Patents

Literature

40results about How to "Achieving Measurement Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

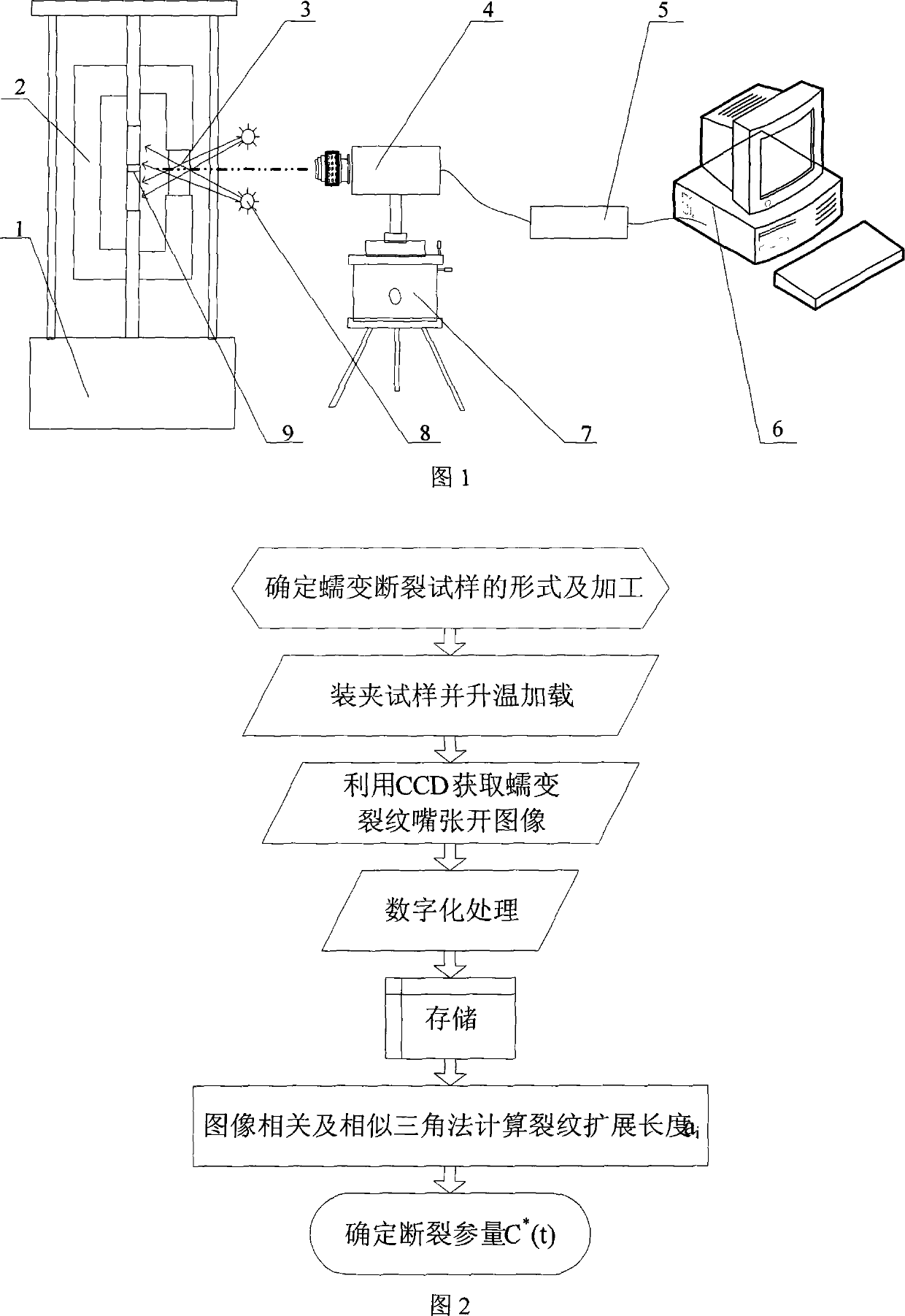

High temperature fracture parameter test method and its device

InactiveCN101144785AAchieving Measurement AccuracyHigh precisionOptically investigating flaws/contaminationSpecial data processing applicationsData acquisitionEngineering

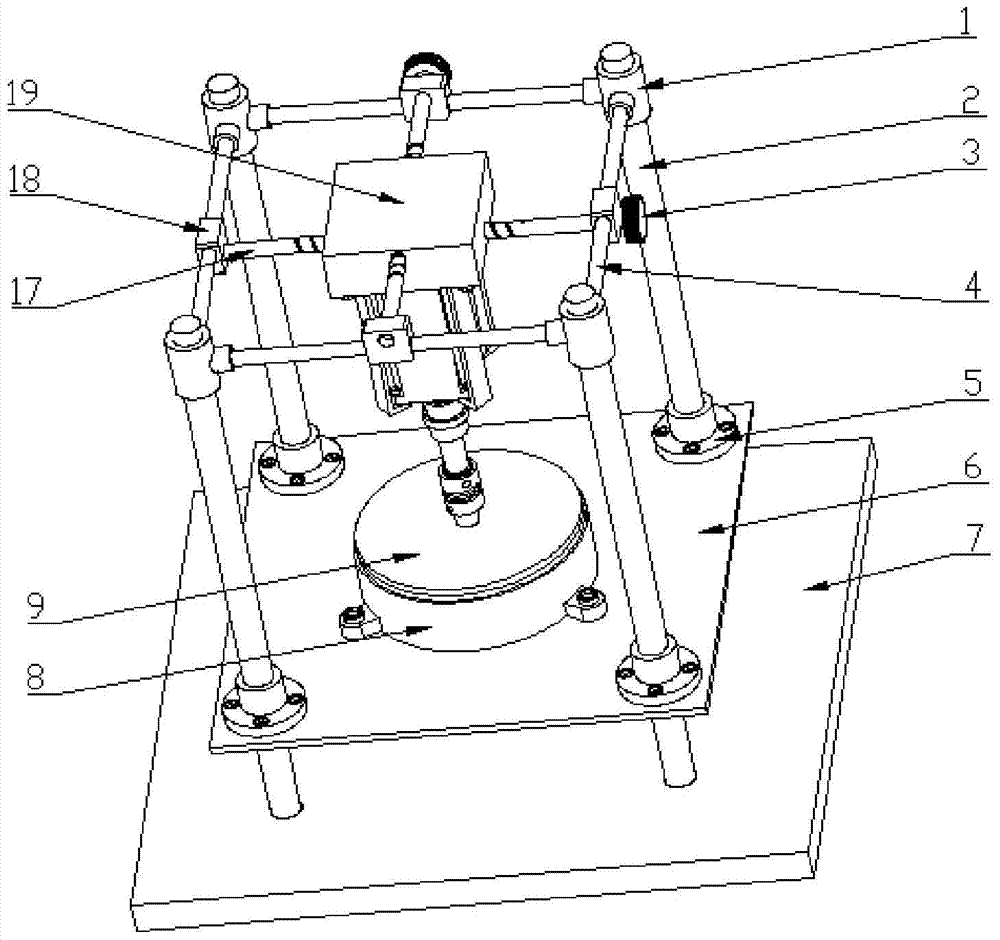

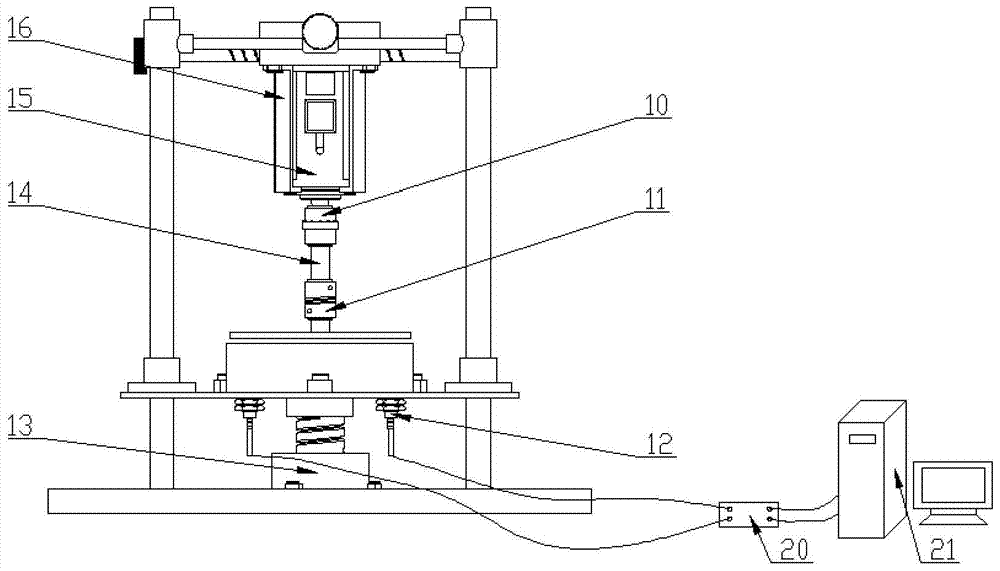

The invention discloses a high-temperature fracture parameter test device, which comprises a loading mechanism, a high-temperature heating furnace arranged inside the loading mechanism, a CCD camera, a data acquisition card and an electronic computer. The invention also discloses a high-temperature fracture parameter test method based on the device. The high-temperature fracture parameter test method and the device of the invention can realize the measurement under the condition of high temperature measurement, the precision is high, which can reach the micron level, and can realize the long-time measurement and accurate calculation of the fracture parameter measurement, and thereby providing basic data for the safety design, as well as the quantitative life assessment of the mechanical structure.

Owner:EAST CHINA UNIV OF SCI & TECH

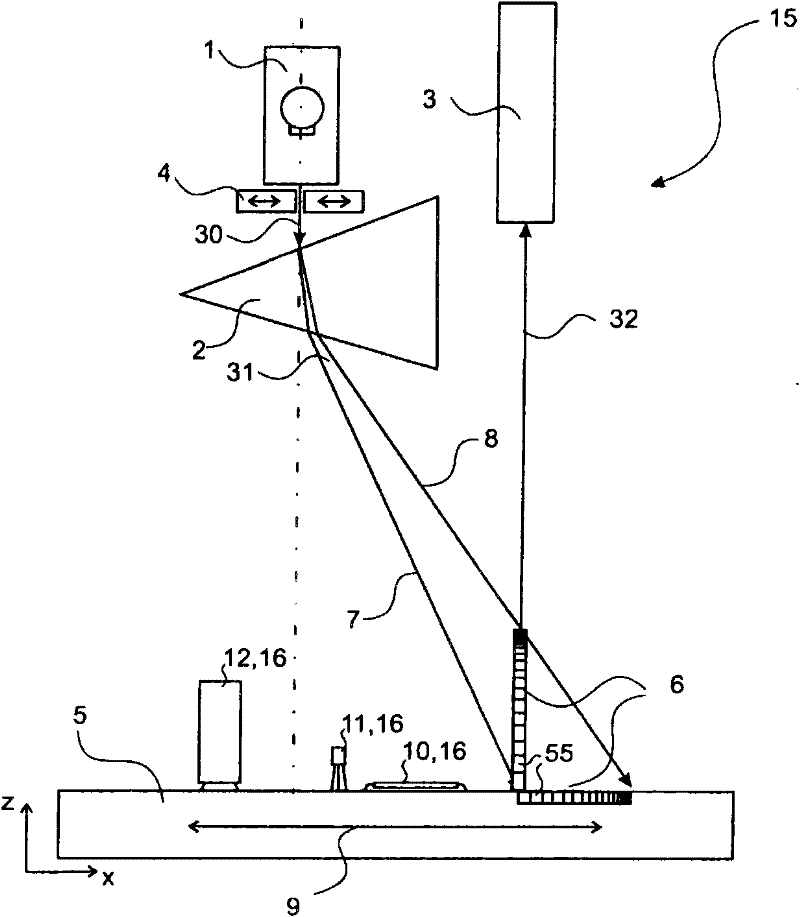

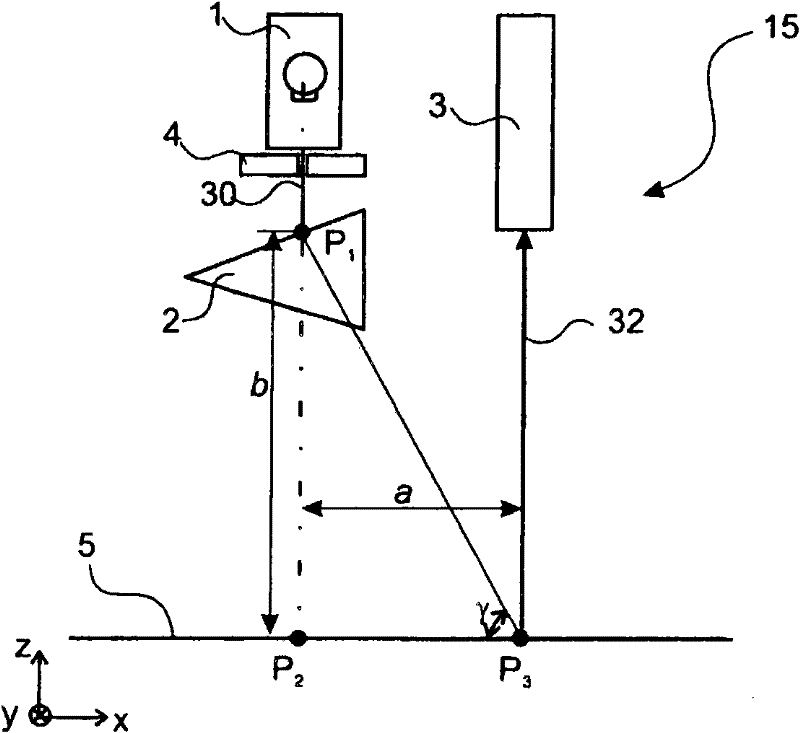

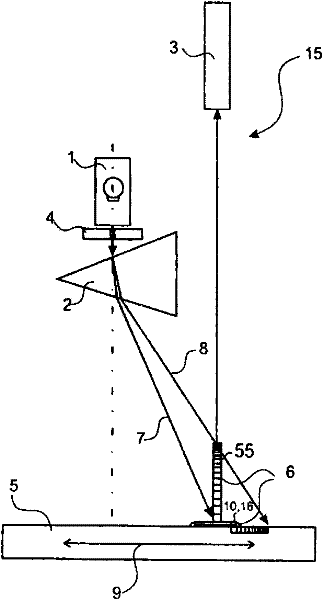

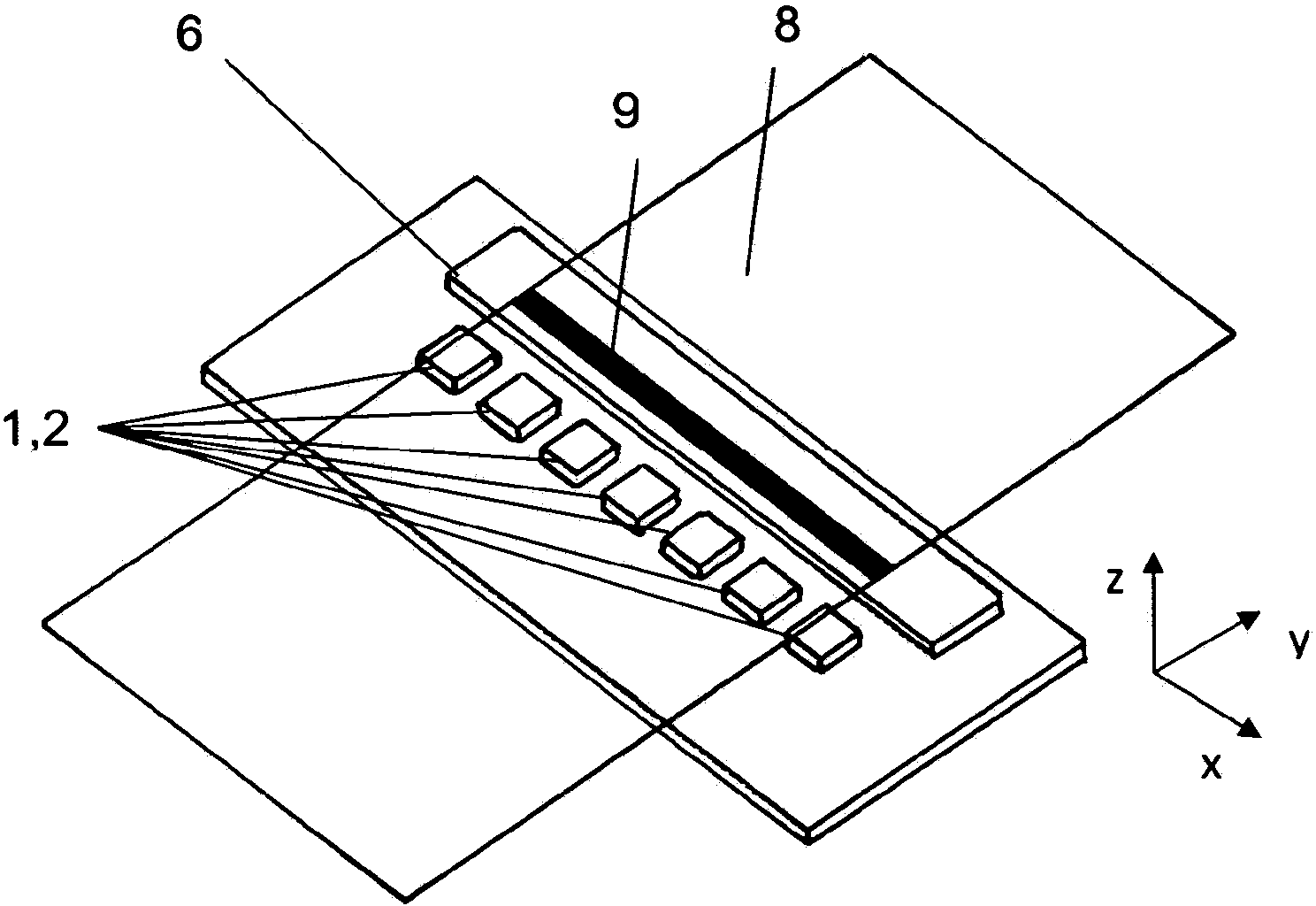

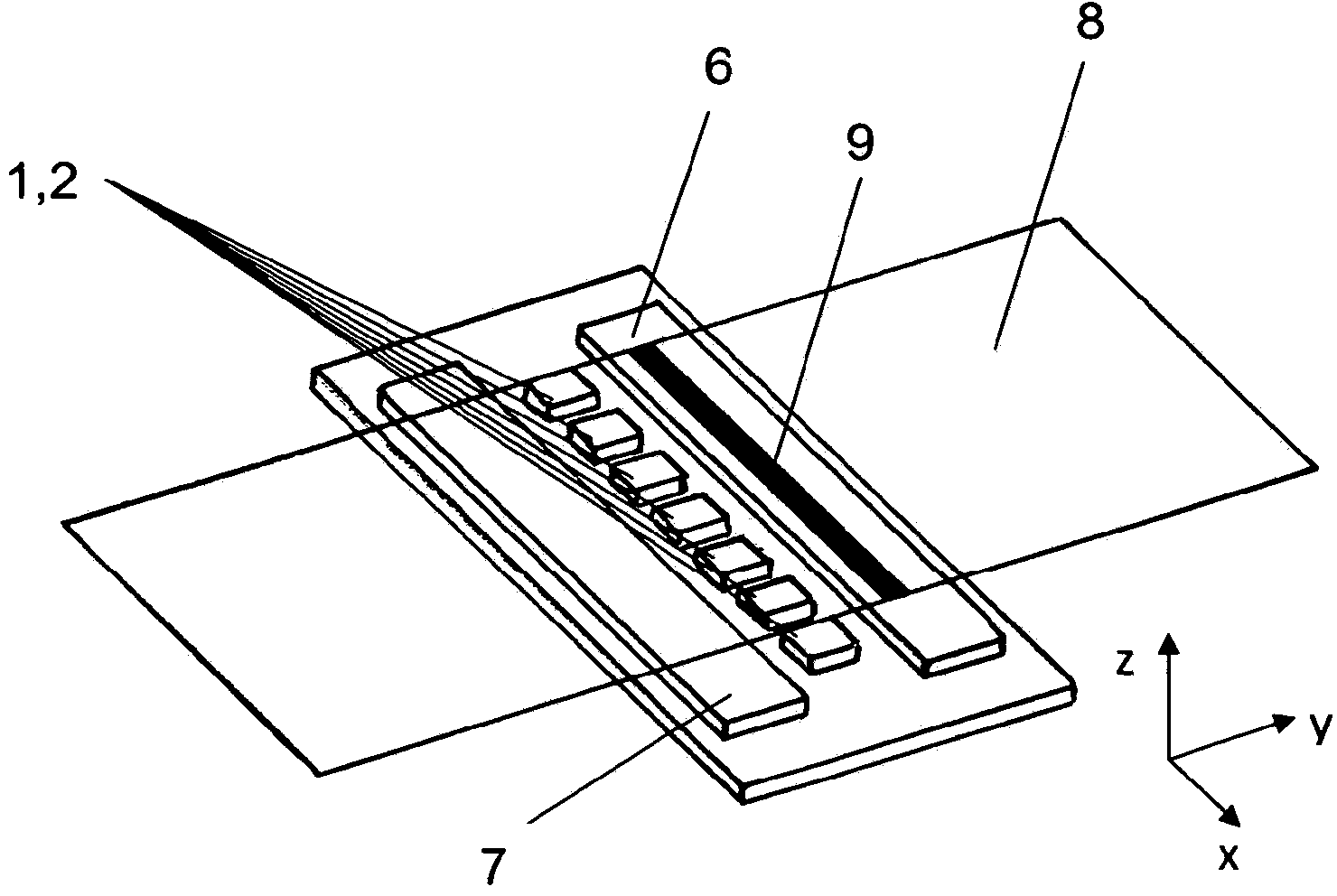

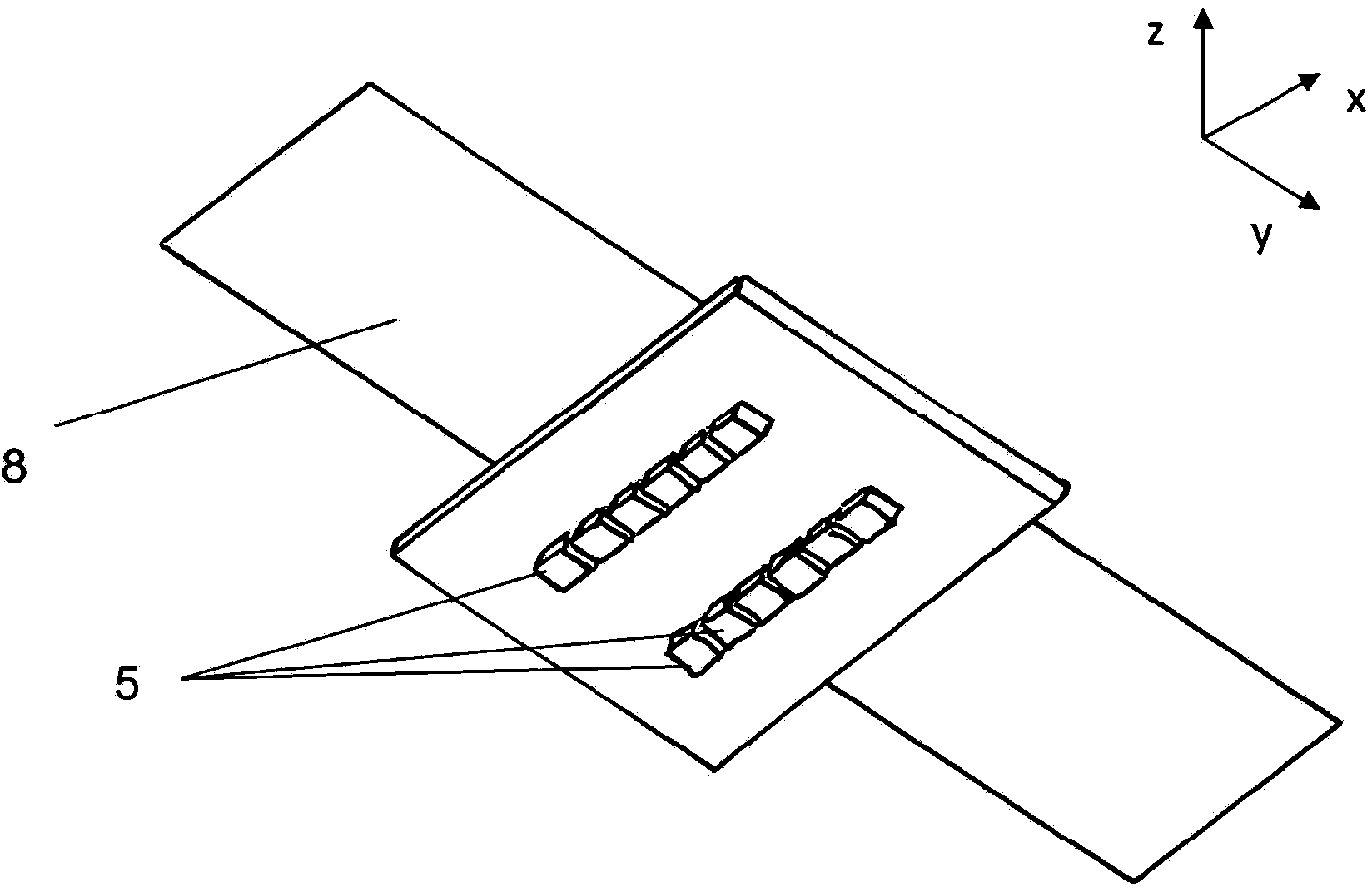

Method and device for optically measuring product surfaces

ActiveCN102282440AShorten test timeIncrease variabilityUsing optical meansElectrical componentsAngle of incidenceGrating

The present invention relates to a device (10), a method and an application thereof for optically measuring the surface of a tested product (5), especially a PCB-product for reflow soldering paste inspection. The device comprises at least one white light source (1) for emitting a beam of white light, at least one collimation unit (4) for collimating said beam of white light (30), at least one spectrometer unit, preferably an optical prism (2) or an optical diffraction grading (51), for splitting said beam of white light (30) into a beam of multichromatic light (31) being directed onto said tested product (5) under a predetermined incident angle γ, and at least one camera (3) for recording a reflected beam of monochromatic light (32) of said tested product (5). Z-axis surface height information of said tested product (5) can be extracted from a hue value of said reflected beam of mono chromatic light (32) while relatively moving said tested product (5) in a x-axis scanning direction (9).

