Patents

Literature

38results about How to "Precise adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

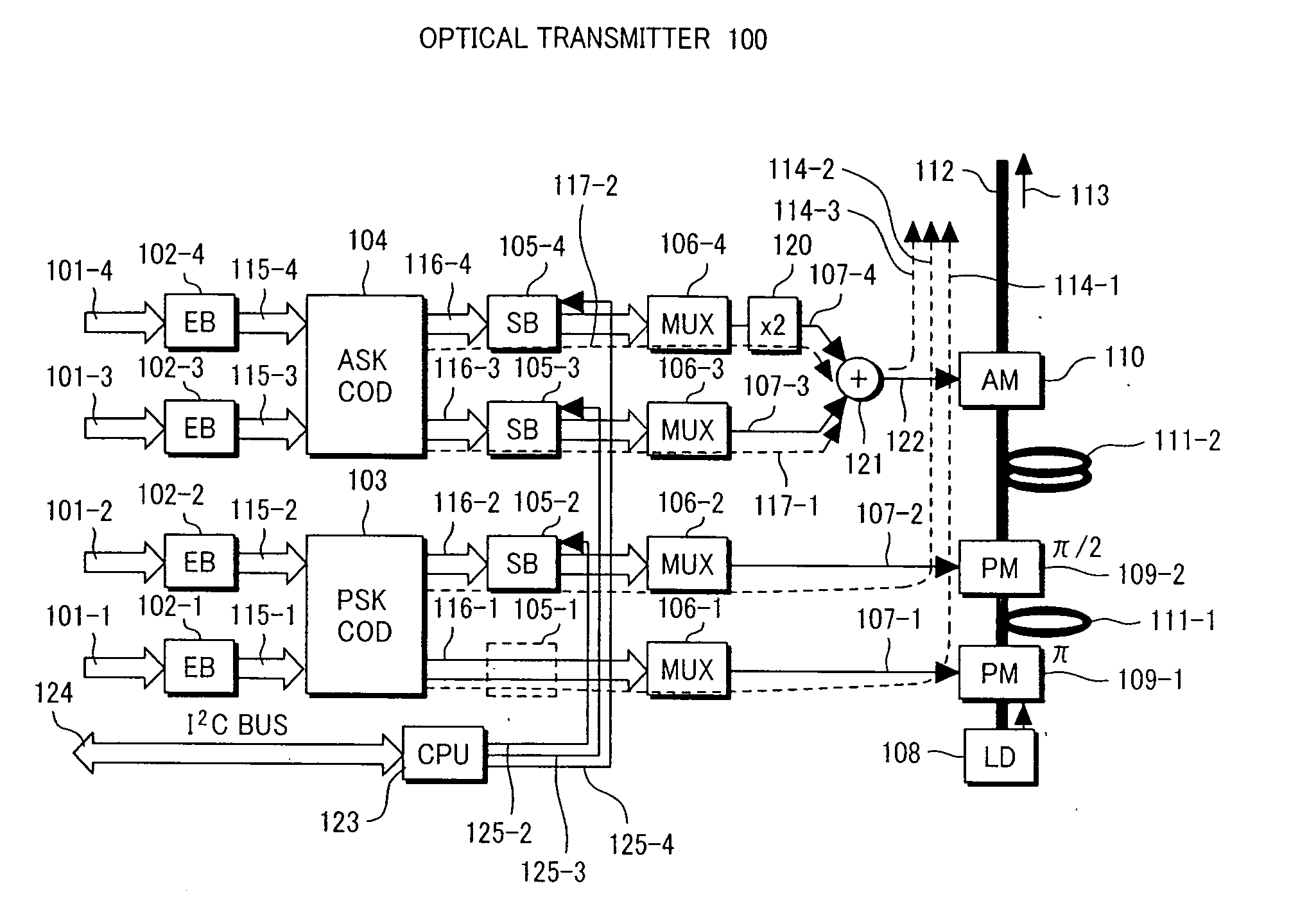

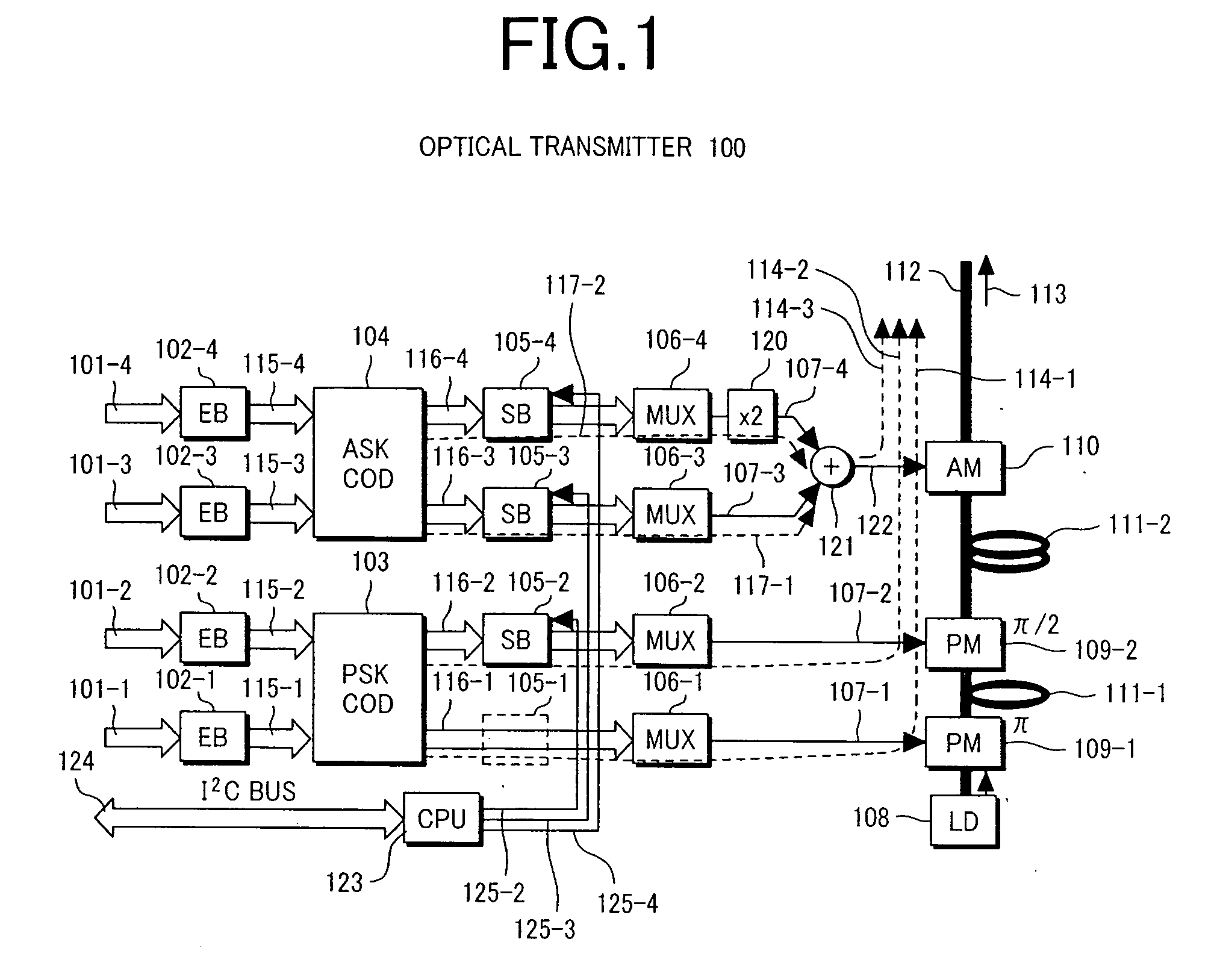

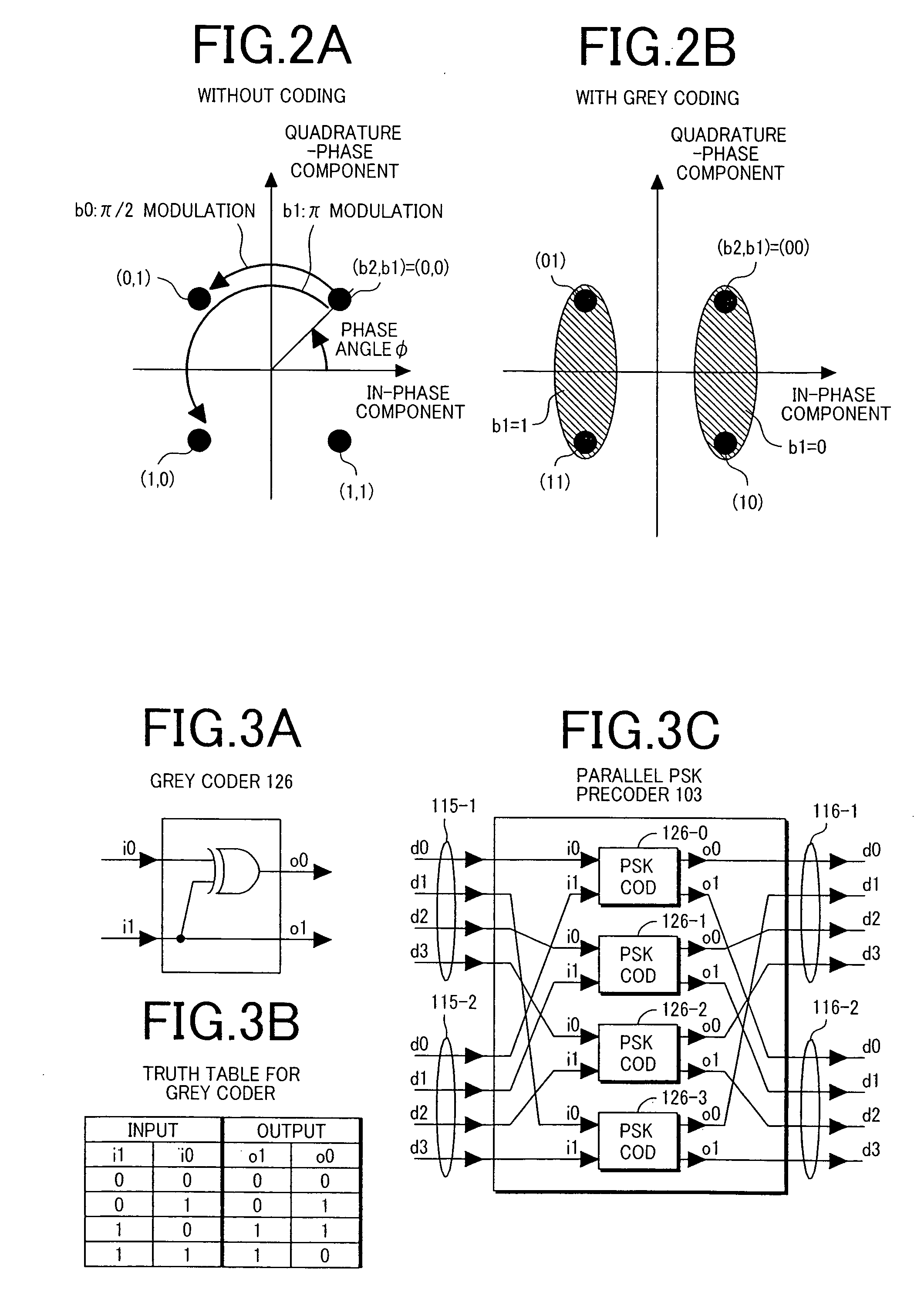

Optical transmission equipment and integrated circuit

InactiveUS20060269294A1Precise adjustmentEasily reproduceTime-division optical multiplex systemsWavelength-division multiplex systemsIntegrated circuitLow speed

Optical transmission equipment, capable of electrically adjusting the delay difference between a plurality of digital signal paths to be connected to a multilevel optical modulation unit or demodulation unit, having multiplexing circuits connected to the digital signal paths and a delay adjustment unit inserted in one of the digital signal paths to adjust delay of N-bit-parallel low-speed digital signals with the timing unit of a bit period of a high-speed serial digital signal to be outputted from multiplexing circuit.

