Coaxiality alignment method

A coaxiality and standard core technology, applied in the field of technology, can solve the problems of unstable parts quality, many human factors, and high labor intensity, and achieve the effects of good alignment accuracy, good economy, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The coaxiality correcting steps of the present invention are as follows:

[0028] A. Making alignment tooling

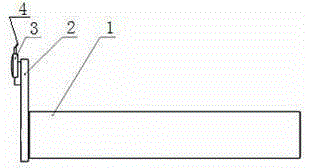

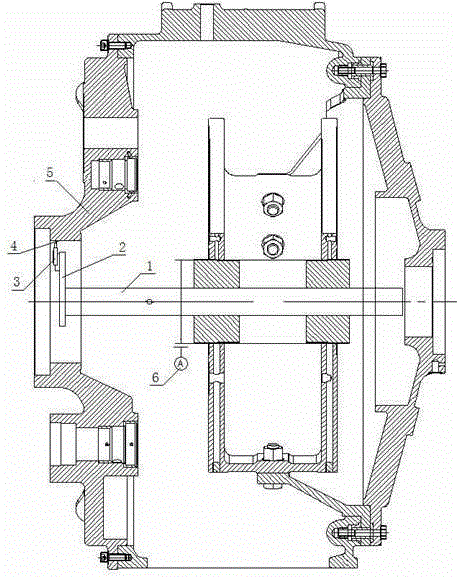

[0029] The alignment tool is composed of a standard mandrel 1, a table frame 2 and a lever dial indicator 3. According to the size of the reference hole of the combined workpiece, the standard mandrel 1 and the table frame 2 are made based on the reference hole. Select the corresponding leverage percentage table 3;

[0030] B. The alignment steps are as follows:

[0031] B0, clamping the combined workpiece 5 on the workbench of the machine tool;

[0032] B1, standard mandrel 1 is packed in the datum hole of the combined workpiece 5 of combined processing;

[0033] B2, paste the supporting end of the table frame 2 on the support end face of the standard mandrel 1;

[0034] B3. Bond the lever dial indicator 3 to the measuring end of the watch frame 2, with the gauge head 4 facing outwards, and the pointer of the lever dial indicator 3 bending inwards at 30 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com