Owner:WITRINS S R O

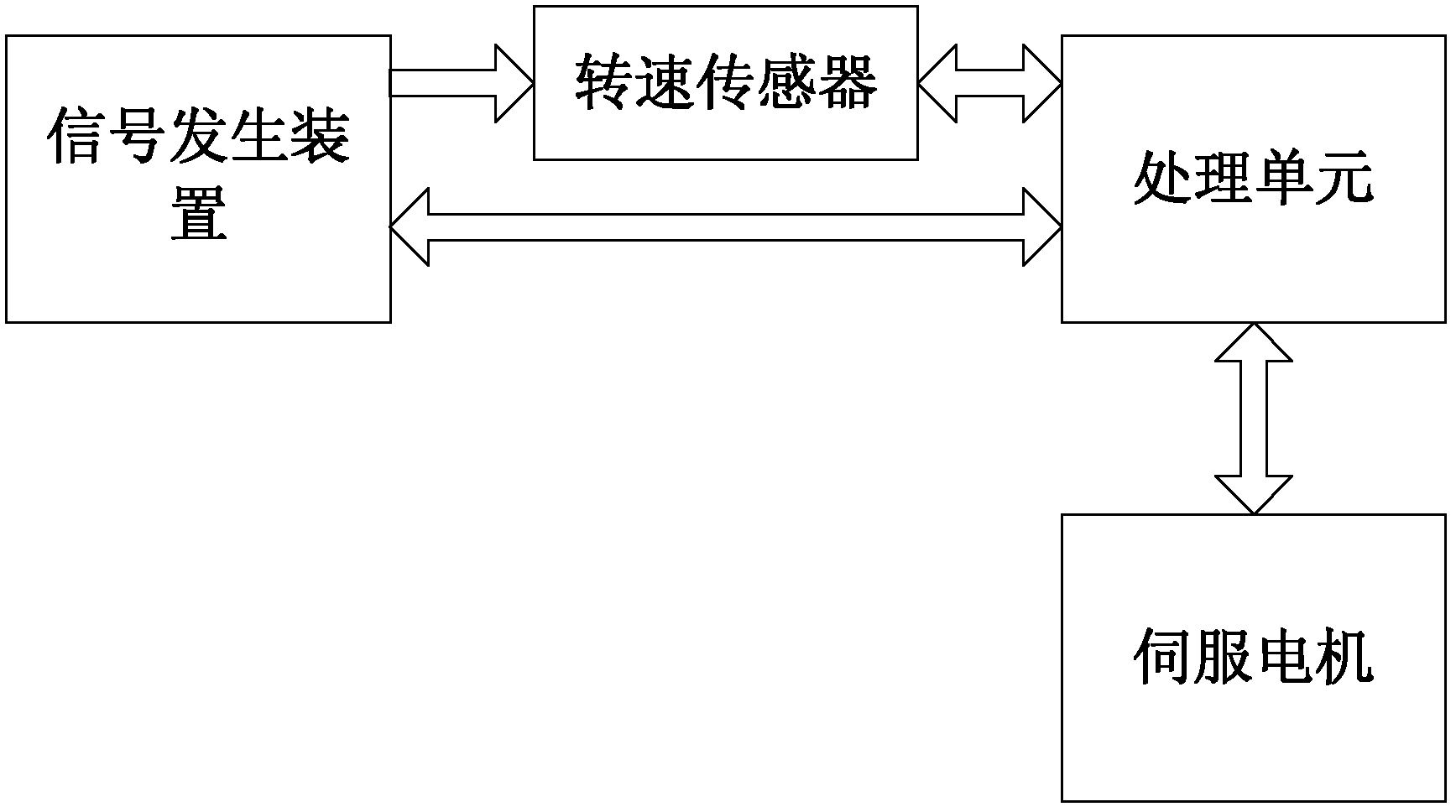

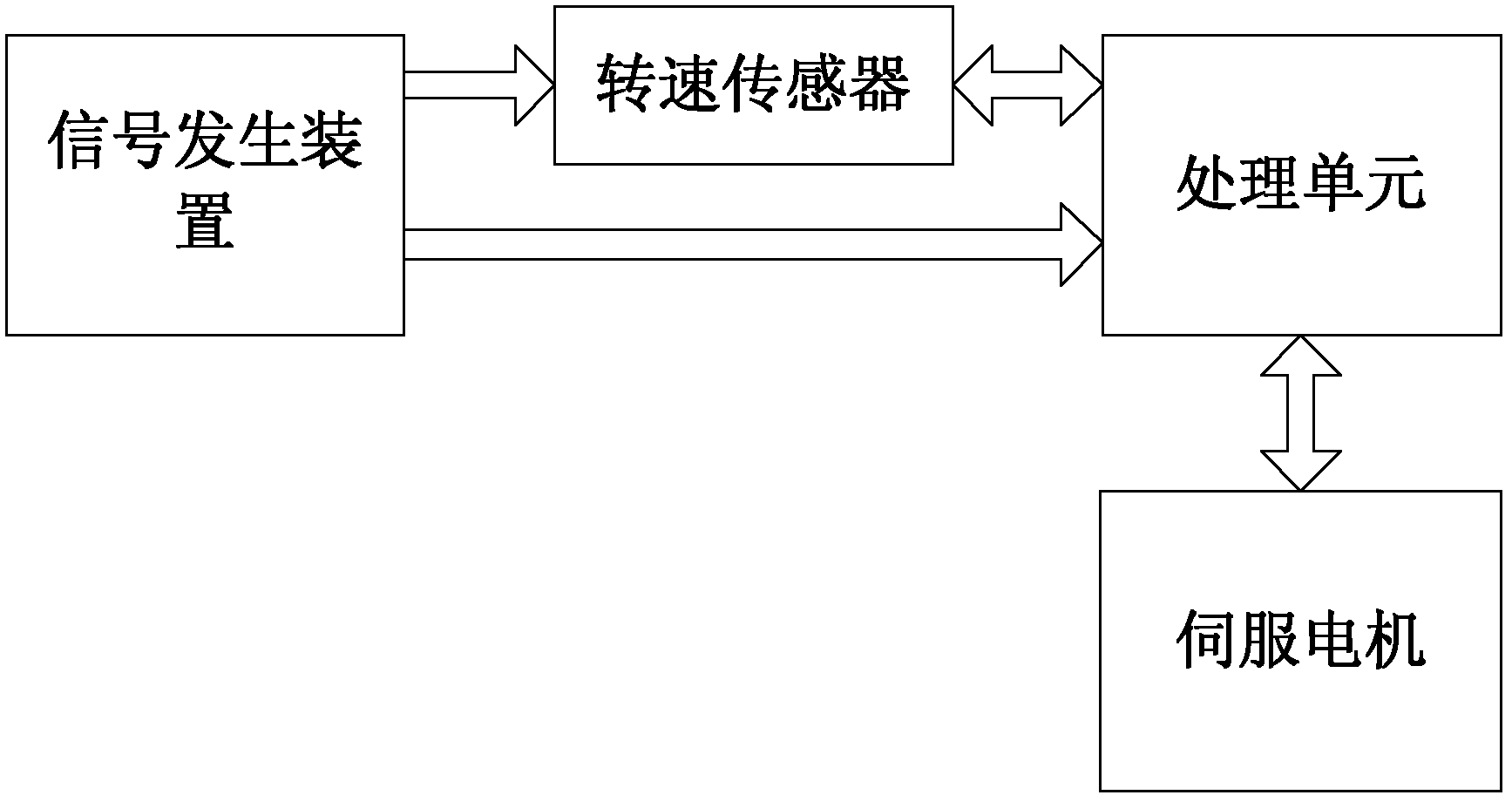

System and method for multi-sensor comparative rotation speed test

InactiveCN102608358AIncrease credibilityAchieving accuracy comparisonTesting/calibration of speed/acceleration/shock measurement devicesSpeed testSignal generator

The invention discloses a system and a method for multi-sensor comparative rotation speed test, which relate to the technical field of rotation speed measurement. The system comprises a servo motor, a signal generator, a processing unit and at least two rotation speed sensors. The servo motor comprises a rotary encoder. The processing unit is respectively connected with the rotary encoder, the rotation speed sensors, the servo motor and the signal generator. The rotation speed measured by the high-precision rotary encoder is used as standard, confidential level of comparison results of the different rotation speed sensors is increased, and accuracy comparison among the different rotation speed sensors and comparison of measuring accuracy and resolution among the different sensors are achieved further.