Owner:HITACHI LTD

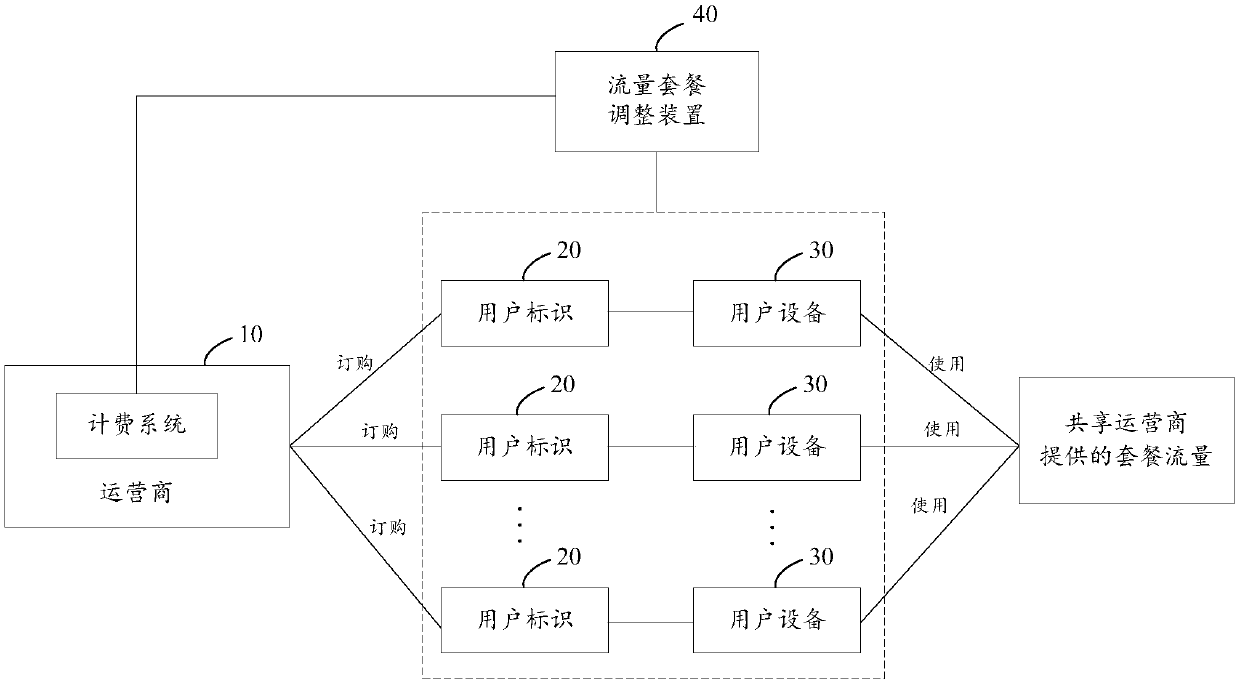

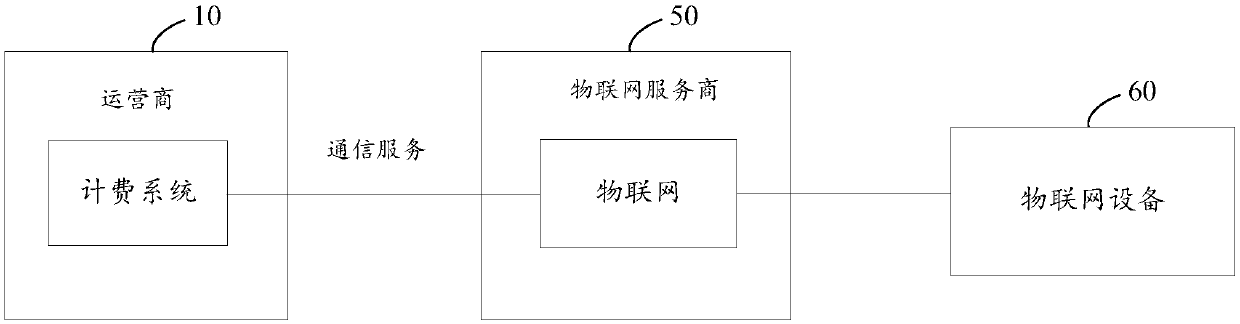

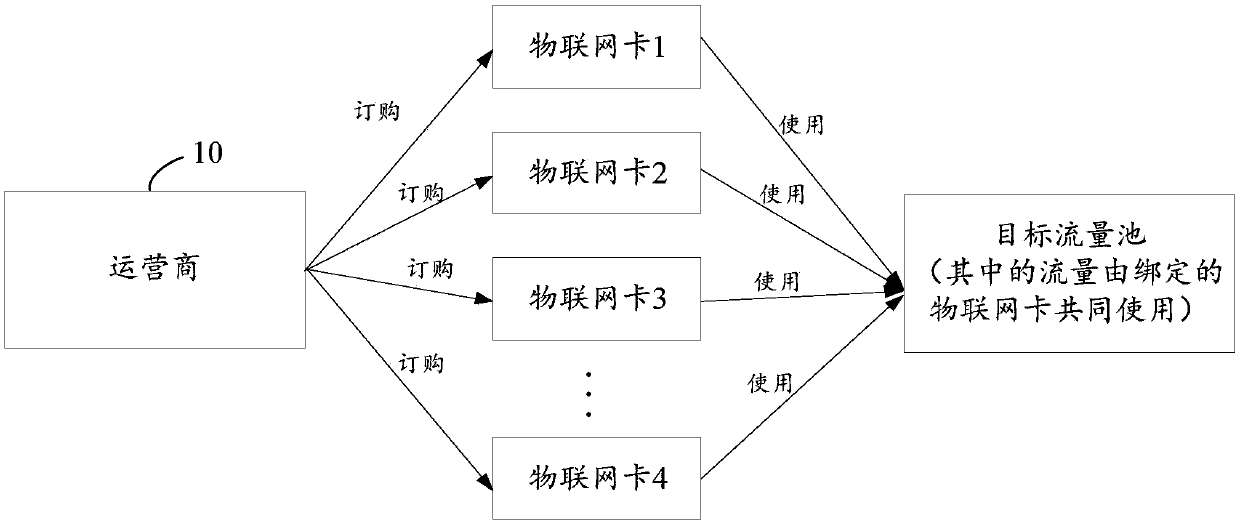

Method and device for adjusting flow packages for multiple user identifiers

ActiveCN110418022AMeet diverse needsImprove experienceMetering/charging/biilling arrangementsAccounting/billing servicesTraffic capacityUser identifier

The invention discloses a method and device for adjusting flow packages for multiple user identifiers, and belongs to the technical field of communication. The plurality of user identifiers share theflow quantity in a package provided by an operator, and the method comprises the following steps: obtaining a flow package and a flow consumption record of each user identifier in the plurality of user identifiers before the current time point of a charging period; predicting the sum of the consumption flows of the plurality of user identifiers in the charging period according to the flow consumption record to obtain a predicted total consumption flow; and according to the predicted total consumption flow and the flow plan of each user identifier, sending flow plan adjustment indication information containing at least one user identifier in the plurality of user identifiers and a corresponding new flow plan to a charging system of the operator so as to indicate adjustment of the flow planfor the at least one user identifier. In this way, the flow package of the current charging period can be automatically adjusted, and the adjustment mode is more timely and accurate.

Owner:HUAWEI TECH CO LTD

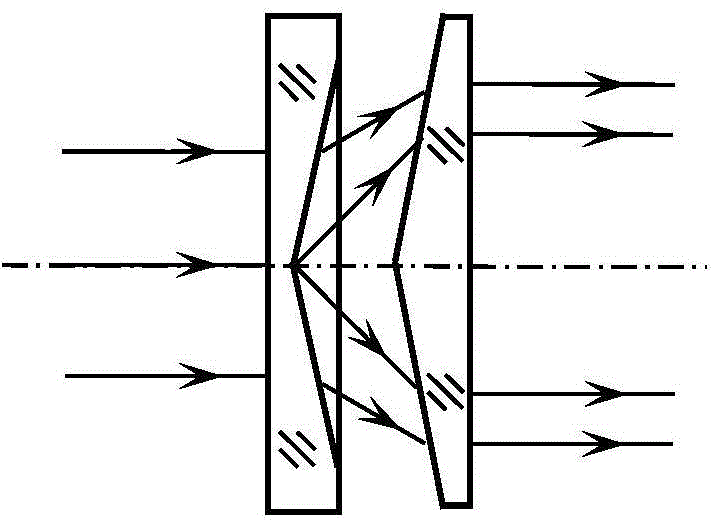

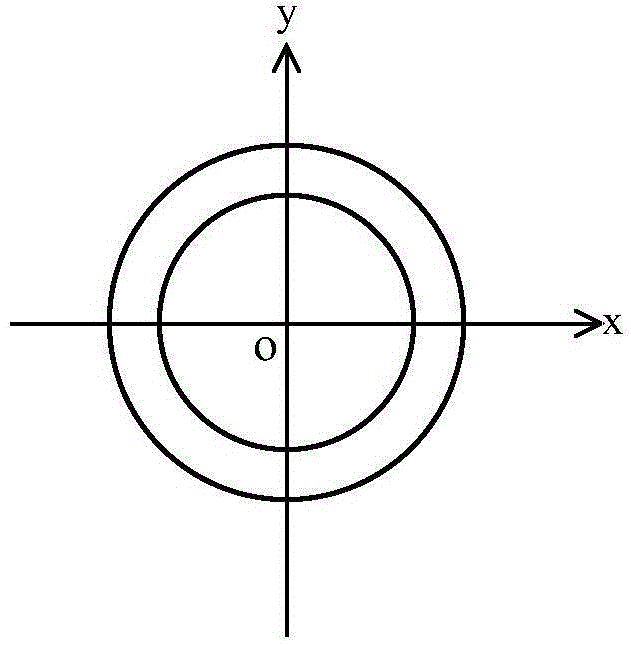

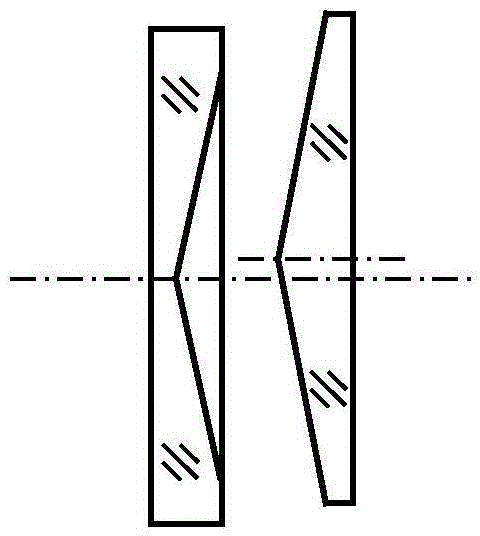

Method for realizing coaxiality of inner and outer cone mirrors for producing hollow beams

InactiveCN104950455APrecise adjustmentAdjustment is effectiveOptical elementsSuperimpositionLight beam

The invention discloses a method for realizing coaxiality of inner and outer cone mirrors for producing hollow beams, belongs to the field of optical technology and aims to solve the problem that an inner and outer cone mirror optical system alignment technology is absent in the prior art. The method comprises the following steps: firstly, a character superimposition module program assigns pixel array centers of CCD (charge coupled device) image sensors to be centers of optical images, and the pixel array centers serving as alignment datum bull's-eyes are displayed; secondly, alignment light is collimated and divided into two beams with mutually perpendicular light paths, then the light is focused and imaged on the CCD image sensors on respective light paths through positive lenses on the respective light paths, obtained alignment light image electric signals are transmitted to a display to be displayed as alignment light images, and the positions of the two positive lenses are adjusted respectively in the horizontal direction and the vertical direction, so that the alignment light images move to the alignment datum bull's-eyes; thirdly, the to-be-aligned inner and outer cone mirror optical system is mounted on an alignment light path, and the positions of the inner cone mirror and the outer cone mirror are adjusted respectively in the horizontal direction and the vertical direction until the alignment light images move to the alignment datum bull's-eyes.

