Electrical connector terminal and manufacturing method thereof

An electrical connector and manufacturing method technology, applied in the direction of connection, fixed connection, welding/welding connection, etc., can solve the problems of hindering the removal of terminals, residual tin material, etc., and achieve the effect of force balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

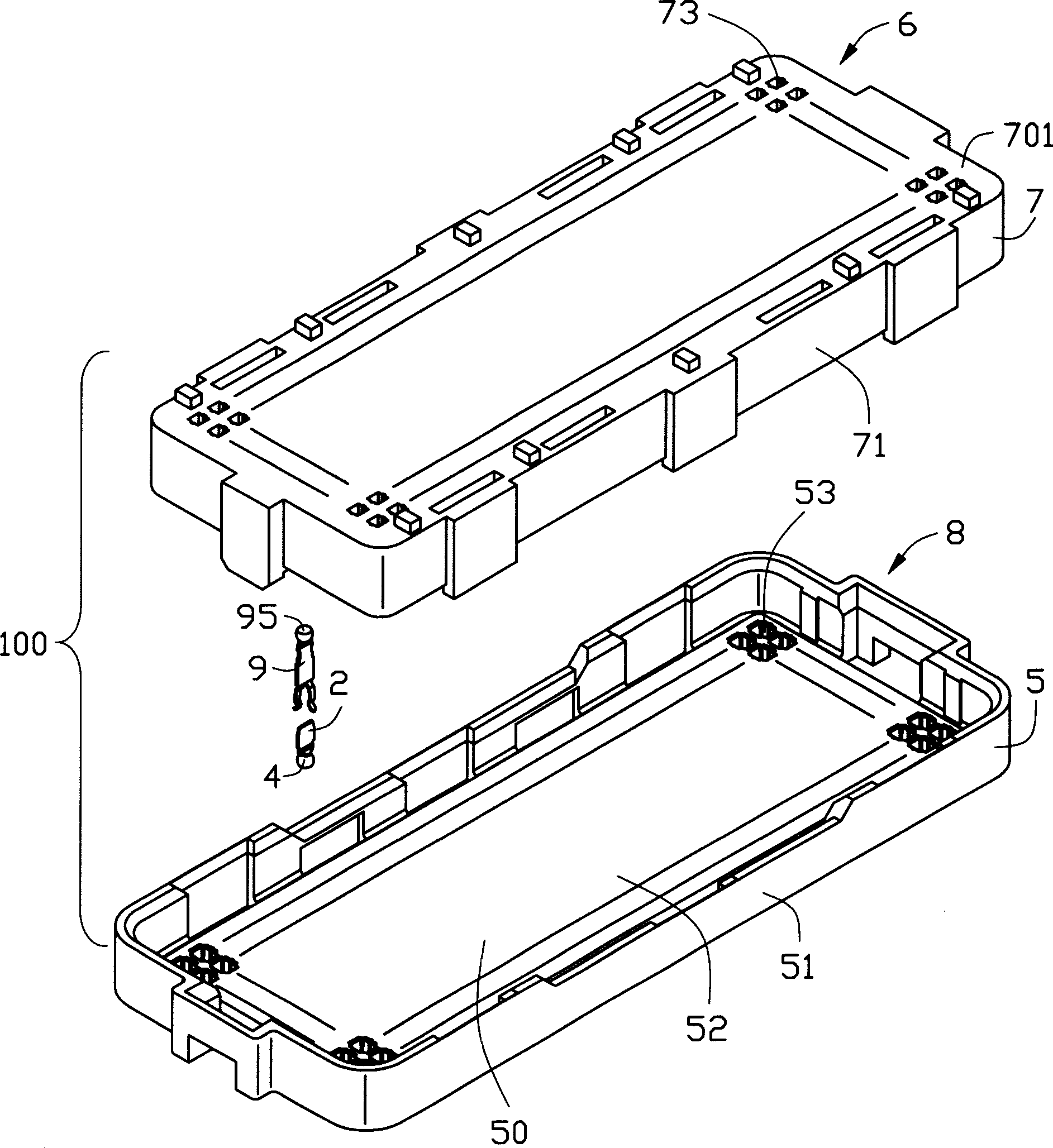

[0040] see figure 1 , the electrical connector assembly 100 of the present invention includes a female connector 6 and a male connector 8 matched therewith.