Owner:CHINA AGRI UNIV

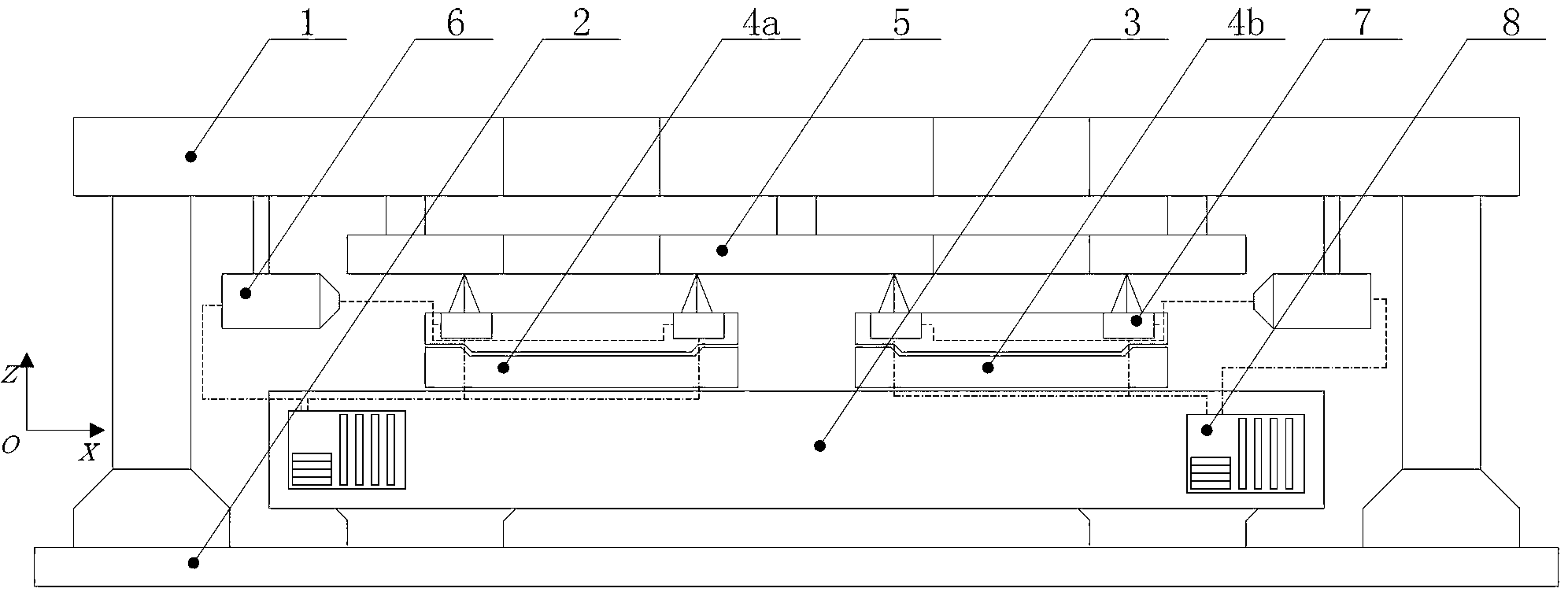

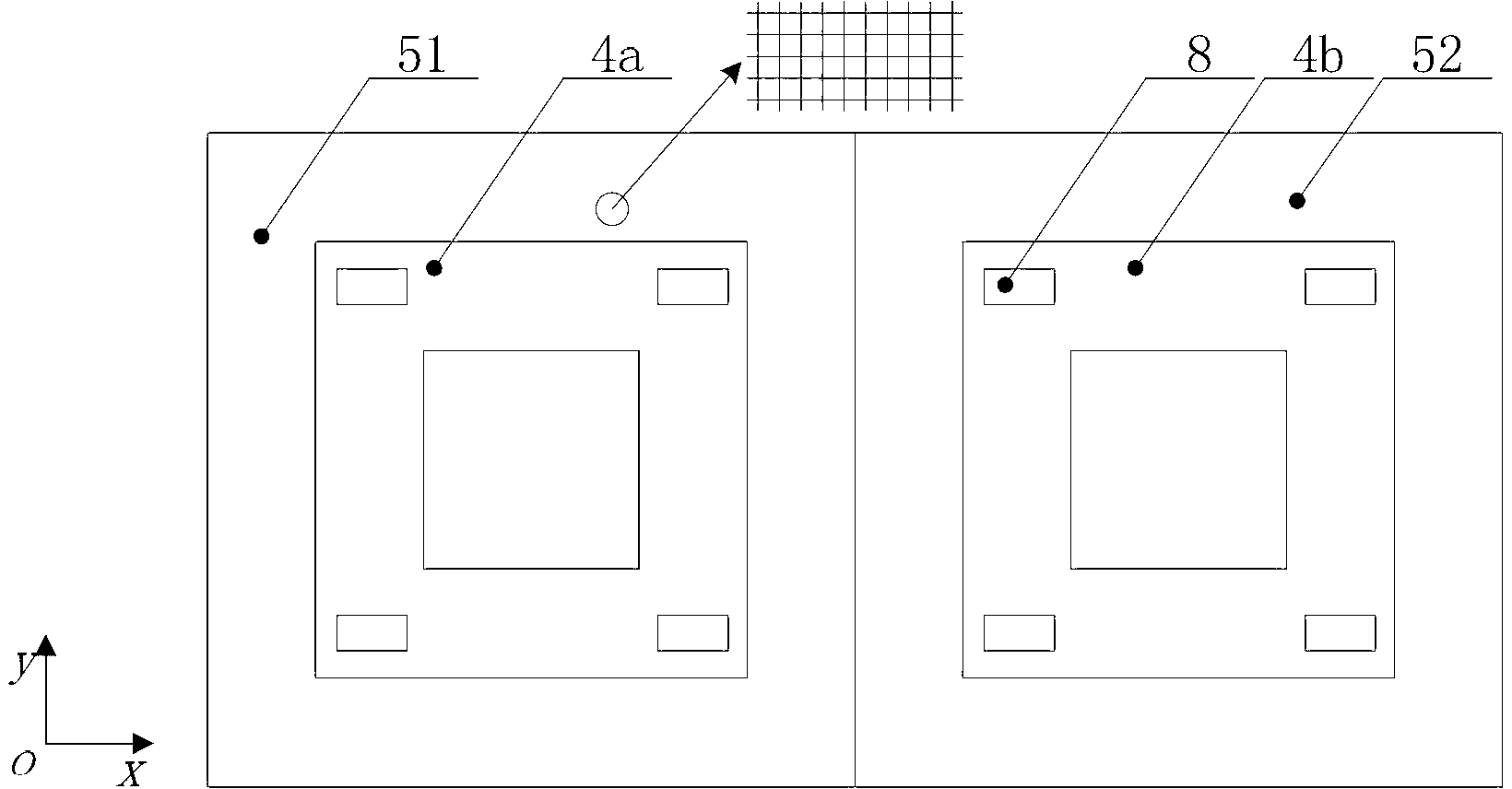

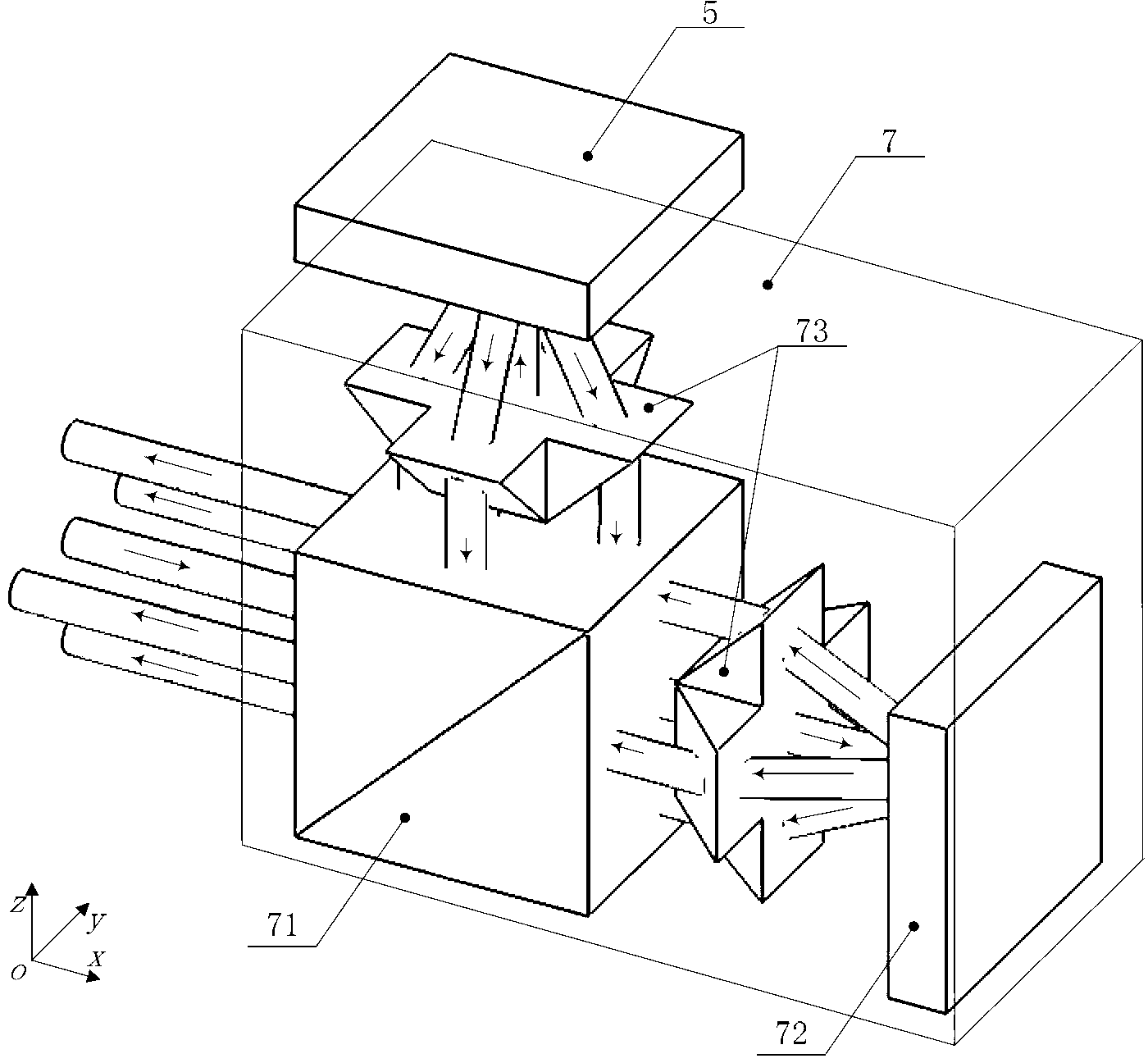

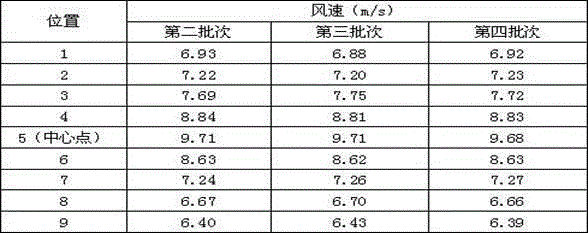

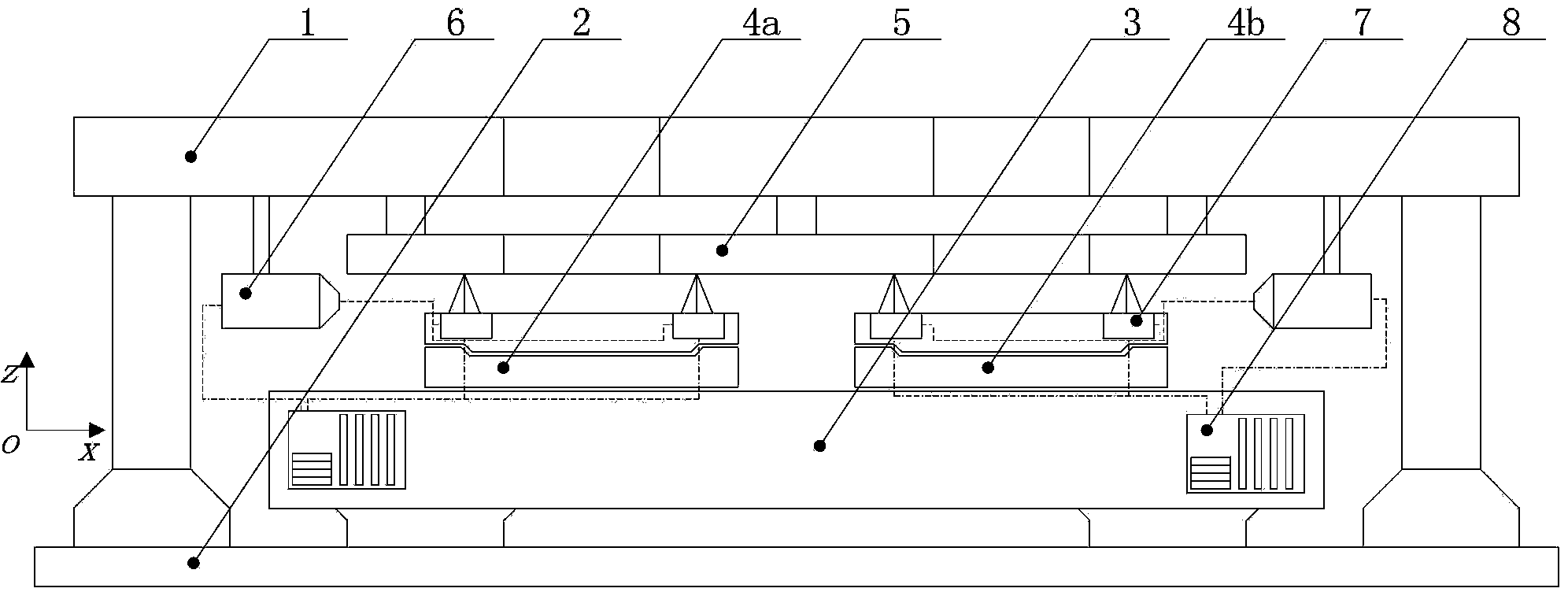

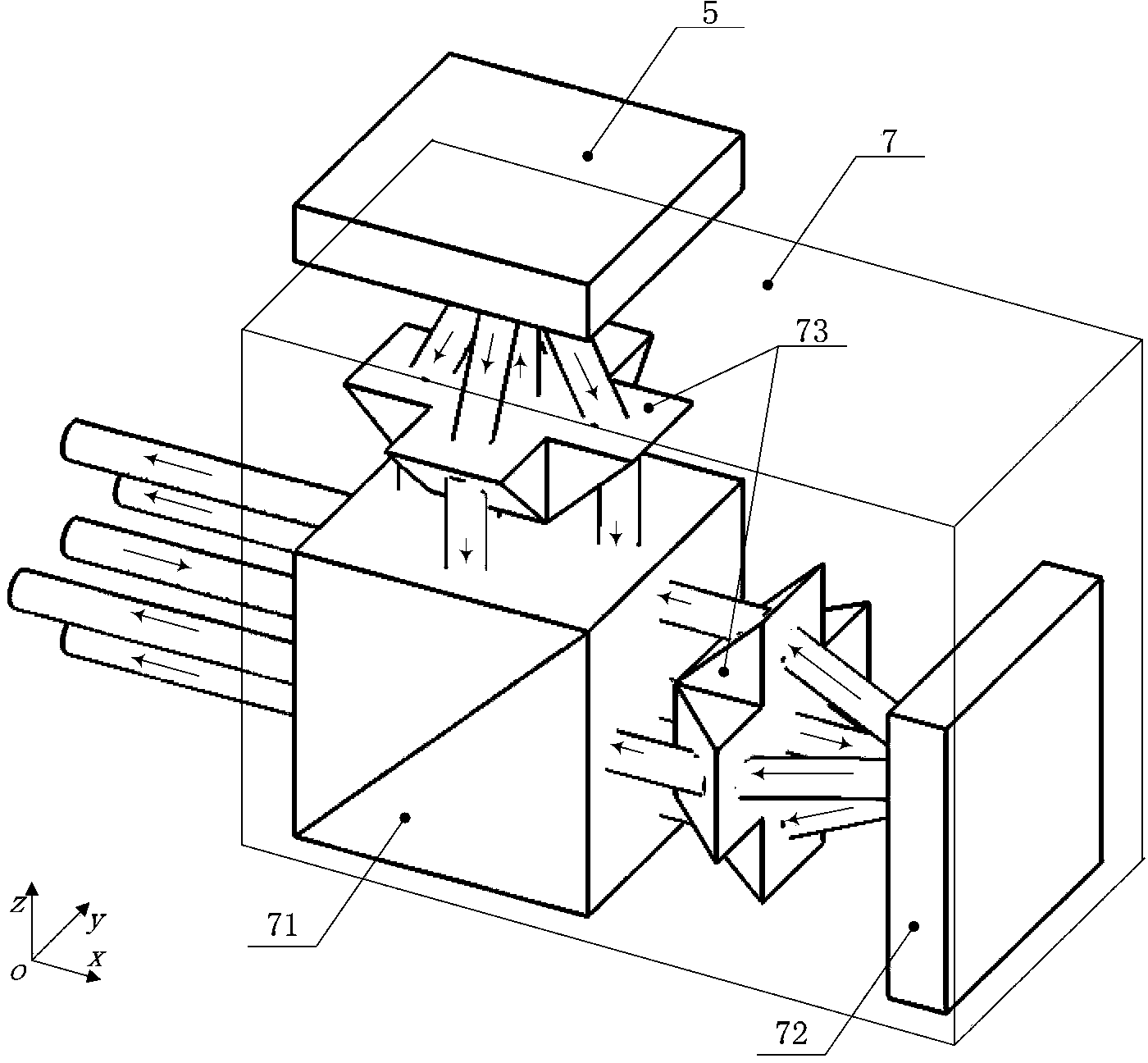

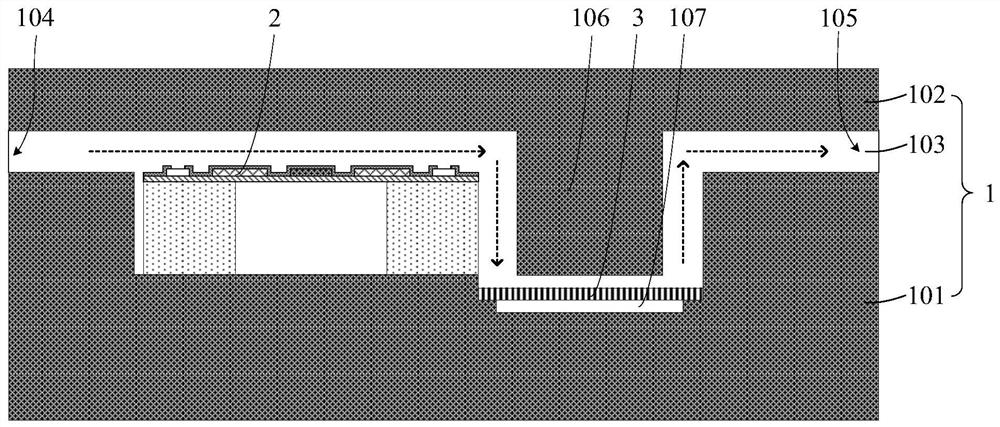

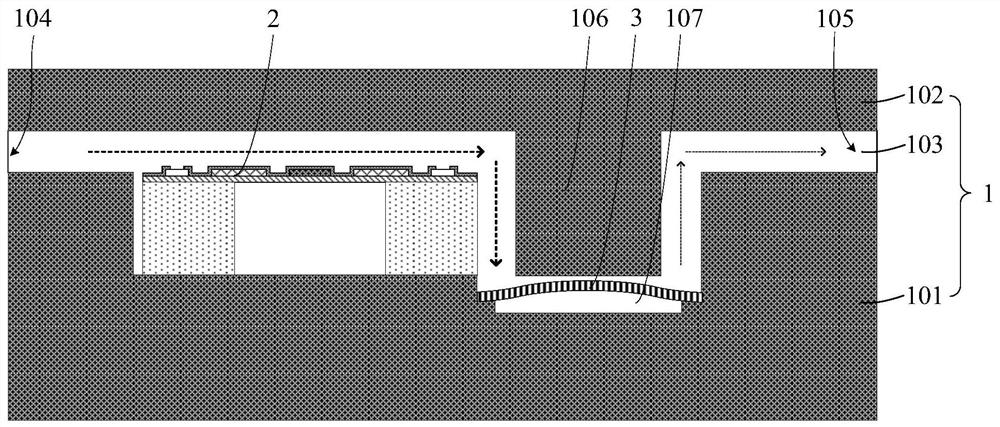

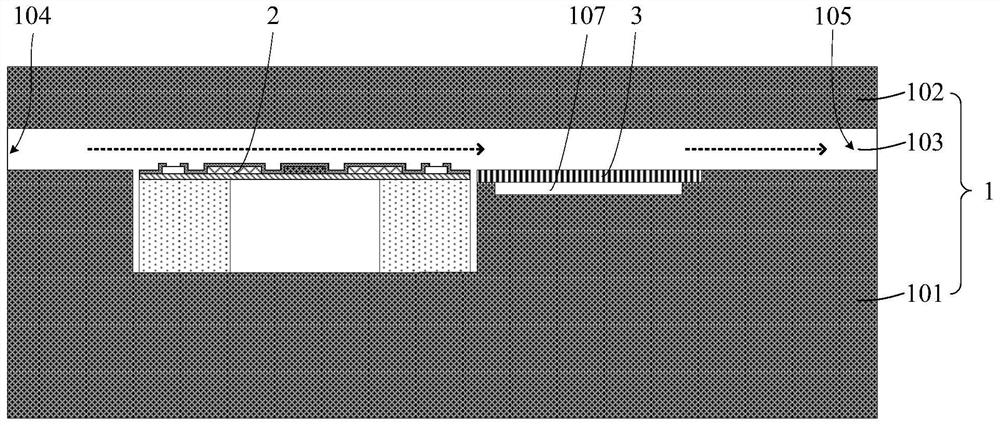

Workpiece platform system of photoetching machine

ActiveCN103309177AReduce volumeReduce quality problemsPhotomechanical exposure apparatusMicrolithography exposure apparatusSilicon chipMeasurement precision

The invention discloses a workpiece platform system of a photoetching machine. The workpiece platform system comprises a rack, a base platform, two silicon-chip platforms, a measuring grating, a dual-frequency laser, three-freedom-degree heterodyne grating interferometers and a signal receiving and processing part, wherein the two silicon-chip platforms operate at an exposure station and a preprocessing station; the four corners of each silicon-chip platform are provided with one three-freedom-degree heterodyne grating interferometer respectively, and the measuring grating is arranged on the rack above the silicon-chip platform. Dual-frequency orthogonal-polarization laser emitted by the dual-frequency laser is transmitted to the three-freedom-degree heterodyne grating interferometers and the measuring grating by optical fiber, four beams of diffraction light of the measuring grating irradiate back to the three-freedom-degree heterodyne grating interferometers, and finally the four beams of measuring light signals are emitted to the signal receiving and processing part. When the silicon-chip platforms move relatively to the measuring grating, the reading in the signal receiving and processing part is utilized for acquiring six-freedom displacement of the silicon-chip platforms by calculation. The workpiece platform system disclosed by the invention has the advantages that the indexes such as measuring accuracy and dynamic performance of the silicon-chip platforms can be improved, and further the whole performance of the workpiece platform system is further improved.

Owner:TSINGHUA UNIV +1

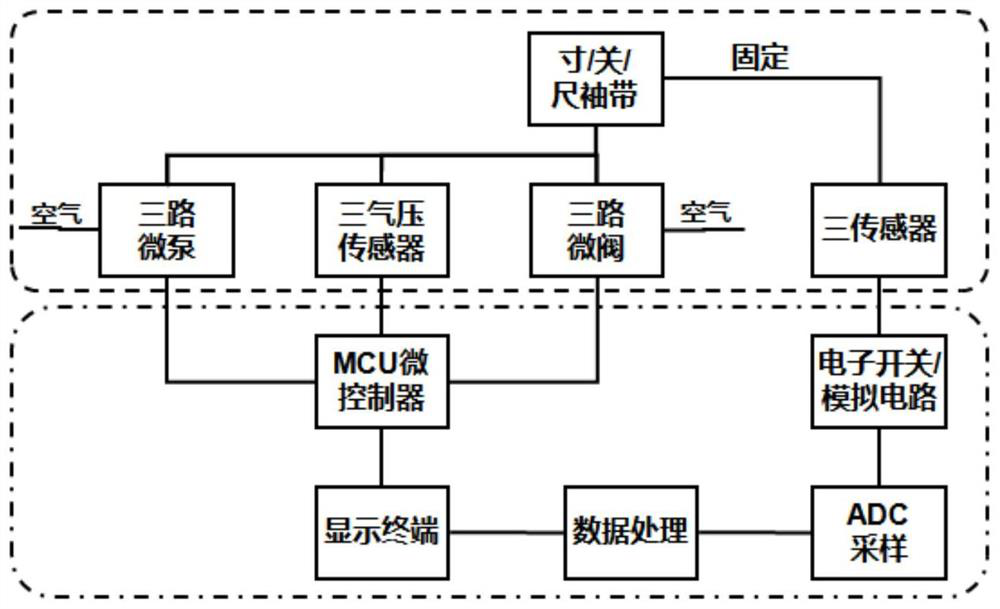

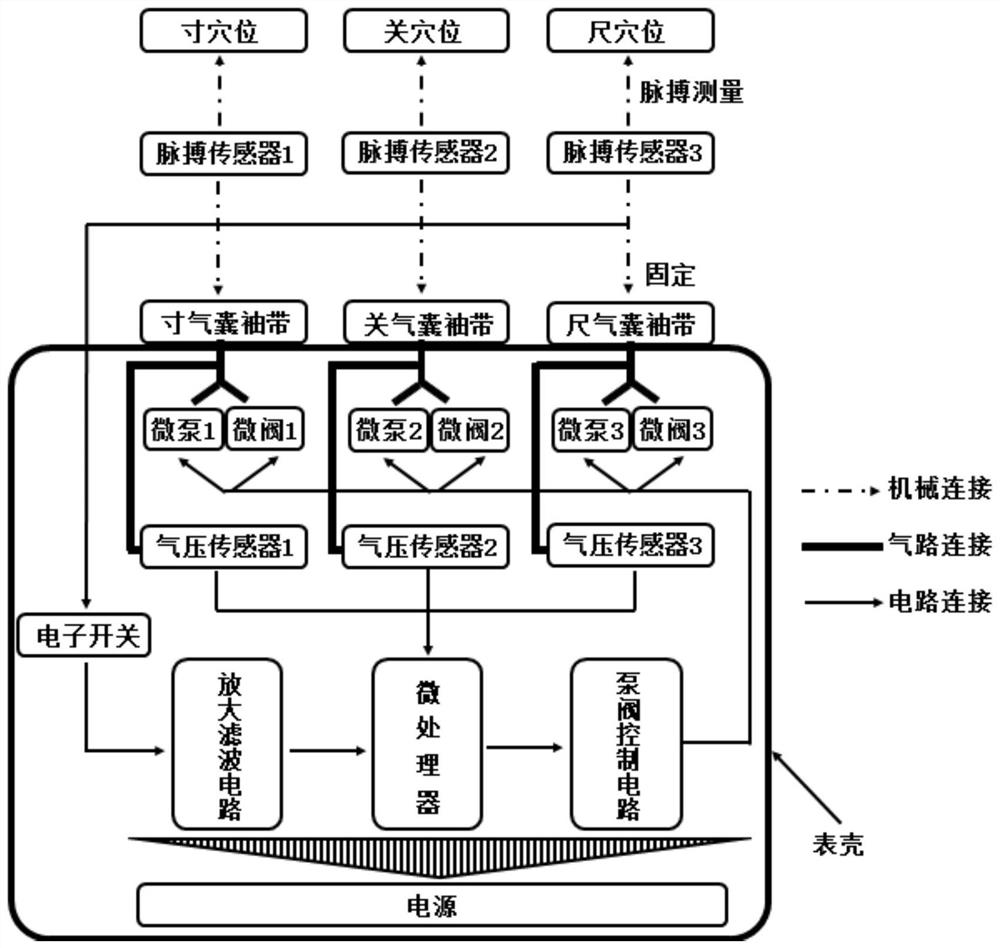

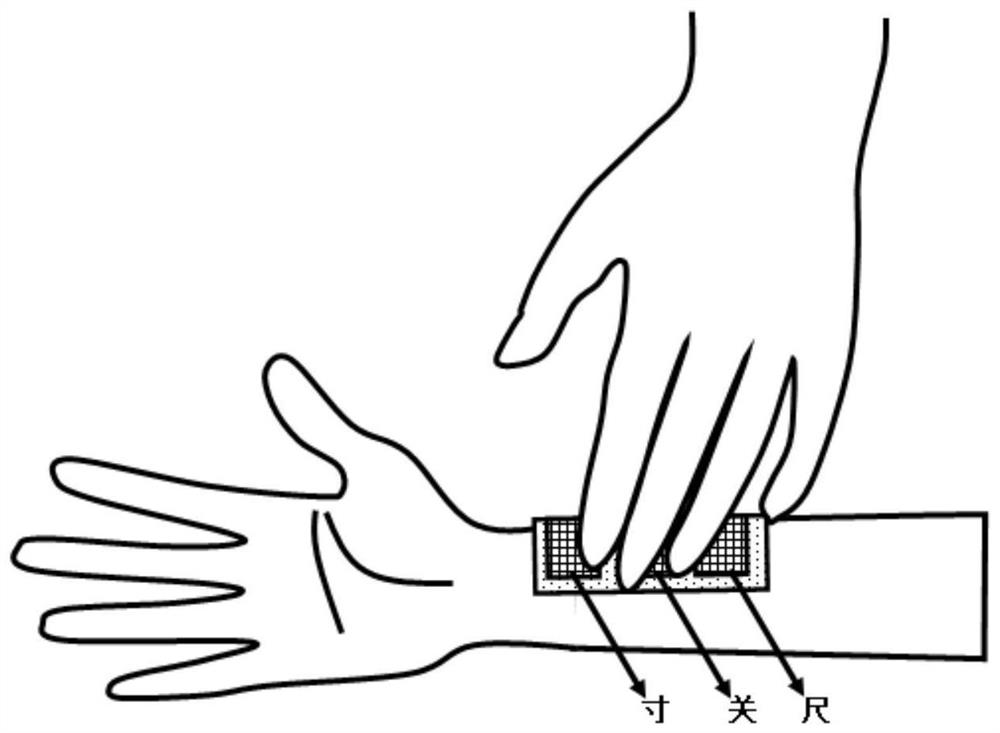

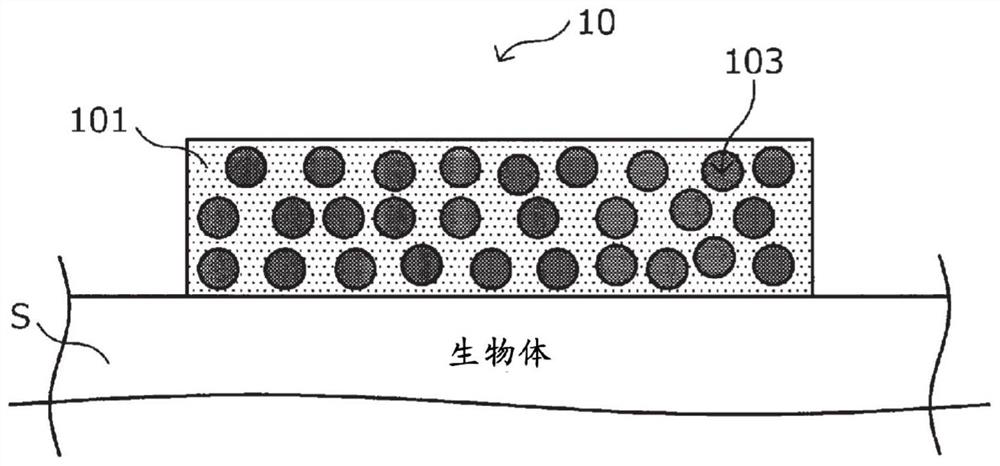

Wearable digital pulse diagnosis instrument

ActiveCN112842292AGo digitalAchieve objectificationCatheterDiagnostic recording/measuringEngineeringGas pressure transducer

The invention relates to a wearable digital pulse diagnosis instrument comprising three paths of pulse feeling assemblies and a processing device, each path of pulse feeling assembly comprises a micro pump, a micro valve, an air bag, an air pressure sensor and a pulse sensor, and the processing device is connected with the micro pump, the micro valve, the air pressure sensor and the pulse sensor of each path of pulse feeling assembly. The micro pumps, the micro valves and the air pressure sensors of all the pulse feeling assemblies are communicated with the air bags, the pulse sensors are fixed to the air bags, the air bags of all the pulse feeling assemblies are used for being worn on different parts of the wrist in the length direction, all the micro pumps inflate all the air bags, and the pulse sensors are pressed on the wrist through the air bags. The air pressure sensors feed back the pressure levels to the processing device in real time, the processing device controls and adjusts the pressure by controlling the micro pumps and the micro valves according to the feedback, and the pulse of each path is measured through each pulse sensor. According to the pulse diagnosis instrument, independent controllable pressurization and independent pulse measurement of Cun, Guan and Chi can be achieved at the same time, digital pulse diagnosis is achieved, and the instrument is small in size and wearable.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

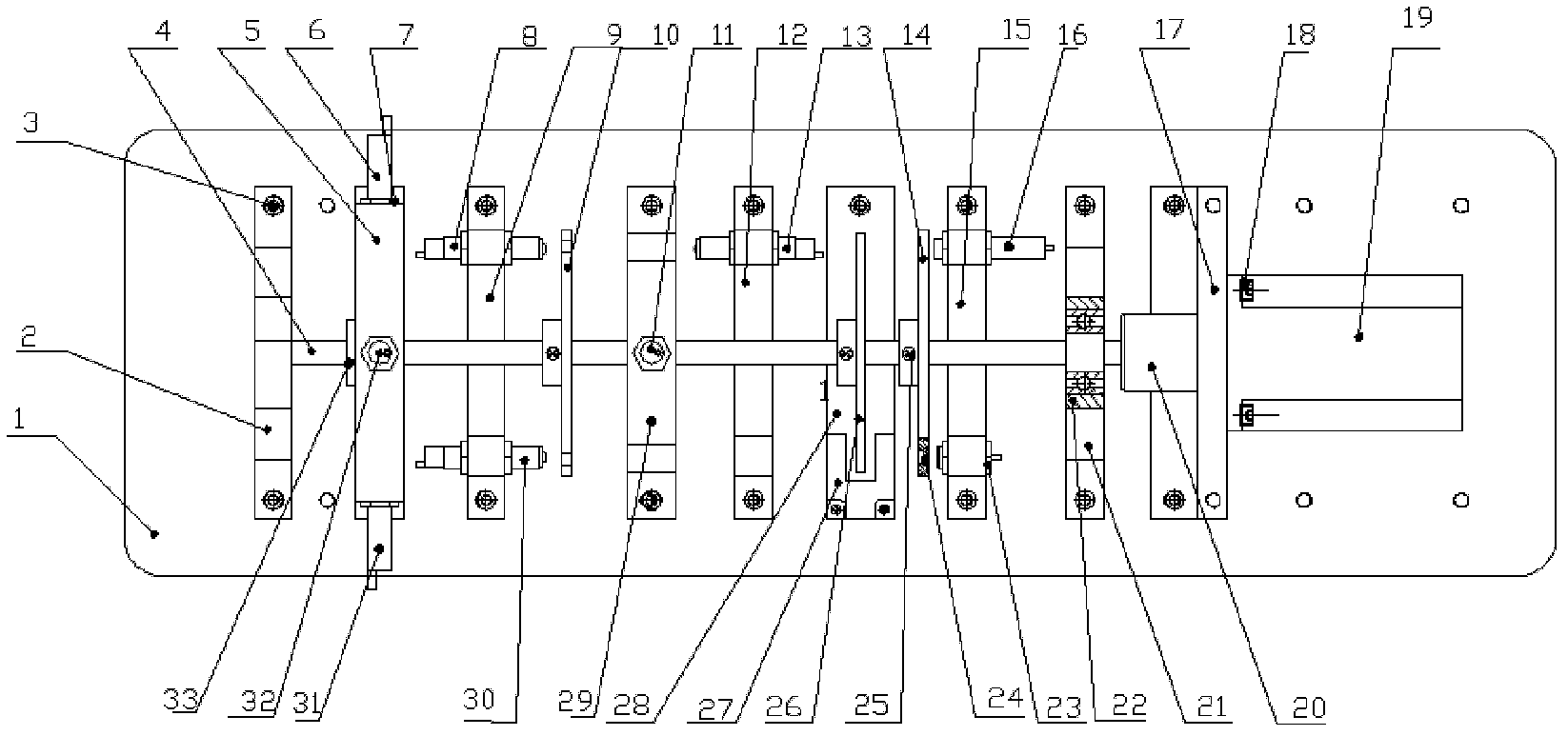

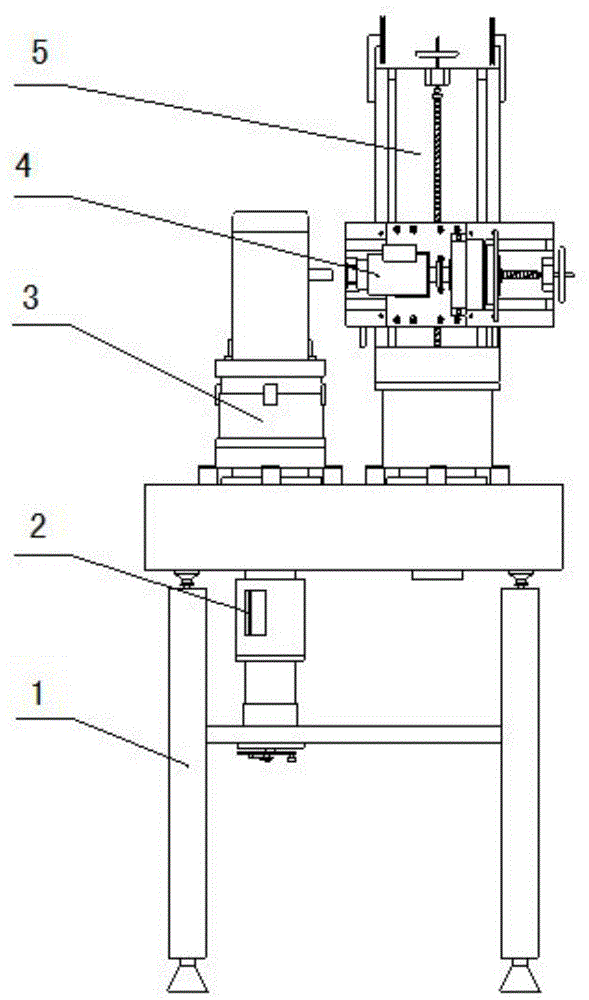

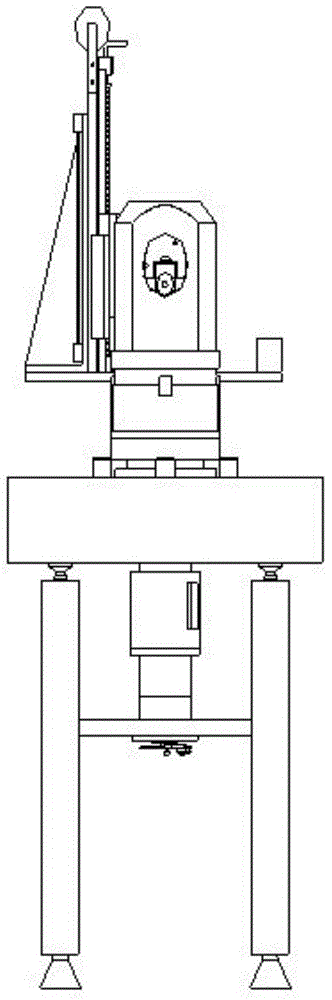

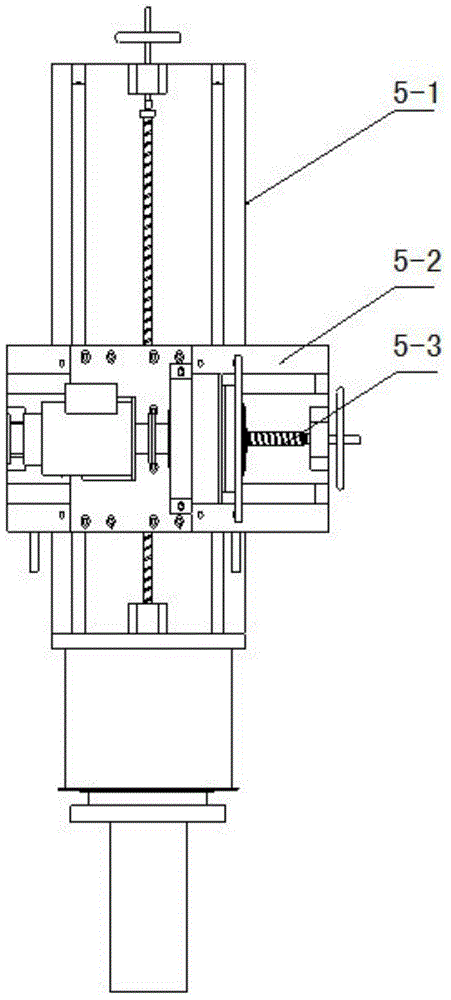

Precise shaft dynamic torque measuring instrument

ActiveCN104977112AAddress reliabilityFix stability issuesApparatus for force/torque/work measurementFriction torqueCoupling

A precise shaft dynamic torque measuring instrument relates to a shaft measurement technology and solves the problem that shaft friction torque can not be accurately measured and the test scope is small. The precise shaft dynamic torque measuring instrument comprises a structure adjusting subsystem, a pitching and yaw detection shaft subsystem, a positioning installation subsystem, a lateral roller detection shaft subsystem and a support and detection platform subsystem and measures friction torque of a fake load on vertical shaft direction. A torque motor drives a torque sensor to rotate through a toothed shaft, the displacement is adjusted on the vertical and horizontal direction, and a handwheel is rotated to move a leading screw nut mechanism vertically or horizontally along a linear guide rail. A rotary table drives a vertical sliding bench fixed together with a connection board to realize rotation of changing angle at certain level. A counterweight block is added on a fixed pulley on the vertical sliding bench to prevent extra torque, and verticality precision is ensured.

Owner:CHANGCHUN UNIV OF SCI & TECH

Measuring device for measuring magnetic properties of surroundings of measuring device

ActiveCN103814399ASensitive authenticationFull verificationMagnetic measurementsPaper-money testing devicesOrthogonal coordinatesMeasurement device

The invention relates to a measuring device for measuring the magnetic properties of the surroundings of the measuring device by means of a sensor line having at least one magnetoresistive sensor element extending in a line direction, which can measure the magnetic properties in the surroundings thereof, wherein the sensor element has a width and a length as well as a height, wherein the height is smaller than the width, and the height is smaller than the length, and the line direction points in the direction of the width or in the direction of the length of the sensor element, and having a support field device which generates a magnetic support field in the area over which the sensor line extends, having a premagnetization device which comprises a premagnetization magnet or several premagnetization magnets, wherein at least one premagnetization magnet is arranged in a direction which is perpendicular to the line direction, spaced from the sensor line, and extends in a direction parallel to the line direction, characterized in that magnetoresistive sensor element can measure the magnetic properties of the surroundings thereof substantially in only one direction, referred to as the measurement direction, of an orthogonal coordinate system, or substantially in only one plane, referred to as the sensor measurement plane, which is defined by two perpendicular measurement directions of an orthogonal coordinate system, in that, in the case of a premagnetization device which consists of only one premagnetization magnet, the properties of the premagnetization magnet, which influence the magnetic field generated by said magnet and the arrangement of said magnet relative to the sensor cell as well as the support field generated by the support field device are selected in such a manner that an overlap magnetic field forms due to the overlap of the magnetic field generated by the premagnetization device and of the support field, wherein the strength of the field component of said overlap magnetic field, which points in the line direction is, at least at one site on the sensor line, greater than the strength of the field component which is perpendicular to the line direction and does not point in the direction of the height of the sensor element, or in the case of a premagnetization device consisting of several premagnetization magnets, the properties of the premagnetization magnet, which influence the magnetic field generated by said magnets, and the arrangement of the premagnetization magnets relative to the sensor cell as well as the support field generated by the support field device are selected in such a manner that an overlap magnetic field forms due to the overlap of the magnetic field generated by the premagnetization device and of the support field, wherein the strength of the field component of said overlap magnetic field, which points in the line direction is, at least at one site on the sensor line, greater than the strength of the field component which is perpendicular to the line direction and does not point in the direction of the height of the sensor element.