Owner:CHANGCHUN UNIV OF SCI & TECH

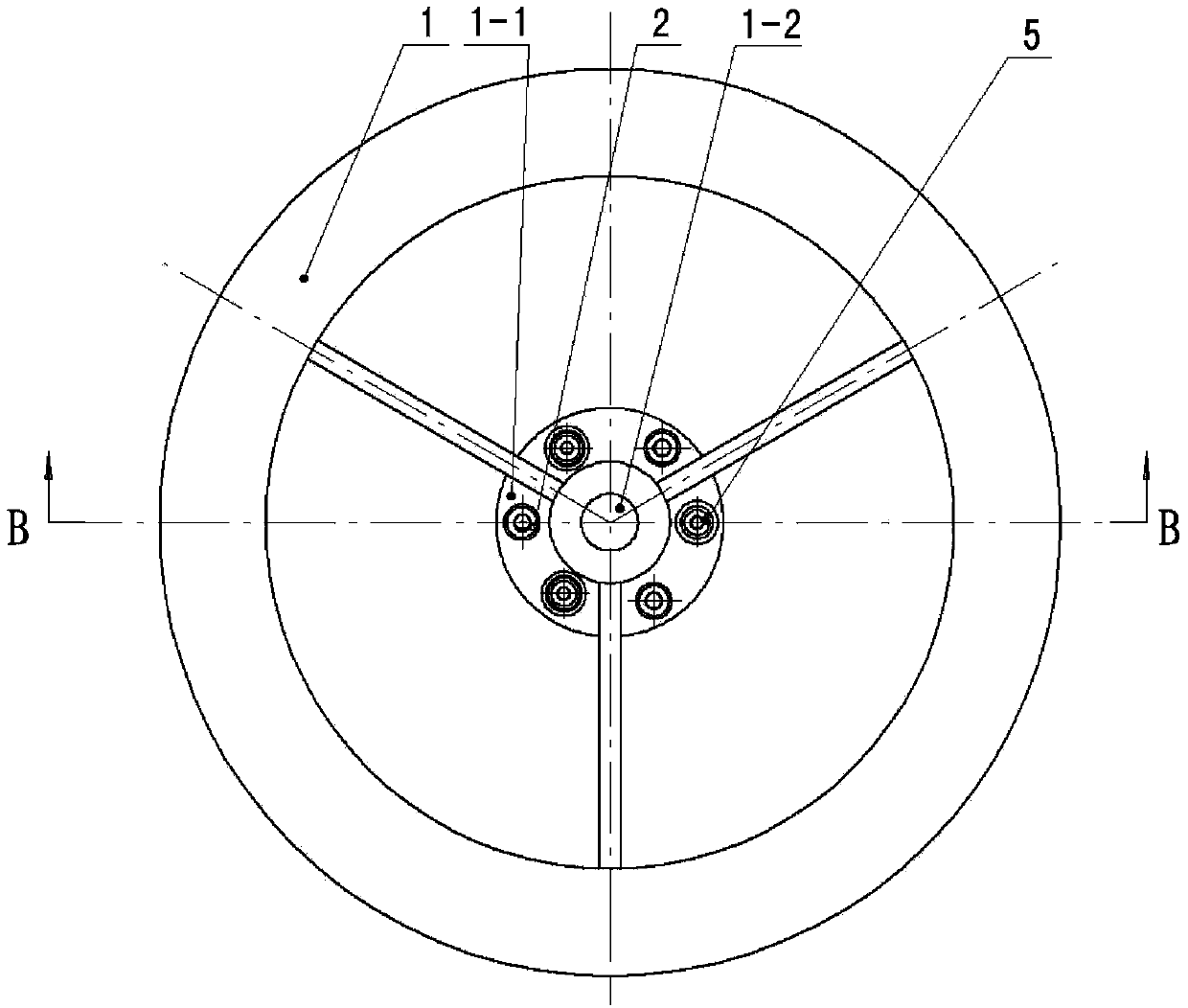

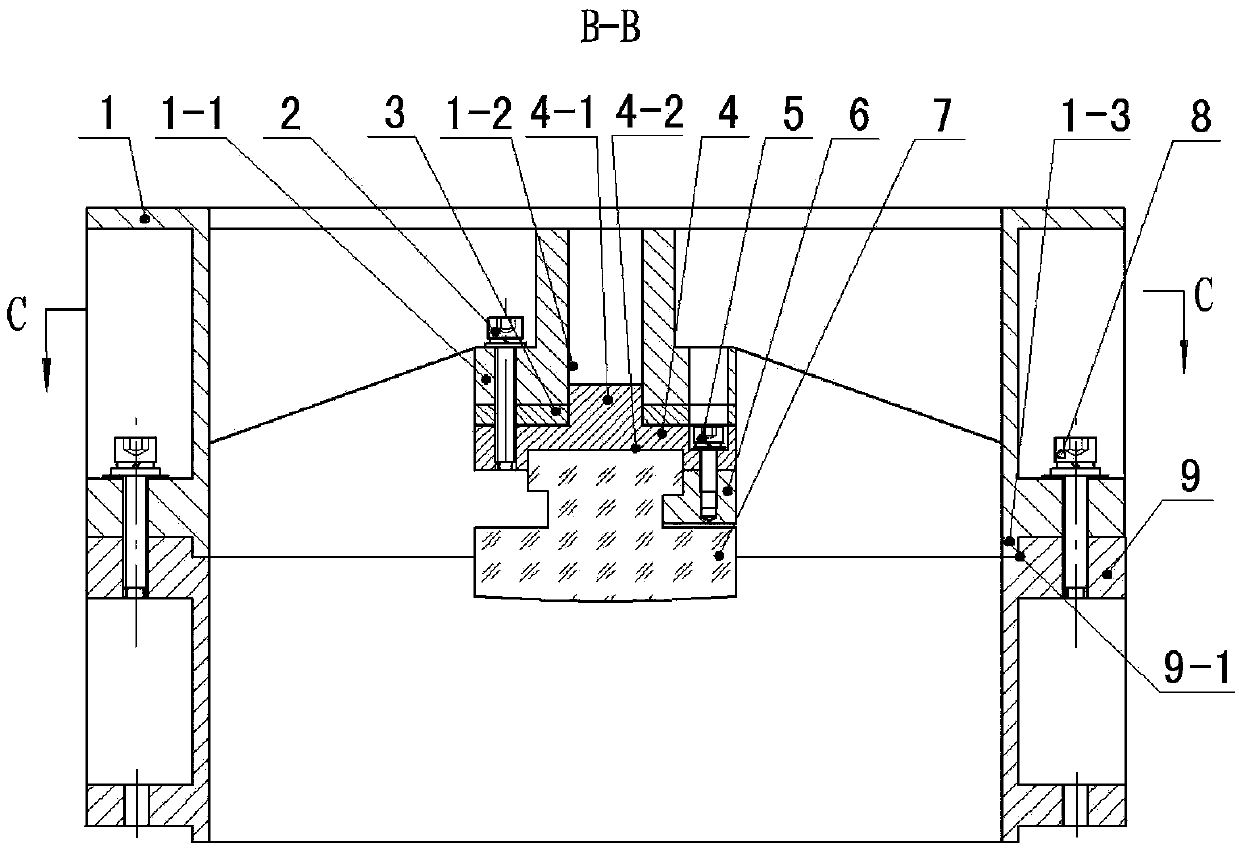

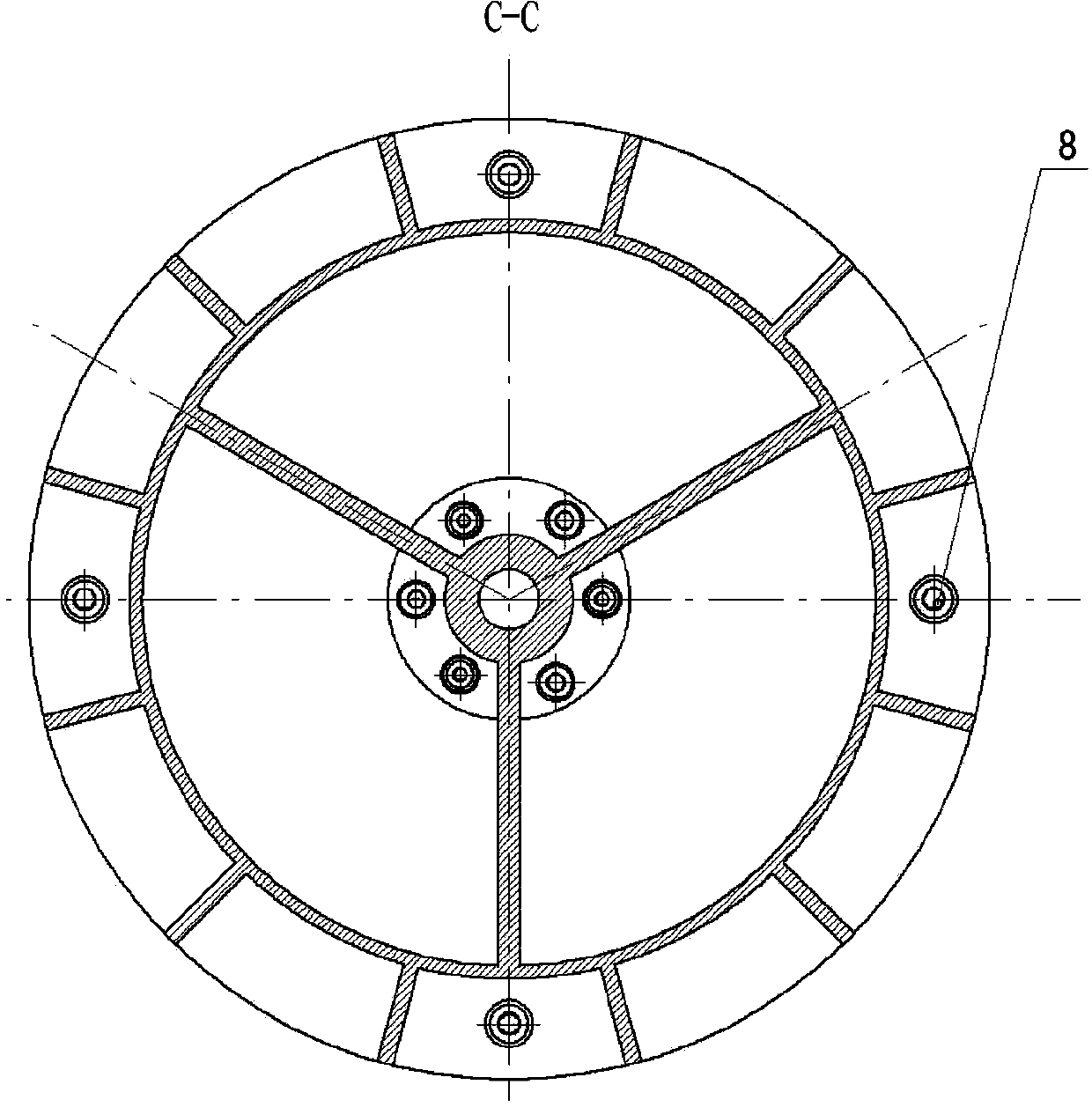

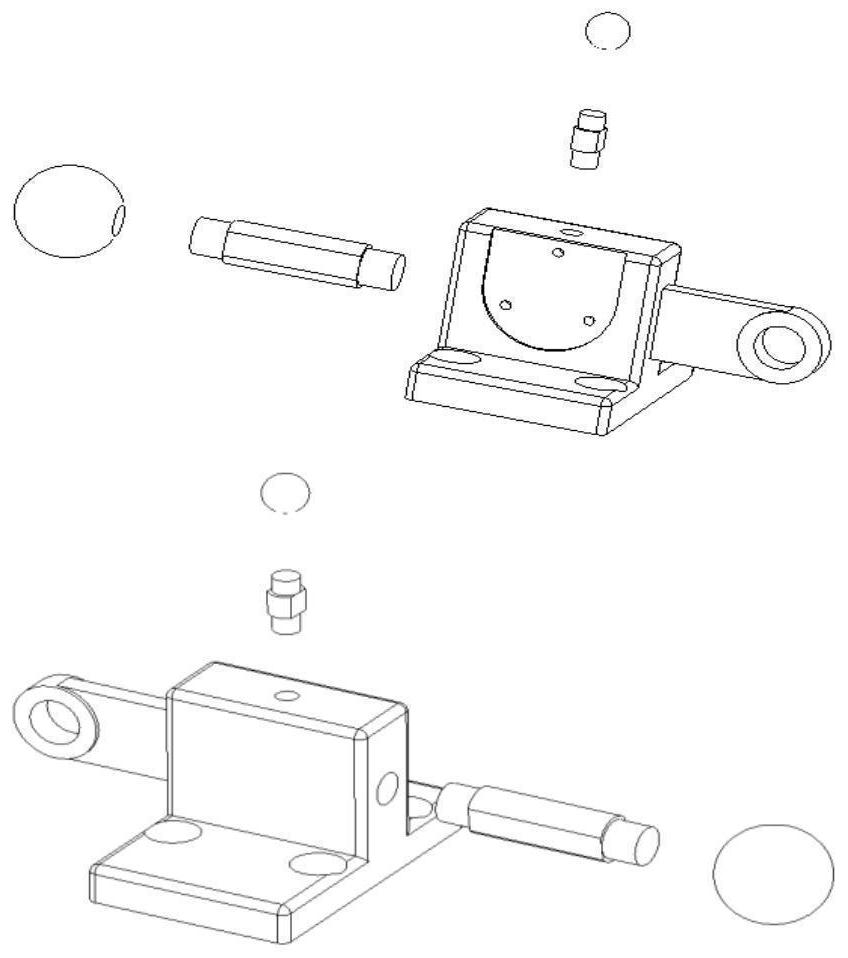

Secondary mirror supporting mechanism capable of quick adjusting

ActiveCN103389555ASimplify the assembly processImprove the efficiency of assembly and adjustmentMountingsTheodolitesFlangeSecondary mirror

A secondary mirror supporting mechanism capable of quick adjusting belongs to the field of secondary mirror supporting mechanisms of electro-optic theodolites, and comprises a secondary mirror barrel, a plurality of first bolts, a secondary mirror seat, a plurality of second bolts, a plurality of secondary mirror pressing blocks, a plurality of third bolts, a plurality of sliding wedge blocks, a plurality of adjusting bolt seats, a plurality of fourth bolts, a plurality of adjusting bolts, a plurality of fixed wedge blocks, and a connecting cylinder, wherein the secondary mirror seat comprises a secondary mirror seat body, a secondary mirror seat boss, and a secondary mirror seat counter bore; the secondary mirror barrel comprises a secondary mirror barrel body, a secondary mirror barrel three-flanged flange, a three-flanged flange center hole, a secondary mirror barrel ring-shaped boss, and a secondary mirror barrel flange; each sliding wedge block comprises a sliding wedge block body, a sliding wedge block round hole, and a sliding wedge block slotted hole; each fixed wedge block comprises a fixed wedge block body and a fixed wedge block round hole; the connecting cylinder comprises a connecting cylinder body, a connecting cylinder flange, and a clamping groove. According to the invention, the optical precision adjusting process can be finished without detaching the secondary mirror repeatedly or repairing a secondary mirror adjusting cushion; the adjusting process of the secondary mirror is simple and accurate, and the adjusting efficiency can be adjusted greatly.

