Interferometer error calibrating device and method

An error calibration and interferometer technology, which is applied in the field of interferometer error calibration devices, can solve the problems that the factors affected by the interferometer cannot be measured in real time, there are differences in the influence of the environment, the installation error of the interferometer, etc., so as to reduce the impact, Increase the assembly error test and improve the effect of assembly and adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

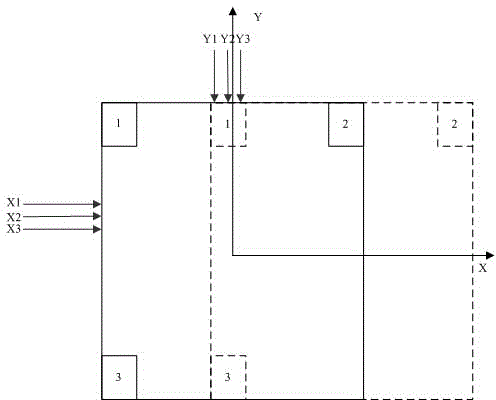

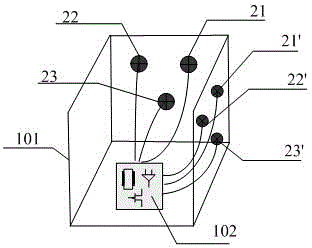

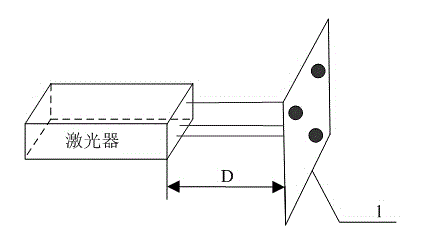

[0020] Such as figure 2 As shown, the calibration device consists of a detection frame 1, three X-direction photoelectric sensors 21,22,23, and three Y-direction photoelectric sensors 21', 22', 23'. Among them, the detection frame 1 is a square empty box, and its inner two adjacent surfaces are composed of 6 circular holes, respectively, each group of 3 circular holes is characterized in that the relative positional relationship of the 3 circular holes and the X-direction The layout of the measuring optical axis of the interferometer is consistent, and the relative position relationship between the three circular holes is consistent with the layout of the measuring optical axis of the Y-direction interferometer; the three X-direction photoelectric sensors 21, 22, 23 are installed on three In the three circular holes, three X-direction photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com