Method and device for optically measuring product surfaces

An optical and product technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of scanning speed limitation, not allowing access to surface height information, maximum scanning width limitation, etc., to increase measurement accuracy and reduce shadows and lighting effects, the effect of increasing the scan width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 15

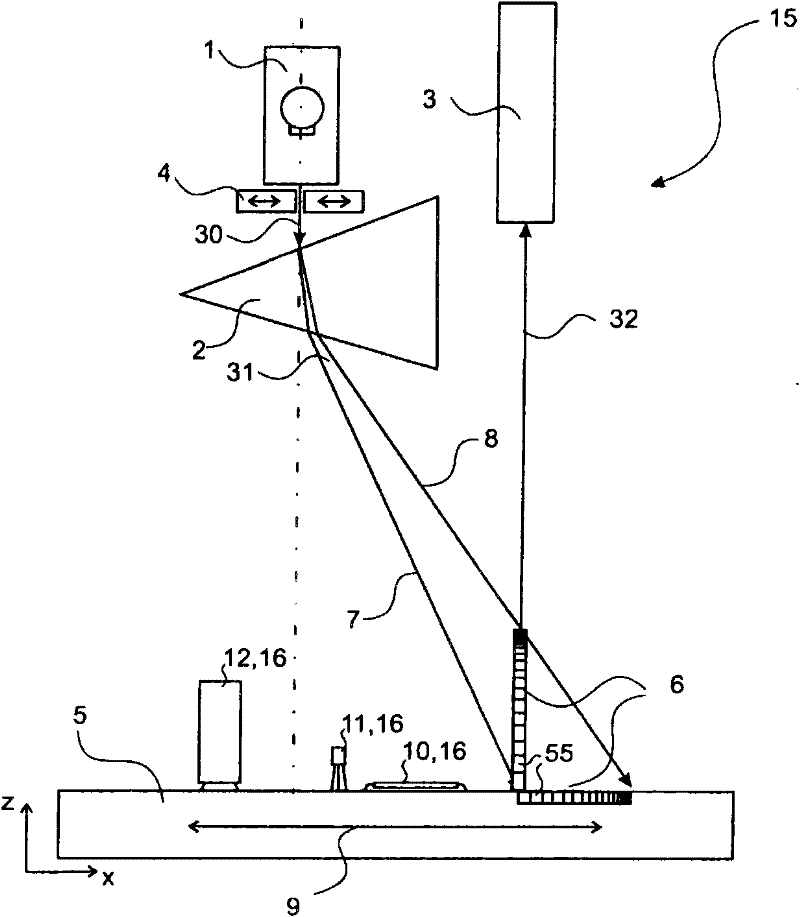

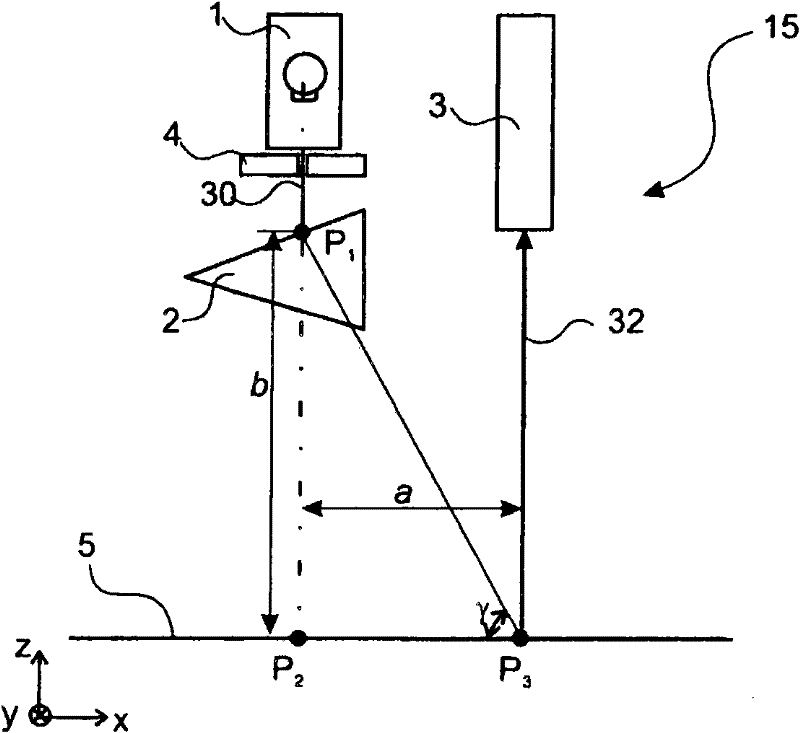

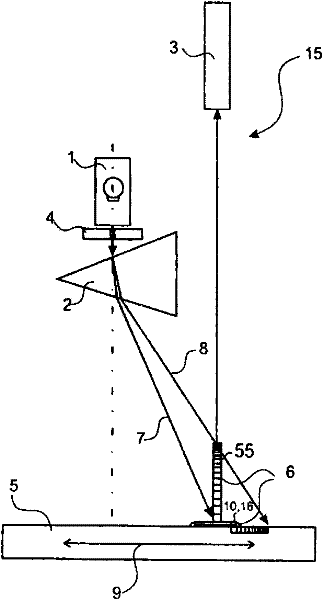

[0072] A first embodiment 15 for measuring a product under test in order to optically create a 3D model is shown in FIG. 1 and comprises a white light source 1 with white light of a continuous spectrum, for rectifying the white light and Optical unit 4 for collimation into collimated white light beam 30 , optical prism 2 for splitting collimated white light beam 30 into polychromatic beam 31 and RGB line scan camera 3 . The light from the source 1 is collimated by the optical unit 4 into parallel narrow beams 30 which then pass through the optical prism 2 which acts as a spectrometer unit and intermediaries to facilitate the splitting of the light into spectra 13( Figure 5 ). The collimated light 30 entering the prism 2 contains all color elements. After passing through the optical prism 2, the white light 30 is resolved into individual colors 31 according to the laws of refraction of light. These individual components are monochromatic and are reflected via monochromatic l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com