MEMS mass flow controller based on piezoelectric control valve and control method

A technology of mass flow and control valves, which is applied in the direction of flow control using electric devices, flow control, non-electric variable control, etc., and can solve the problems of zero drift and particle pollution, high price and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

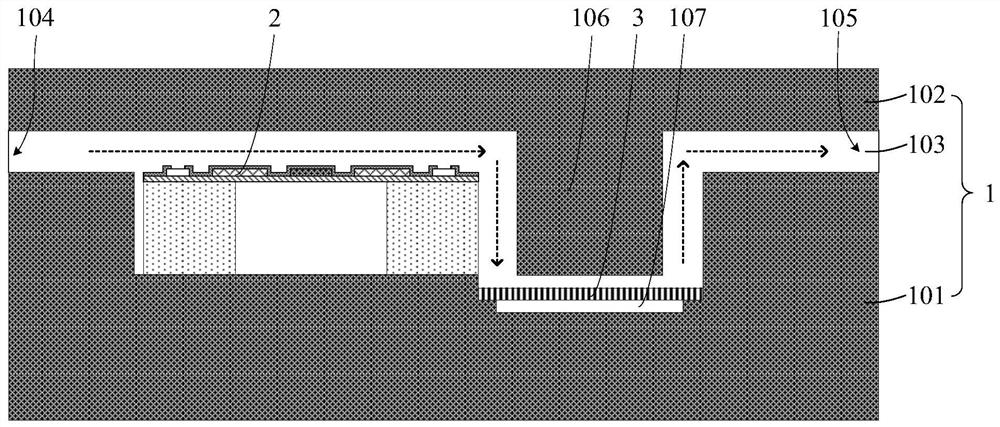

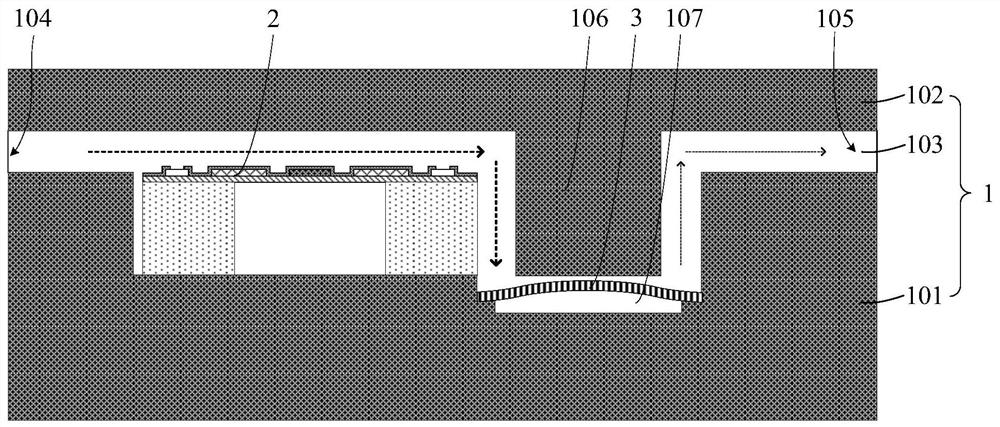

[0036] see figure 1 and figure 2 , a MEMS mass flow controller based on a piezoelectric control valve includes a housing 1, a mass flow sensor 2 and a piezoelectric diaphragm 3; channel 103; the mass flow sensor 2 is arranged on the relative left side of the lower substrate 101, that is, on the side near the inlet 104 of the airflow passage 103; side, the position of the piezoelectric diaphragm 3 is lower than the position of the mass flow sensor 2, and a downward protrusion 106 is provided on the inner side of the upper cover plate 102 corresponding to the position of the piezoelectric diaphragm 3, and the protrusion 106 is used to define the air flow channel The orientation of 103 makes the airflow channel 103 into a zigzag shape, so the airflow can be buffered to a certain extent. Both ends of the piezoelectric membrane 3 are disposed on the lower substrate 101 , and a vibration gap 107 is provided between the middle of the piezoelectric membrane 3 and the lower substrat...

Embodiment 2

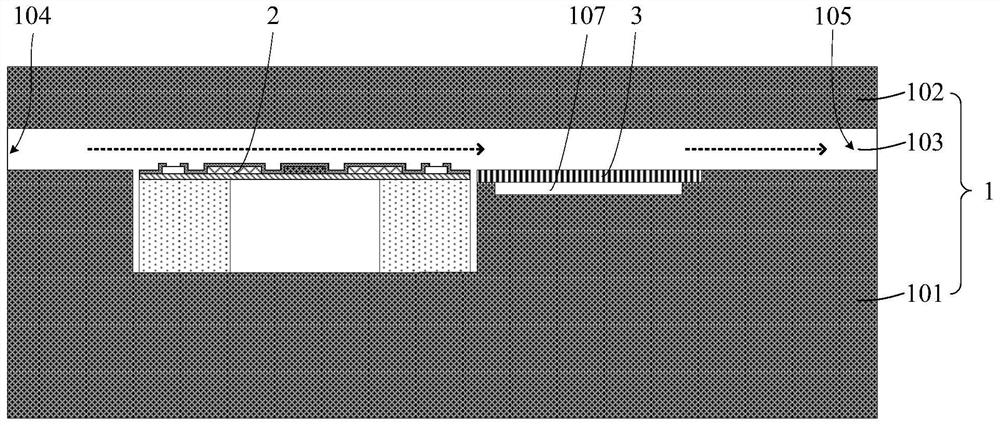

[0038] see image 3 and Figure 4 , a MEMS mass flow controller based on a piezoelectric control valve includes a housing 1, a mass flow sensor 2 and a piezoelectric diaphragm 3; channel 103; the mass flow sensor 2 is arranged on the relative left side of the lower substrate 101, that is, on the side near the inlet 104 of the airflow passage 103; On the side, both ends of the piezoelectric membrane 3 are arranged on the lower substrate 101 , and a vibration gap 107 is provided between the middle of the piezoelectric membrane 3 and the lower substrate 101 . The upper surfaces of the mass flow sensor 2 and the piezoelectric membrane 3 are located at the same level, and the airflow channel 103 is in the shape of a horizontal line.

[0039] Specifically, the casing 1 is made of airtight hard material, the lower base plate 101 and the upper base plate 102 are connected and fixed by methods such as welding, crimping, fastening, buckling, etc., and the cross-sectional shape of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com