Owner:长春长光辰英生物科学仪器有限公司

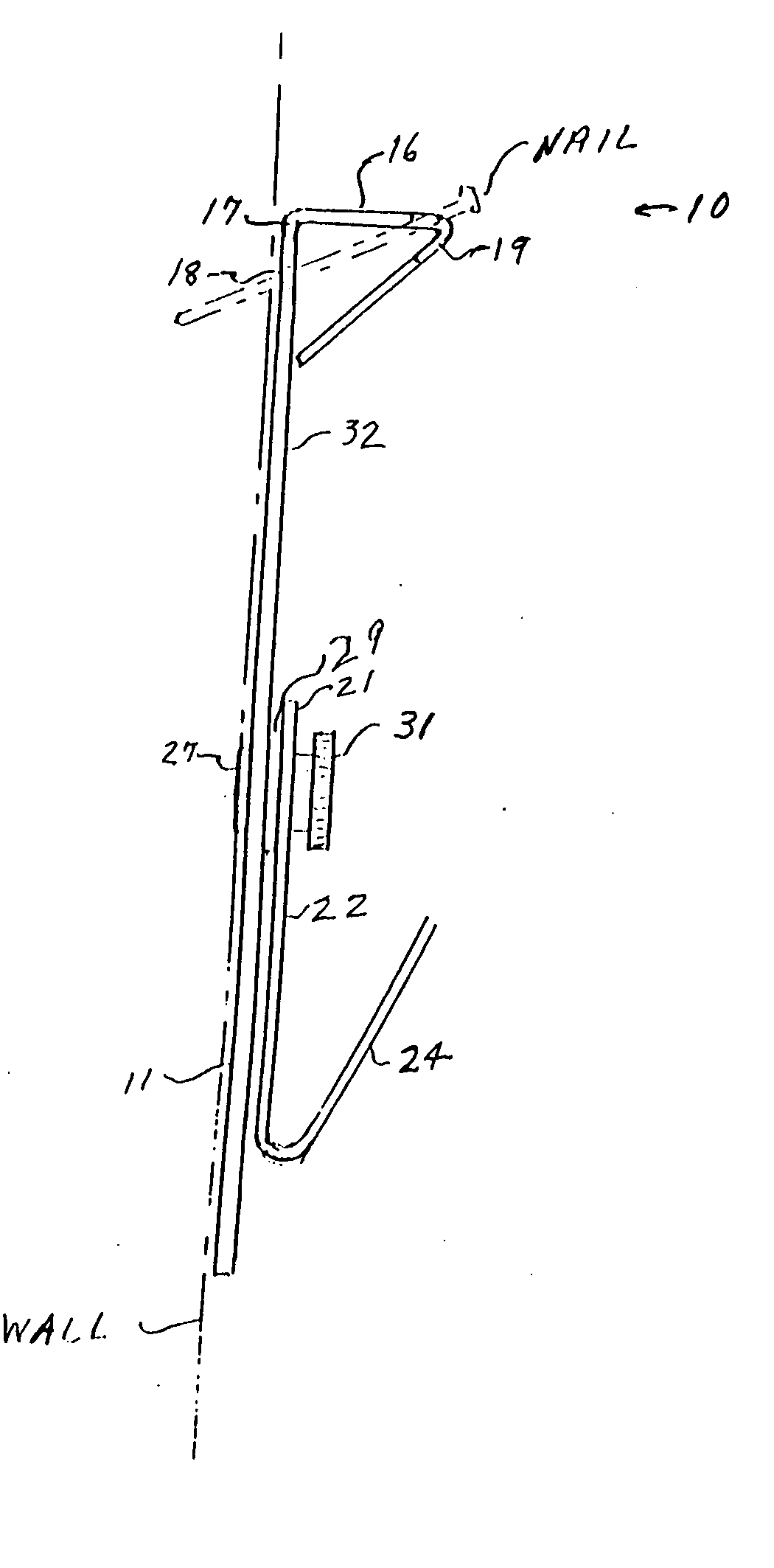

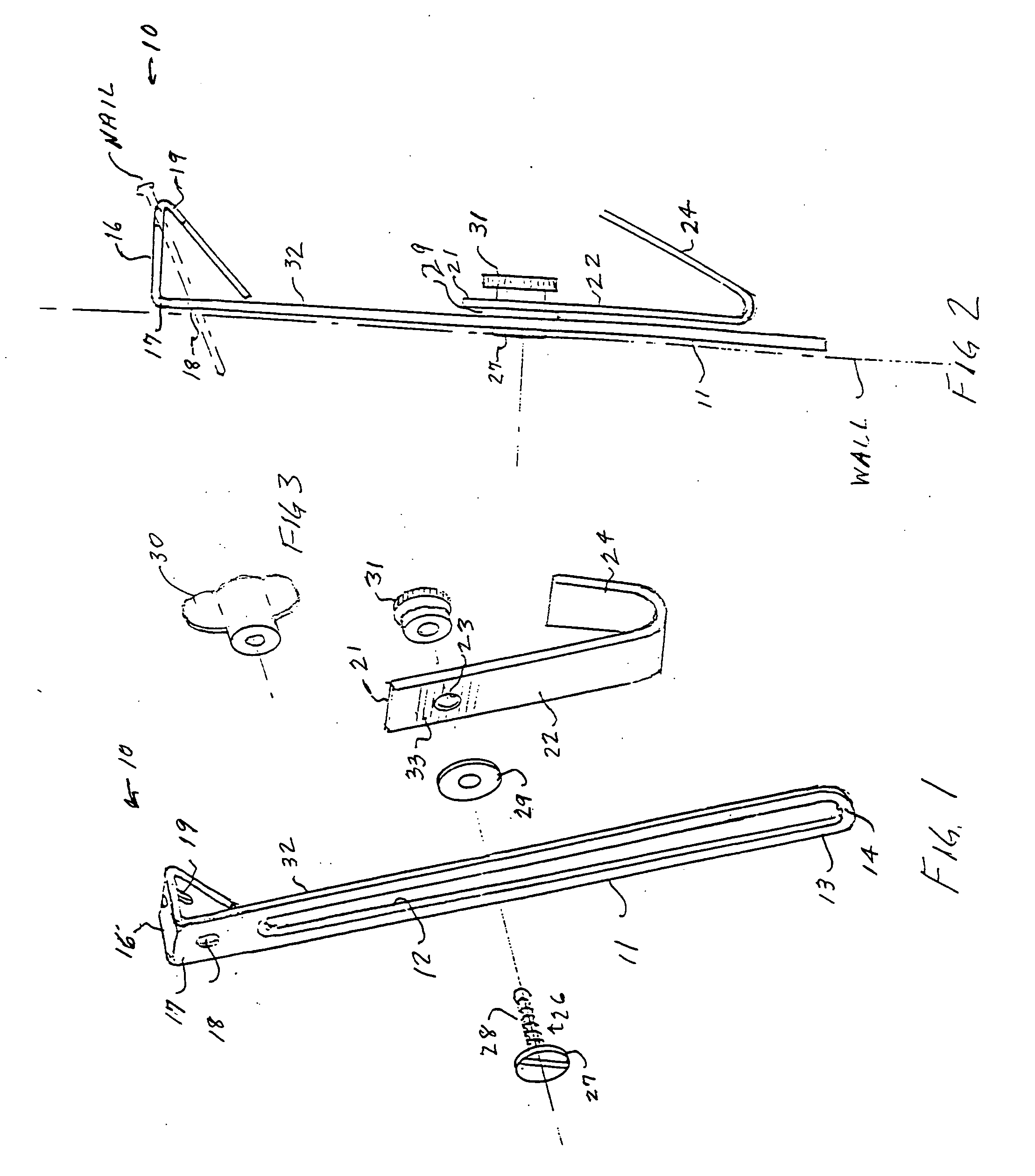

Adjustable hanger

InactiveUS20060060748A1Precise adjustmentCandle holdersLighting support devicesEngineeringWall mount

An adjustable hanger for hanging pictures, tools, or the like has an elongated, slotted bracket member having a wall mounting portion at one end thereof. A hanger hook member has a vertical portion with a bolt hole adjacent one end and is adapted to be positioned anywhere along the bracket by means of a bolt member and a resilient washer. The surfaces of the bracket and the vertical portion of the hook member may be roughened or striated to insure better purchase of the resilient washer between those two members when compressed by the action of the bolt member.