Owner:精量电子(德国)公司

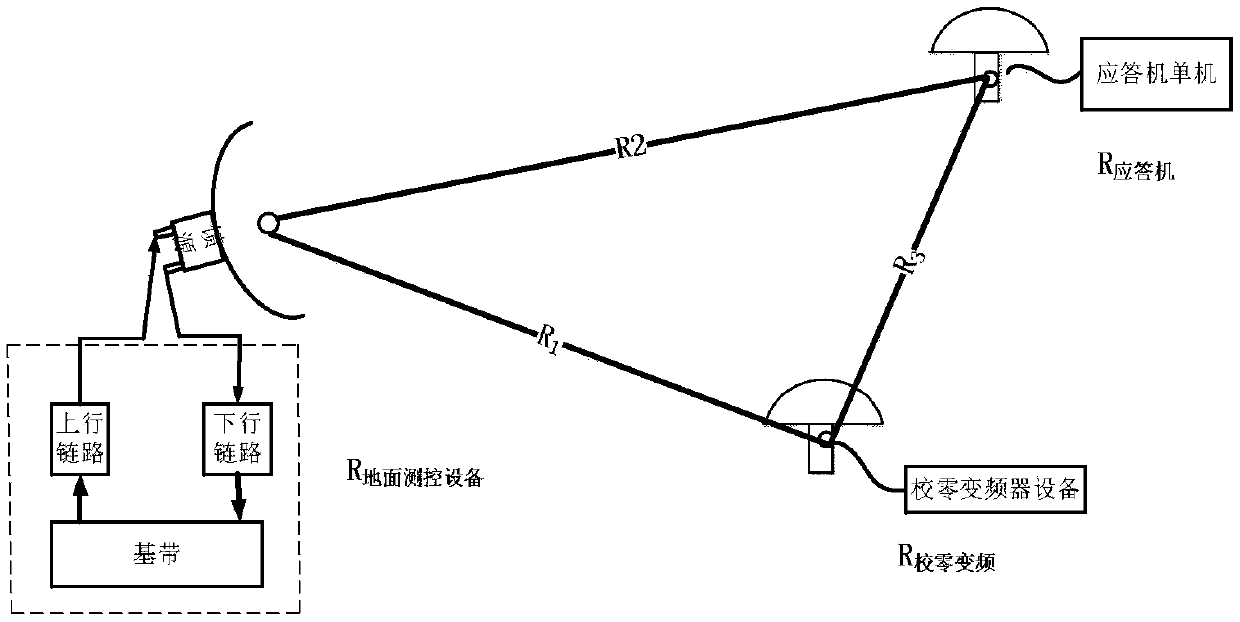

Multi-wireless link joint calculating spread spectrum measurement and control equipment zero value method

ActiveCN109581447AAchieving Measurement AccuracyMeet the needs of high-precision measurementRadio transmissionSatellite radio beaconingEngineeringChanging equipment

The invention discloses a multi-wireless link joint calculating spread spectrum measurement and control equipment zero value method, and aims to provide a high-precision spread spectrum measurement and control equipment zero value calibration method. According to the technical scheme, the multi-wireless link joint calculating spread spectrum measurement and control equipment zero value method comprises the steps that the distance between the ground measurement and control equipment antenna phase center and the satellite responder antenna phase center, the distance between the ground measurement and control equipment phase center and the zero calibration spectrum changing equipment antenna phase center and the distance between the satellite responder antenna phase center and the zero calibration spectrum changing equipment antenna phase center are separately measured through geodetic measurement equipment; the spread spectrum distance measurement among three wireless links of ground measurement and control equipment and a responder, the ground measurement and control equipment and zero calibration spectrum changing equipment and the responder and the zero calibration spectrum changing equipment are separately completed; and an observation equation of three distance measurement is constructed according to the spread spectrum distance measurement among three wireless links, and ahigh-precision equipment zero value of the spread spectrum distance measurement is obtained by using the observation equation of the three distance measurement to jointly calculate a ground measurement and control equipment zero value, a zero calibration spectrum changing equipment zero value and a responder zero value.

Owner:10TH RES INST OF CETC

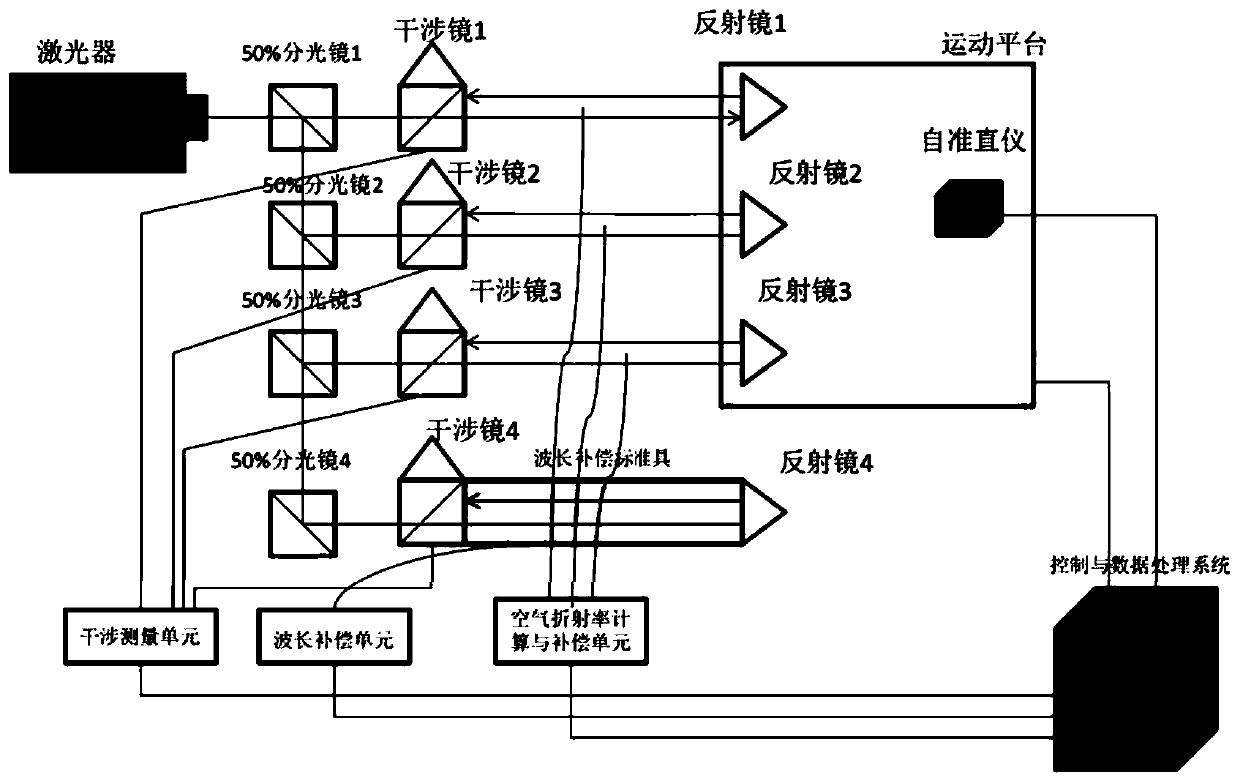

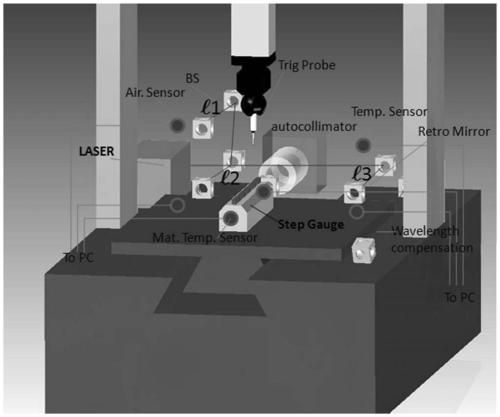

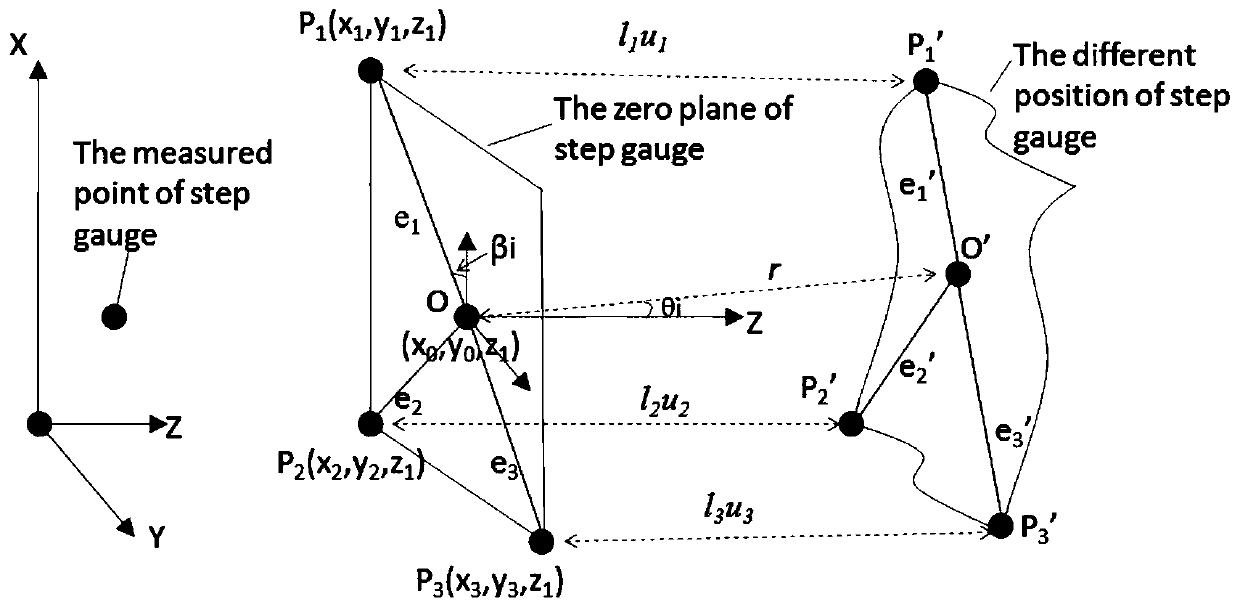

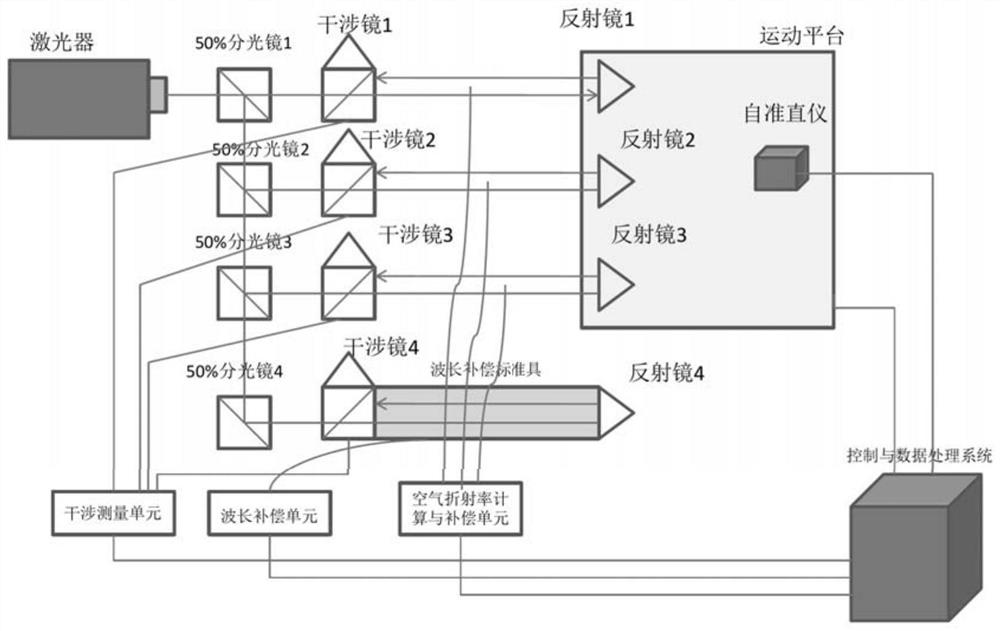

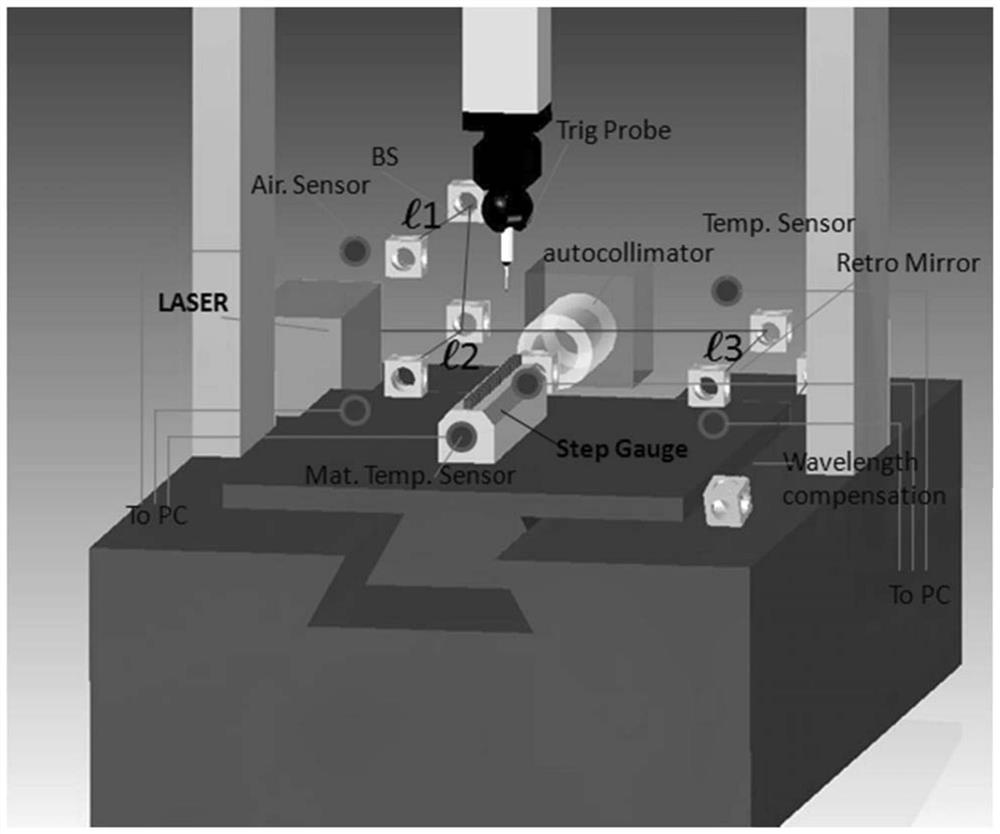

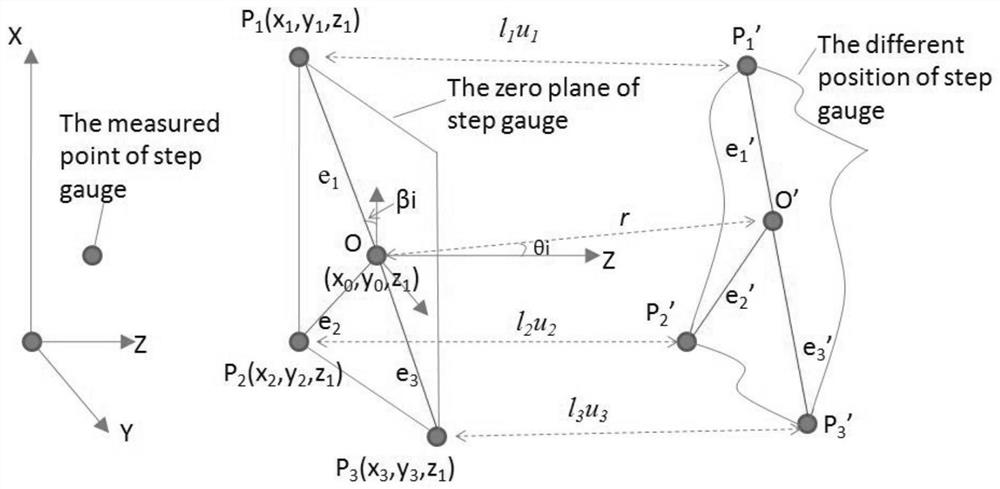

Step gauge calibration method and system capable of eliminating abbe errors based on laser interference

ActiveCN111238337AEliminate displacement valueAchieving Measurement AccuracyMechanical measuring arrangementsBeam splitterLaser light

The invention mainly relates to the technical field of length measurement. The invention provides a step gauge calibration system capable of eliminating abbe errors based on laser interference. The systemcomprises three laser interference light paths which can form any triangular prism shape in space, and afourth laser interference light path which is arranged in the space, is parallel to the three laser interference light paths and is used for wavelength compensation; one part of laser beams emitted by the laser passes through the spectroscope and then is reflected to the interference mirroras reference signals; one part is projected to the reflector to be reflected and then enters the interference mirror to form a measurement signal; when the measured step gauge is displaced, the displacement value of the measured step gauge without the abbe error is calculated through the measurement signal and the reference signal according to the measurement model; three laser light paths are combined to a measurement model on a measurement line of the step gauge to be measured, and no matter where the step gauge is installed on a measurement platform of a coordinate measuring machine, the measurement accuracy of the laser interference method step gauge based on the abbe principle can be achieved very conveniently.

Owner:NAT INST OF METROLOGY CHINA

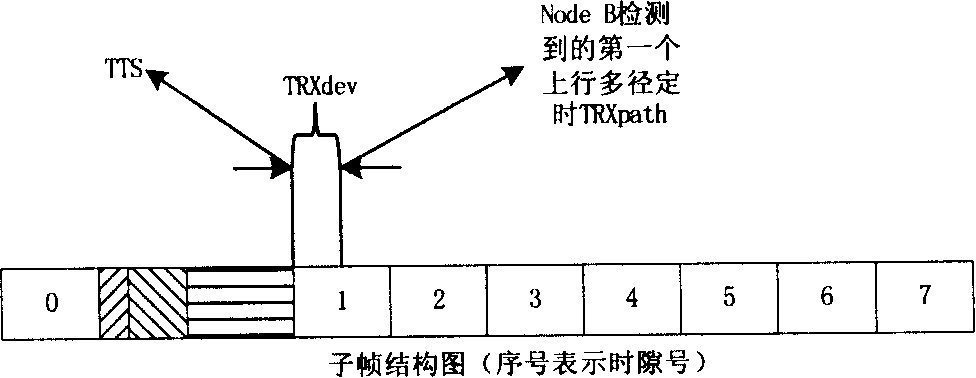

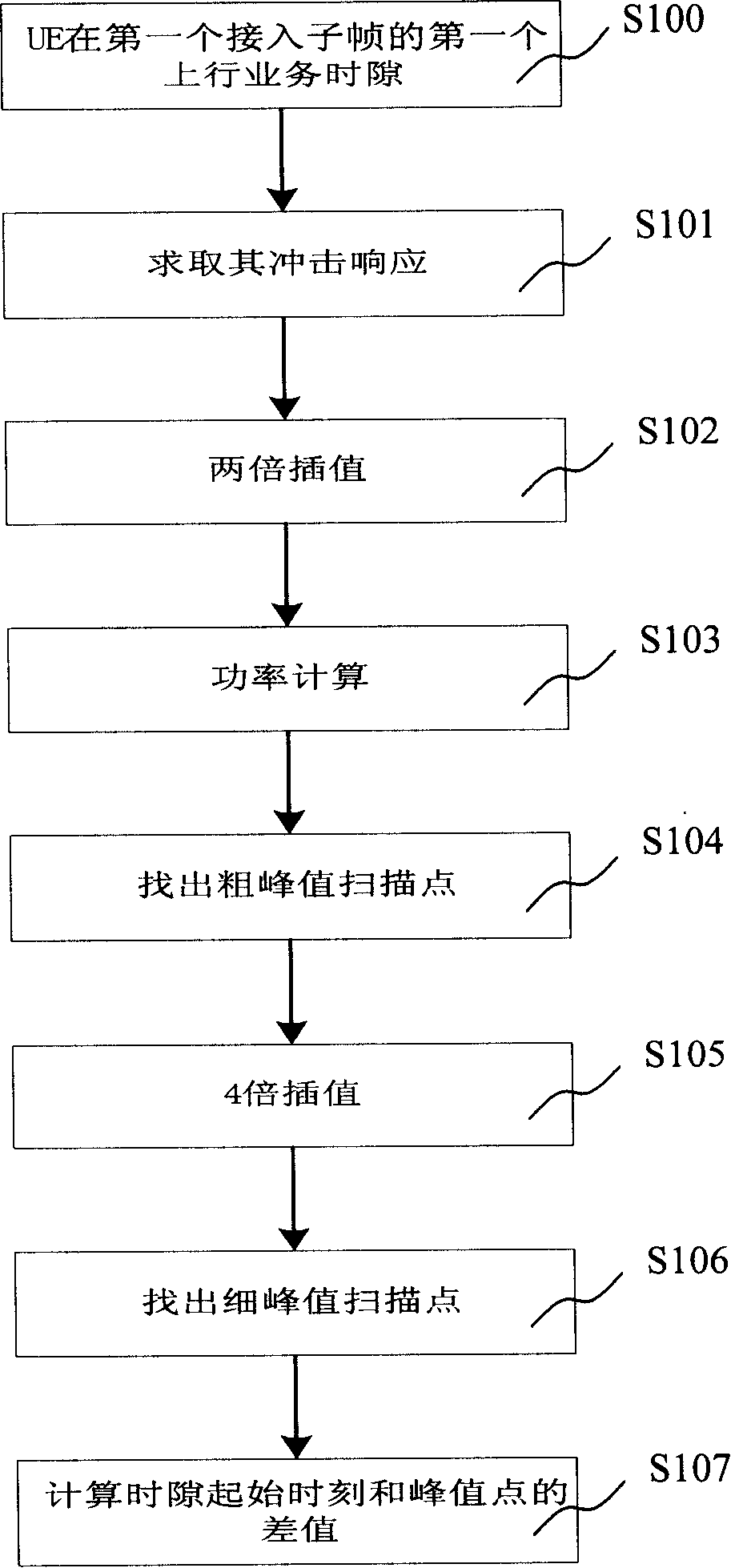

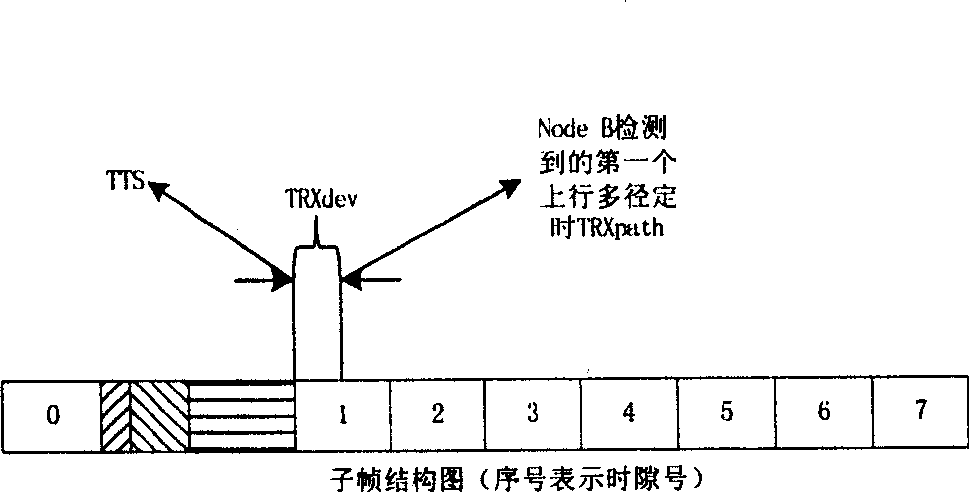

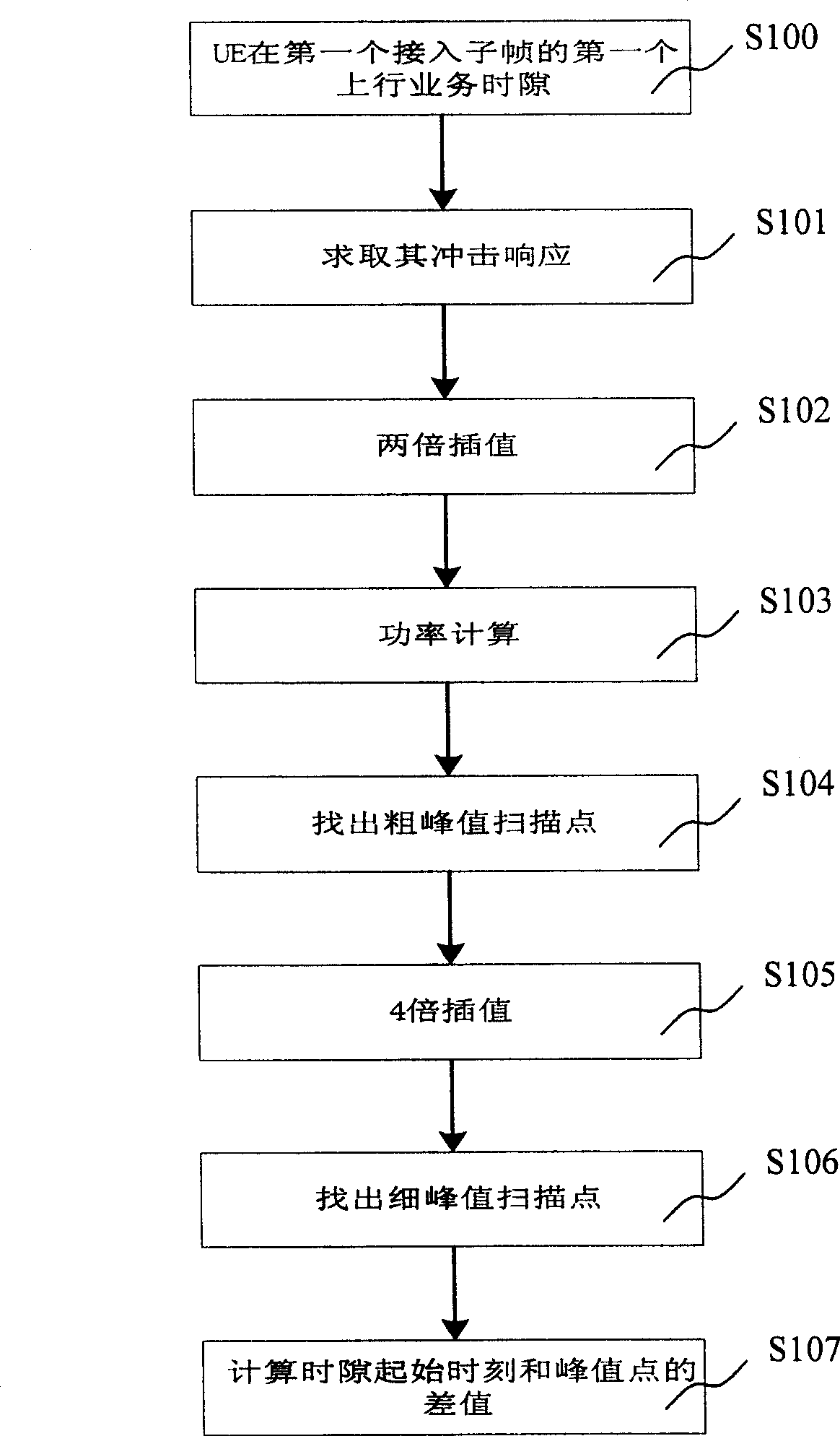

Realizing method for TD-SCDMA receiving timed error LCR measurement

InactiveCN1707972ASolve the positioning problemAchieving Measurement AccuracyRadio transmission for post communicationTime errorStart time

The present invention is LCR measurement method of reception timing deviation in TD-SCDMA. LCR measurement of reception timing deviation is realized through calculating the difference between the starting time corresponding to the time slot of the user's equipment and the first received upwards multipath timing, and is used in providing the user's equipment with time preact information and location service. The starting time corresponding to the time slot is calculated with the timing GPS, the first received upwards multipath timing is obtained through processing the channel impact response peak the user's equipment receives in the time slot, and the impact response peak is extracted from the first upward time slot in the first upward frame the user's equipment receives in the time slot. The present invention can reach measurement accuracy of 1 / 8 chip.

