General container for powder and liquid transportation

A container and powder technology, applied in the field of material transportation, can solve the problems of low efficiency of packaging, bag sealing and transfer, high degree of manual participation, floating waste of powder, etc., to improve market competitiveness, reduce workload, save occupation The effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

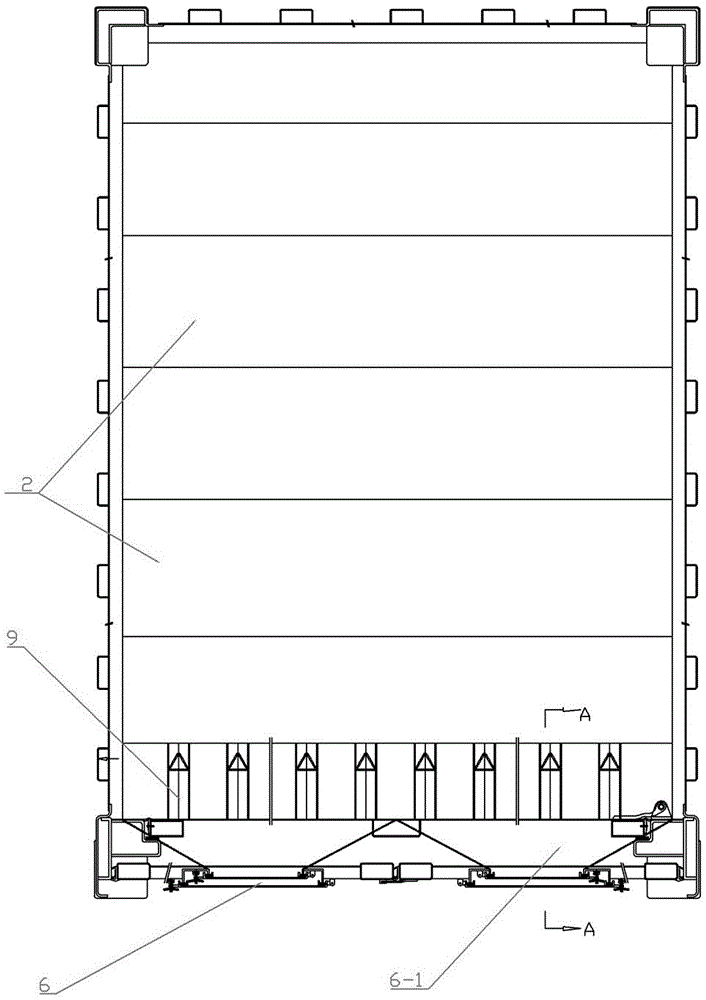

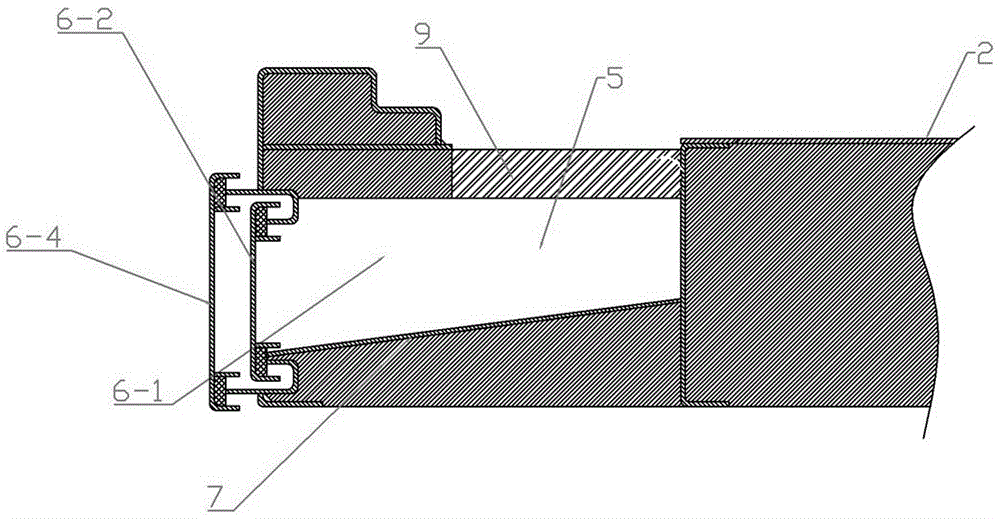

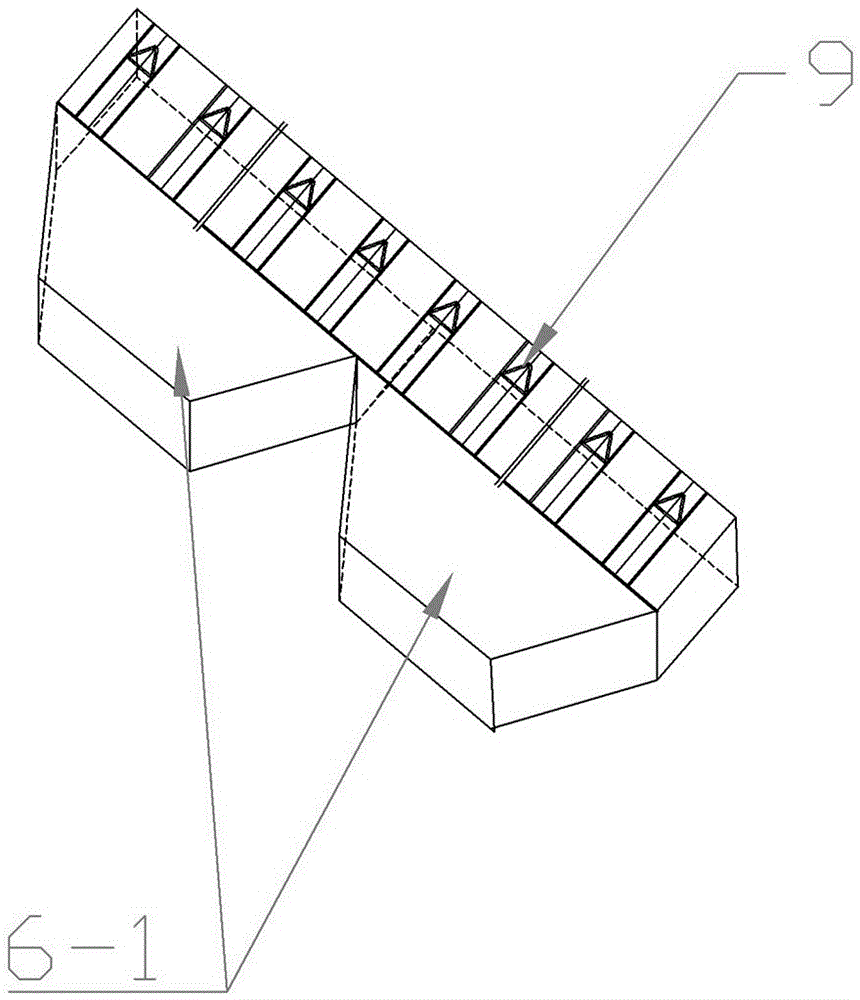

[0045] Example 1: see Figure 1-9 As shown, a general-purpose container for powder transportation includes a container body 2. The container body 2 includes a six-sided box composed of a top side, a bottom side, a front side, a rear side, a left side, and a right side. The container box 2 is provided with two feed ports 21 on the top side, a feed sealing cover 22 is installed on the feed port 21, one end or one side of the bottom side of the container box body 2 is provided with two feed ports, the container box body The bottom side of 2 is provided with a blanking device corresponding to the discharge port. The blanking device includes a blanking mechanism fixedly connected to the bottom side of the container box 2 and a blanking cavity 6-1 connected with the blanking mechanism. The blanking chamber 6-1 is in communication with the discharge port, and the blanking mechanism includes a blanking support beam 9 arranged in parallel with each other and a material containing cavity ...

Embodiment 2

