Infrared lens precision centering device and centering method on basis of low-stress clamping

A centering device and low-stress technology, which can be used in installation, optics, instruments, etc., can solve the problem of easy chipping of the lens, achieve the effect of overcoming the adjustment error and improving the adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

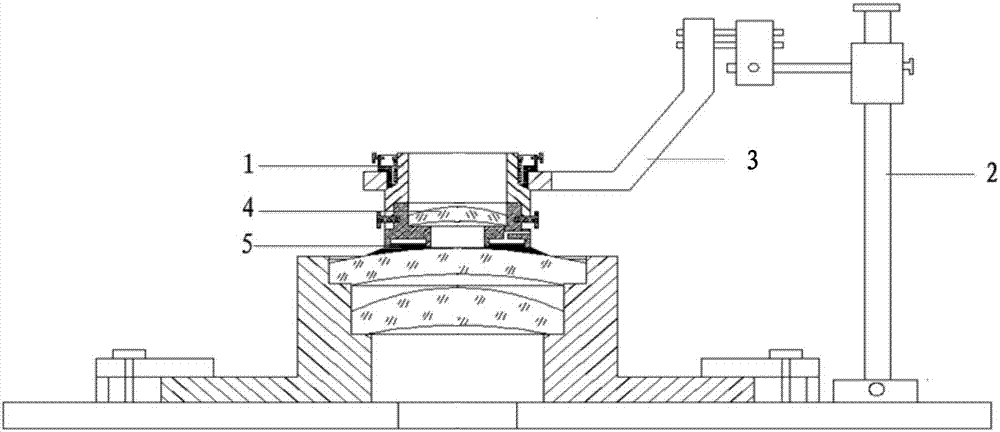

[0028] A precision centering device for infrared lenses based on low-stress clamping includes: a two-dimensional rotation mechanism 1, a three-dimensional translation mechanism 2, a cantilever mechanism 3, and also includes: a positioning conversion lens 4 and a micro-stress clamping positioning device 5.

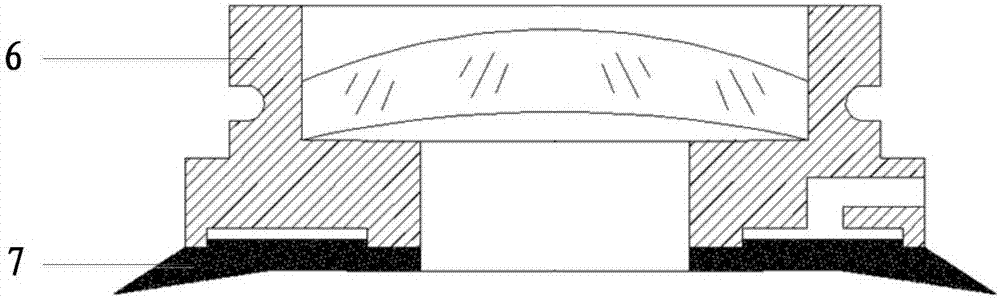

[0029] The micro-stress clamping and positioning device 5 includes a suction cup 7 and a bracket 6, wherein the bracket 6 is a hollow cylindrical structure, and the center hole of the bracket 6 has an annular mounting platform. The suction cup 7 is circular and coaxially bonded to the bottom end of the bracket 6 . Wherein the positioning conversion lens 4 is bonded on the annular mounting platform in the central circular hole of the support 6 .

[0030] The two-dimensional rotating mechanism 1 is a rotating mechanism capable of translation in two directions perpendicular to each other. The three-dimensional adjustment mechanism is an adjustment mechanism capable of moving ...

Embodiment 2

[0034] The specific steps of an infrared lens precision centering method based on low stress clamping are:

[0035] Step 1 Calibration of the lens to be installed

[0036] Pre-install the lens to be installed in the lens barrel, observe the spherical center image of the upper and lower surfaces of the lens to be installed on the turntable of the double optical path centering instrument, and adjust the translation and tilt of the centering instrument turntable so that the optical axis of the lens to be installed is coaxial with the rotary axis of the centering instrument turntable .

[0037] The second step is to position the conversion lens 4 and calibrate

[0038] Put the entire precision centering device into the upper optical path of the double optical path centering instrument, use the upper optical path of the centering instrument to observe the upper and lower spherical center images of the positioning conversion lens 4, and adjust the optical axis of the positioning co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com