Owner:DARRE LAURA

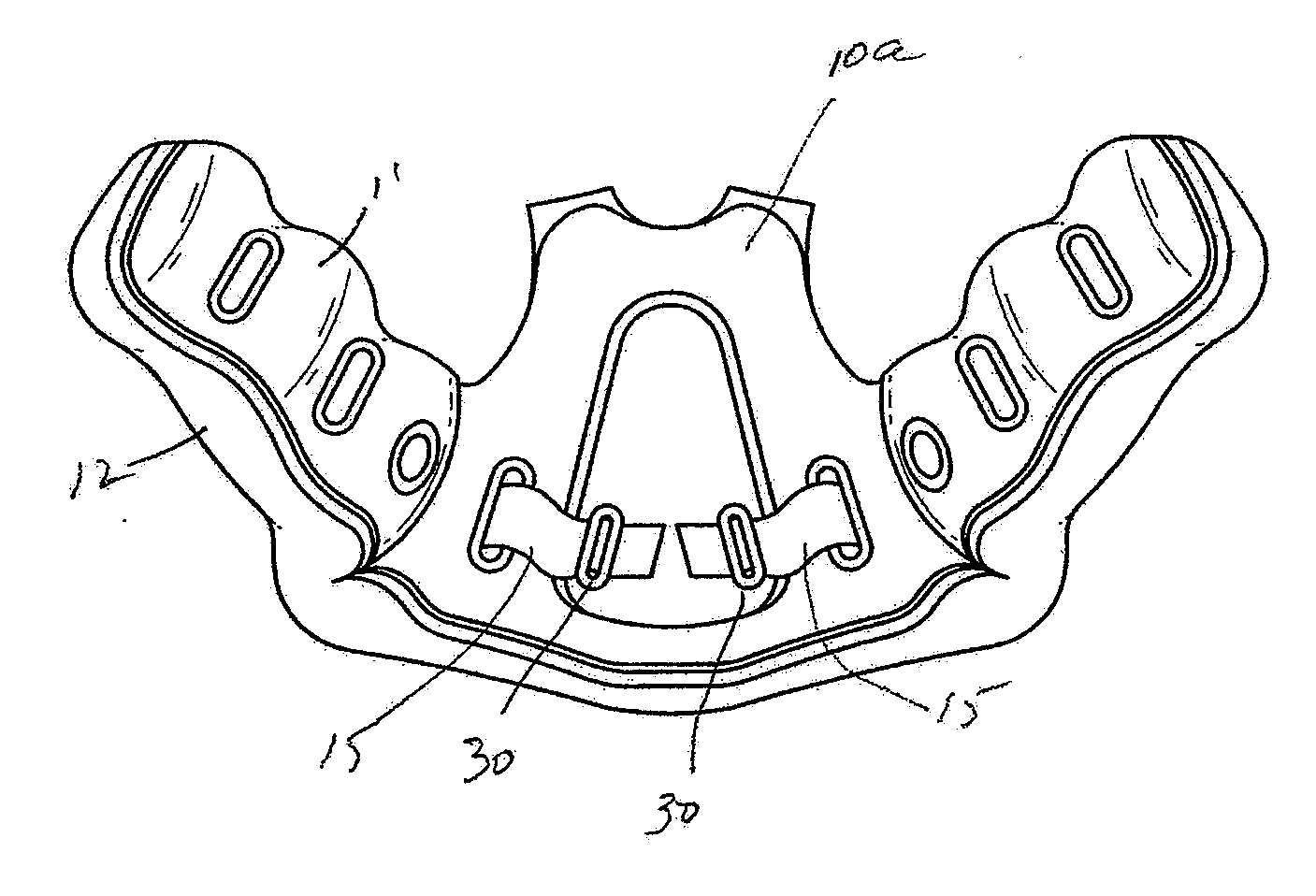

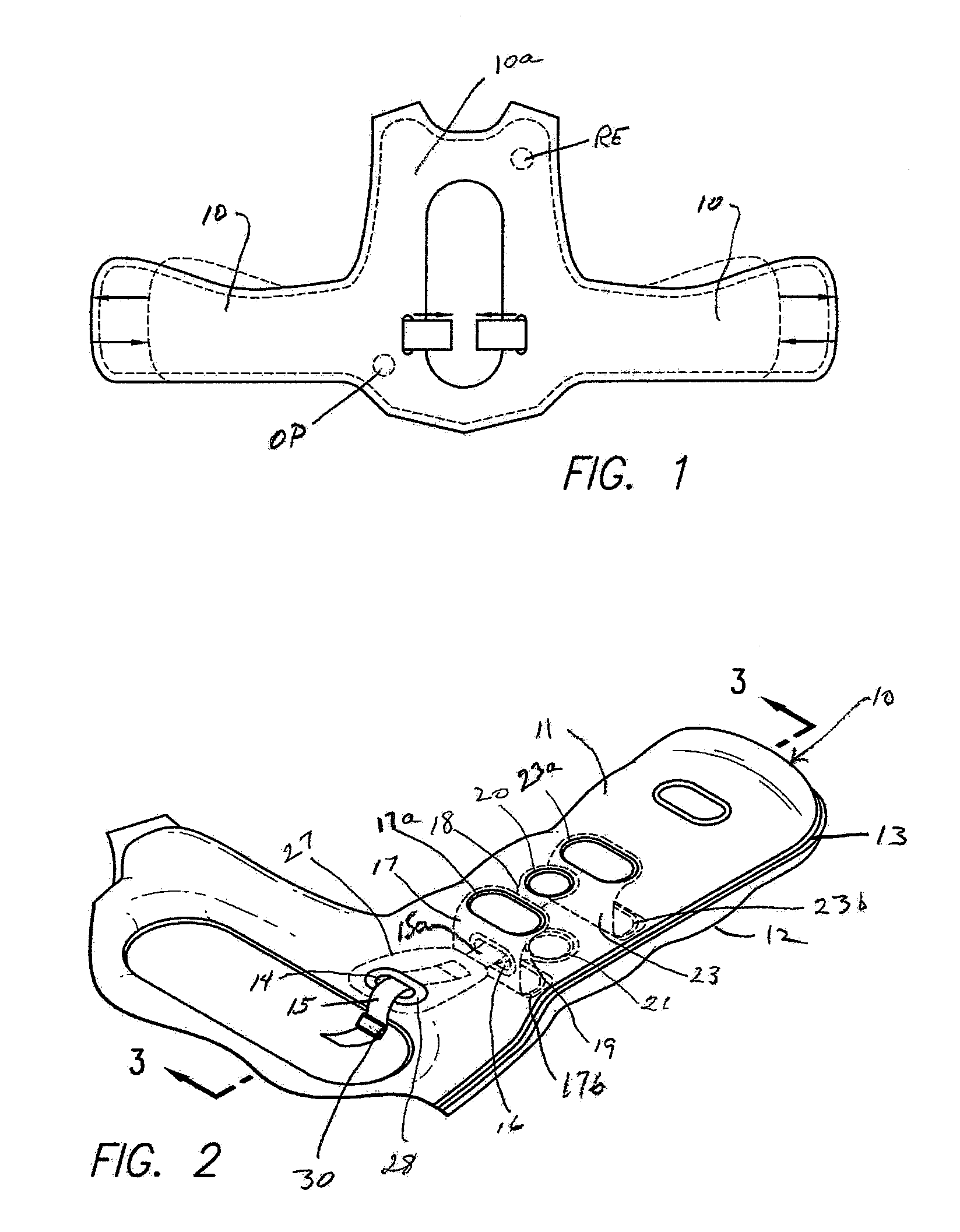

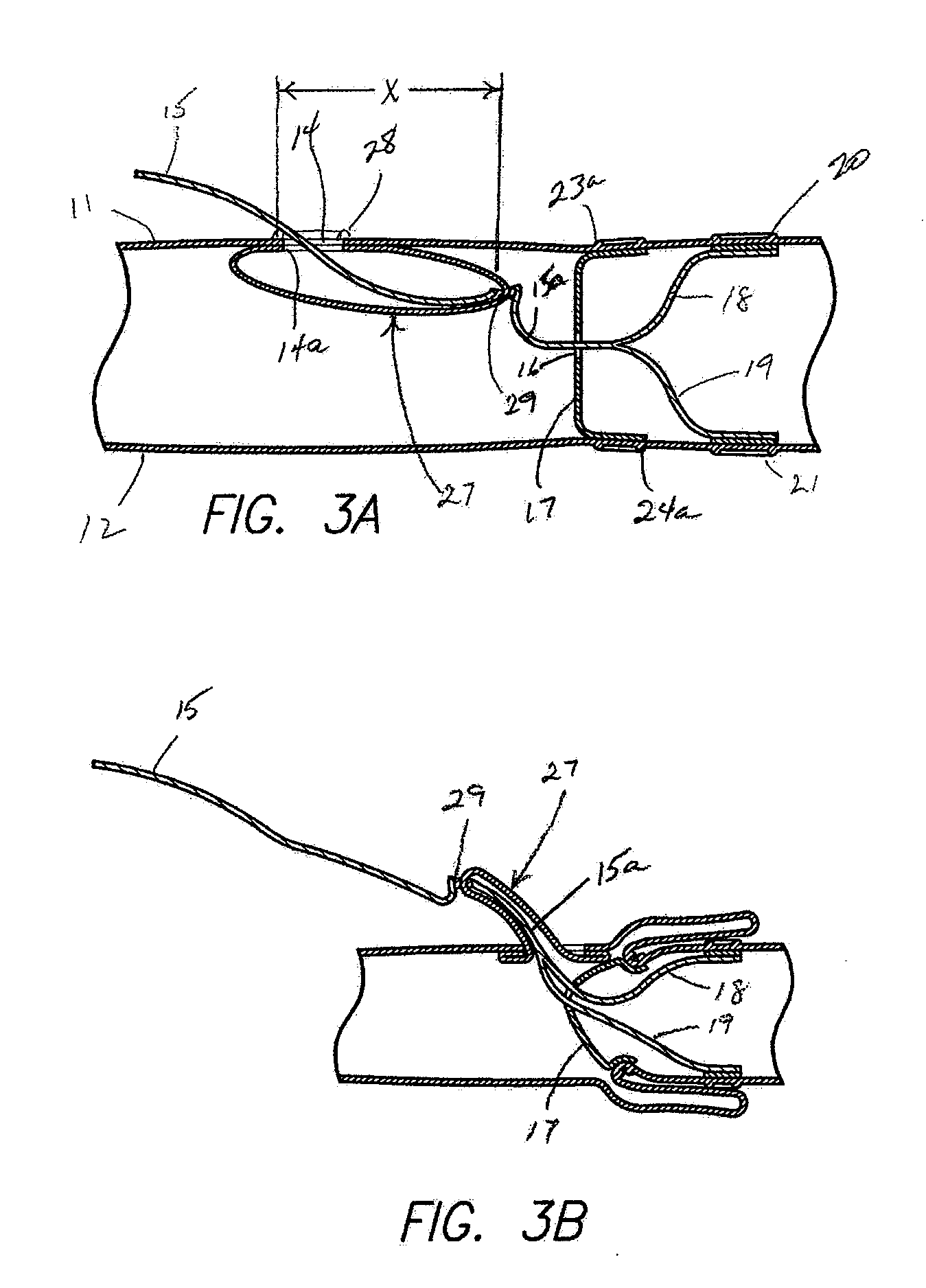

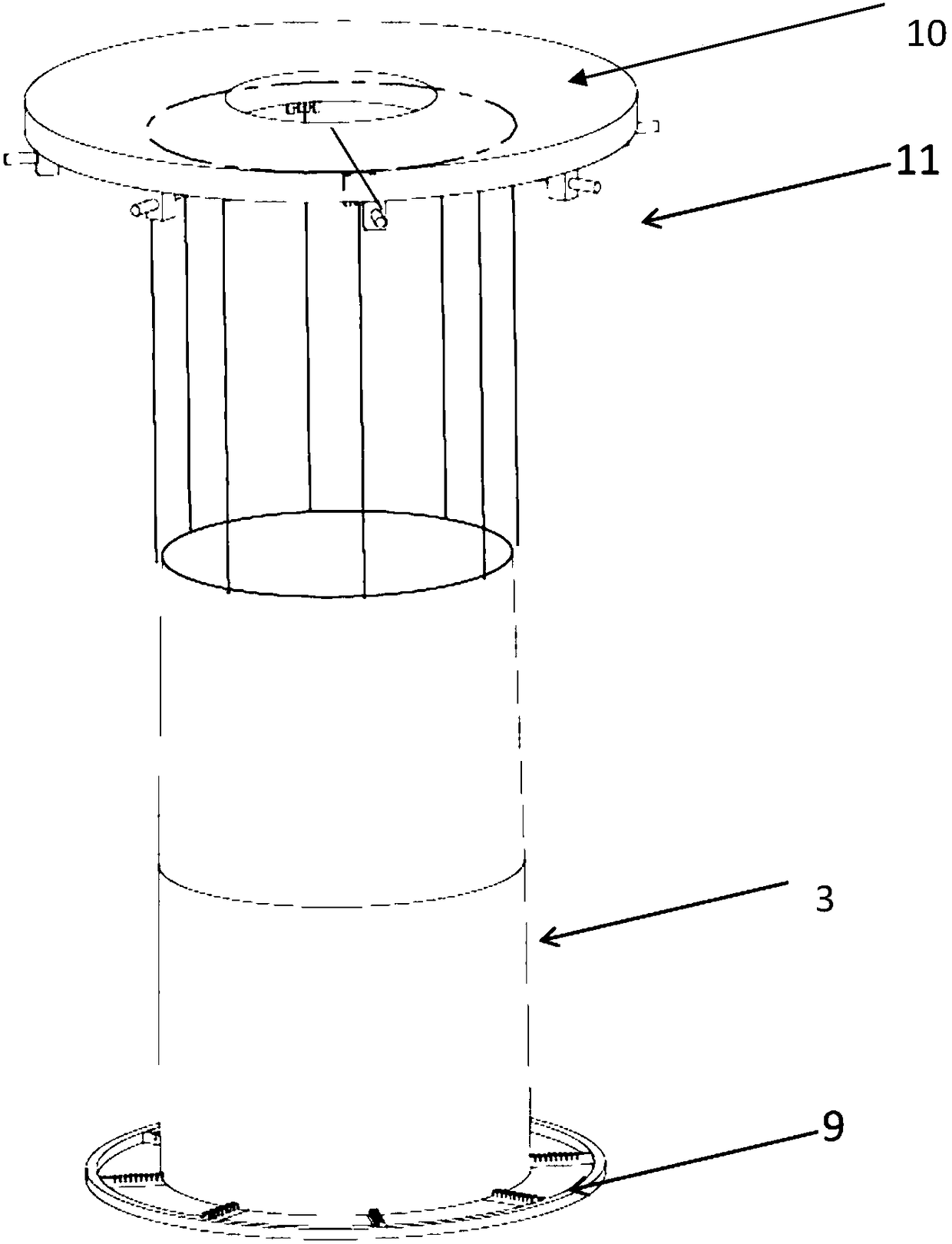

Adjustable size buoyancy compensator

InactiveUS20070077126A1Precise adjustmentSecure attachmentLife-buoysUnderwater equipmentWaist sizeBody size

A buoyancy compensator vest for providing adjustable buoyancy at various underwater depths by having a back portion for supporting an air tank and an air bladder for inflating and deflating, a portion of the air bladder of which is situated in the arms which surround the waist of the wearer. The improvement of an adjustment strap which can provide continuous variation within limits, of the reach of each of the inflatable arms of the vest whereby the girth of the vest can be continuously and uniformly adjusted to accommodate a wide range of body sizes, in particular waist sizes.