Owner:晋江市高新技术开发办公室

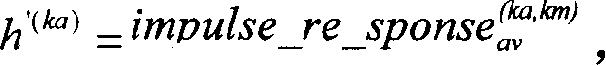

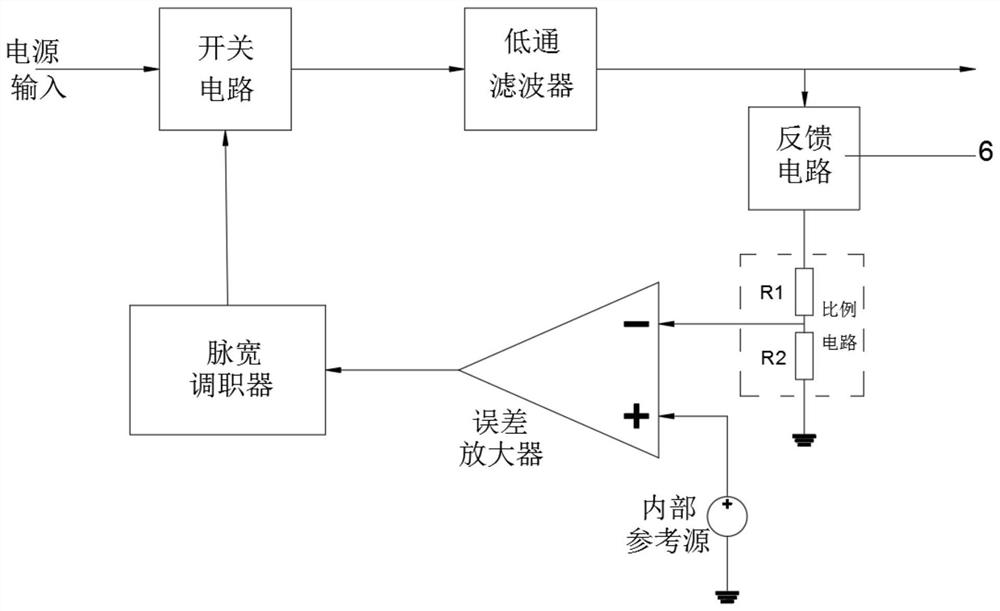

High-precision wide-range current measurement system

InactiveCN113514690AHigh precisionIncrease the current valueMeasurement using digital techniquesShunt DeviceElectrical connection

The invention relates to the technical field of low-power-consumption equipment current detection and transient current detection, and discloses a high-precision wide-range current measurement system. The system comprises a power supply module, the output end of the power supply module is in signal connection with a diverter, the output end of the top end of the diverter is electrically connected with an amplifier, and the output end of the amplifier is electrically connected with an AD rotating ring and a display module. According to the high-precision wide-range current measurement system, current enters the diverter, the diverter guides the entering current to enter different gain circuits, high-precision measurement of a low current value and wide-range measurement of a large current value are achieved, the requirements for measurement precision and measurement range are achieved; then the current enters the amplifier after passing through the diverter, the amplifier amplifies the current output by the diverter to improve the measurement precision and range, and then the AD rotating ring and the display module are mainly used for carrying out digital-to-analog conversion and display on the signal output by the amplifier.

Owner:黄森源

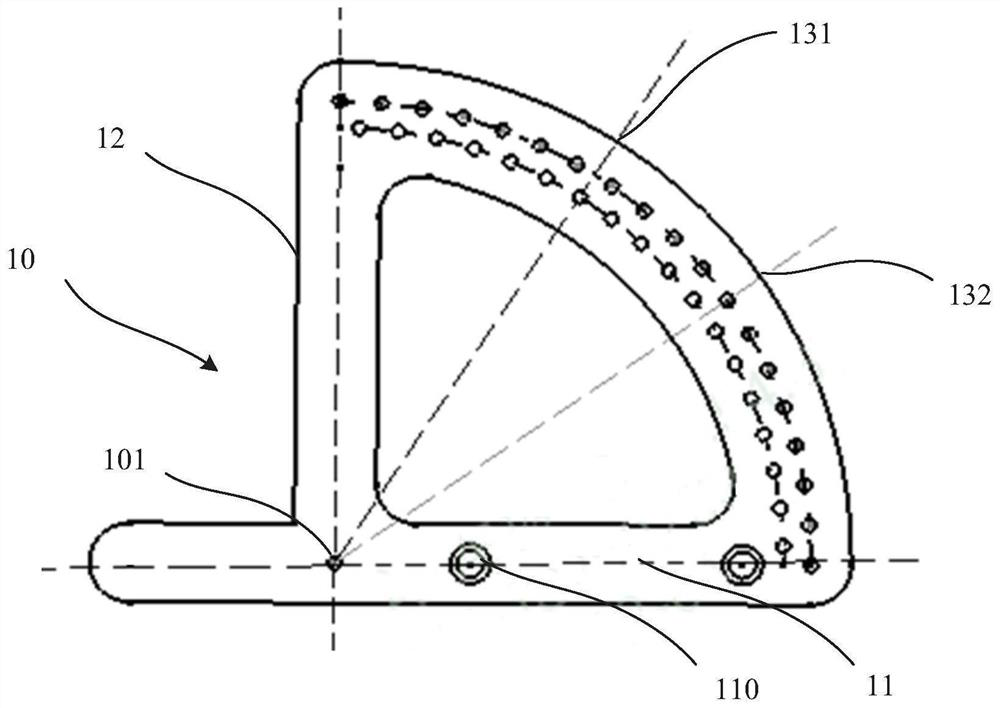

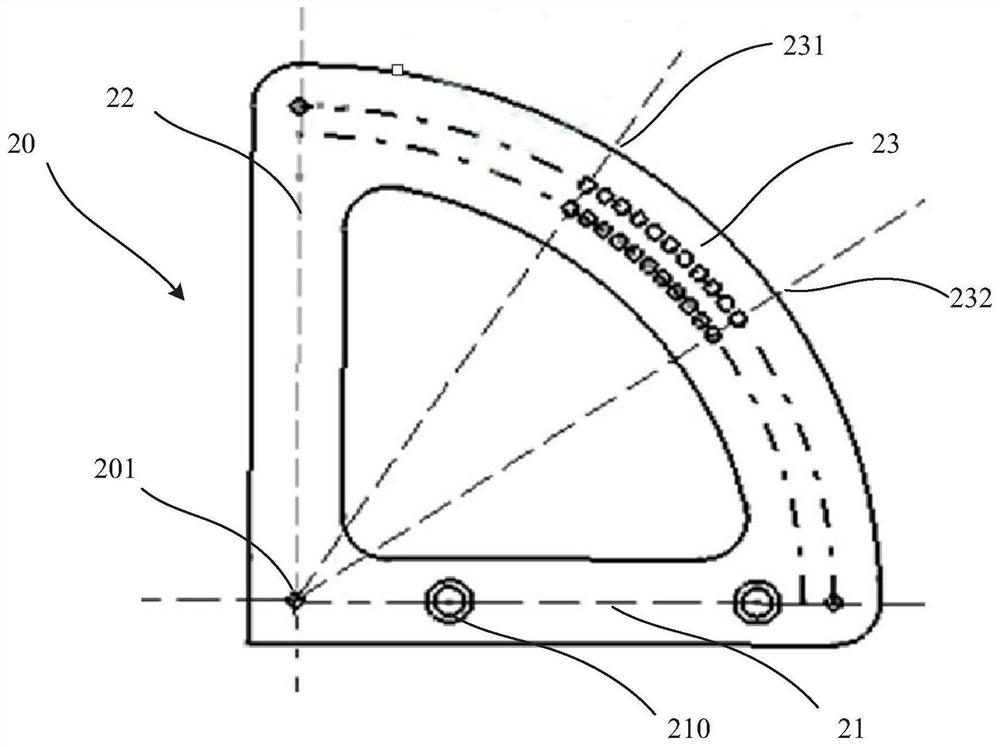

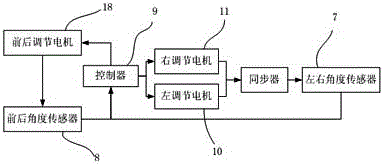

Balancing angle adjusting device for horizontal tail

ActiveCN112960140AAchieving Measurement AccuracyAngles/taper measurementsAircraft components testingFlight vehicleModel test

The invention relates to a balancing angle adjusting device for a horizontal tail. The balancing angle adjusting device for the horizontal tail comprises a first scale, first uniform scales and a first attachment structure, wherein the first uniform scales are circumferentially arranged on the first scale; the first attachment structure is suitable for being attached to a horizontal tail box section of the horizontal tail; and a second scale, a second uniform scale circumferentially arranged on the second scale, and a second attachment structure adapted to be attached to the elevator of the horizontal tail, and wherein an indexing value of the first uniform scale is not equal to an indexing value of the second uniform scale. The angle adjusting device can adjust a series of deflection angles of the elevator so as to determine the initial attitude of the horizontal tail, thereby researching the stability of the whole structure of the aircraft under the action of dynamic load. The angle adjusting device is simple in structure and easy to operate, facilitates quick reloading of a model test and can quickly and accurately obtain the deflection angle of the elevator, the accuracy of the angle adjusting device can meet the test requirement, and the expected invention purpose is achieved.

Owner:COMAC +1

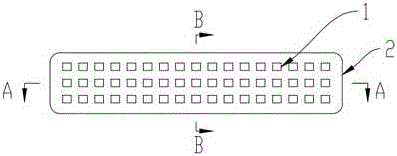

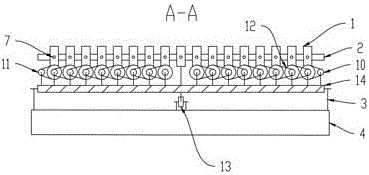

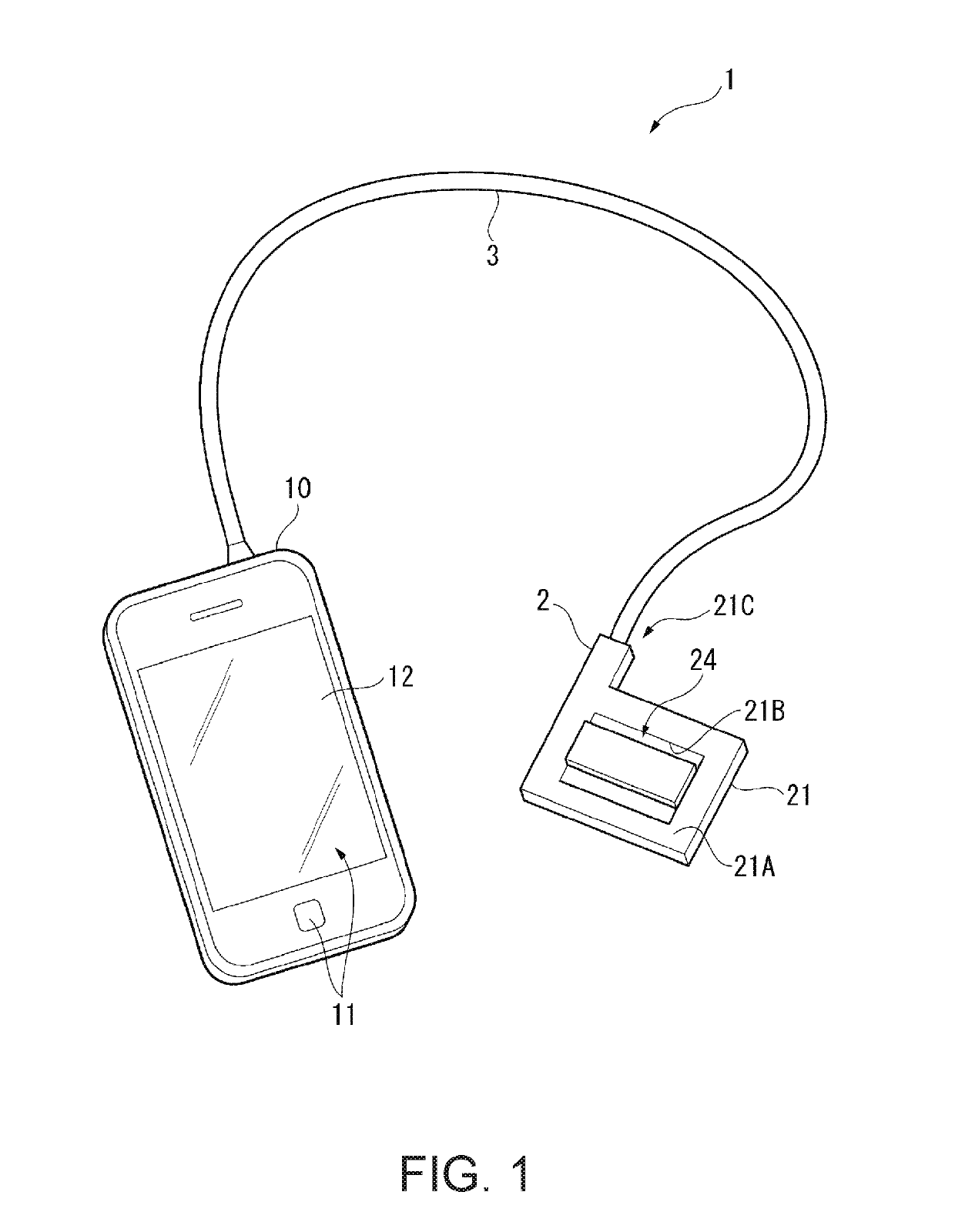

Space scanning system and method of combining adjustable laser ranging probe array and intelligent terminal

PendingCN106840007AGuaranteed measurement accuracySolve a wide range of measurement needsUsing optical meansControl using feedbackLaser rangingEngineering

The invention discloses a space scanning system and method of combining an adjustable laser ranging probe array and an intelligent terminal. The system comprises a distance collection subsystem, an angle control subsystem and a control management subsystem, wherein the distance collection subsystem comprises a probe array formed by adjustable laser ranging probes; the probe array is arranged on a support plate; each adjustable laser ranging probe swings left and right and back and forth to expand the scanning range of the probe array; the angle control subsystem is used for adjusting the directions of the adjustable laser ranging probes, so that the probe array is aligned at a calibration direction and is matched with the distance collection subsystem to complete scanning locating operation; and the control management subsystem is connected with the distance collection subsystem and the angle control subsystem separately, is used for displaying the measurement distance and the deviation angle, calculating, recording and sharing scanning coordinate data. According to the space scanning system and method, a simple logic and multi-probe measurement are utilized, so that the large-range measurement requirements can be met on the premise of ensuring the measurement accuracy.

Owner:赵怡

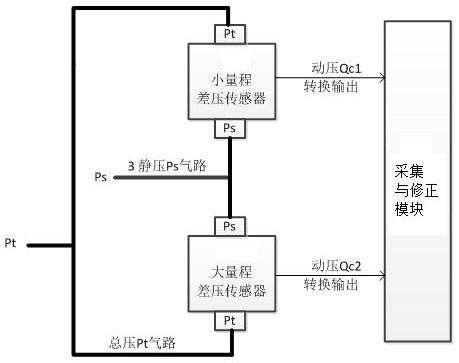

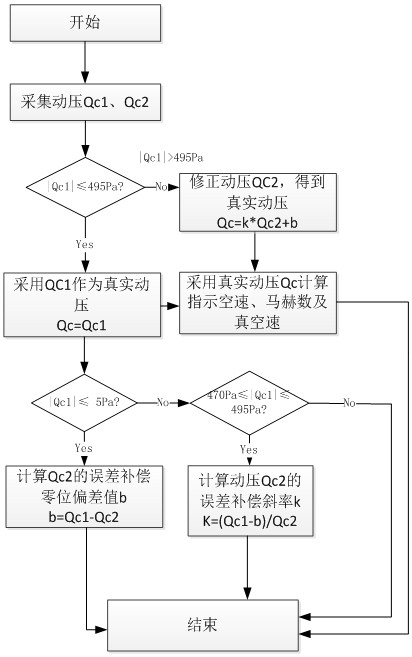

High-precision dynamic pressure measurement method and system with long-term stability

InactiveCN112504547AAchieving Measurement AccuracyAchieve long-term stabilityMultiple fluid pressure valves simultaneous measurementDifferential pressureMechanical engineering

The invention discloses a high-precision dynamic pressure measurement method and system with long-term stability. The system comprises a wide-range differential pressure sensor and a small-range differential pressure sensor. The range of the wide-range differential pressure sensor covers the dynamic pressure measurement range. When Qc1 is close to 0Pa, the zero deviation b of the measurement dynamic pressure Qc2 of the wide-range differential pressure sensor is calculated; when Qc1 is close to the range end value of the small-range differential pressure sensor, the error correction slope k ofthe dynamic pressure Qc2 is calculated; when the dynamic pressure Qc is within the measurement range of the small-range differential pressure sensor, the measurement dynamic pressure Qc1 of the small-range differential pressure sensor is the real dynamic pressure, namely Qc = Qc1; otherwise, the real dynamic pressure is obtained by correcting the dynamic pressure Qc2. Measurement configurations ofthe small-range differential pressure sensor and the wide-range differential pressure sensor are constructed, and through cooperative work of the small-range differential pressure sensor and the wide-range differential pressure sensor, measurement precision and long-term stability within the dynamic pressure full-pressure range are achieved.

Owner:CHENGDU KAITIAN ELECTRONICS

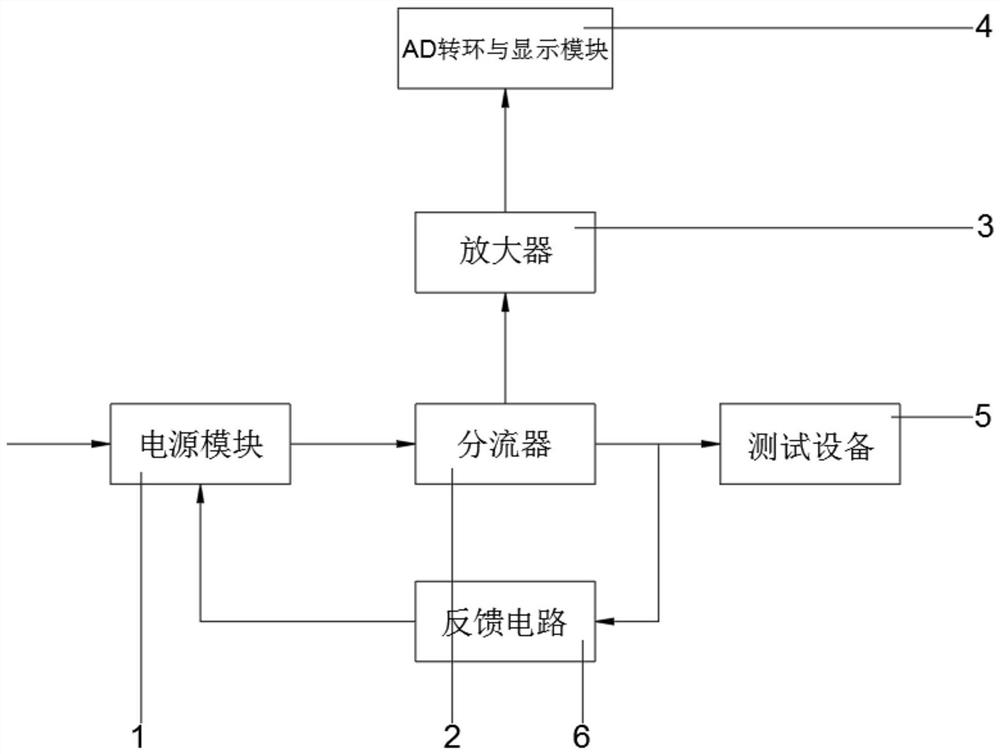

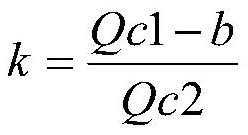

All-fiber current transformer control system

InactiveCN106124827ASimple structureHighly integratedCurrent/voltage measurementConverting sensor output opticallyDriver circuitFiber

The invention provides an all-optical current transformer control system, which belongs to the field of optical fiber communication, and includes an optical fiber sensing probe, an optical phase modulator, a photoelectric converter, an amplification and filtering circuit, an A / D conversion circuit, a controller circuit, a computer, D / A conversion circuit and drive circuit. The output end of the optical fiber sensing probe is connected to the input end of the optical phase modulator; the output end of the optical phase modulator is connected to the input end of the photoelectric converter; the output end of the photoelectric converter is connected to the input end of the amplification and filtering circuit; the amplification And the output end of the filter circuit is connected with the input end of the A / D conversion circuit. The output end of the A / D conversion circuit is connected to the controller circuit; one output end of the controller circuit is connected to the D / A conversion circuit, and the other output end is connected to the computer; the output end of the D / A conversion circuit is connected to the optical phase through the drive circuit Modulator connection.

