Precise shaft dynamic torque measuring instrument

A dynamic torque, precision shafting technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of small test range and inaccurate measurement of shafting friction torque, so as to improve work stability, The effect of improving low-speed performance and improving the accuracy of assembly and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

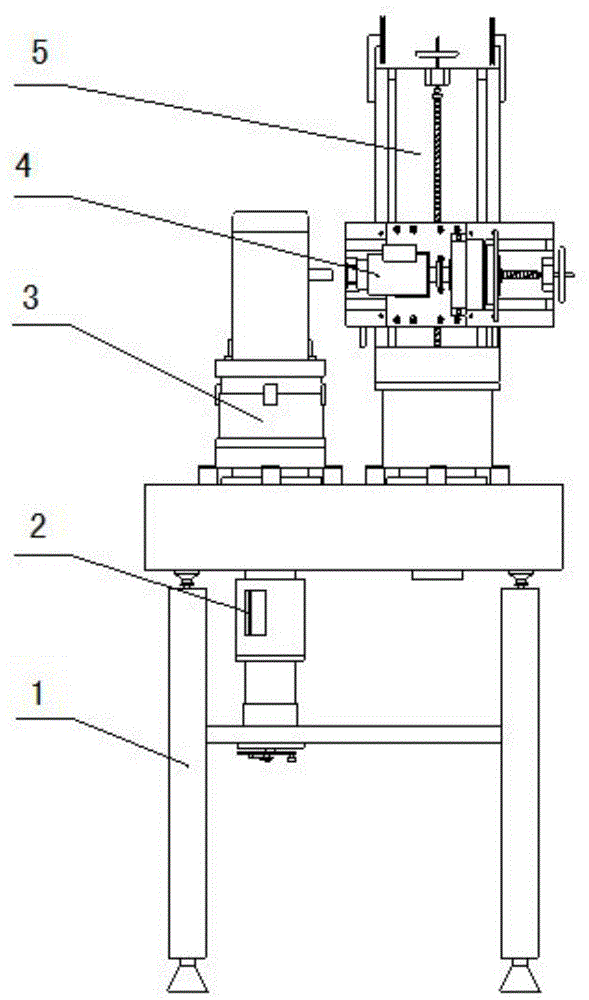

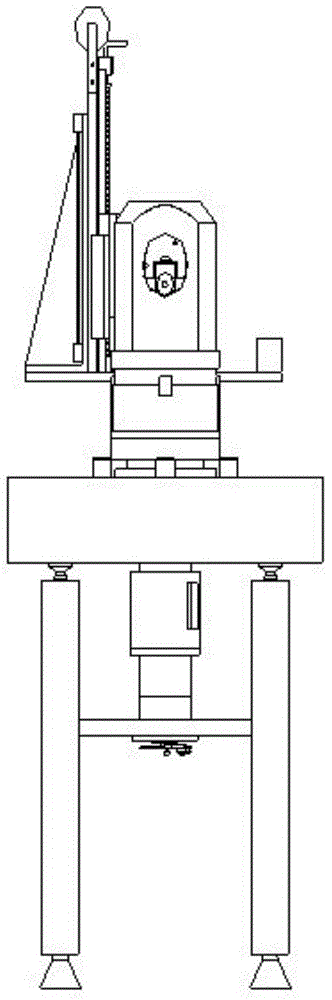

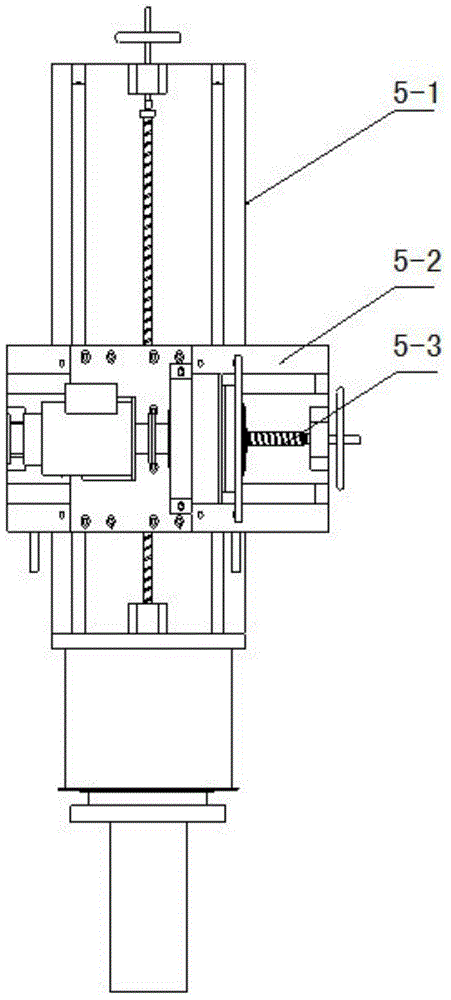

[0026] Specific implementation mode 1. Combination Figure 1 to Figure 10 Description of this embodiment, the precision shafting dynamic torque measuring instrument, is used to accurately measure the friction torque of the complex precision shafting in the three-axis stabilization system, realize the accurate measurement of the shafting torque and its uniformity evaluation, including the support and detection platform subsystem 1. Roll axis detection axis subsystem 2. Positioning and installation subsystem 3. Pitch and yaw detection axis subsystem 4 and structure adjustment subsystem 5;

[0027] The support and detection platform subsystem 1 includes a marble test platform 1-1 and a support frame 1-2, and the test platform 1-1 is placed on the support frame 1-2; the impact of external vibration on the inspection equipment is reduced, And adjust the marble platform to the level through the leveling mechanism on the support frame, so as to clearly understand the influence of gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com