Owner:PARKER DAVID

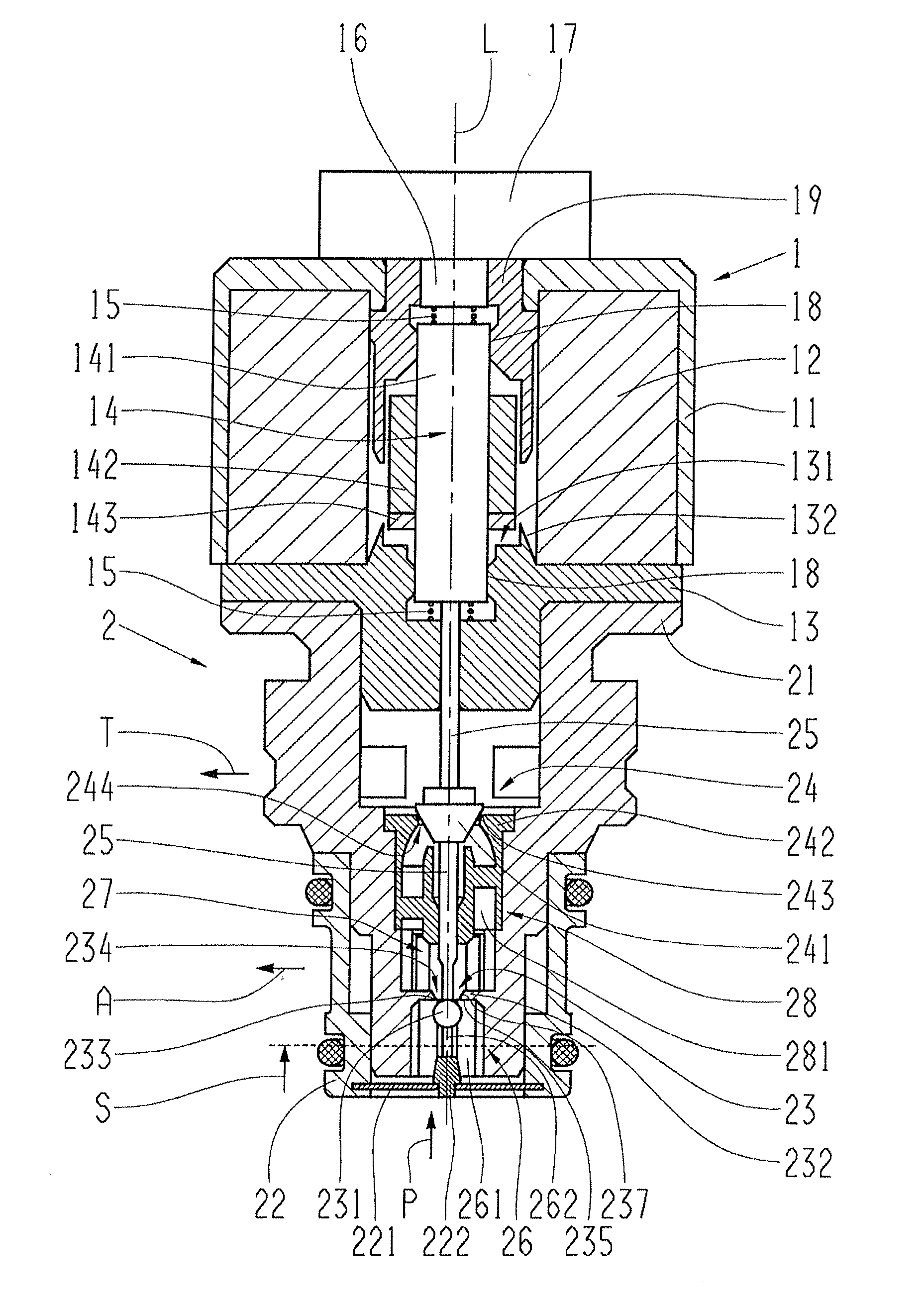

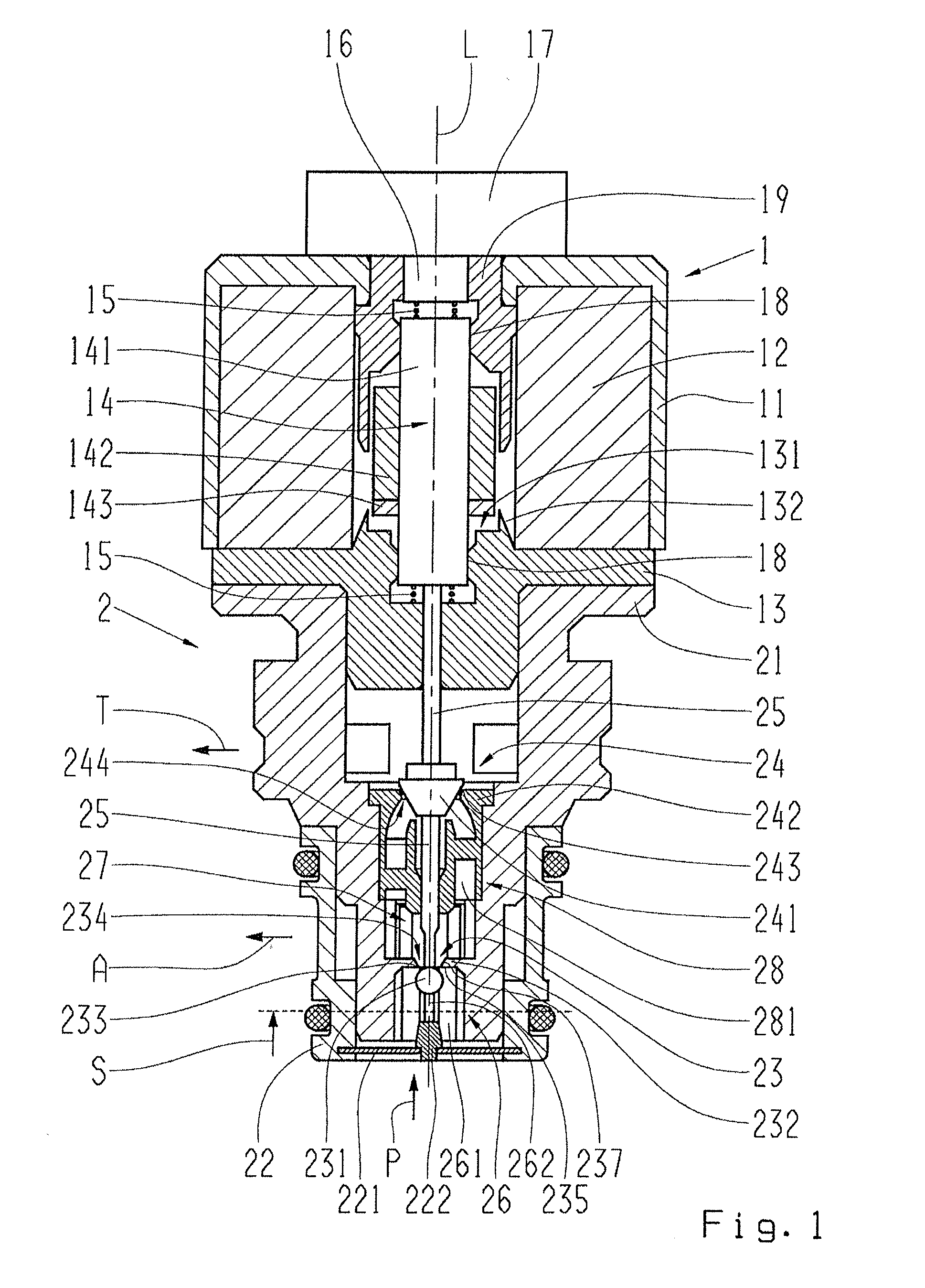

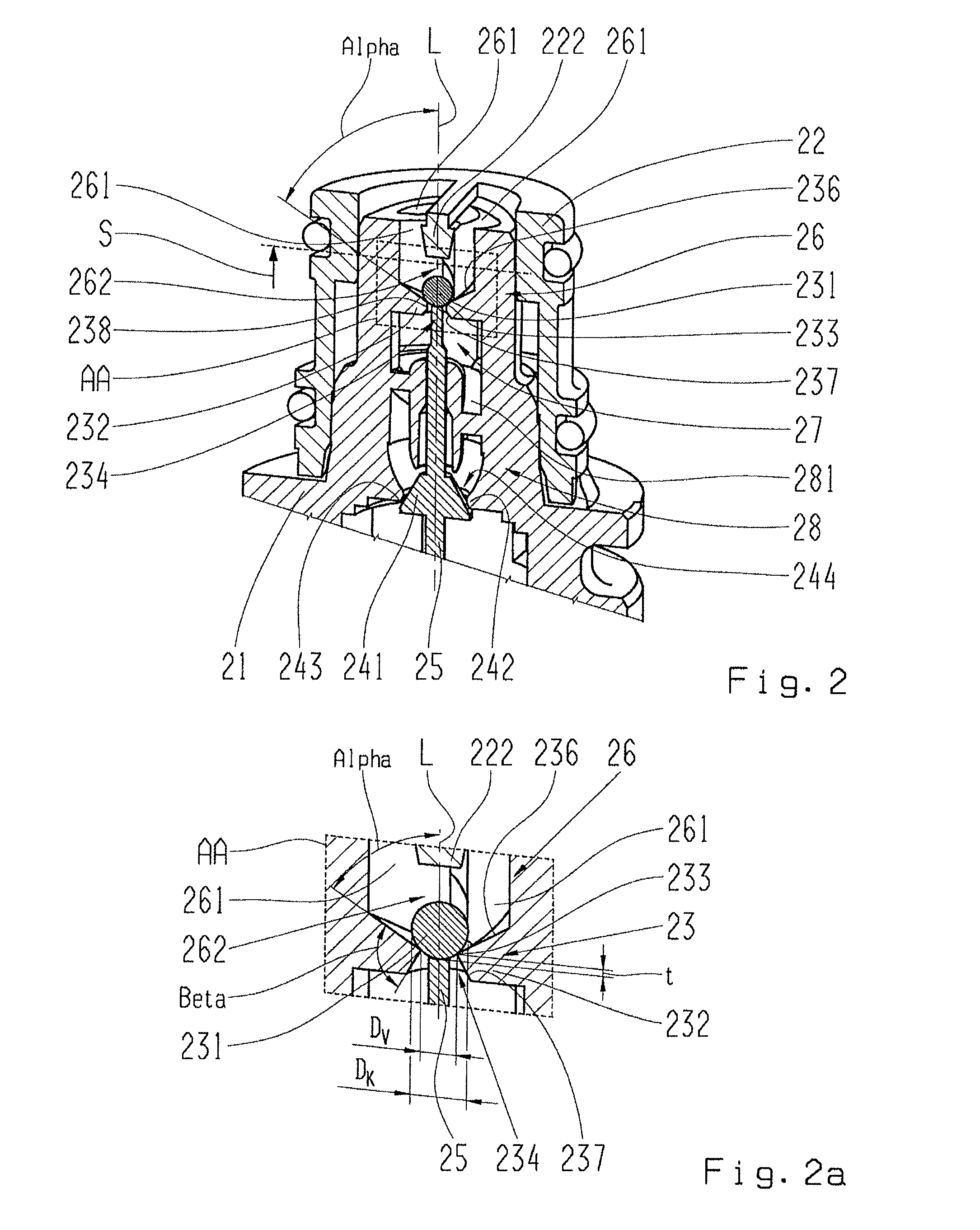

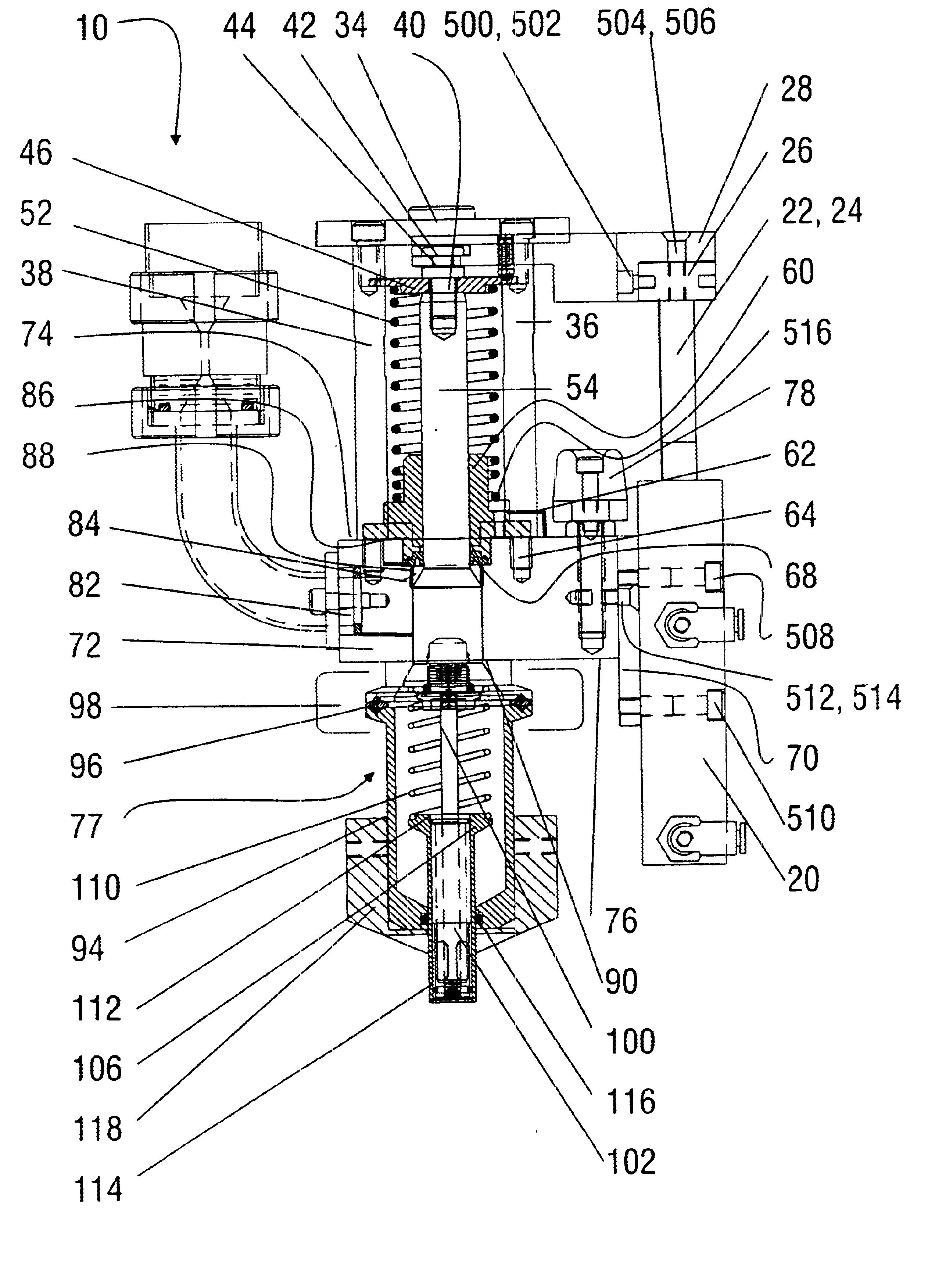

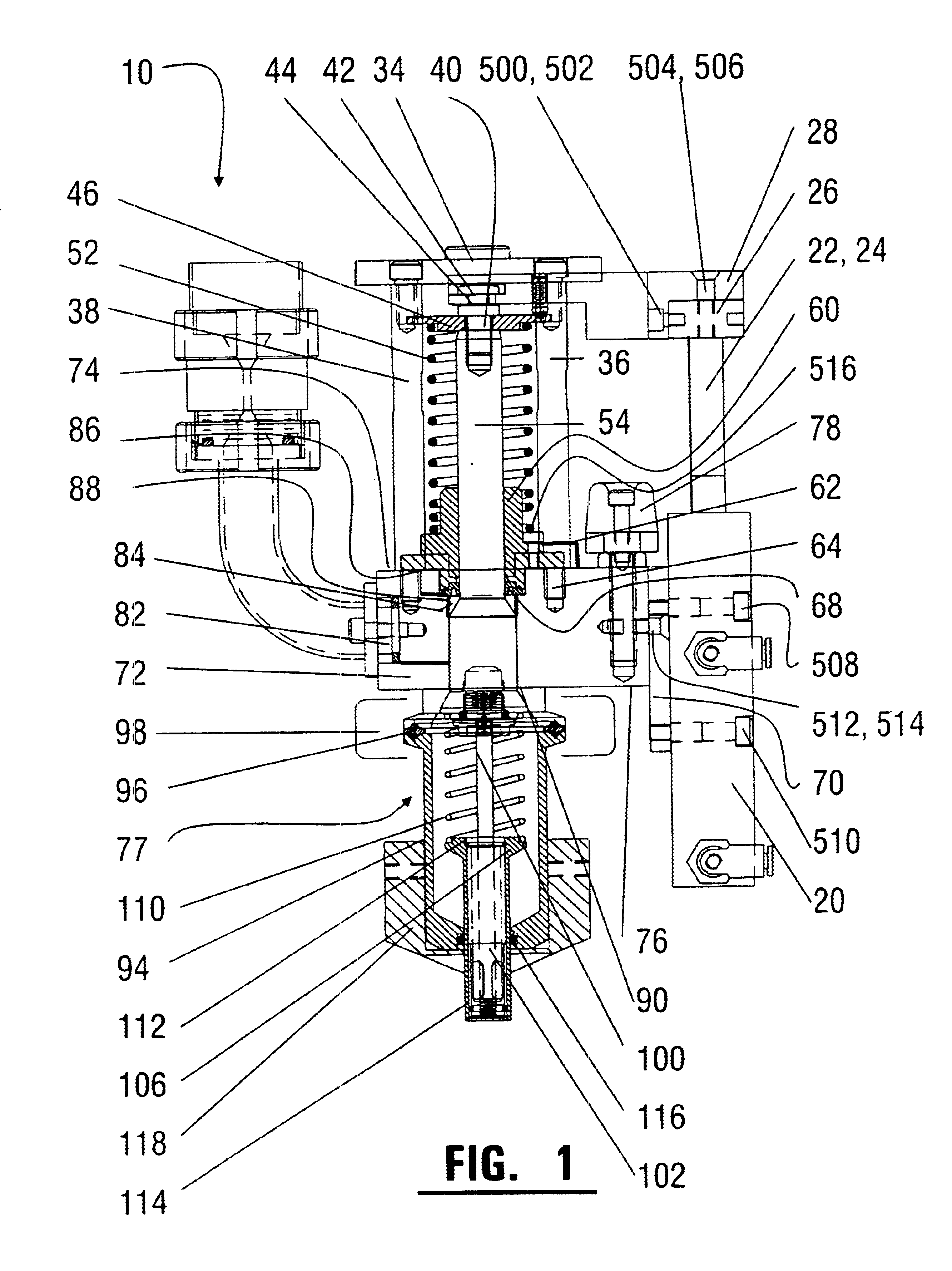

Pressure control valve device

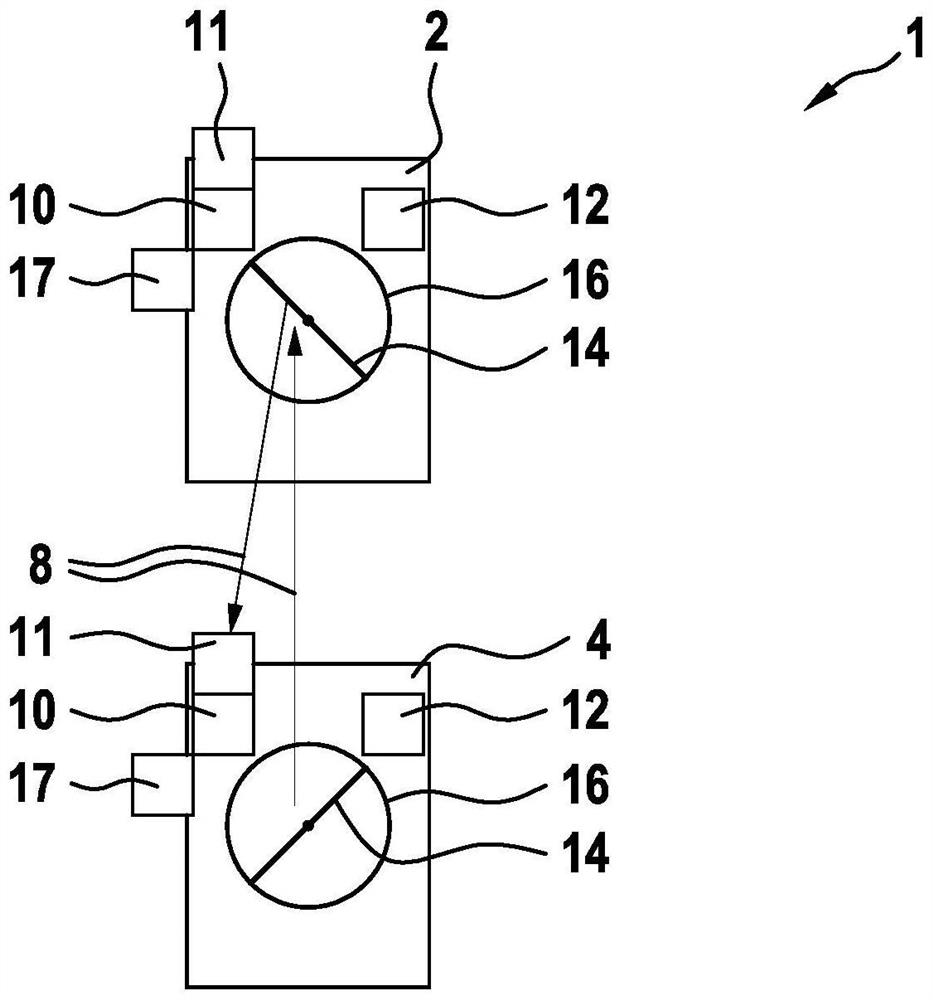

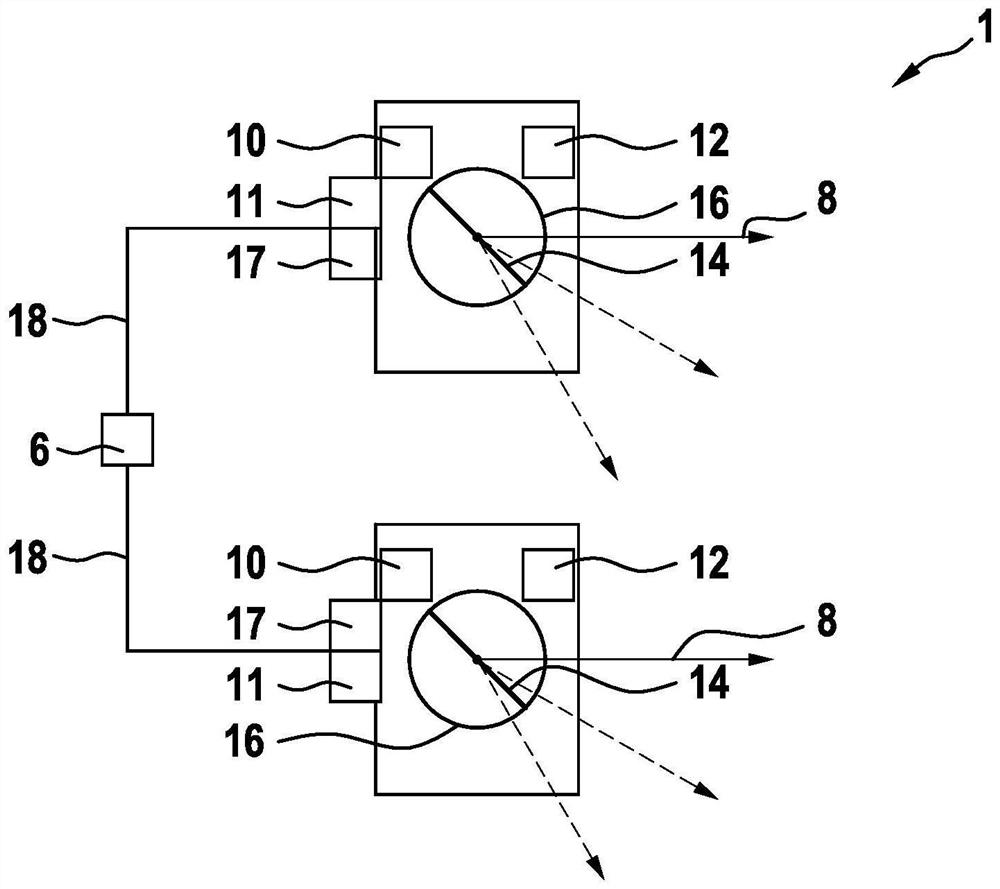

ActiveUS20130133767A1Reduce pressure fluctuationPrecise adjustmentOperating means/releasing devices for valvesEqualizing valvesValve openingEngineering

A pressure-control valve device for a fluid, having at least one inlet area and first and second outlet areas that can be flow-connected to one another by two seat valves coupled to one another, in which a fluid flow from the inlet area to the first and second outlet areas can be adjusted by the first seat valve and a fluid flow between the first and second outlet areas can be adjusted by the second seat valve. The first seat valve is designed as a valve aperture with a valve opening and a valve control edge and with a ball-shaped closing element that co-operates with the valve control edge. The valve opening and the ball-shaped closing element are designed such that the ratio of the diameter of the valve opening to the diameter of the ball-shaped closing element is equal to at least 0.75.

Owner:ZF FRIEDRICHSHAFEN AG

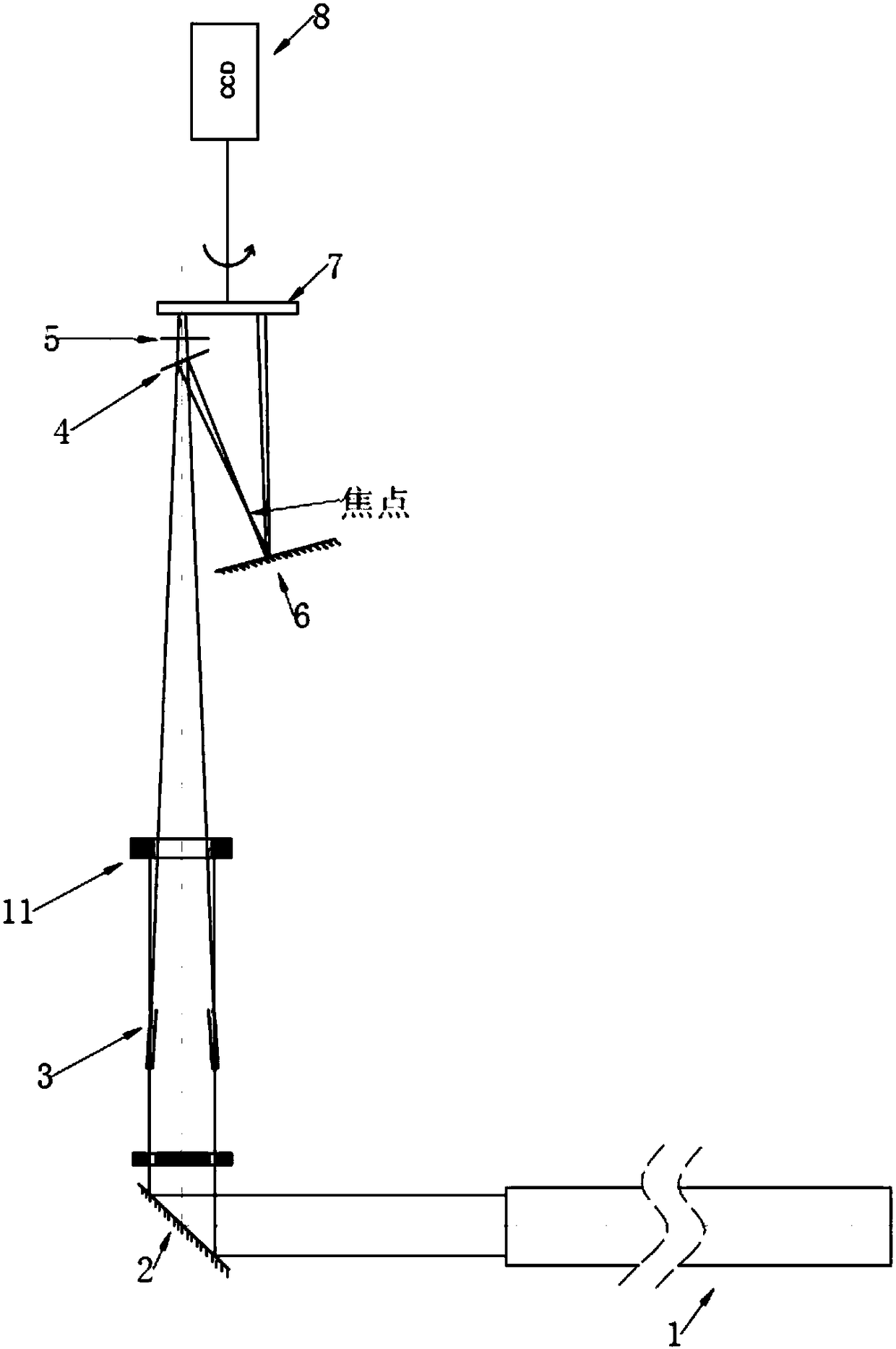

Laser reception debugging method and apparatus

ActiveCN105301578AEasy to operateLow skill level and experience requirements for workersWave based measurement systemsOptical pathLaser ranging

The invention relates to the optical adjusting field of a laser range finding machine, and specifically relates to a laser reception debugging method and apparatus. The laser reception debugging method comprises adjusting a reception light path; performing convergence and at least two-level replication for a laser echo signal generated after reflection of the signal emitted from the laser range finding machine through a detection object, and converging the laser echo signal at the photosensitive surface position of the detector eventually; setting an endoscope which can convert the invisible light into visible light, at the position of the photosensitive surface of the detector; and then adjusting the detector. The laser reception debugging method and apparatus can utilize the endoscope to display the invisible light as the visible light so that visual adjusting of a laser optical axis can be realized and accurate adjusting of the light path can be realized. The laser reception debugging method and apparatus can solve the problem about offset of the optical axis because of blind adjusting of laser optical axis, optical component machining error and adjusting error of an assembling staff, and has the advantages of being simple in operation, having no requirement for the skill level and the experience of workers, reducing the adjusting time, effectively improving the adjusting accuracy, and being able to realize accurate and effective adjusting of the laser optical axis.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

