Single-pulse laser dynamic focal spot position measuring device and method

A measuring device and single-pulse technology, applied in the field of optics, can solve problems such as small measurement range and low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

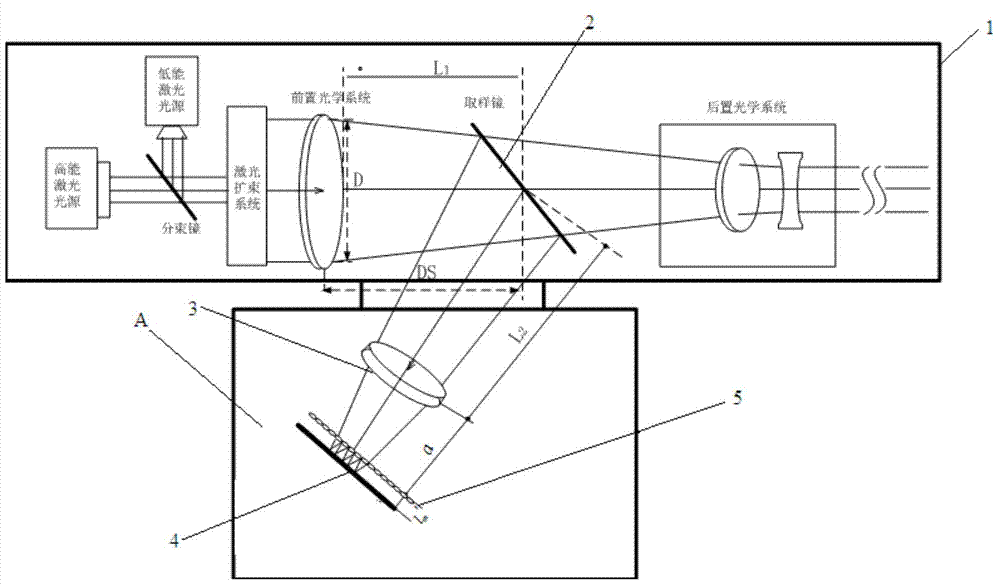

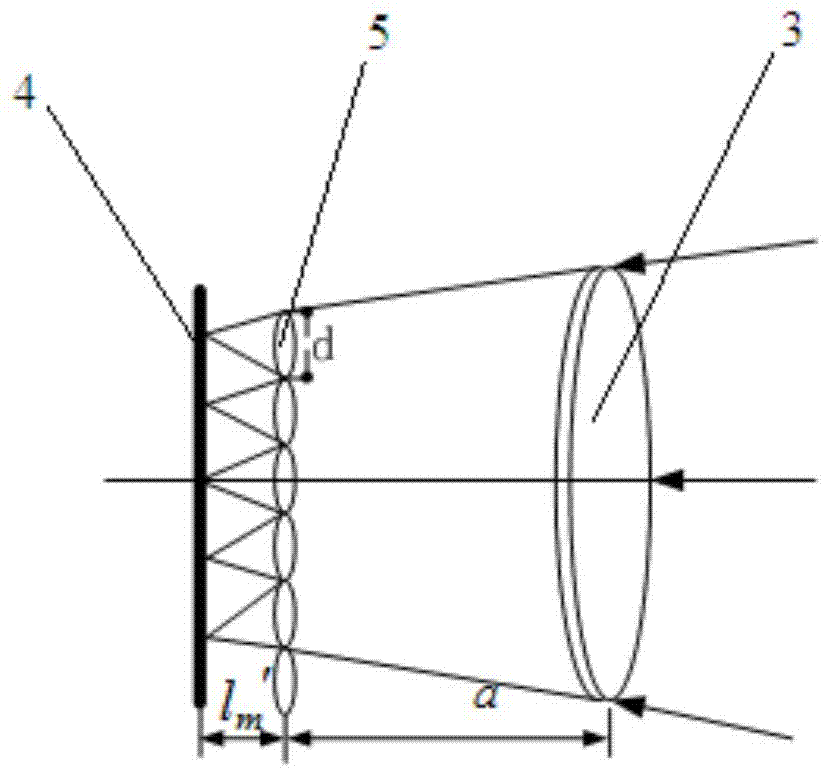

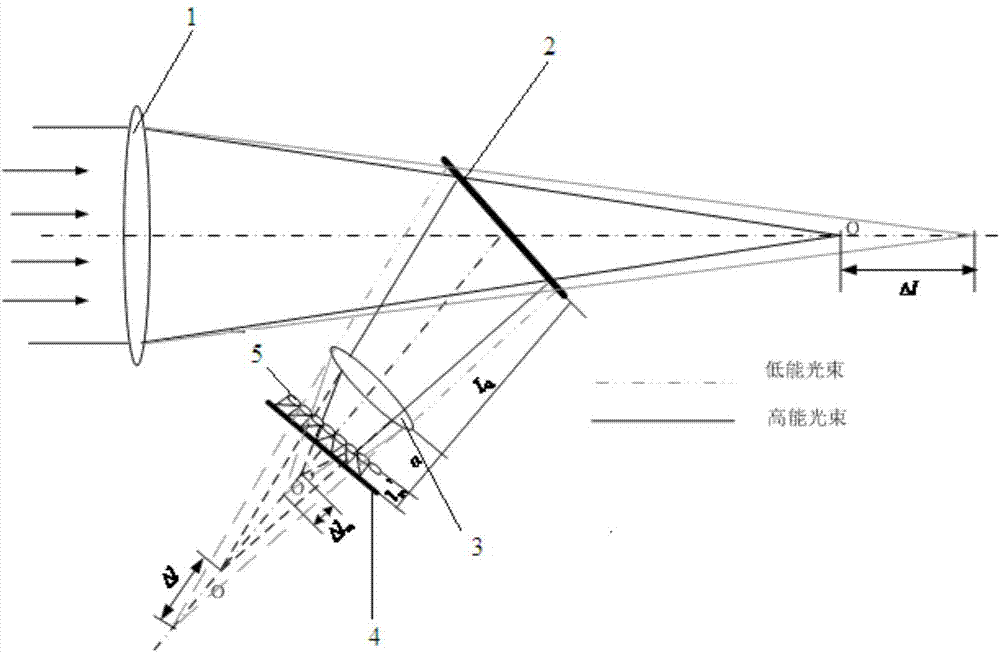

[0059] Such as figure 1 , figure 2 As shown, the laser dynamic focal spot position measurement device includes five parts: an optical system to be tested 1, a sampling mirror 2, a standard converging lens 3, a microlens array 5, a CCD detector 4 and a mechanical casing. The sampling mirror samples the beam to be measured, the converging lens converges the sampled beam, and the converged beam is sent to the microlens array, and the beam is imaged on the CCD detector after being converged by the microlens array. The mechanical casing covers and packages all the devices together, and the mechanical parts ensure the structural parameters of the system while preventing external stray light from affecting the measurement. In the low-energy state, the focus position of the system under test is o. The standard converging lens takes the focus of the system under test as the object for primary imaging, and the microlens array takes the image point of the converging lens as the object ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com