[0047] Example 2: see Figure 1~12 As shown, it is basically the same as the first embodiment, the difference is that: the blanking device also includes a movable cover 8 movably arranged on the upper part of the blanking mechanism, and the upper and lower surfaces of the movable cover 8 are respectively provided with pull rings, so The pull ring is fixed in the movable cover 8 by the pull ring cover. Before the material is loaded, the staff pulls the ring to open the movable cover 8. The discharge port is sealed by the discharge sealing cover 6 to load the material. The loading is completed and After completing the transportation and unloading of materials, close the movable cover to keep the bottom surface of the bottom side of the container flat, so that other materials can be loaded and transported to improve the transportation capacity.

Embodiment 3

[0048] Example three: see Figure 1~15 As shown, it is basically the same as the second embodiment, the difference is that: the blanking device also includes a movable cover 8 movably arranged on the upper part of the blanking mechanism, and the upper and lower surfaces of the movable cover 8 are respectively provided with pull rings, so The pull ring is fixed in the movable cover plate 8 by the pull ring cover plate, which facilitates the closing and opening of the unloading mechanism. Both the upper pull ring and the lower ring are provided with a pull ring cover plate to keep the surface of the cover plate flat. The cover plate 8 is movably connected to the container box 2 through at least one turning mechanism, which includes a first connecting piece, a second connecting piece, a first connecting seat 8-1 fixed on the cover plate and a material containing The second connecting seat 8-2 on the vertical surface of the cavity body of the cavity 5, one end of the first connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com