Owner:GUILIN TRYIN TECH CO LTD

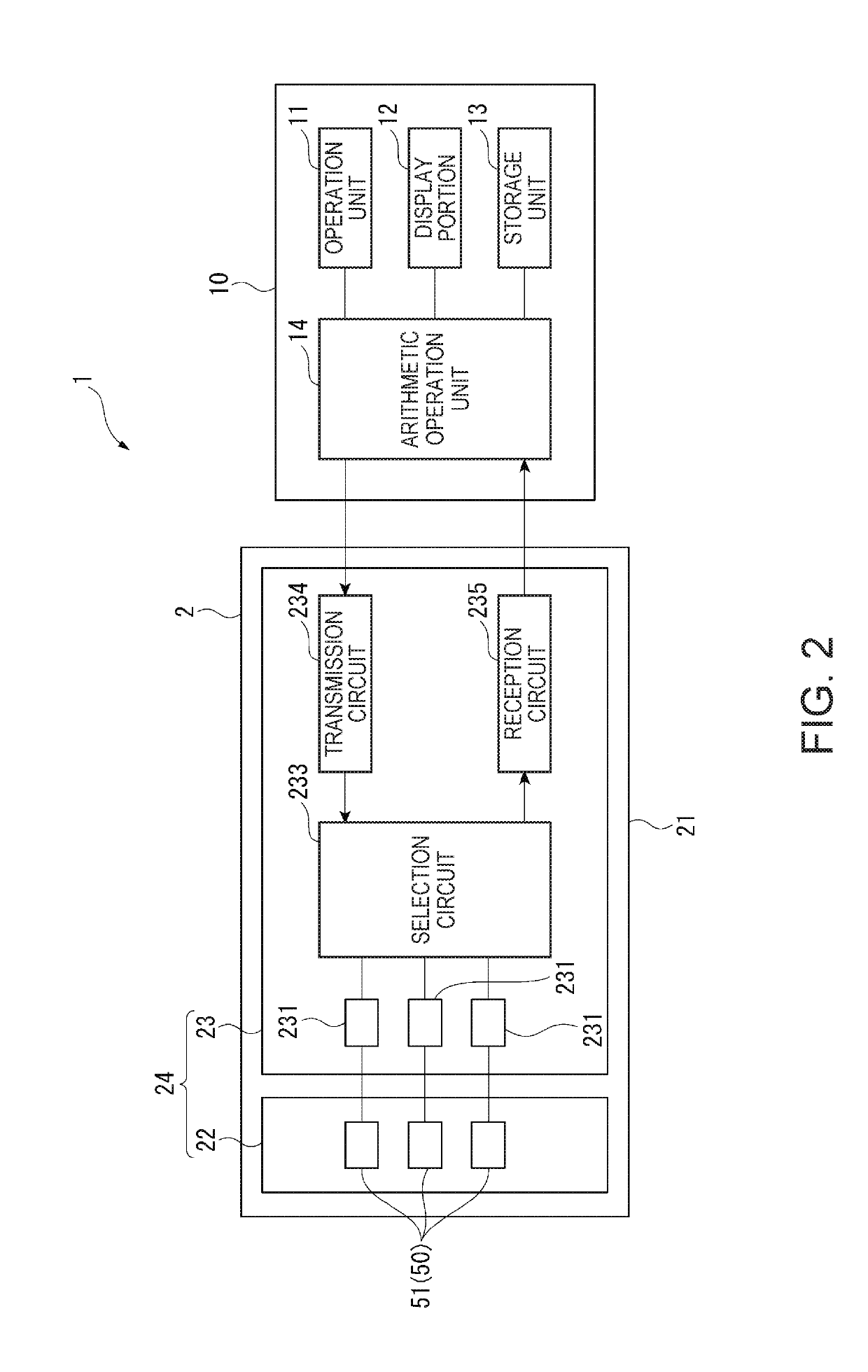

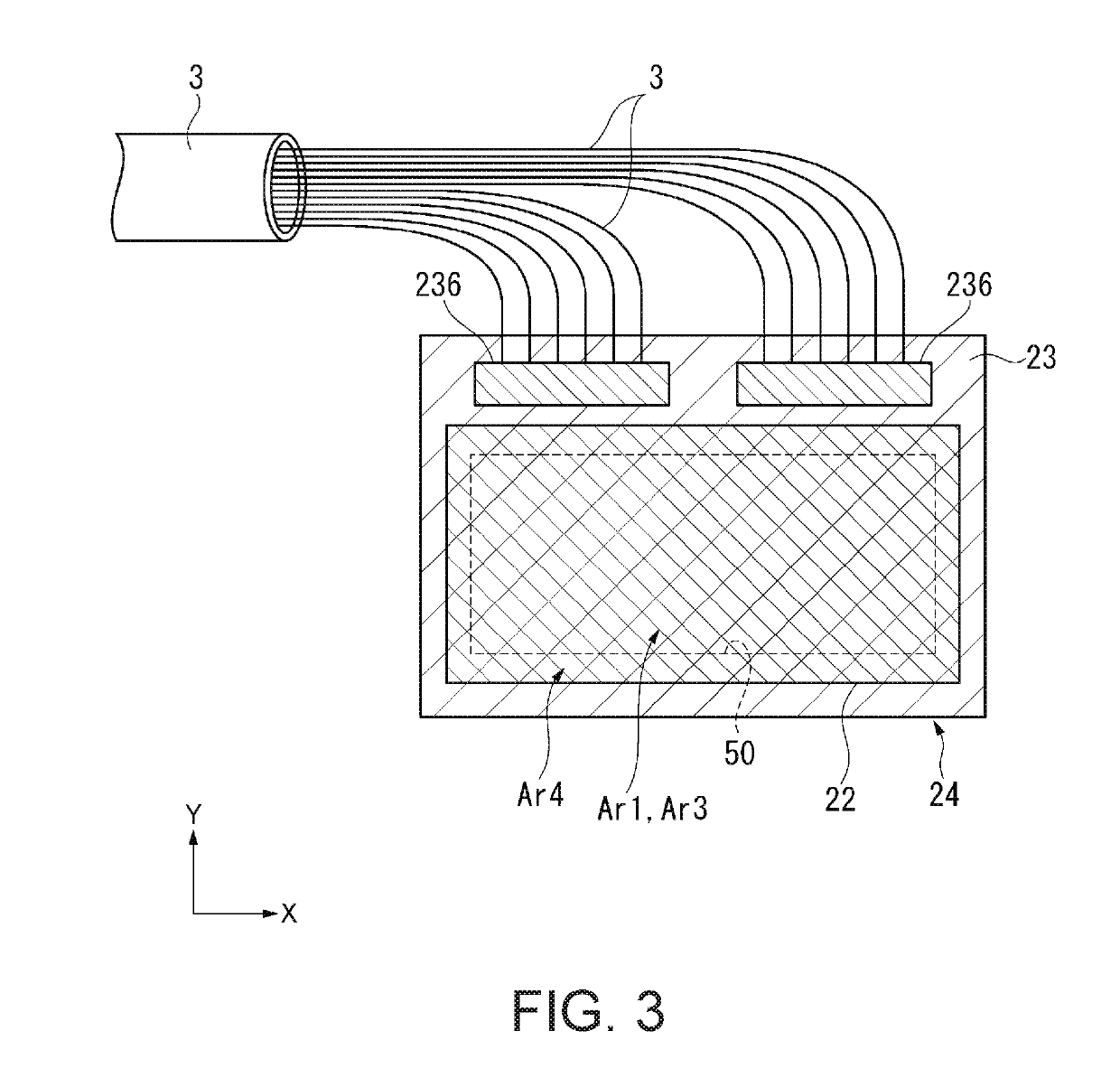

Piezoelectric device, piezoelectric module, and electronic apparatus

ActiveUS10424720B2Damage suppressionHigh strengthBlood flow measurement devicesPiezoelectric/electrostrictive transducersComputer moduleEngineering

A piezoelectric device includes an element substrate that includes a first surface (operating surface) and a second surface (back surface) on a side opposite to the first surface, and includes a recessed opening provided on the first surface and a supporting portion surrounding the recessed opening, a piezoelectric body that is provided on the second surface of the recessed opening, a plurality of connection electrodes (lower connection electrode and upper connection electrode) that are connected to the piezoelectric body and are drawn to the second surface of the supporting portion from the piezoelectric body, a reinforcement plate that is bonded to the second surface side of the element substrate, and a plurality of through electrodes that are provided at a position of the reinforcement plate which faces the supporting portion, pass through the reinforcement plate in a thickness direction, and are respectively connected to the plurality of connection electrodes.

Owner:SEIKO EPSON CORP

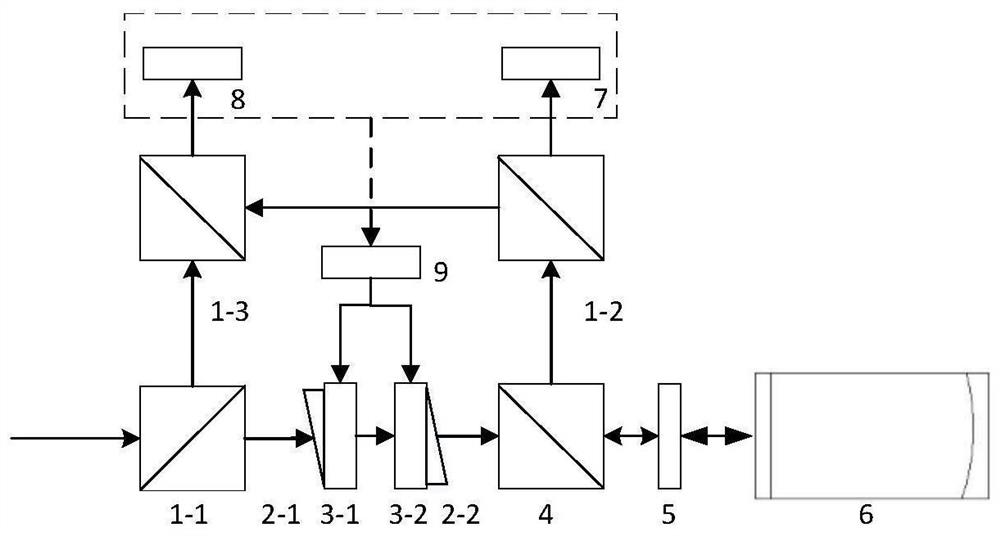

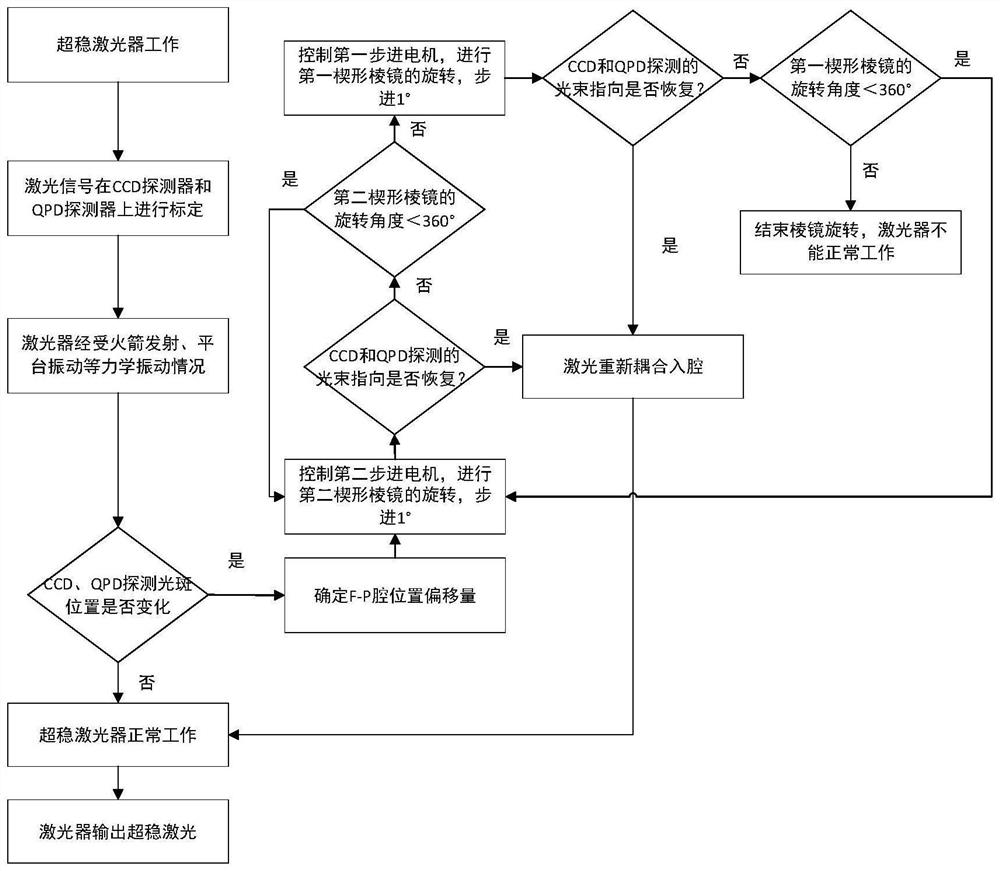

Ultra-stable laser device laser self-adaptive coupling cavity-entering matching system and method

ActiveCN113991415AFor fine tuningAchieving Active CompensationLaser detailsImage analysisPhotovoltaic detectorsLight spot

The invention provides an ultra-stable laser device laser self-adaptive coupling cavity-entering matching system and method, and the method comprises the steps: the precise measurement of light beam pointing is achieved through a charge coupling element light spot mass center detection technology and a four-quadrant photoelectric detector phase detection technology, and the offset of an F-P cavity is obtained; besides, a wedge-shaped prism pair is adjusted through a stepping motor to achieve precise adjustment of a laser light path, precise measurement of light beam pointing and precise adjustment of the light path form a closed loop, and active compensation of F-P cavity position deviation is achieved. According to the laser self-adaptive coupling in-cavity matching system and method for the ultra-stable laser, the structure is simple, adjustment and correction are automatic, the in-cavity matching precision is high, and the system and method have wide application prospects in the fields of ultra-stable lasers in space application and optical communication.

