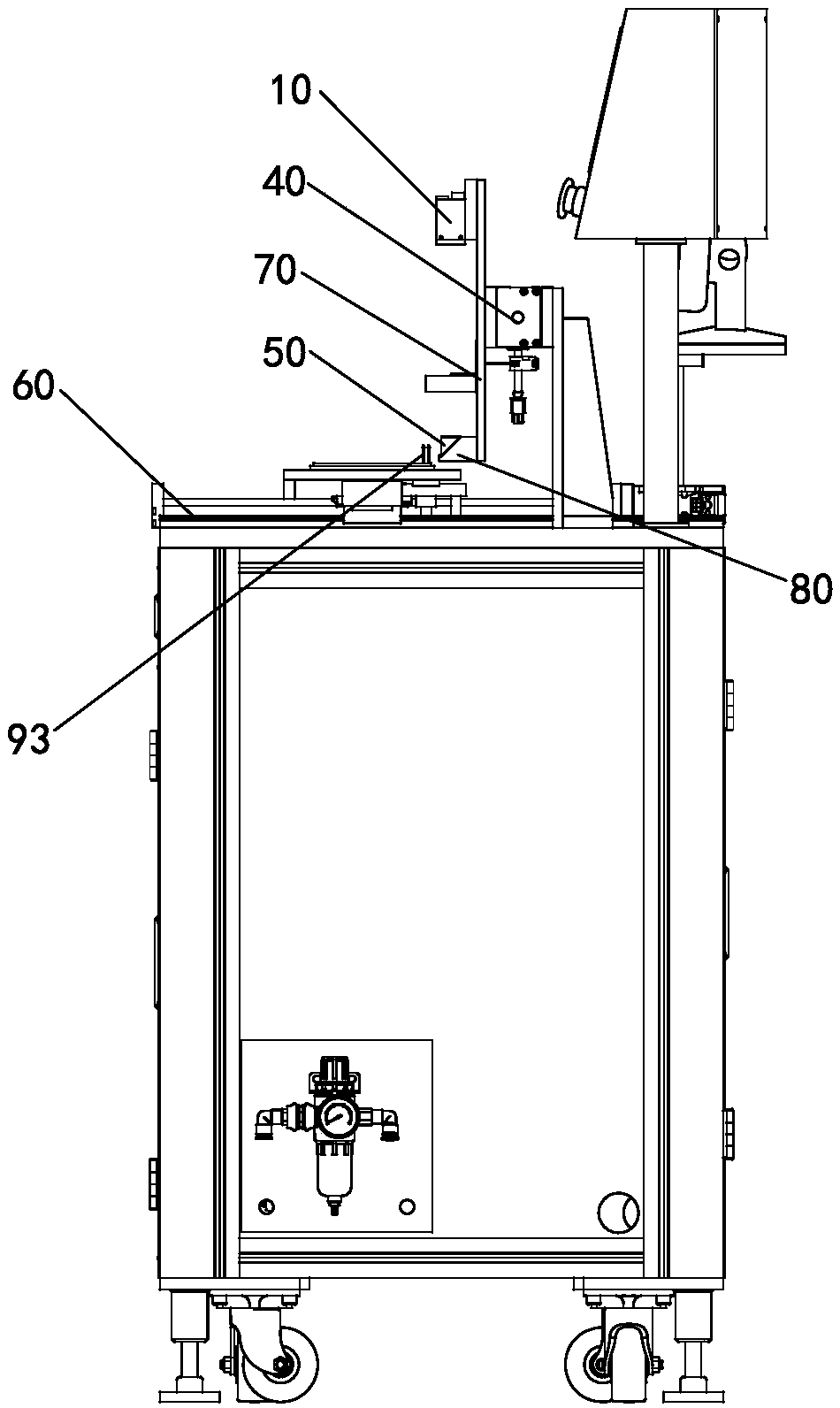

[0022] see figure 1 with 2 The PIN foot height automatic detection equipment shown is equipped with a machine vision system including two sets of CCD cameras 10 and two sets of light sources 20. In addition, the detection equipment table is also provided with a camera module The stage 30, and the first displacement mechanism 40 that drives the CCD camera 10 to move step by step.

[0023] The first displacement mechanism 40 is set up along the X-axis direction, and is erected on the top of the stage 30 by a bracket. A vertical mounting plate 70 is installed on the slider of the first displacement mechanism 40, and two groups of CCDs are fixed side by side on the mounting plate 70. side. A fixing seat 80 is respectively disposed on the mounting plate 70 below the light source 20 .

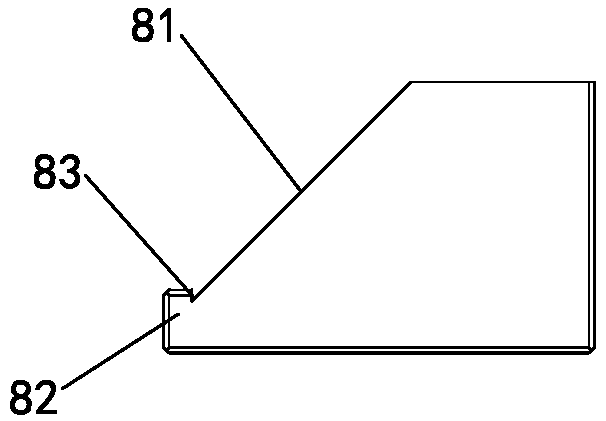

[0024] see image 3 , each fixing seat 80 has a mounting slope 81 inclined at 45°, and a stopper 82 located at the bottom of the mounting slope 81 and protruding outward, and a triangular slot 83...

Embodiment 2

[0036] The size of the camera module is small, and the PIN pin may be partially or completely submerged in the plastic frame, so that the CCD camera 10 cannot collect the side image of the PIN, so this embodiment makes further improvements on the basis of Embodiment 1 to solve the problem. this technical problem.

[0037] A pneumatic ejection mechanism for lifting the camera module from the carrier tray is provided below the carrier platform 30 . Preferably, the pneumatic ejection mechanism is composed of a cylinder 91 and a top plate 92, the top plate 92 is fixed on the top of the telescopic rod of the cylinder 91, and is located below the carrier 30; the top plate 92 is provided with four ejector pins 93 corresponding to each product.

[0038] When the camera module to be checked comes to the detection position, the cylinder 91 drives the thimble 93 to eject the camera module from the plastic frame, so that the PIN pin is completely exposed to the outside of the plastic fram...

Embodiment 3

[0041] Due to the small size of the camera module, the sudden ejection of the thimble 93 may cause the module to fall. In order to prevent this phenomenon, the thimble 93 in the second embodiment can be designed as a hollow structure, and all thimbles 93 are made of air tubes. It is connected with the vacuum generating device, and before the cylinder 91 acts, the vacuum generating device works to generate negative pressure to tightly adsorb the camera module on the thimble 93 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com