Spring mattress

A mattress and spacer technology, applied in the field of mattresses, can solve the problems of insufficient elasticity and the inability to adjust the thickness of the mattress, and achieve the effects of good elasticity, avoiding left and right swing or dislocation, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

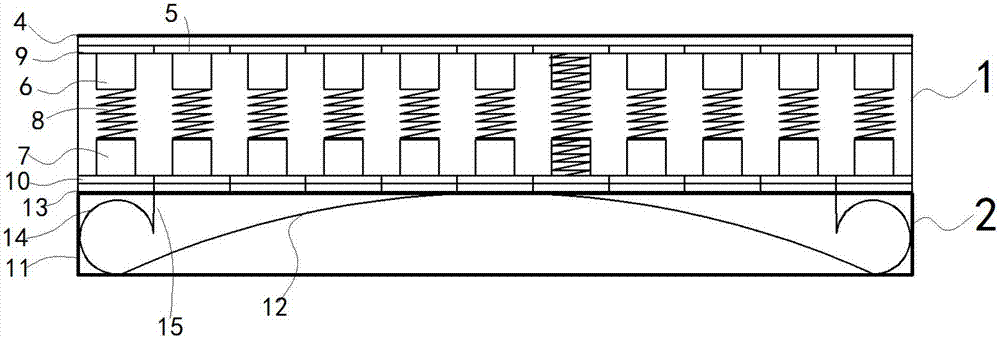

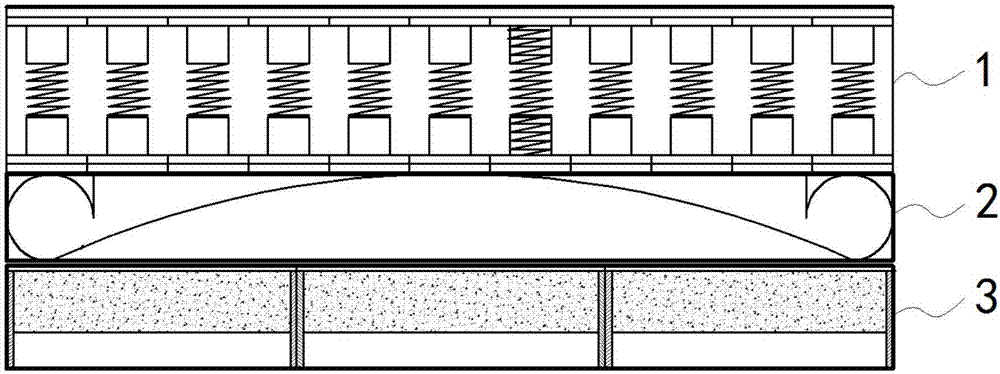

[0031] like figure 1 , 2 , Shown in 3 and 4, a kind of spring mattress comprises:

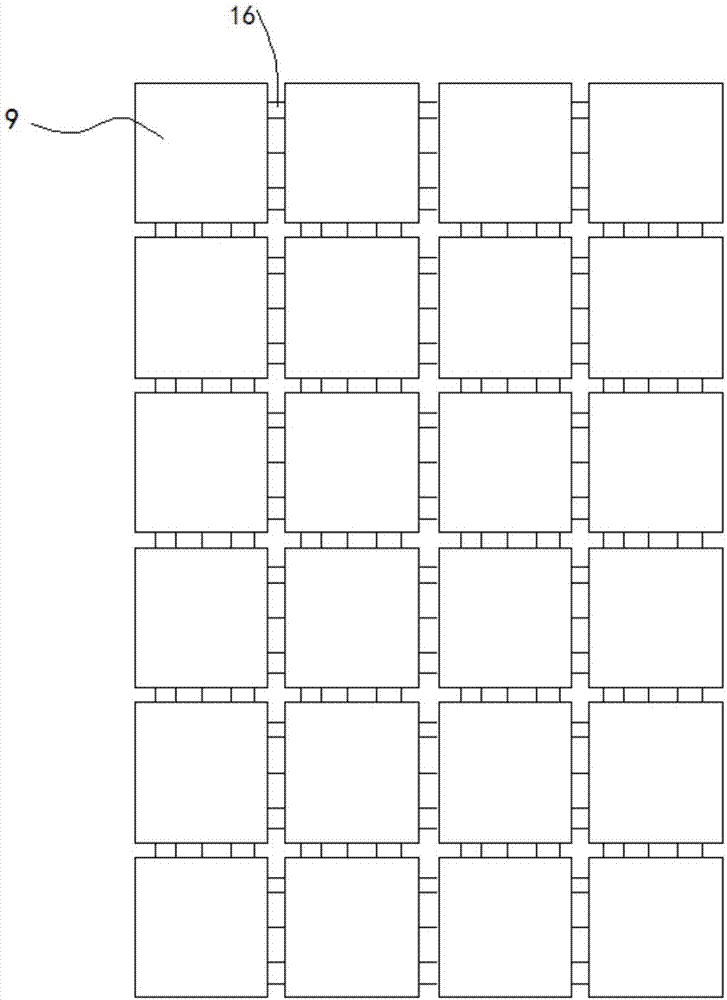

[0032] The first buffer layer 1 includes an upper pad 4, a lower pad, and a plurality of elastic units 5 arranged in the middle of the upper and lower pads, wherein the elastic unit 5 includes an upper sleeve 6, a lower sleeve 7, and is sleeved on The spring 8 inside the upper and lower sleeves and the elastic package wrapped outside the upper and lower sleeves, the spring 8 pushes the upper sleeve 6 up without pressure so that the gap between the upper sleeve and the lower sleeve 7 There is a compression distance and the upper and lower sleeves are pressed against each other after the spring is compressed, the upper end of the upper sleeve 6 is provided with a square upper gasket 9 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com