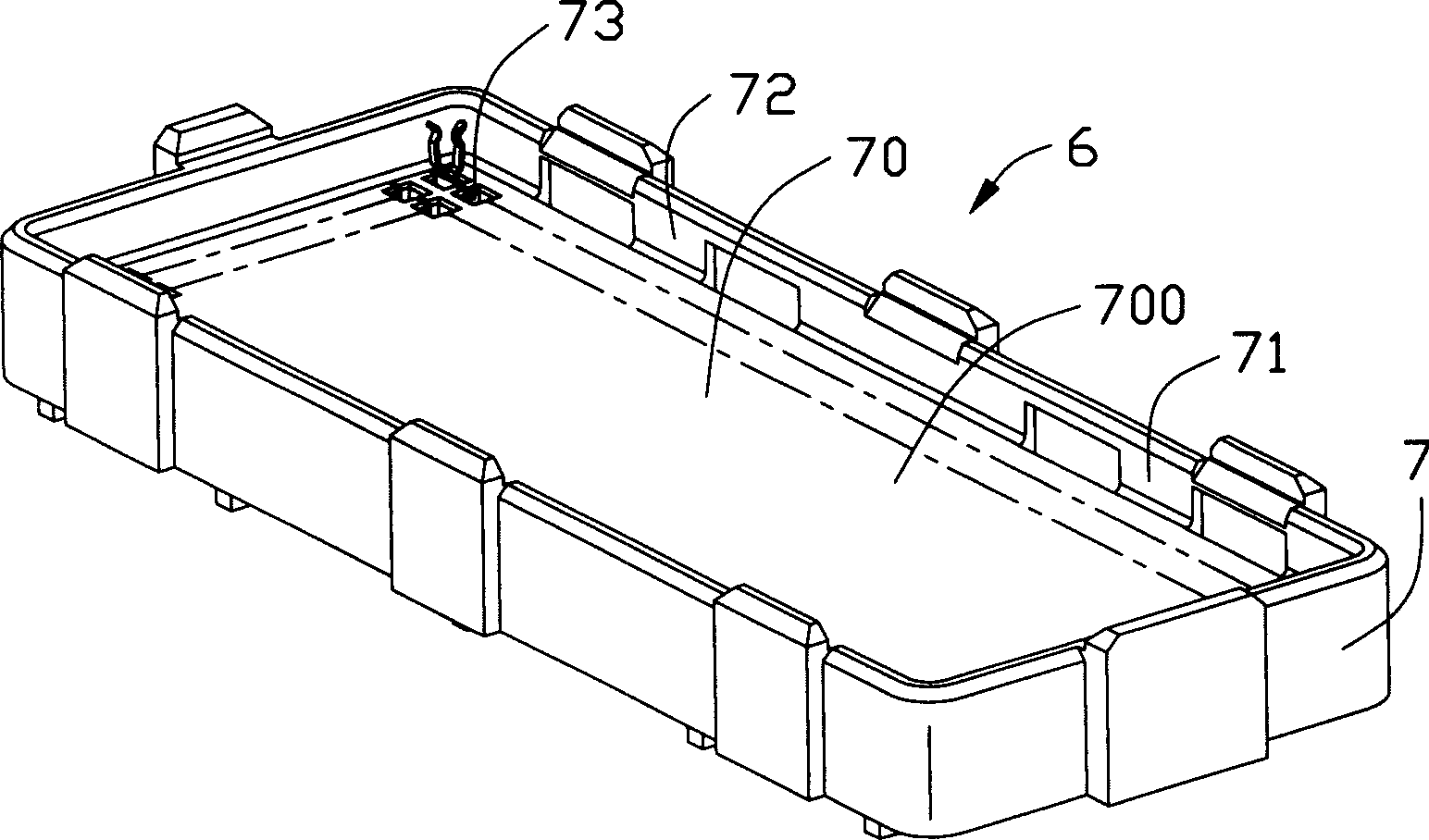

[0041] Please also see figure 1 and figure 2, the female connector 6 includes a female body 7, the female body 7 has a first base 70 and a first side wall 71 formed by extending from the periphery of the first base 70 to one side, the first base 70 and the first side wall 71 surround Set as chamber 72. The first base 70 has a first mating surface 700 facing the male connector 8 and a first mounting surface 701 opposite to the first