Owner:HANGZHOU INST FOR ADVANCED STUDY UCAS

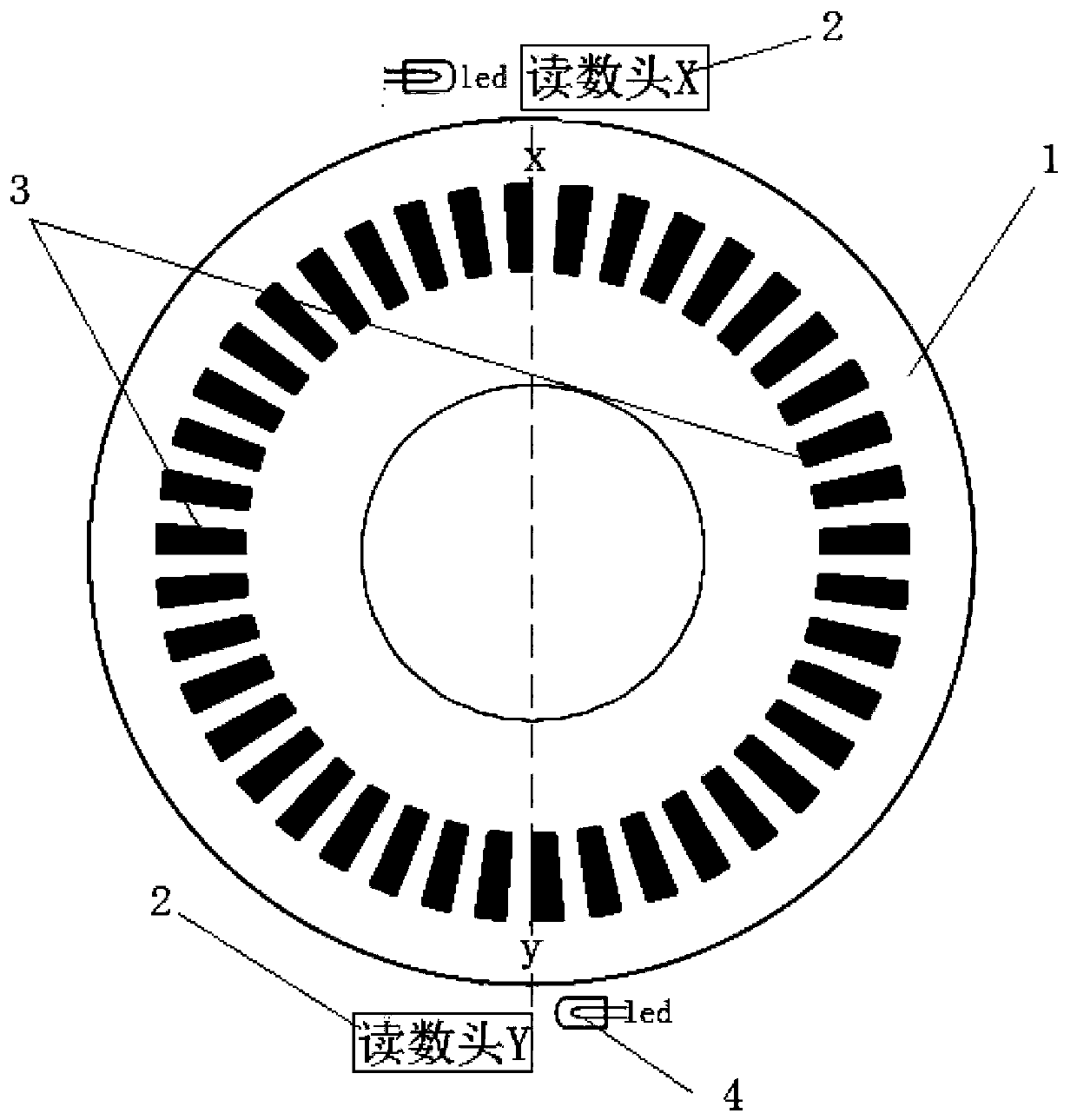

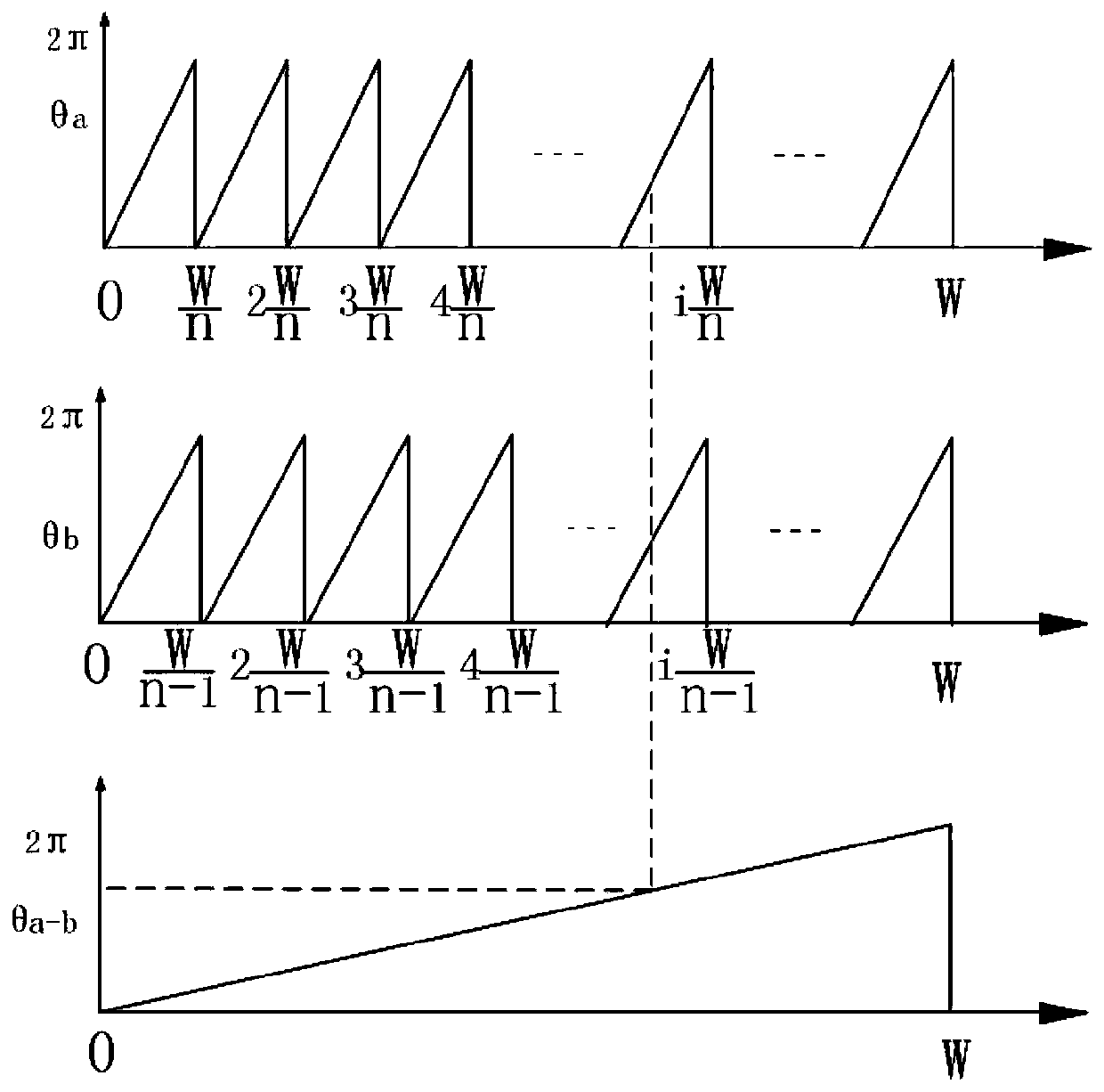

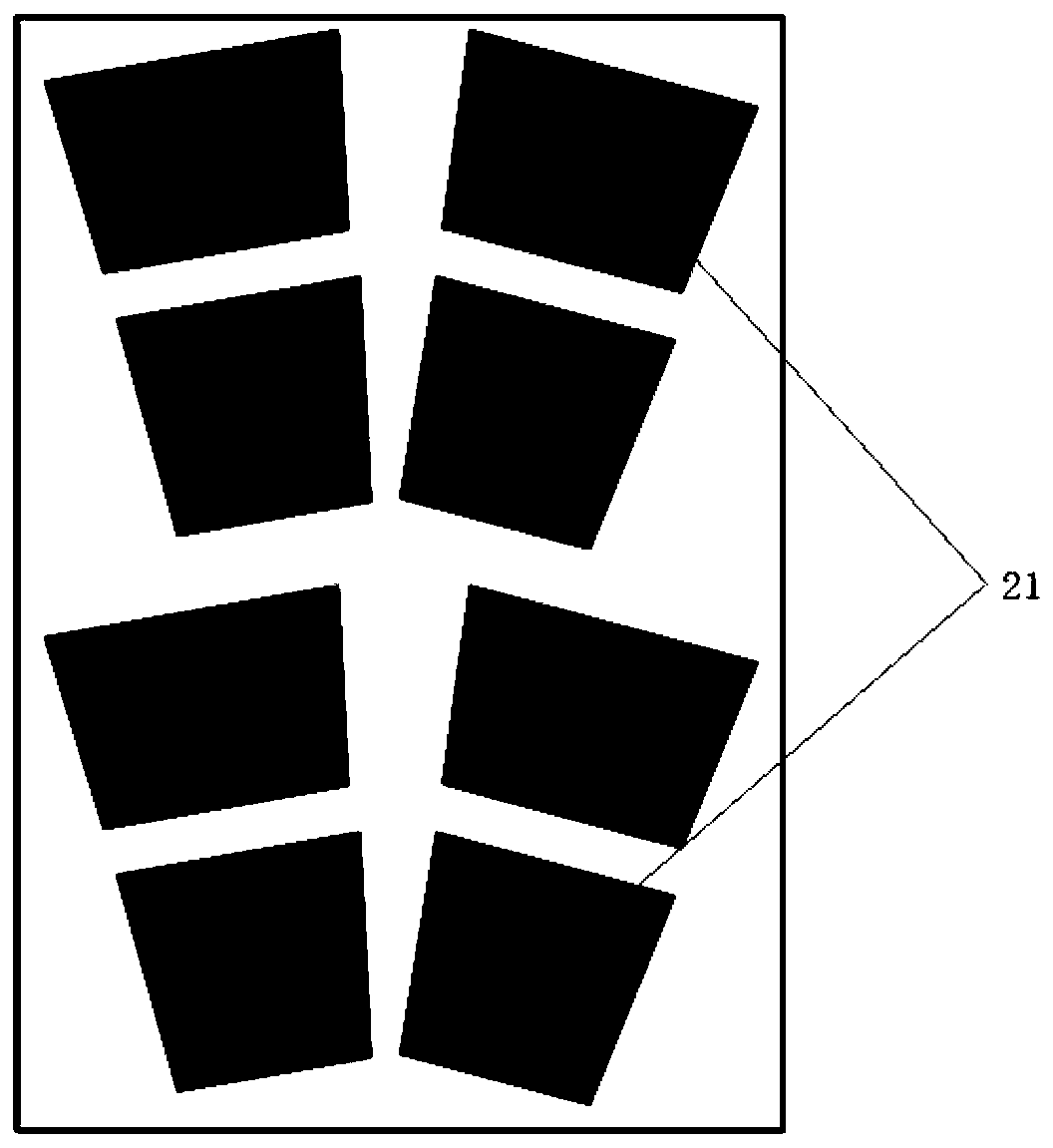

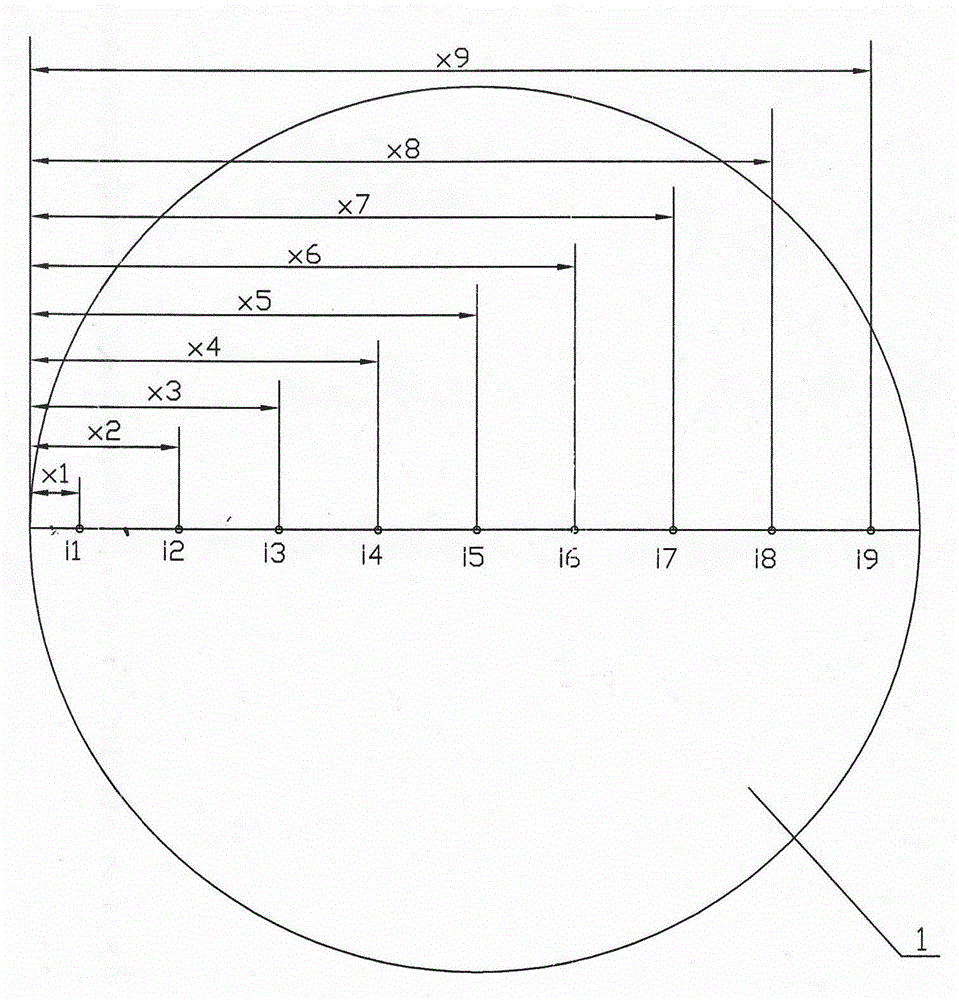

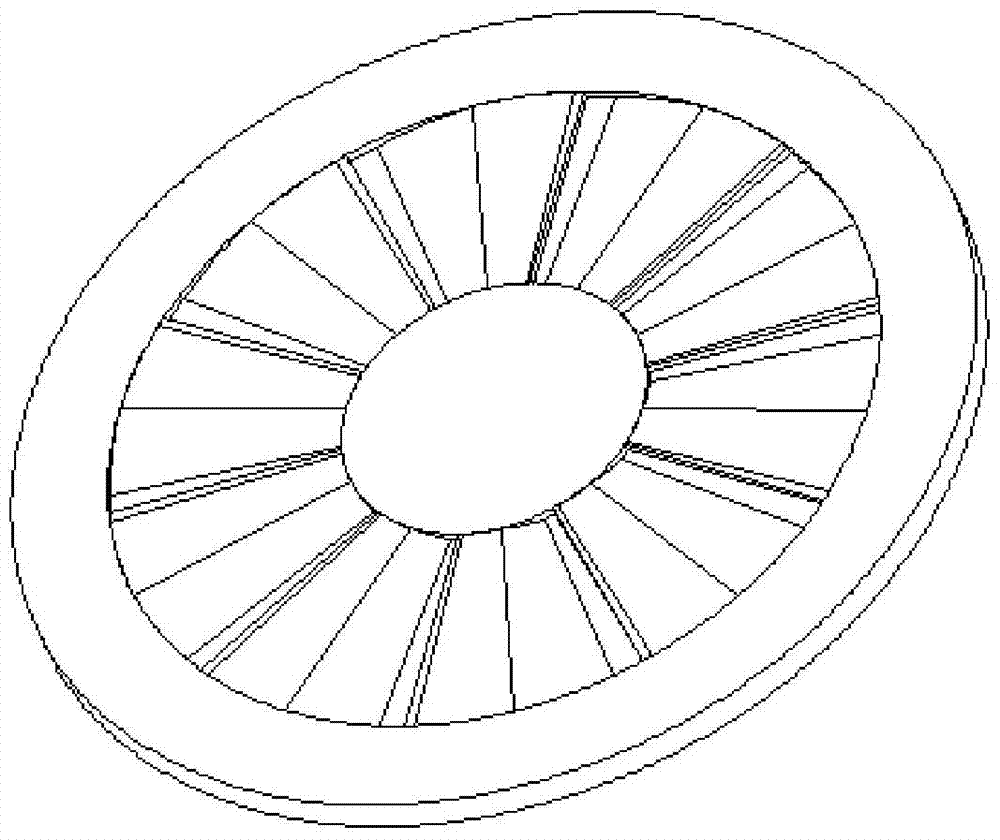

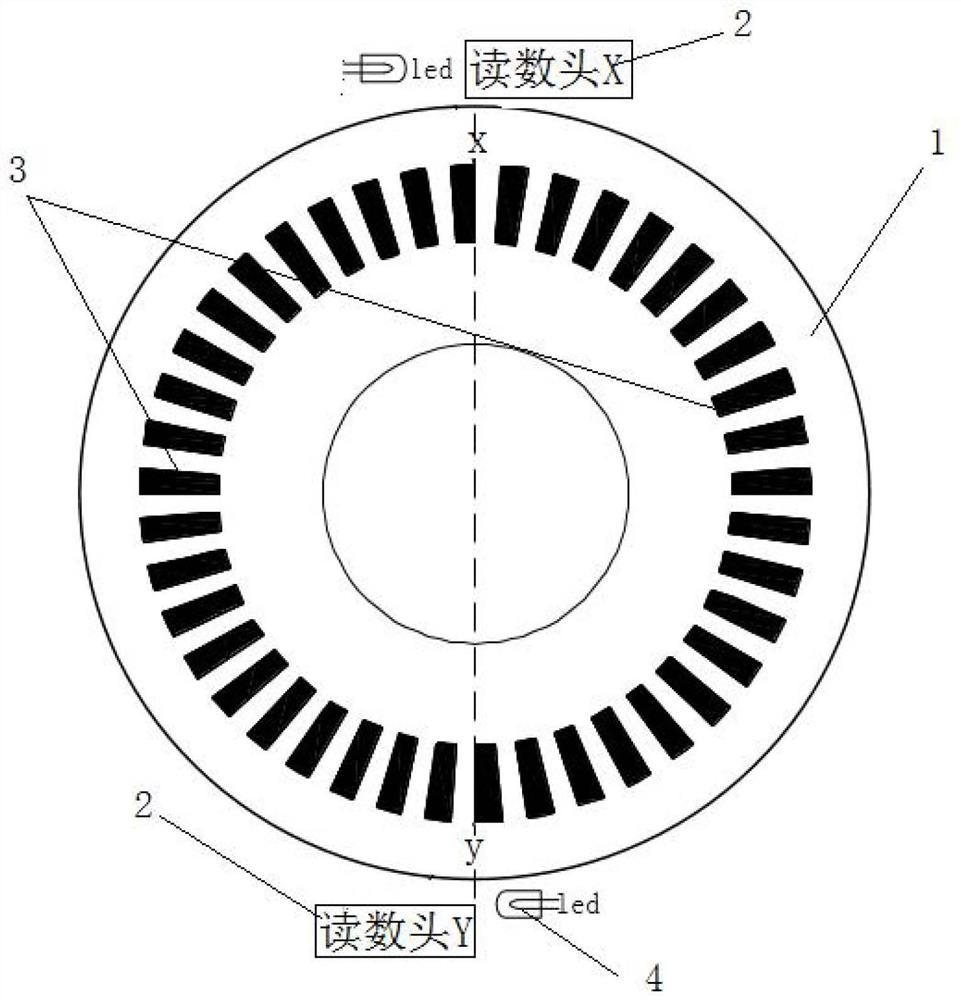

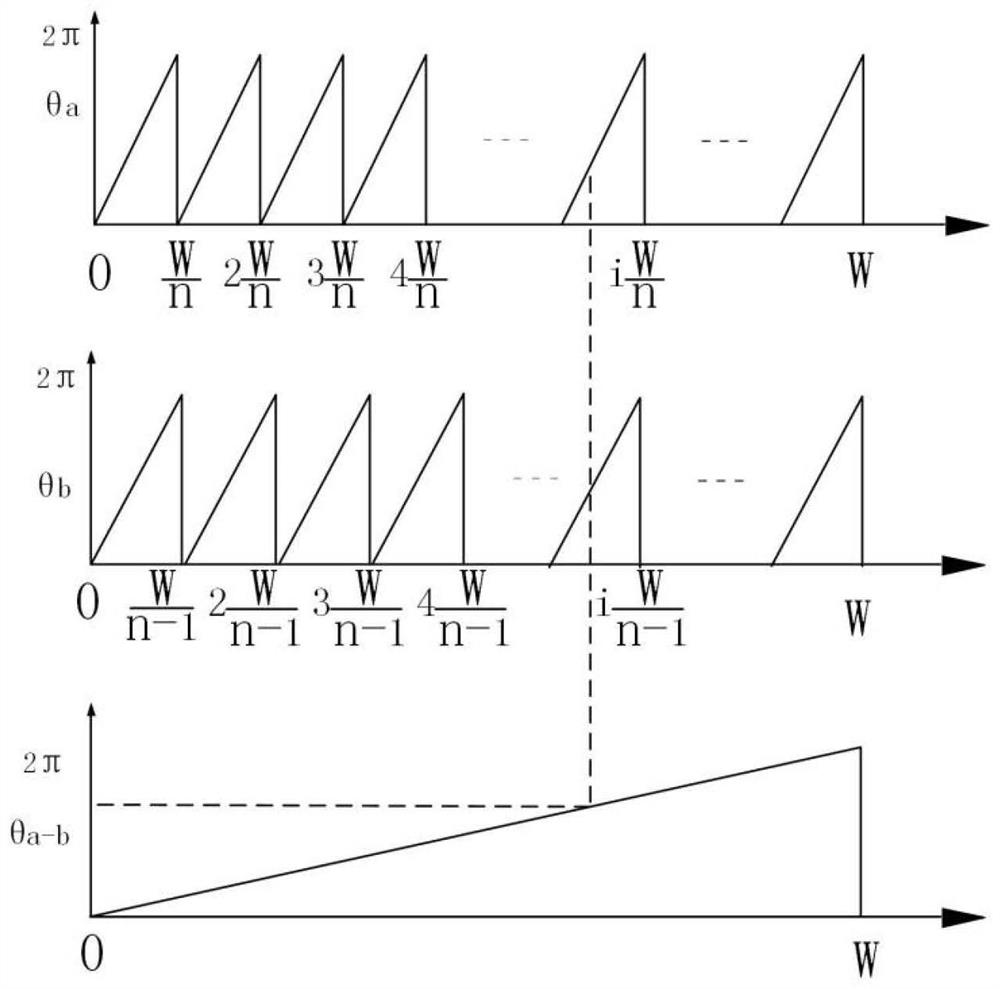

Rotary encoder

ActiveCN110375776AReduce the number of code lanesAchieving Measurement AccuracyConverting sensor outputMiniaturizationComputer science

The invention discloses a rotary encoder, which comprises an encoder disk having an annular code channel, a reading head and a light source device, wherein the annular code channel comprises two semicircular subcode channels, bright and dark stripes with the same width are evenly distributed on each subcode channel, and the widths of the bright and dark stripes of the two subcode channels are different; the number of reading heads is two, and the two reading heads are respectively arranged at two end positions corresponding to annular code channel diameters; and the light source device is usedfor providing illumination for each reading head respectively. The rotary encoder combines the plurality of code channels on the same code channel, so that one annular code channel in the encoder canachieve the measurement precision of a plurality of annular code channels in the prior art, thereby being capable of satisfying dual requirements for high precision and miniaturization of the encoder.

Owner:GUANGDONG UNIV OF TECH

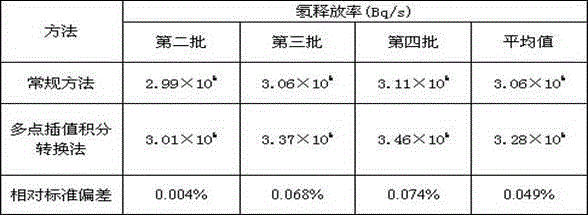

Method for measuring uranium mine air return shaft radon emissions

ActiveCN104880726AReliable and convenient measurementAchieving Measurement AccuracyX/gamma/cosmic radiation measurmentSpecial data processing applicationsAir velocityUranium mine

Provided is a method for measuring uranium mine air return shaft radon emissions. Firstly, a multi-point method is adopted to perform radon concentration measurement on the specific sample points at the uranium mine air return shaft head, and average outlet air speed and average radon concentration in a radial specific area at the air return shaft head are calculated, and the product of the average air speed value and radon concentration mean value of each area and the area of the specific area is weighted to calculate the radon release rate of the air return shaft. For a specific air return shaft, a constant numerical relationship exists between the release rate and the shaft center air speed and the shaft center radon concentration of a cross section and the area of the cross section, and the conversion coefficient of the air return shaft is obtained based on the rule and through the calculation of measured data. In the subsequent measurement of the radon release rate of the uranium mine air return shaft, one only needs to measure the shaft center radon concentration and air speed of the cross section of the air return shaft, multiplies the radon concentration and air speed values by the conversion coefficient and the sectional area of the air return shaft outlet to obtain the radon release rate of the uranium mine air return shaft, and then multiplies the radon release rate by the radon emission time of the air return shaft to calculate the radon emission value of the uranium mine air return shaft.

Owner:NANHUA UNIV

Workpiece platform system of photoetching machine

ActiveCN103309177BReduce volumeReduce quality problemsPhotomechanical exposure apparatusMicrolithography exposure apparatusGrating interferometerDual frequency

Owner:TSINGHUA UNIV +1

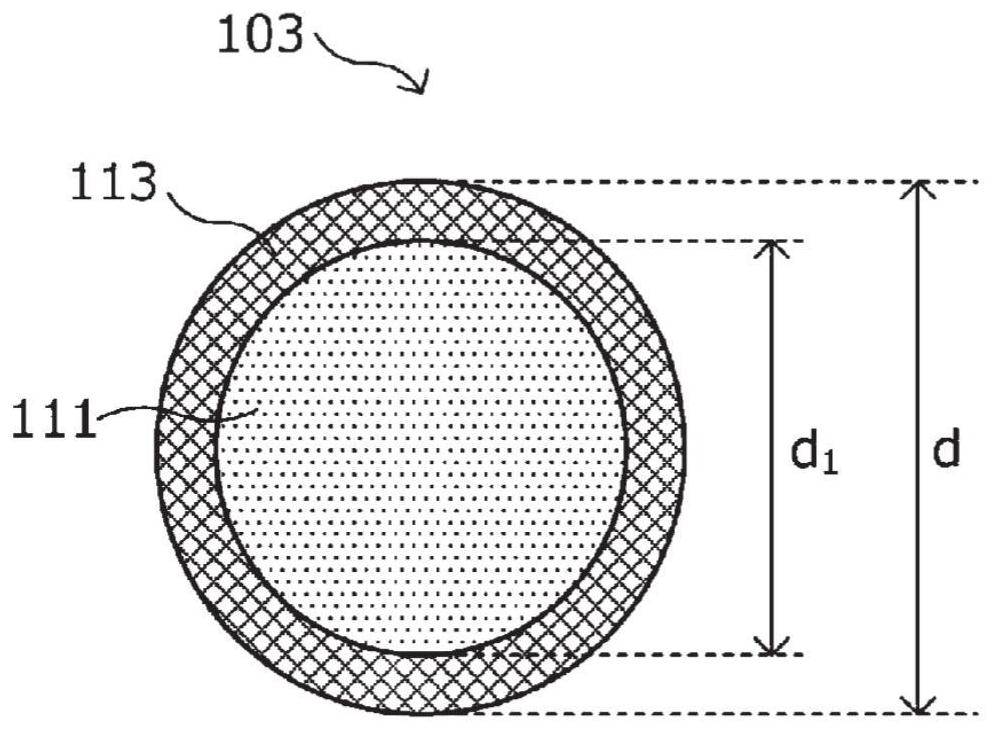

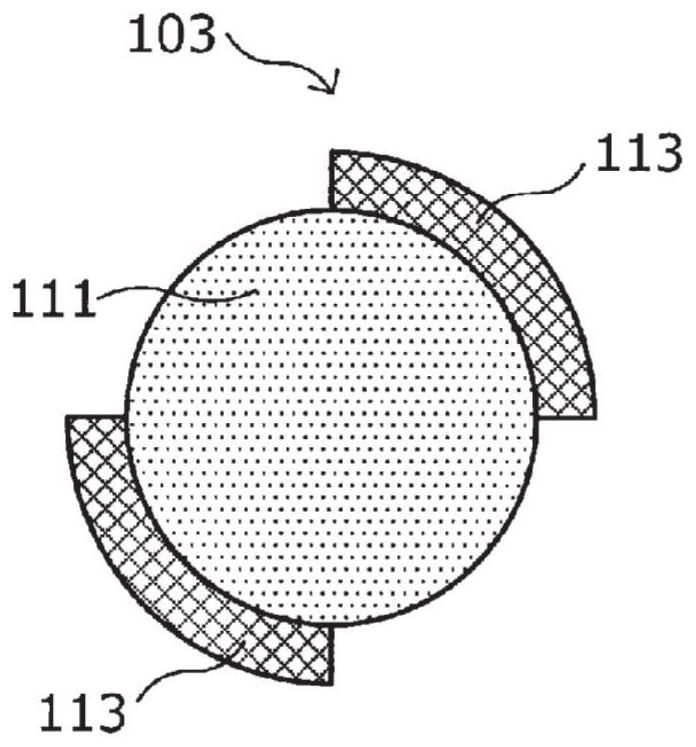

Electrode for biopotential measurement and biopotential measurement device

PendingCN112105295ADoes not reduce adhesionImprove convenienceMaterial nanotechnologyNanosensorsElastomerLiving body

The present invention makes it possible to achieve both convenience for the user and measurement accuracy without reducing reliability. The electrode for biopotential measurements according to the present invention includes, in at least a portion that comes into contact with a living body, a base resin layer that is composed mainly of a predetermined resin material, rubber, or elastomer, and conductive particles contained in the base resin layer. The conductive particles each has a predetermined base particle and a surface treatment region which is at least a portion of the surface of the baseparticle that is covered or substituted by a predetermined material.

Owner:SONY CORP

A gap detection method for suspension polishing

The invention discloses a suspension polishing machining gap detecting method. Adopted hydrodynamic polishing equipment comprises a polishing disk, a polishing solution container, a polishing solution container fixing plate, a distance measuring sensor, a screw mechanism and a fine adjustment mechanism. The centers of the polishing disk and the polishing solution container are aligned by adjusting the fine adjustment mechanism, and the screw mechanism is adjusted to achieve relative movement of the polishing disk and the polishing solution container in the Z-axis direction, so that machining gaps of suspension polishing are adjusted. Then the moving distance of the polishing solution container is detected through the distance measuring sensor disposed at the bottom of a polishing solution, and the machining gaps between the polishing disk and the polishing solution container are worked out. By means of the suspension polishing machining gap detecting method, the machining gaps can be accurately detected, the change values of the machining gaps due to generation of hydrodynamic pressure can be detected in real time, and the micrometer-level measurement accuracy can be achieved. An adopted electric eddy current displacement sensor has high displacement measurement accuracy, is adaptable to complex testing environments and guarantees the experimental accuracy.

Owner:ZHEJIANG UNIV OF TECH

Realizing method for TD-SCDMA receiving timed error LCR measurement

InactiveCN100473220CSolve the positioning problemAchieving Measurement AccuracySpatial transmit diversityRadio transmission for post communicationTime errorStart time

The present invention is LCR measurement method of reception timing deviation in TD-SCDMA. LCR measurement of reception timing deviation is realized through calculating the difference between the starting time corresponding to the time slot of the user's equipment and the first received upwards multipath timing, and is used in providing the user's equipment with time preact information and location service. The starting time corresponding to the time slot is calculated with the timing GPS, the first received upwards multipath timing is obtained through processing the channel impact response peak the user's equipment receives in the time slot, and the impact response peak is extracted from the first upward time slot in the first upward frame the user's equipment receives in the time slot. The present invention can reach measurement accuracy of 1 / 8 chip.

Owner:晋江市高新技术开发办公室

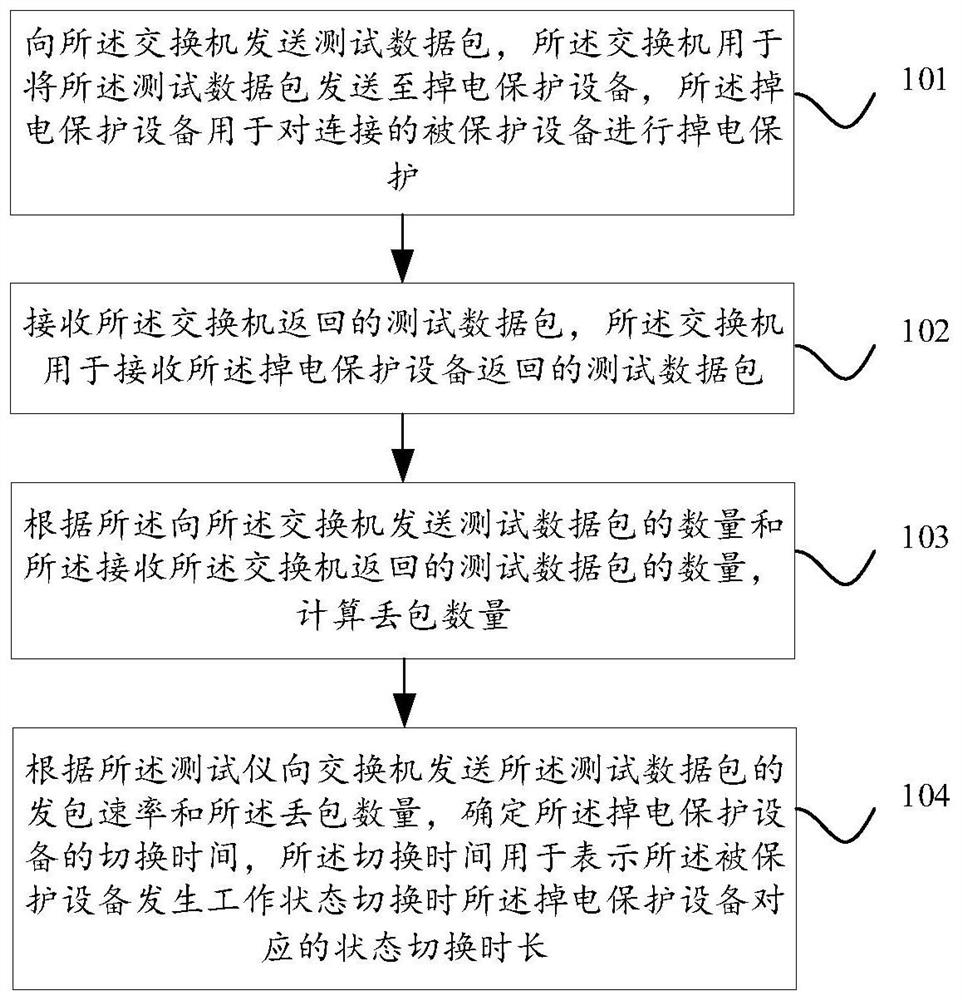

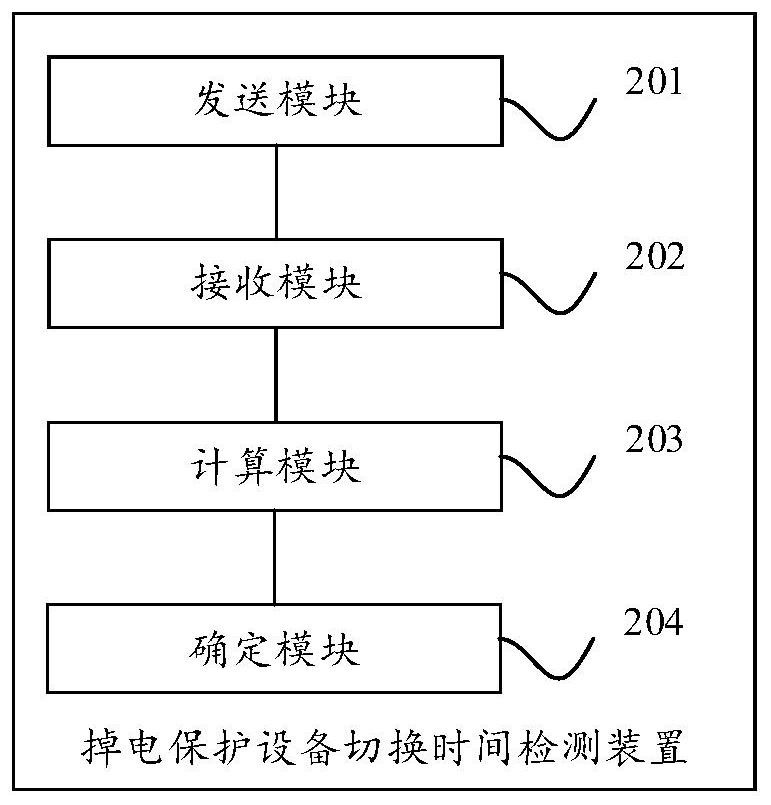

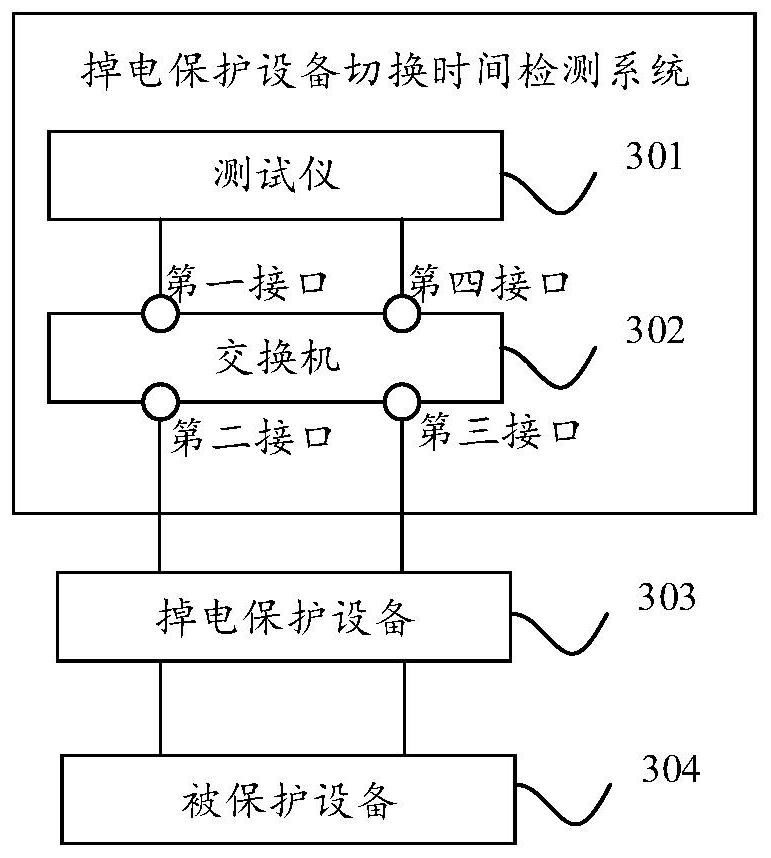

Method, device, device and system for detecting switching time of power-down protection equipment

ActiveCN110708218BGuaranteed working conditionAchieving Measurement AccuracyError preventionData switching current supplyData packTester device

The present application provides a method, device, device and system for detecting switching time of a power-down protection device. The method is executed by a tester, and the tester is connected to a switch. The method includes: sending a test data packet to the switch, and the switch is used to send the test data packet To the power-down protection device, the power-down protection device is used for power-down protection of the connected protected device; receiving the test data packet returned by the switch, and the switch is used to receive the test data packet returned by the power-down protection device; according to sending the test data packet to the switch The number of data packets and the number of test data packets returned by the receiving switch are used to calculate the number of packet loss; according to the packet sending rate and the number of packet loss sent by the tester to the switch, the switching time of the power-down protection device is determined, and the switching time is used for Indicates the state switching duration corresponding to the power-down protection device when the protected device switches its working state. Therefore, when the switching time of the power-down protection device is relatively long, the switching time can also be accurately detected.

Owner:HANGZHOU DPTECH TECH

a rotary encoder

ActiveCN110375776BReduce the number of code lanesAchieving Measurement AccuracyConverting sensor outputComputer hardwareMiniaturization

The invention discloses a rotary encoder, which comprises a code disk with a ring code track, a reading head and a light source device; the ring code track includes two semicircular sub-code tracks, wherein each sub-code track is evenly distributed with The light and dark stripes of the two sub-code tracks have different widths; the number of reading heads is two, and the two reading heads are respectively set at the two ends of the diameter of the ring code track; the light source device is used to provide illumination for each reading head . In the present invention, multiple code tracks are combined on the same code track, so that one ring code track in the encoder can achieve the measurement accuracy of multiple ring code tracks in the prior art, and can meet the dual requirements of high precision and miniaturization of the encoder. need.

