Four-axis magnetic suction cup tool

A magnetic sucker and tooling technology, which is applied to positioning devices, manufacturing tools, metal processing equipment, etc., can solve the problems of lack of easy disassembly and assembly, and achieve the effects of saving research and development costs, simple and convenient assembly and disassembly, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

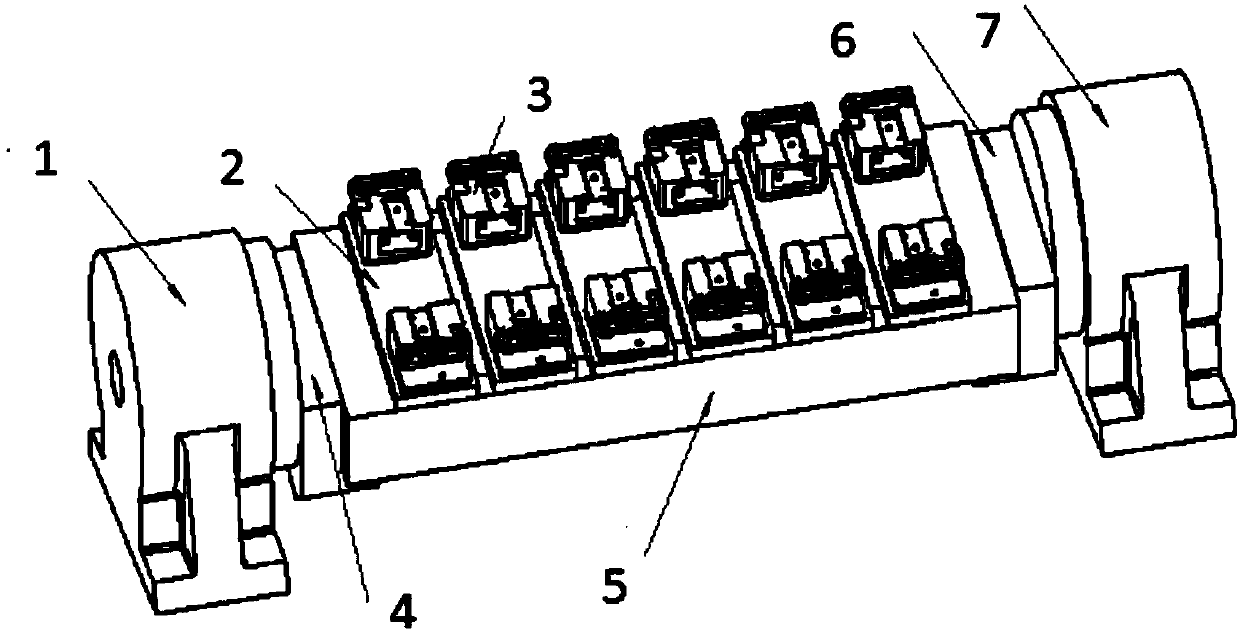

[0021] like figure 1 The shown four-axis magnetic chuck tooling is characterized in that: it comprises a tailstock 1, a turntable 7 and a chuck 6;

[0022] A first positioning plate 4 is rotatably installed on the tailstock 1, and a second positioning plate 6 is rotatably installed on the turntable 7; the first positioning plate 4 and the second positioning plate 6 are arranged opposite to each other, and the rotation axes of the two are collinear;

[0023] The suction cup 5 is fixedly installed between the first positioning plate 4 and the second positioning plate 6, wherein the first end of the suction cup 5 is detachably connected to the first positioning plate 4, and the second end of the suction cup 5 is detachable from the second positioning plate 6. Dismantling and connecting; a plurality of templates 2 are magnetically adsorbed and fixed on the suction cup 5 , and the template 2 is provided with a station for installing the workpiece 3 .

[0024] In this embodiment, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com