mating surface 700 and used for mounting on the first circuit board. The plurality of rectangular female terminal holes 73 are arranged in multiple rows and pass through the first mating surface 700 and the first installation surface 701 of the first base 70 , and are used to accommodate a plurality of corresponding female terminals 9 .

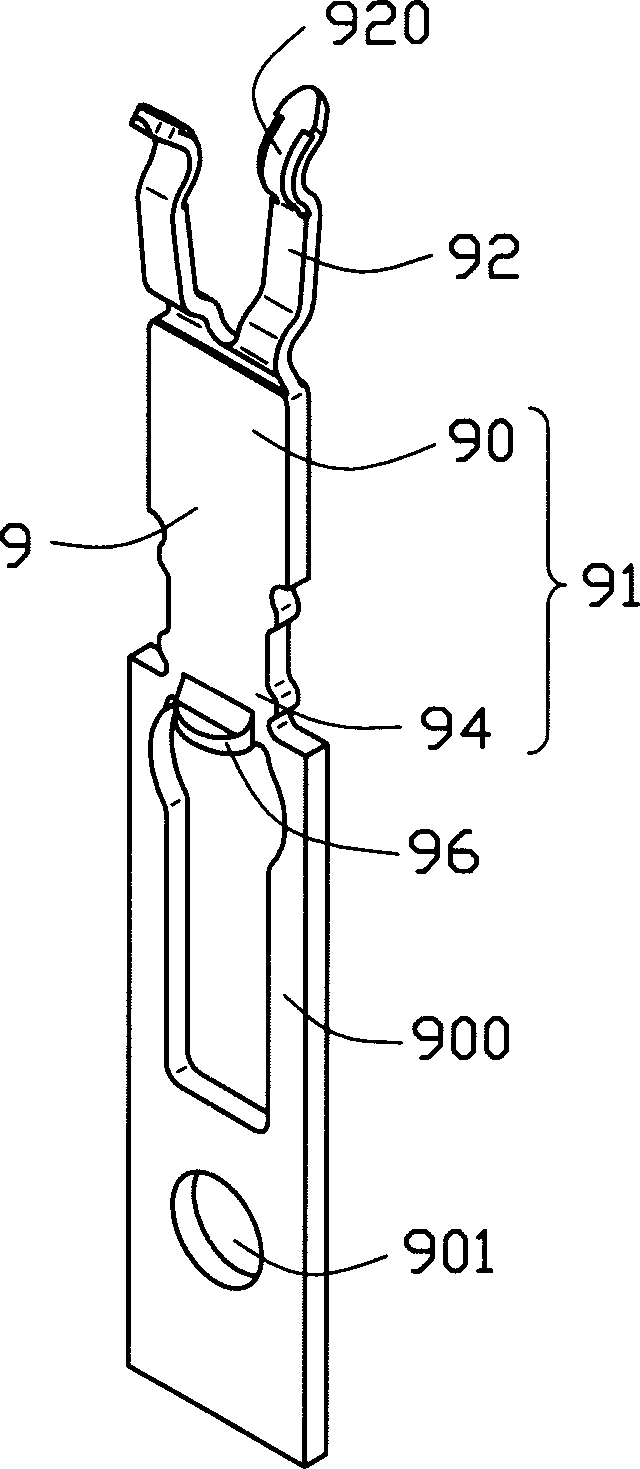

[0042] image 3 A female terminal 9 die cut fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com