Owner:GUANGDONG UNIV OF TECH

MEMS mass flow controller based on piezoelectric control valve and control method

PendingCN113190050ASimple structureImprove stabilityTelevision system detailsImpedence networksStructural engineeringControl valves

The invention discloses an MEMS mass flow controller based on a piezoelectric control valve and a control method. The MEMS mass flow controller comprises a shell, a mass flow sensor and a piezoelectric diaphragm, wherein the mass flow sensor and the piezoelectric diaphragm are located in the shell, the shell comprises a lower base plate, an upper cover plate and an airflow channel defined by the lower base plate and the upper cover plate, the mass flow sensor is arranged on the side, close to an inlet of the airflow channel, of the lower base plate, the piezoelectric diaphragm is arranged on one side, close to the outlet of the airflow channel, of the lower substrate, the two ends of the piezoelectric diaphragm are arranged on the lower substrate, and a vibration gap is formed between the middle of the piezoelectric diaphragm and the lower substrate. According to the invention, the mass flow sensor is used for accurately measuring gas flow and feeding back the gas flow in real time, the gas flow serves as an adjusting basis of driving voltage of the piezoelectric diaphragm, and then high-precision control over micro flow can be achieved through deformation of the piezoelectric diaphragm; and the MEMS mass flow controller has the advantages of being simple in structure, small in size, low in cost, high in preparation controllability and the like.

Owner:青岛芯笙微纳电子科技有限公司

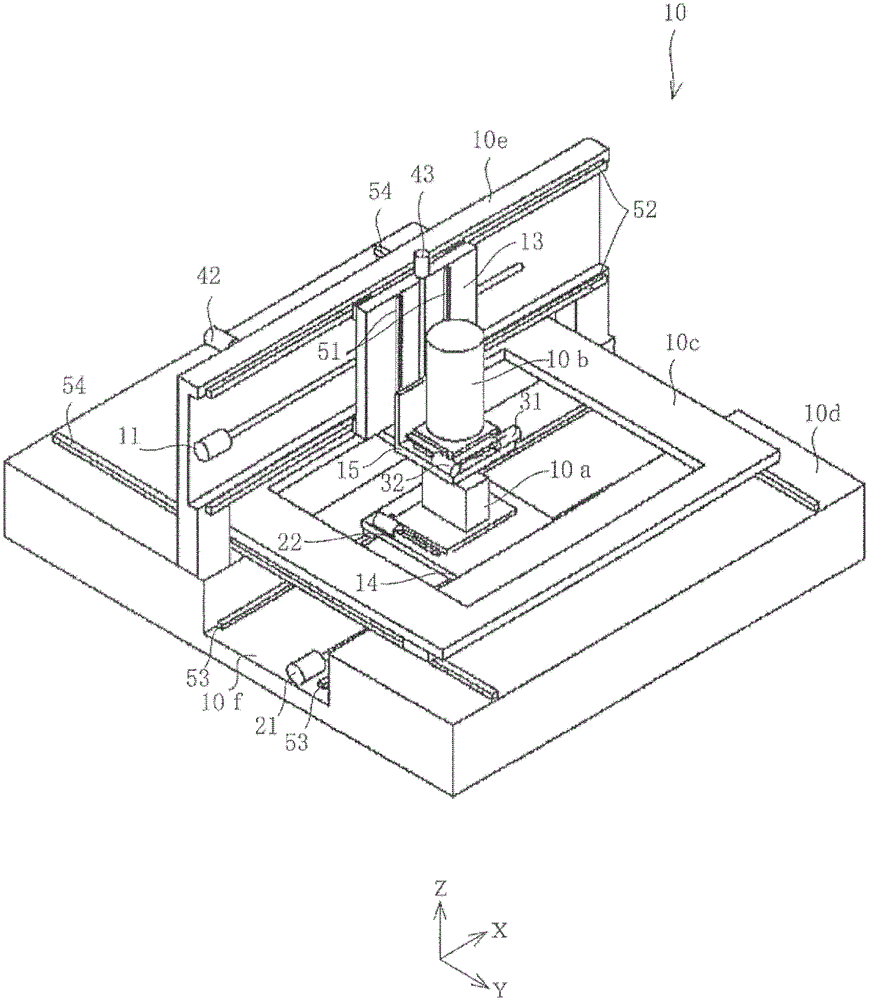

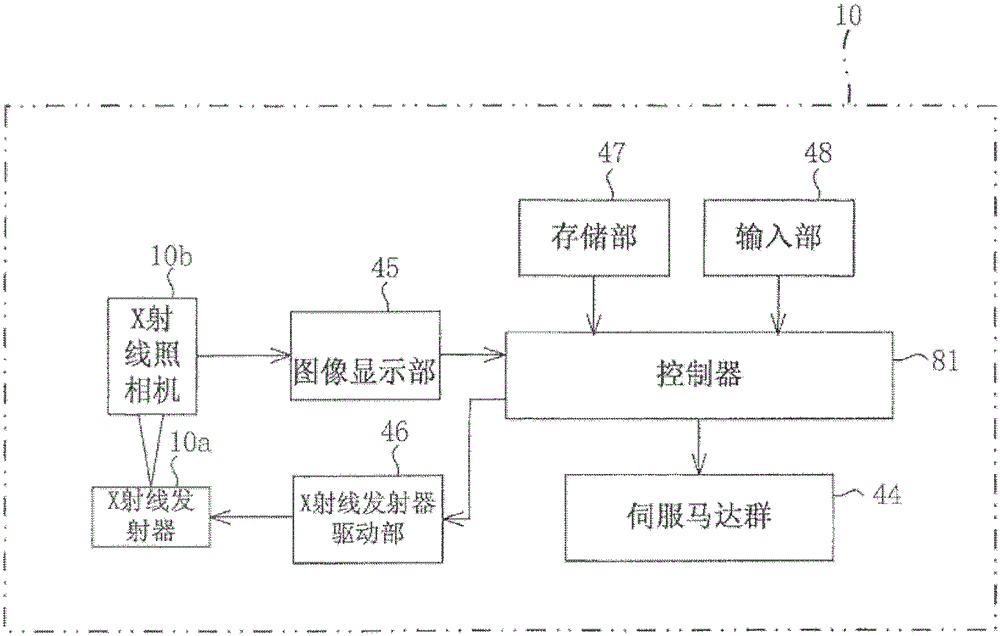

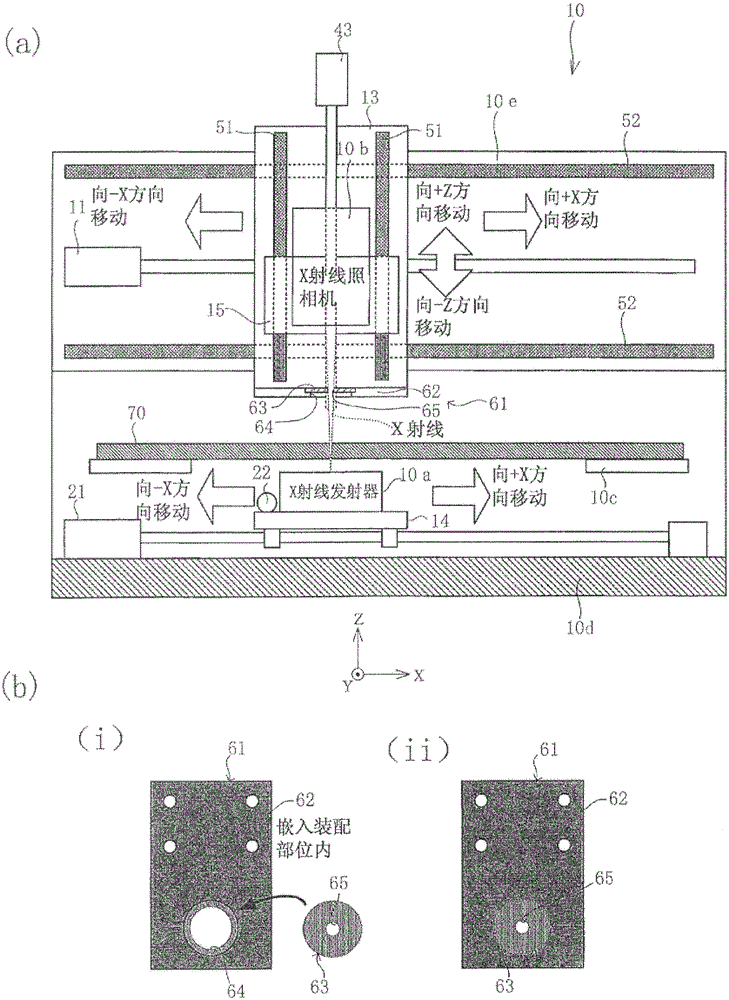

X-ray position measuring device, position measuring method of the device, and program for measuring the position of the device

ActiveCN102564360BAchieving Measurement AccuracyLow costMethod using image detector and image signal processingMaterial analysis using wave/particle radiationMeasurement deviceOptical axis

The invention provides an X-ray position measuring device capable of realizing high-precision position measurement without increasing the cost. The X-ray position measuring device 10 includes a first moving unit that moves the X-ray emitter 10a and the X-ray camera 10b to a position where the position measurement is performed on the measurement object; Measure the positional offset between the reference position and the position of the second X-ray projection image, and store the positional offset as a correction amount corresponding to the measurement position in the first measurement storage unit of the storage unit; The 2nd moving unit that X-ray emitter 10a and X-ray camera 10b move to the position that carries out position measurement; And the position that is used for carrying out position measurement, make the emission center of X-ray emitter 10a and X-ray according to the correction amount The optical axis of the camera 10b coincides with the first position measurement unit that simultaneously measures the position of the measurement object.

Owner:SEIKO TIME CREATION INC

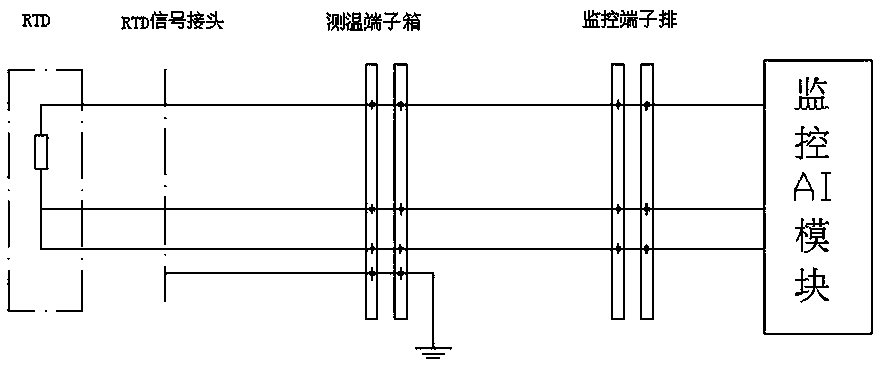

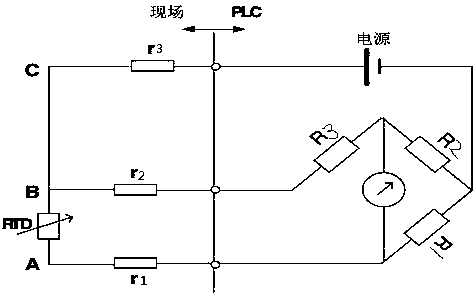

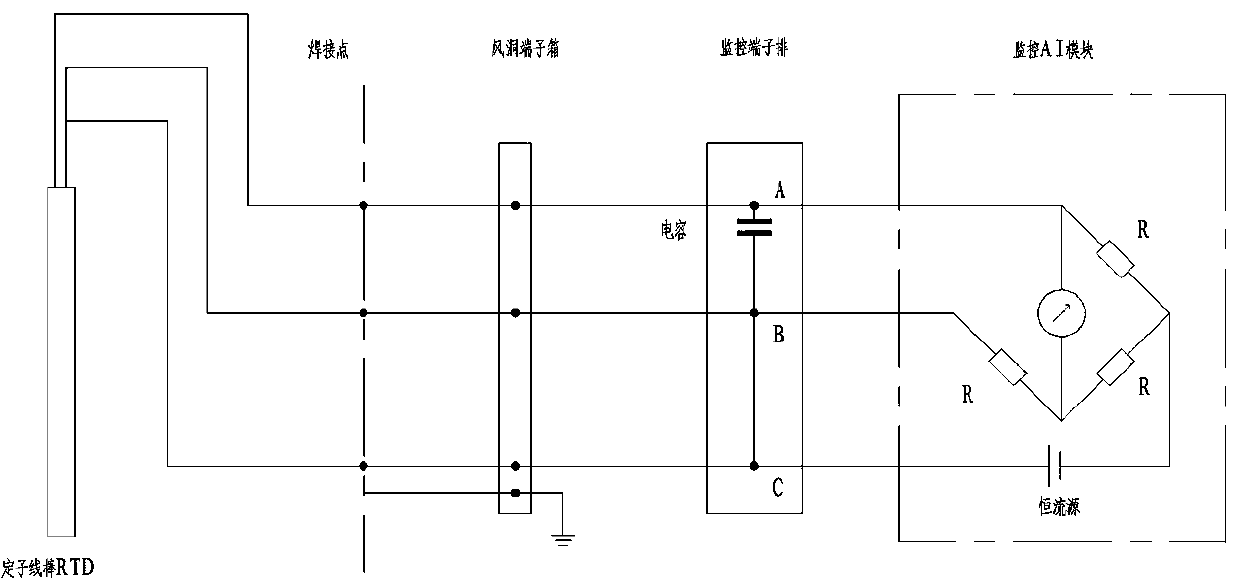

Anti-interference RTD measurement loop

InactiveCN111289135AImmune to electromagnetic interferenceReduce usageThermometers using electric/magnetic elementsUsing electrical meansCapacitanceInterference resistance

The invention relates to an anti-interference RTD measurement loop. The device comprises a stator bar RTD, an RTD transfer joint, a temperature measurement terminal box, a monitoring terminal strip and a monitoring AI module. The stator bar RTD adopts a three-wire system connection method, and a stator bar RTD is connected with a monitoring AI module through an RTD transit joint, the temperature measurement terminal box and the monitoring terminal strip. The RTD transit joint, the temperature measurement terminal box and an anti-interference single-ended ground are also arranged, wherein a point C and a point B of the monitoring terminal strip are short-circuited; the point A and the point B are connected through a filter capacitor; the point C is a power supply terminal of the monitoringterminal strip and is connected with a power supply of the monitoring AI module, the point B is a terminal to which the monitoring terminal strip and an R3 bridge arm of the monitoring AI module are connected, and the point A is a third terminal to which the monitoring terminal strip and the monitoring AI module are connected. According to the invention, the problem that the RTD signal of the stator bar in the low-rotating-speed section of the unit is interfered is effectively solved.

Owner:STATE GRID CORP OF CHINA +2

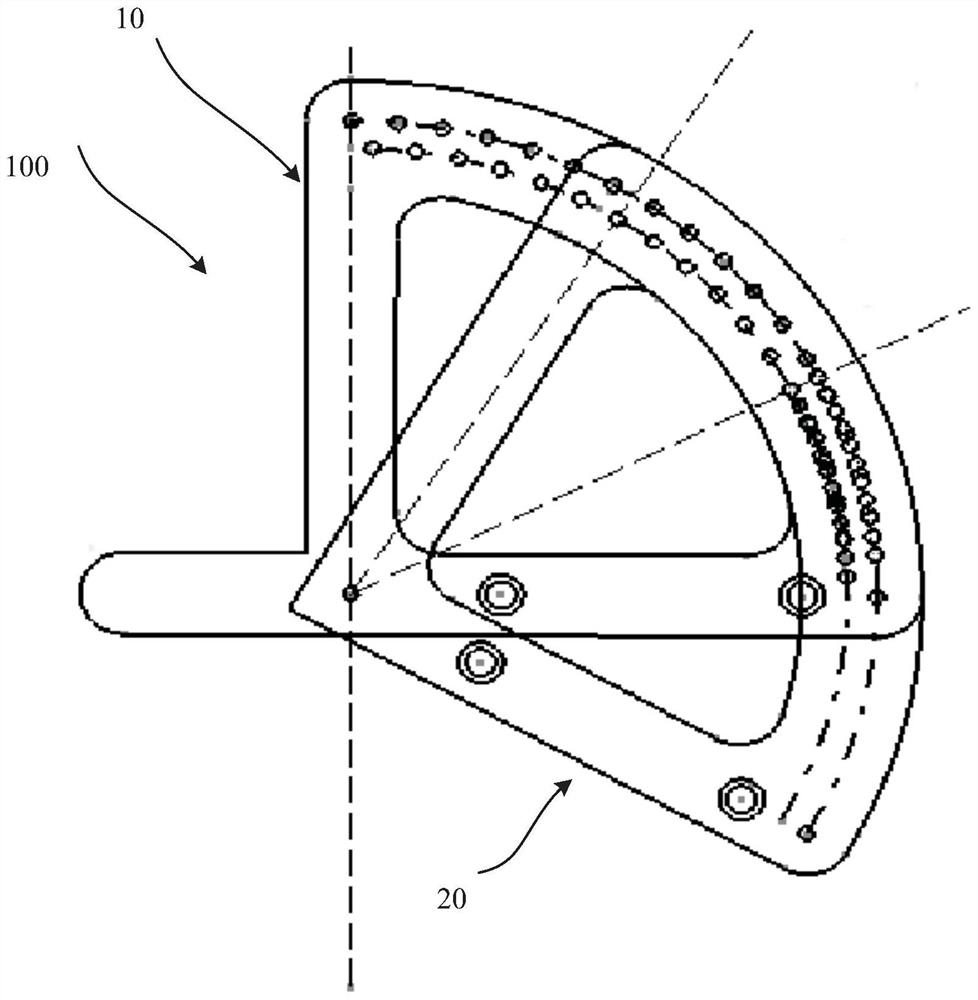

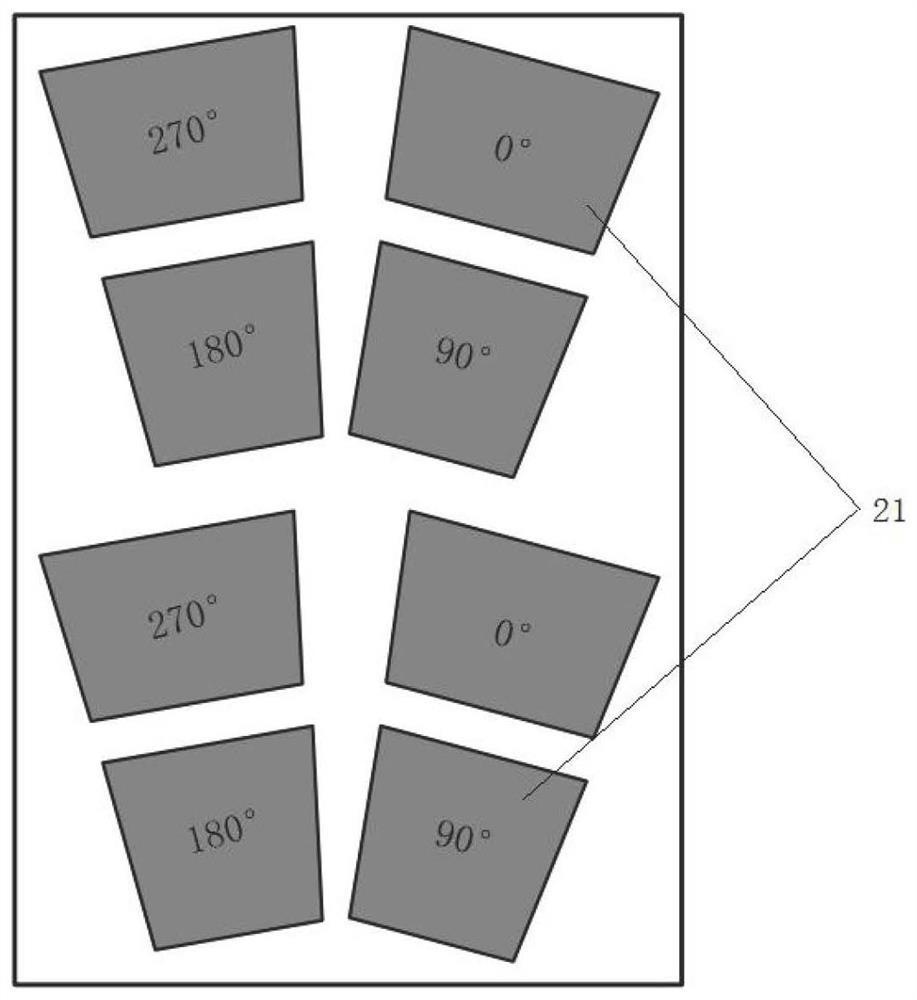

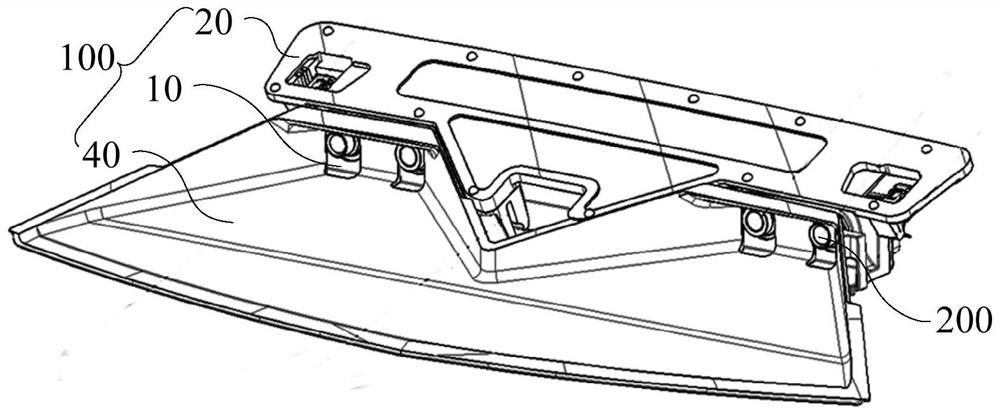

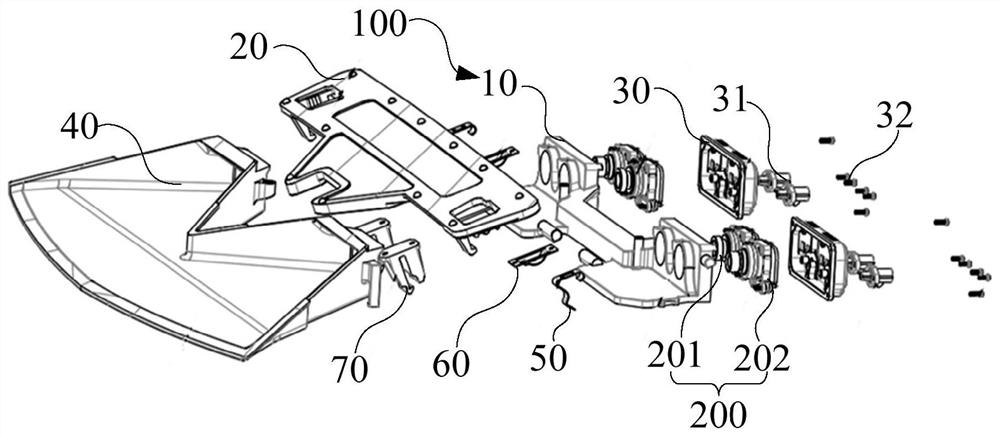

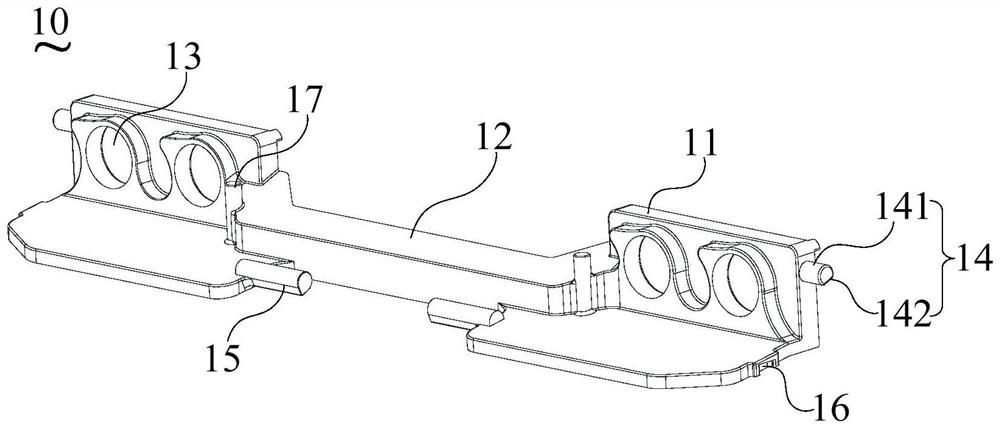

Vehicle-mounted multi-view structure and vehicle

PendingCN113272180AAchieving Measurement AccuracyTelevision system detailsColor television detailsIn vehicleEngineering

A vehicle-mounted multi-view structure and a vehicle, the vehicle-mounted multi-view structure comprises a mounting bracket (100) and a plurality of shooting assemblies (200), the mounting bracket (100) comprises a mounting part (10) and a connecting part (20), and the connecting part (20) is used for mounting the multi-view structure on the vehicle; the plurality of shooting assemblies (200) are arranged in the mounting part (10); the plurality of shooting assemblies (200) comprise at least two first shooting assemblies (201) and at least two second shooting assemblies (202), the at least two first shooting assemblies (201) have an overlapped first observation range, and the at least two first shooting assemblies (201) are used for measuring the distance between a scene object in the first observation range and the vehicle; the at least two second shooting assemblies (202) have an overlapped second observation range, and the at least two second shooting assemblies (202) are used for measuring the distance between the scene object in the second observation range and the vehicle; the observation range of the first shooting assembly (201) is different from that of the second shooting assembly (202). According to the vehicle-mounted multi-view structure and the vehicle, the relative distance between the scene object and the vehicle can be judged through the first shooting assembly and the second shooting assembly, and accurate measurement of the large-range distance is achieved.

Owner:SZ DJI TECH CO LTD

Method and system for calibrating step gauges that can eliminate Abbe errors based on laser interferometry

ActiveCN111238337BEliminate displacement valueAchieving Measurement AccuracyMechanical measuring arrangementsBeam splitterMirror reflection

Owner:NAT INST OF METROLOGY CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com