Locking support mechanism and exposure device of material exposure test box

A technology of exposure test and support mechanism, which is applied in the field of external exposure of space station materials, to achieve the effect of compact overall structure, stable and firm structure, and high space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

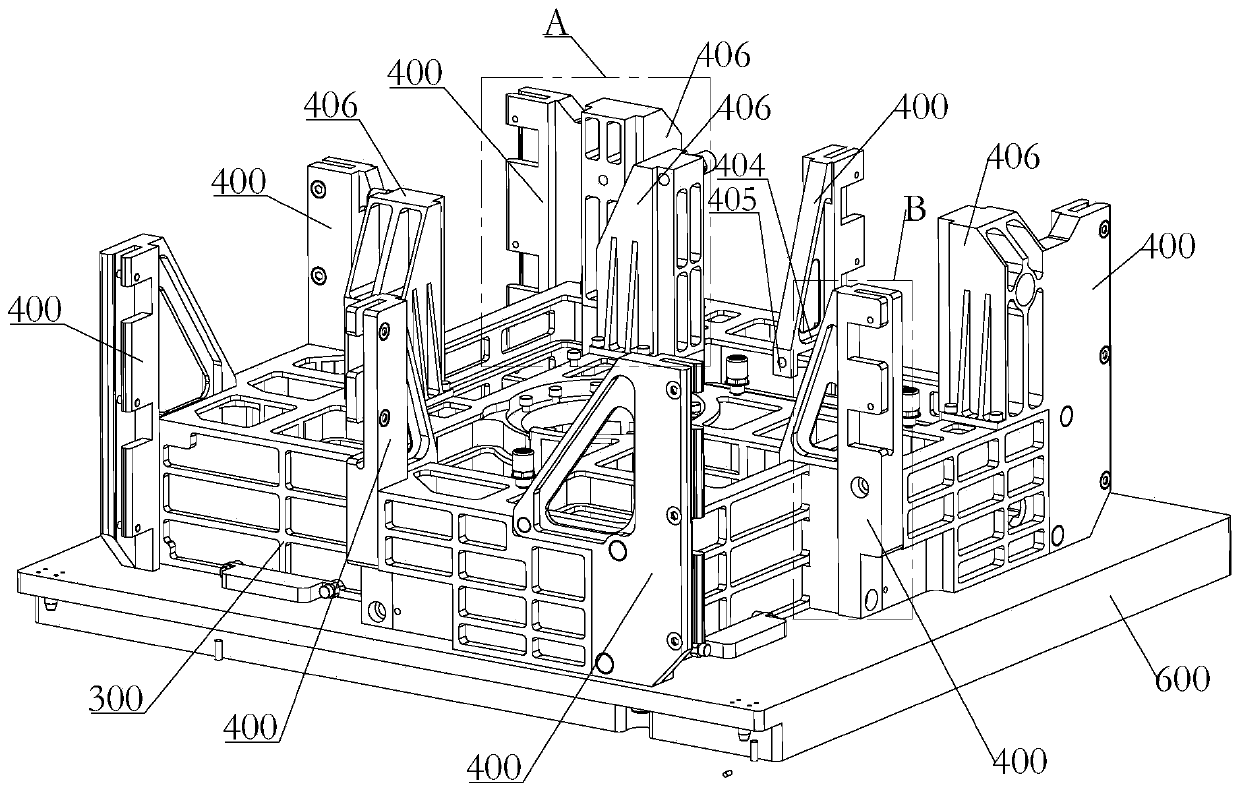

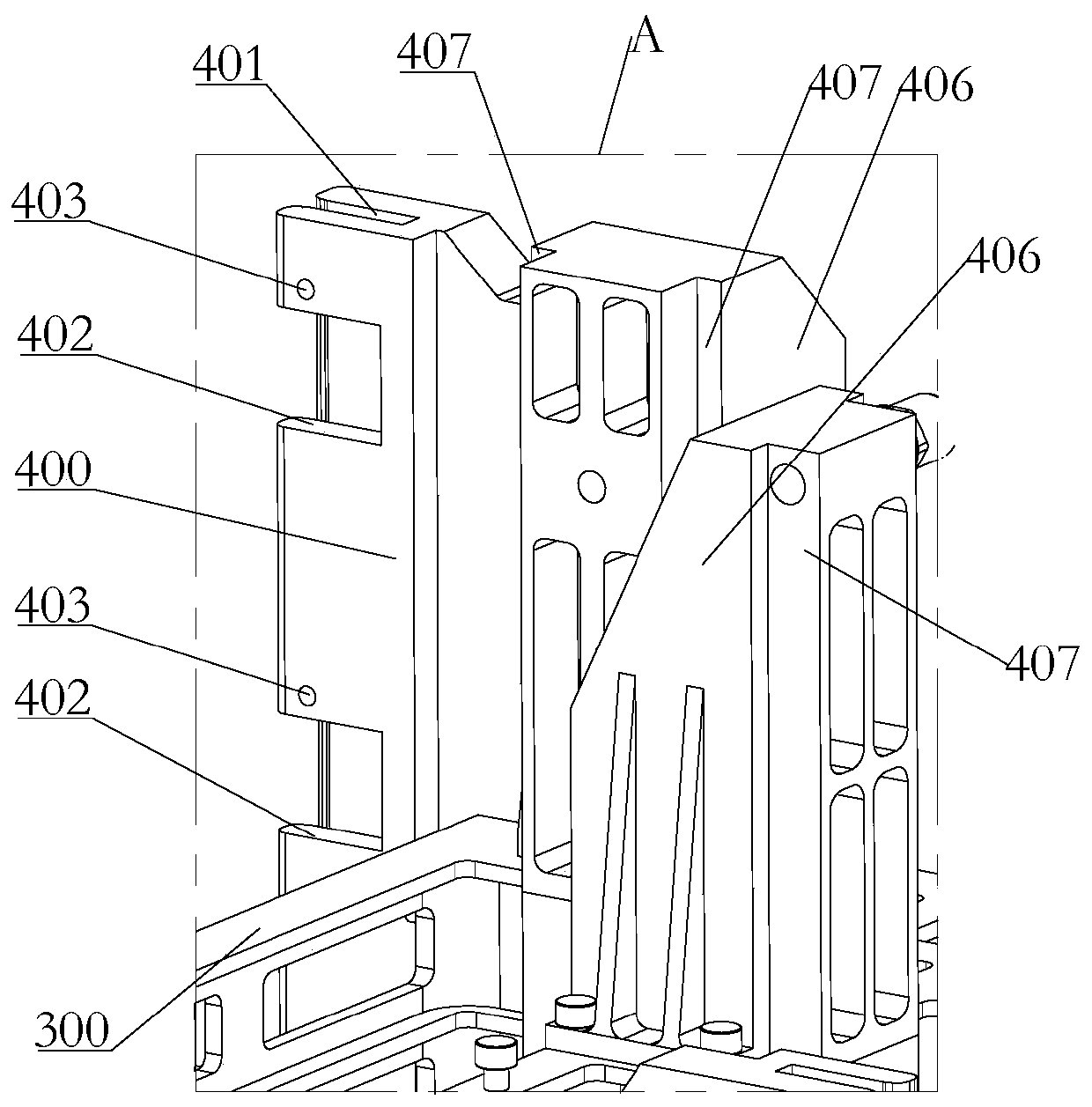

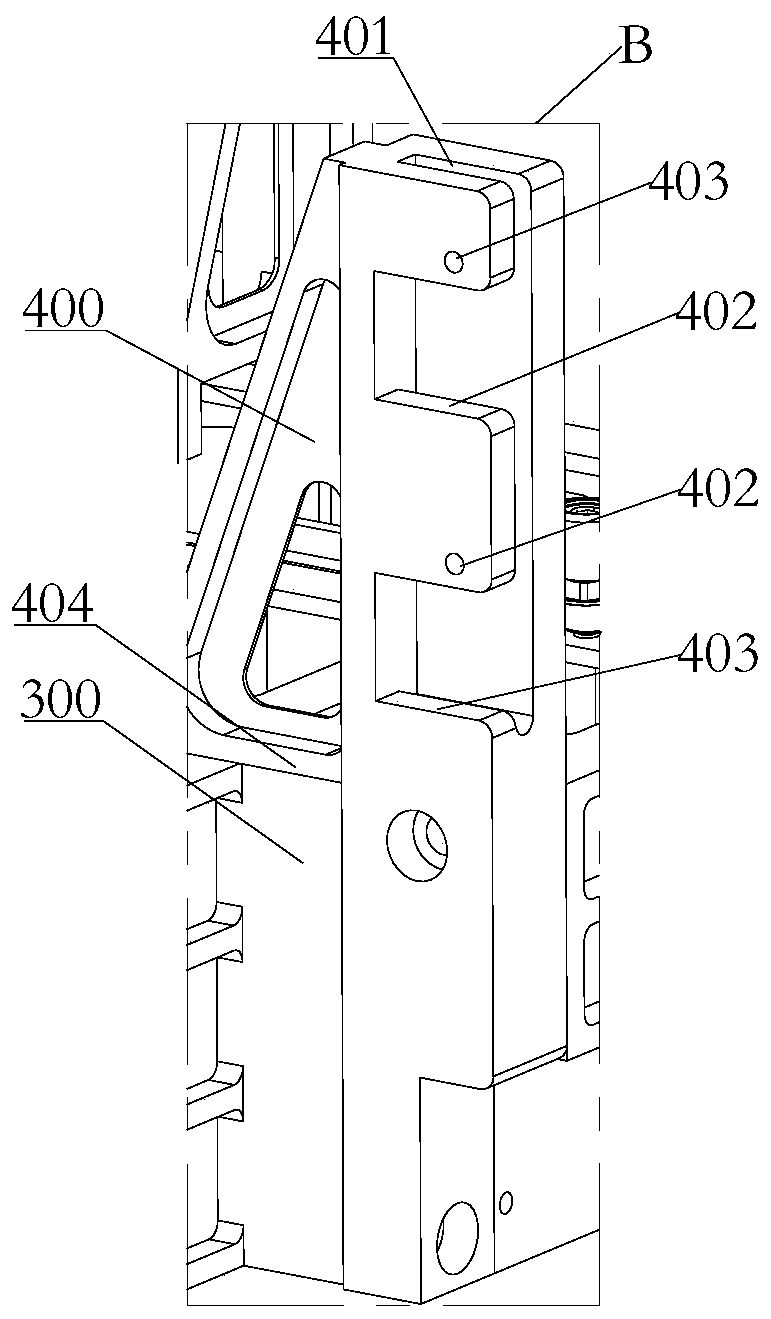

[0063] Such as Figure 1-Figure 7 As shown, the locking support mechanism of a material exposure test chamber in this embodiment includes a locking bracket 400 and a load-bearing mechanism 300. There are a plurality of locking brackets 400 and they are respectively vertically fixed on the load-bearing mechanism 300. On the outer peripheral side; one side of the