Multi-directional rotating tooling

A multi-directional, tooling technology, applied to positioning devices, workbenches, manufacturing tools, etc., can solve the problems of low processing quality, processing dead angle, mechanical processing rigidity, etc., to improve production efficiency, reduce the number of times of loading and unloading, and save up and down The effect of feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

[0030] The orientations involved in this specification are all subject to the orientations shown in the drawings, which only represent relative positional relationships, not absolute positional relationships.

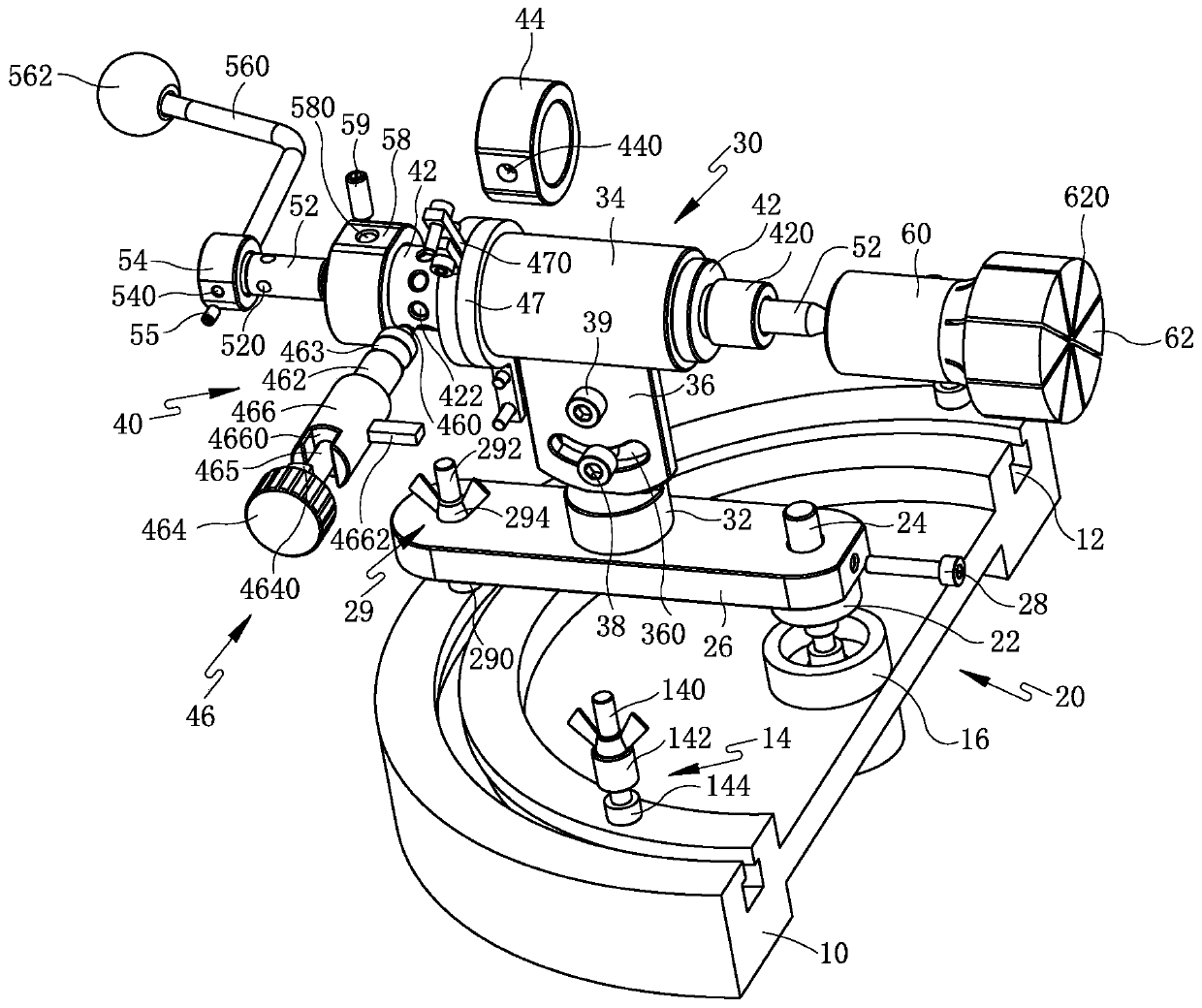

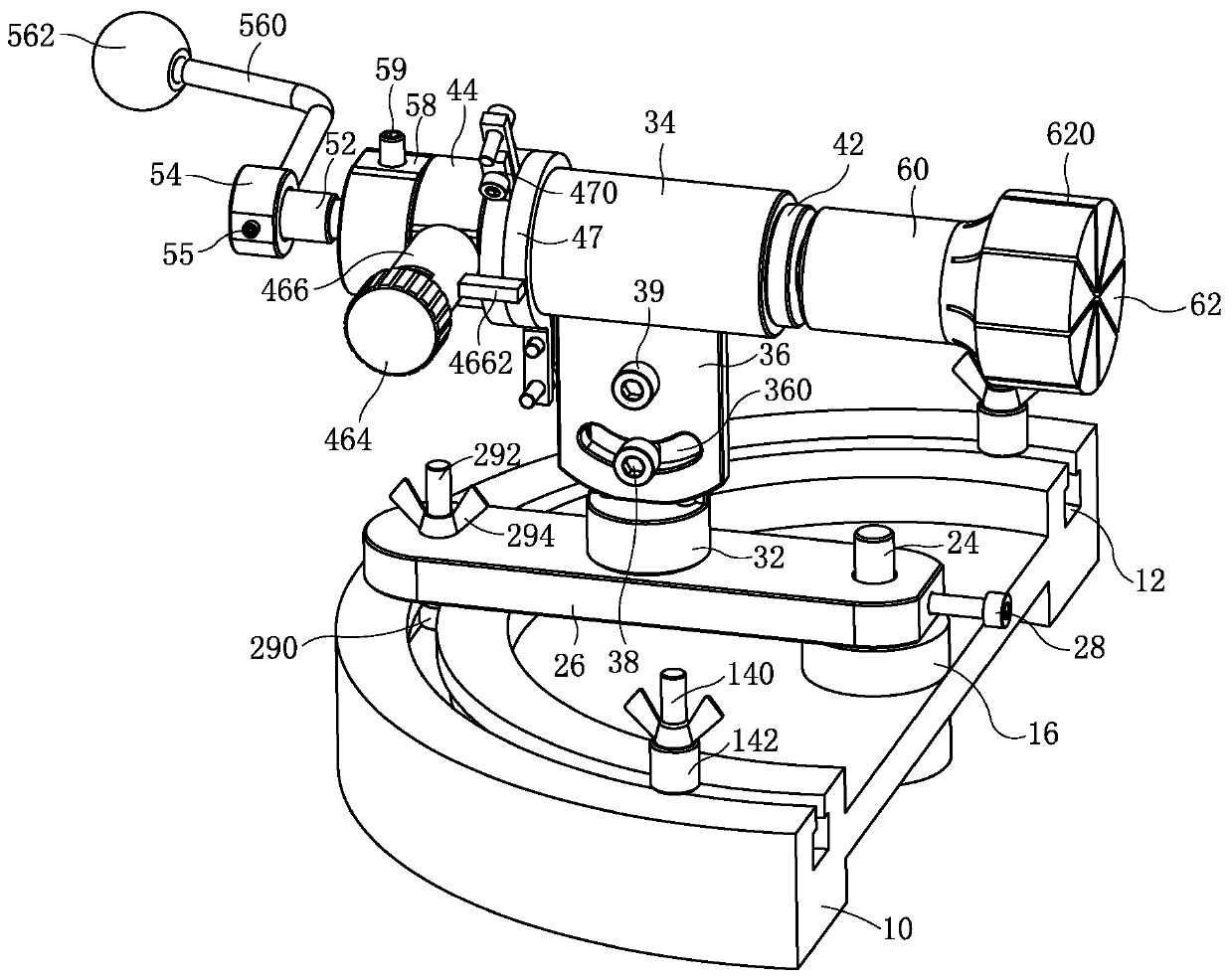

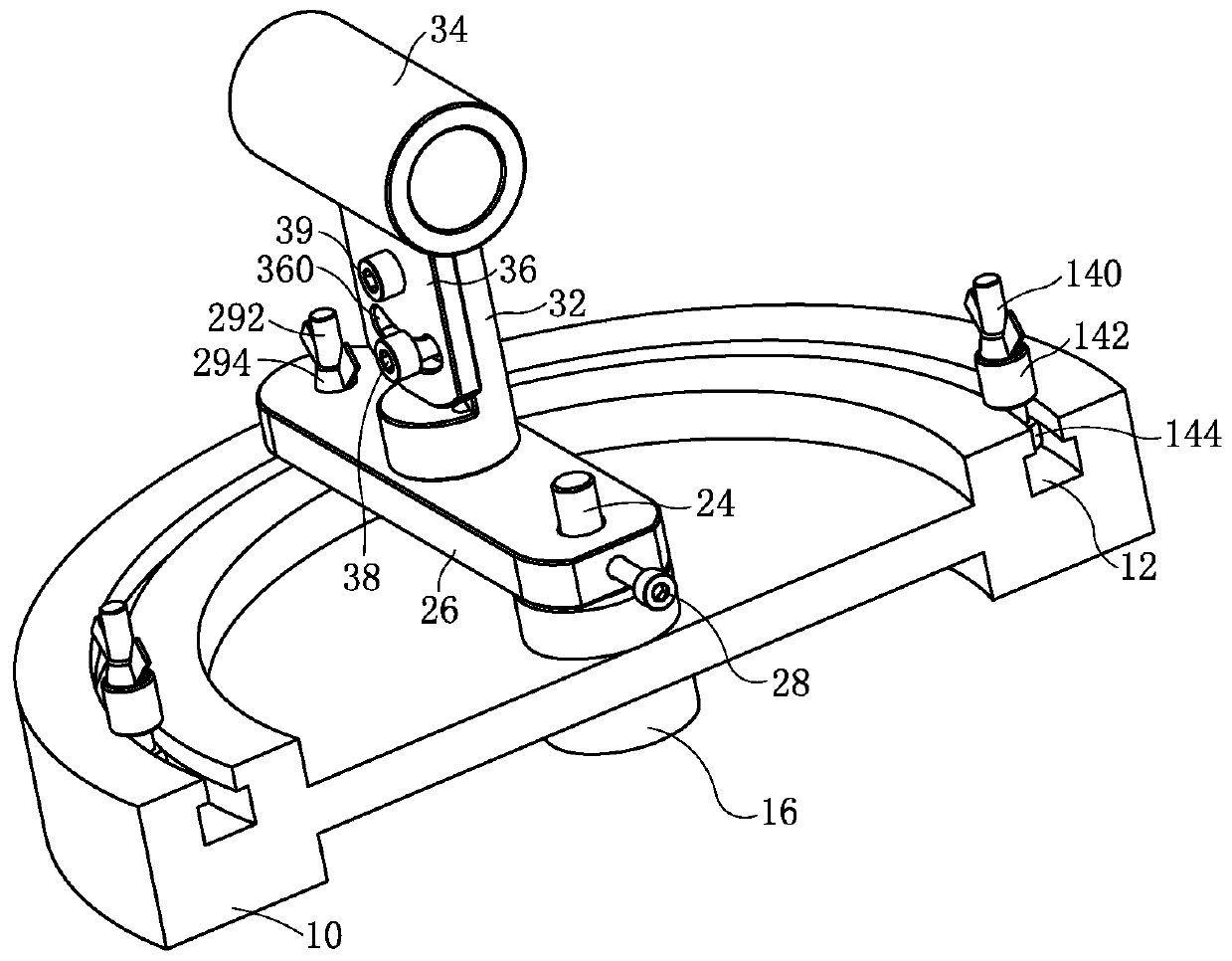

[0031] Such as figure 1 As shown, a multi-directional rotating tooling includes a base 10, on which a z-axis rotating mechanism 20 is installed, the z-axis rotating mechanism includes a rotating block 26 capable of rotating around the z-axis, and a y-axis rotating mechanism is installed on the rotating block 26 30. The y-axis rotation mechanism 30 includes a support cylinder 34 capable of rotating around the y-axis, and an x-axis transfer mechanism 40 is installed on the support cylinder 34 . The x-axis rotation mechanism includes a rotating cylinder 42 installed in the support cylinder 34. Both ends of the rotating cylinder 42 pass through the supporting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com