Pneumatic self-locking clamping fixture

A self-locking clamping and clamping technology, which is applied in the direction of clamping, manufacturing tools, metal processing machinery parts, etc., can solve the problems that affect the normal processing quality of the processed parts, cannot guarantee the accurate positioning of the processed parts, and the clamping position is unstable. , to achieve the effect of convenient and fast disassembly, precise positioning, and improved loading and unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

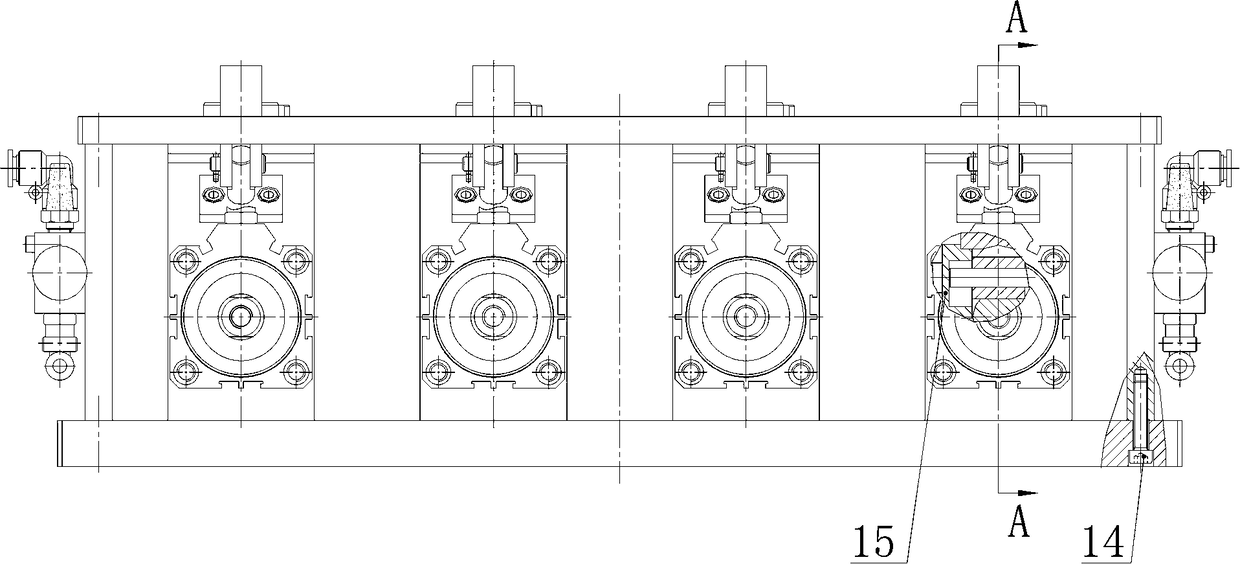

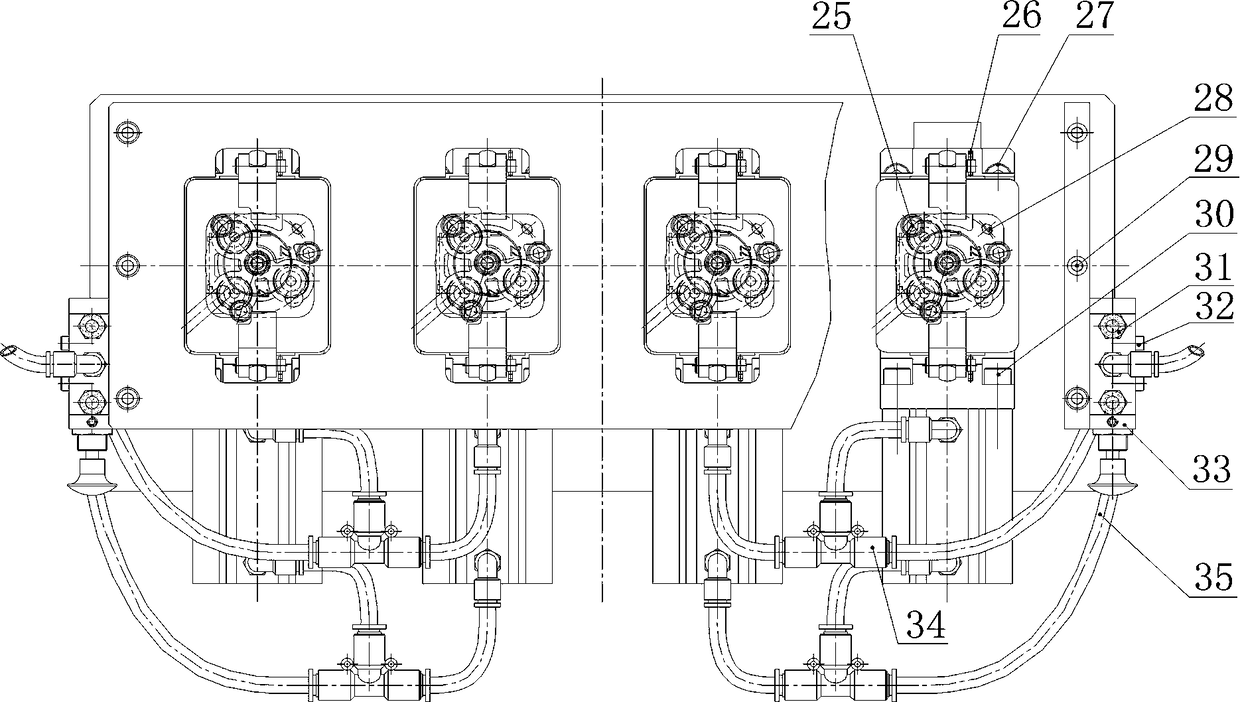

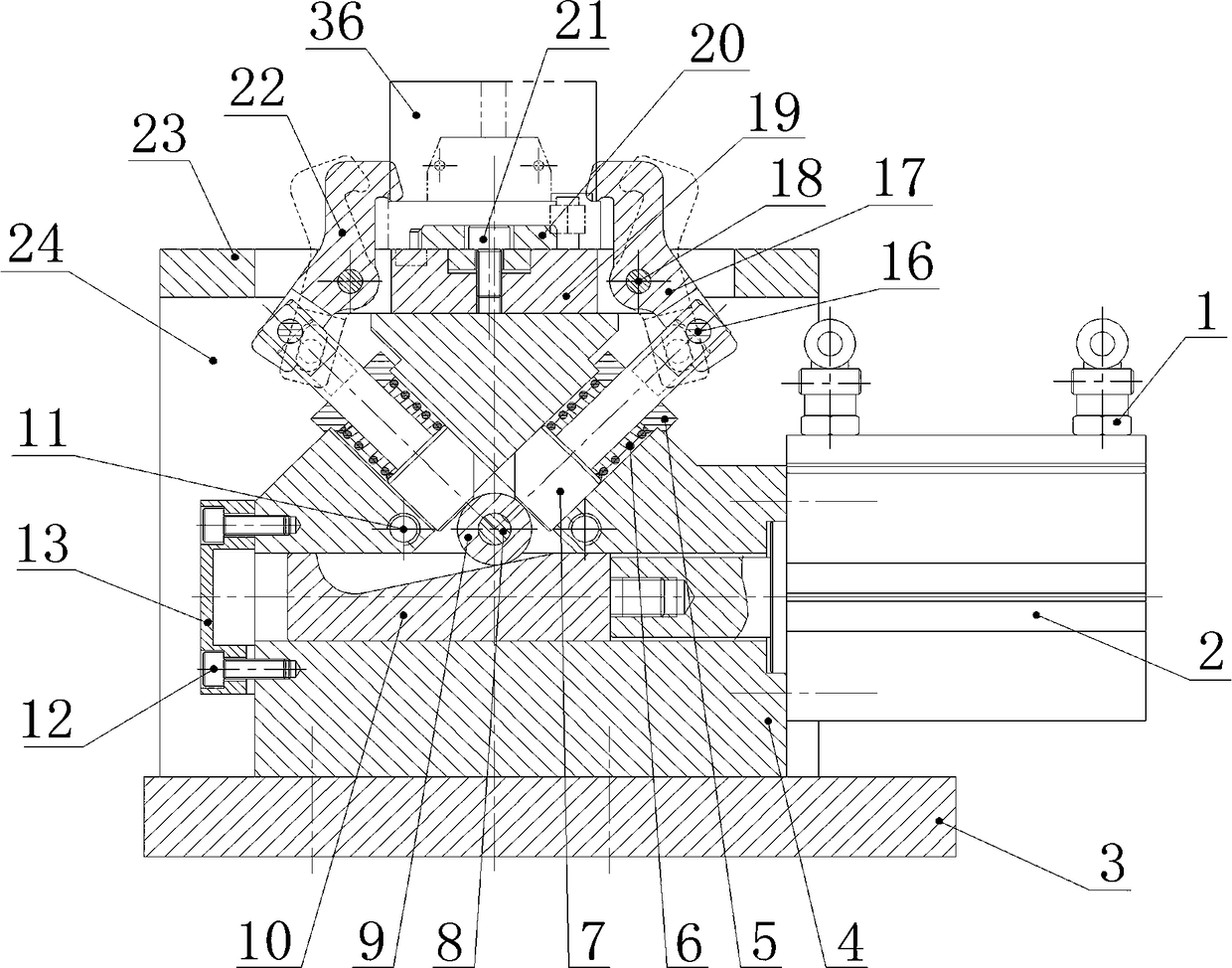

[0039] Such as Figure 1-3 As shown, the pneumatic self-locking clamping fixture includes a clamping device, and the clamping device adopts a wedge clamping mechanism, and the wedge clamping mechanism includes a wedge column 10 and a roller 9, and one end of the wedge column 10 is provided with There is a piston rod mounting stud, and a roller 9 is arranged on the working slope of the wedge column 10. The working slope is the contact surface of the clamping stroke between the wedge column 10 and the roller 9, and the self-locking angle of the clamping stroke Set to 5 degrees, the wedge clamping mechanism includes a power element, the power element adopts a cylinder, the cylinder adopts a double-acting cylinder, and the double-acting cylinder adopts a thin cylinder 2, and the thin cylinder 2 includes a piston rod. One end of the piston rod is provided with an internal thread interface, and the internal thread interface forms a fastening connection with the piston rod mounting s...

Embodiment 2

[0048] The pneumatic self-locking clamping fixture is similar to Embodiment 1, except that the self-locking angle of the clamping stroke is set to 10 degrees.

Embodiment 3

[0050] The pneumatic self-locking clamping fixture is similar to Embodiment 1, except that the self-locking angle of the clamping stroke is set to 15 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com