locking bracket 400 is provided with a chute 401, a limit gap 402 is formed on the groove wall of the chute 401, and a guide locking member 403 is provided on the locking bracket 400, so that The guide locking member 403 is set through the two groove walls of the chute 401; the side walls of the test box 200 are respectively provided with baffle plates 201 arranged at intervals, and one end of the baffle plate 201 is connected to the test box An installation opening 208 is formed between the side walls of 200, and a partition rib 202 is provided between the baffle plate 201 and the side wall of the test box 200, and the...

Embodiment 2

[0084] Such as Figure 1-Figure 7 As shown, a material exposure test chamber exposure device in this embodiment includes the locking support mechanism and the base 600, the load-bearing mechanism 300 is installed on the base 600, and the locking bracket 400 is connected to the base 600. The base 600 is vertically arranged, the load-bearing mechanism 300 and the base 600 are polygonal structures respectively, and the corresponding sides are arranged in parallel, and at least one test box 200 is installed on each side of the load-bearing mechanism 300 After the test box 200 is opened, its exposed surface is arranged perpendicular to the base 600 and extends to both ends of the corresponding sides of the bearing mechanism 300 .

[0085] Specifically, such as Figure 1-Figure 7 As shown, the load-bearing mechanism 300 is an integrally formed structure. The load-bearing mechanism 300 is a quadrilateral structure, and one of the test boxes 200 is fixed on each of its four sides by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com