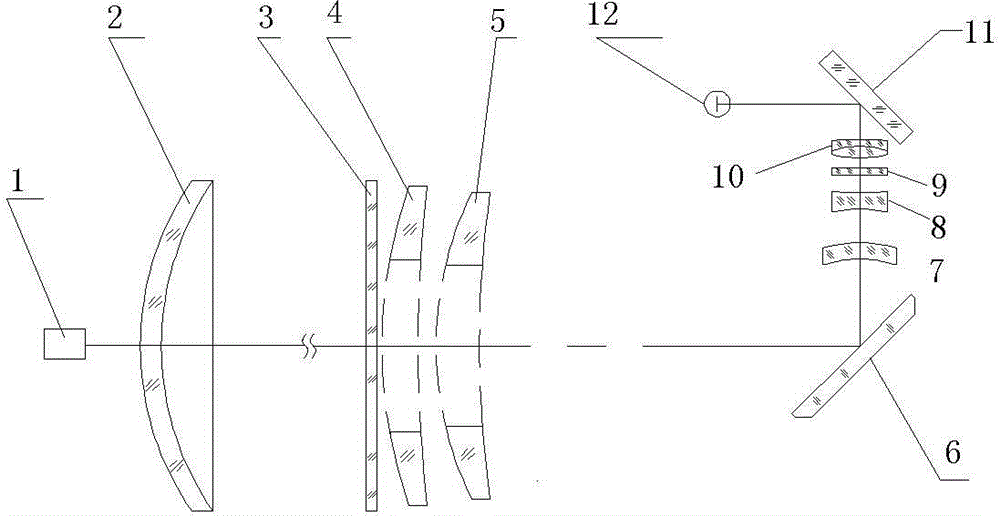

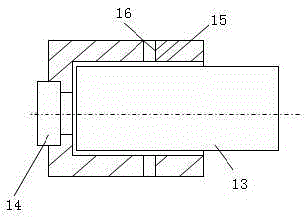

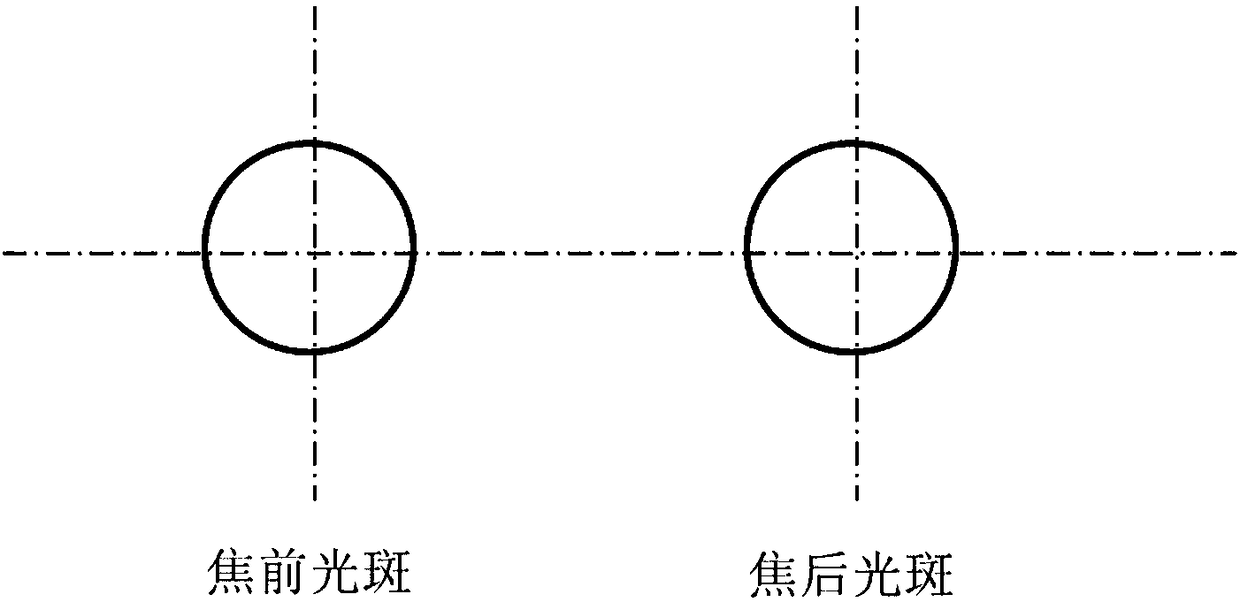

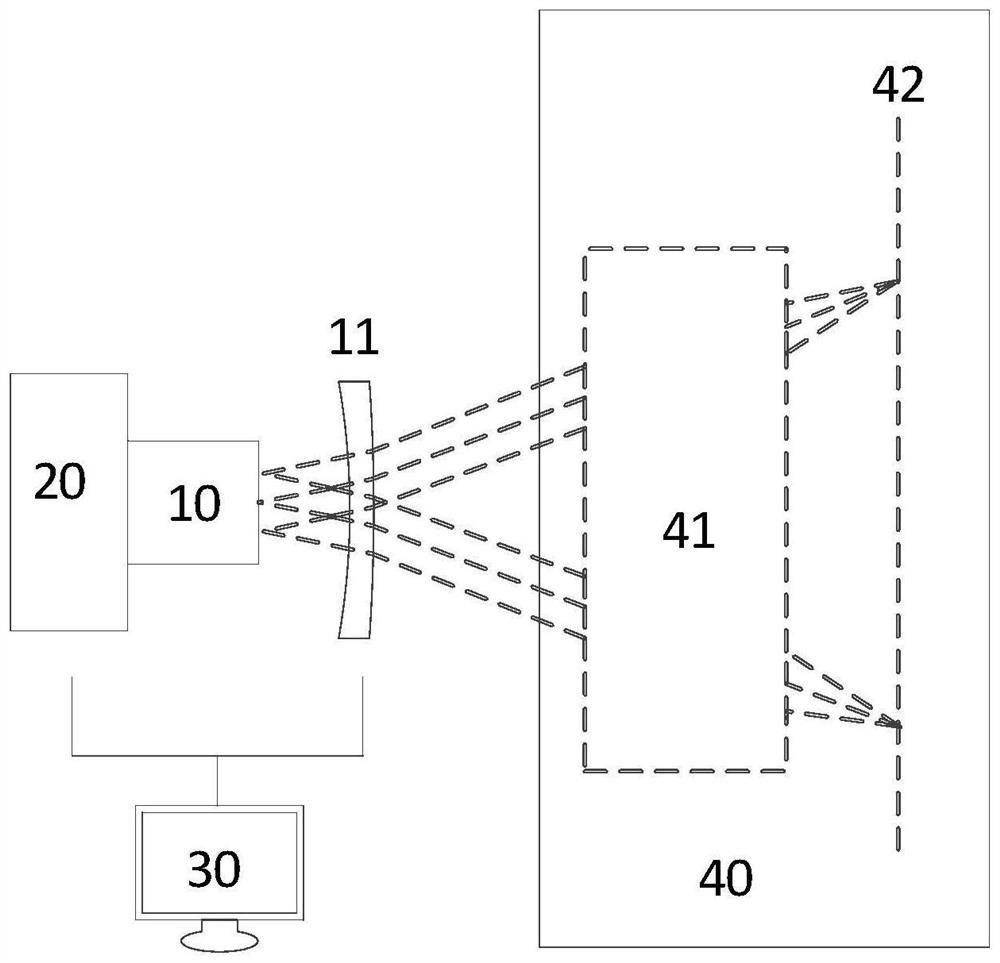

X-ray focus lens vertical installation and adjustment system and method

PendingCN108375453AQuick SetupPrecise adjustmentStatic/dynamic balance measurementBeam deviation/focusing by electric/magnetic meansMicrometerX-ray

The invention relates to an X-ray focus lens vertical installation and adjustment system and method, which solves the problems that the gravity introduced in the assembling process of a focus lens tube influences a facial form and the assembling precision is relatively low. The X-ray focus lens vertical installation and adjustment system comprises a parallel light tube, a focus lens tube, a focuslens installation and adjustmentassembling system, a semitransparent semi-reflective mirror, a reflection mirror, a receiving screen, a CCD camera and a computer; the focus lens installation and adjustmentassembling system comprises a fixed disc, a micrometer head, a suspension rope and a pulley, the pulley is fixedly arranged on the fixed disc, one end of the suspension rope is connected with themicrometer head, and the other end is connected with the focus lens tube; and the outgoing light of the parallel light tube perpendicularly enters the focus lens tube, the outgoing light of the focuslens tube is divided into two beams by virtue of the semitransparent semi-reflective mirror, one beam directly enters the receiving screen, the other beam is reflected by the reflection mirror to receiving the screen, the two beams of light form the centroid of focal spot in front of and behind a focus, and the CCD camera records and transfers the centroid of focal spot to the computer. The invention also provides an installation and adjustmentassembling method based on the system.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

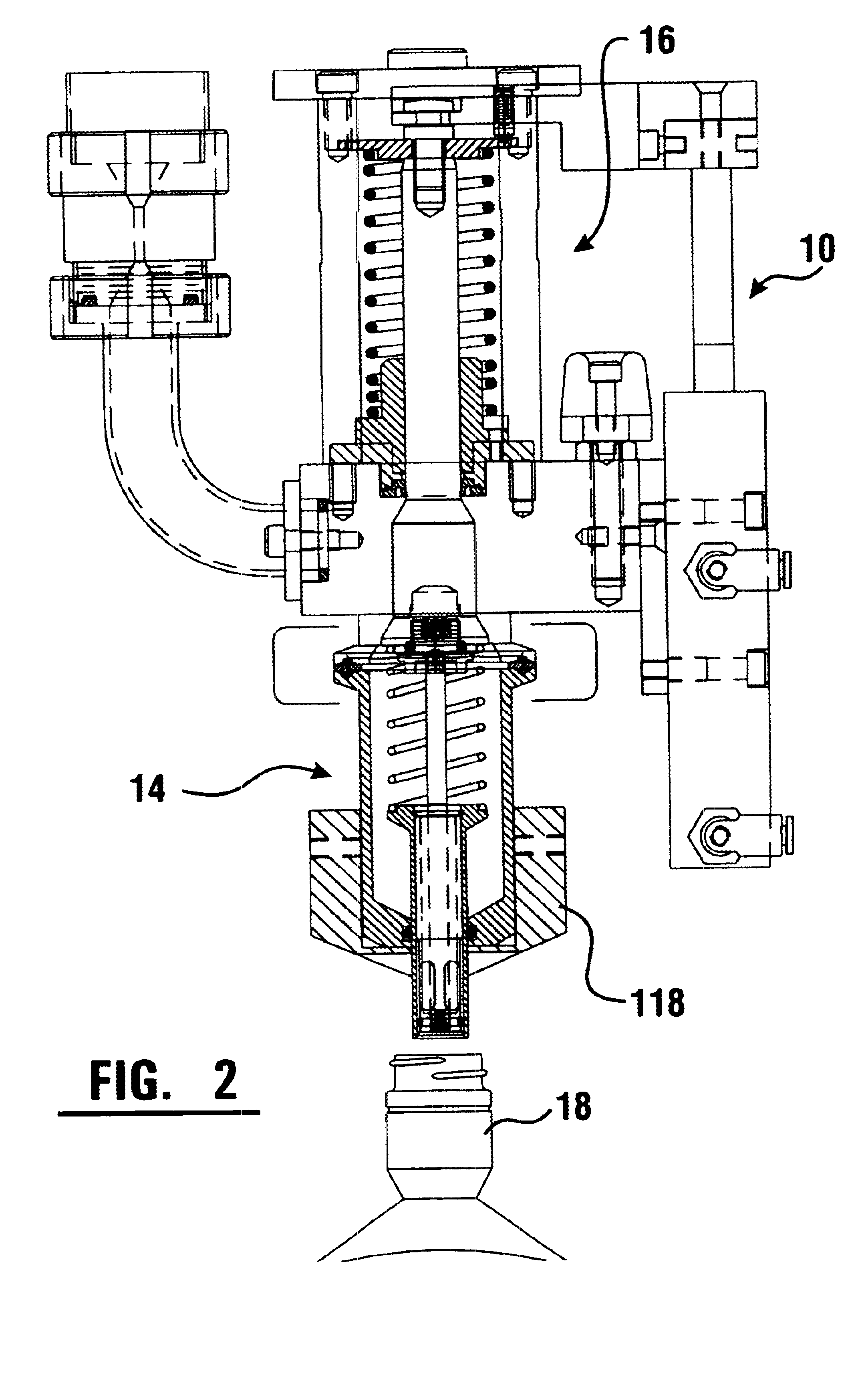

Telescoping filling head

InactiveUS6662828B1Precise adjustmentIntroduction of foaming liquids into a bottle more quicklyBarrels/casks fillingSolid materialEngineeringNozzle

A telescoping filling head comprising a driving portion, a nozzle block portion and a two-stage telescoping nozzle, the innermost portion of the nozzle having positionable apertures. A telescoping filling head can be retrofitted on an existing filling device, or can be incorporated in a newly manufactured filling device. The telescoping action permits a longer nozzle to be used in any given space, because the two portions which extend to create a relatively long filling nozzle retract within a relatively short outer nozzle. The longer nozzle increases the rate at which foaming liquids can be introduced into a container. The positionable apertures can also direct the flow of the liquid at the shoulders of the bottle, further increasing the rate at which foaming liquids can be introduced into a container.

Owner:STOVER CLIFFORD W +2

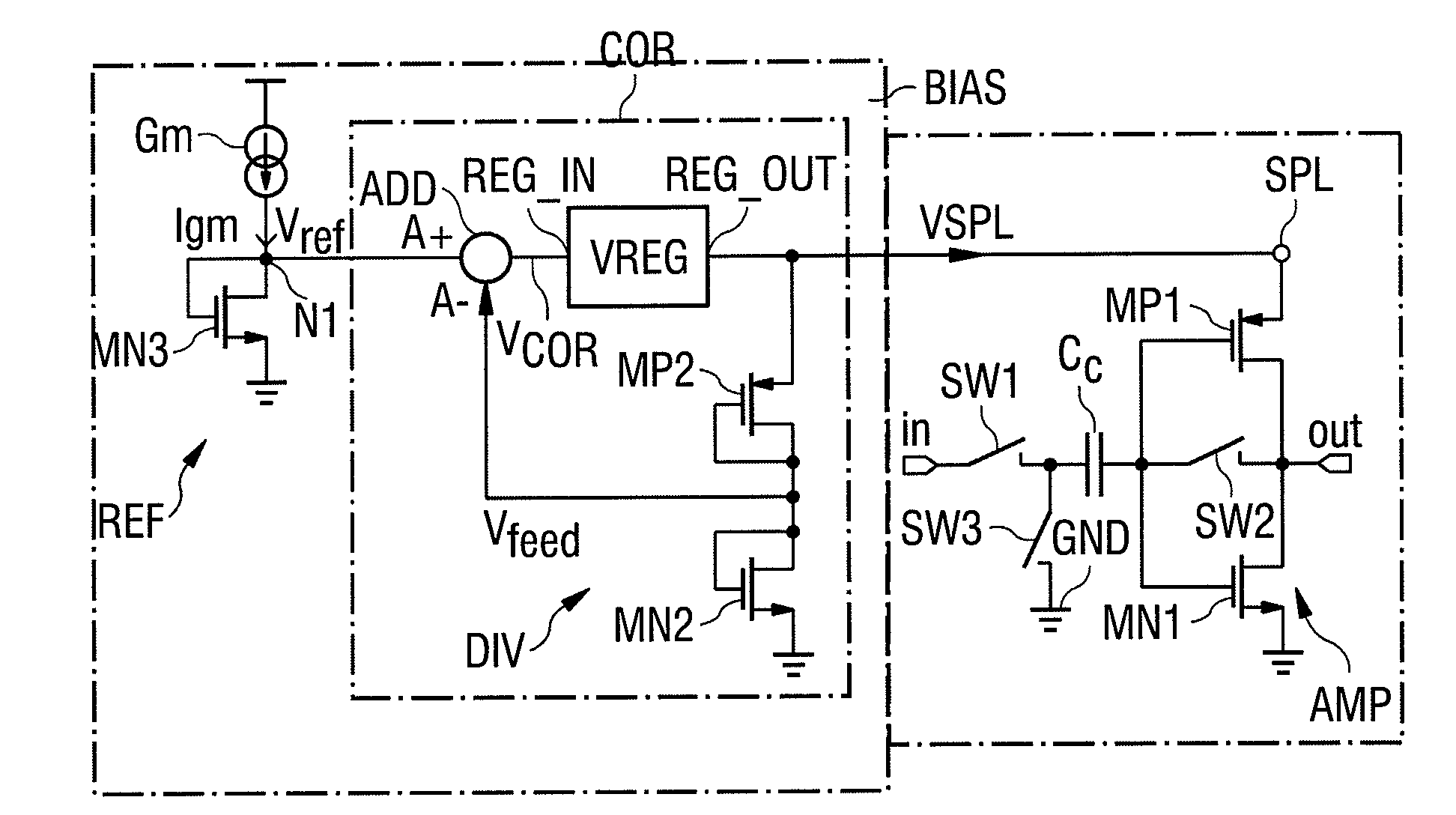

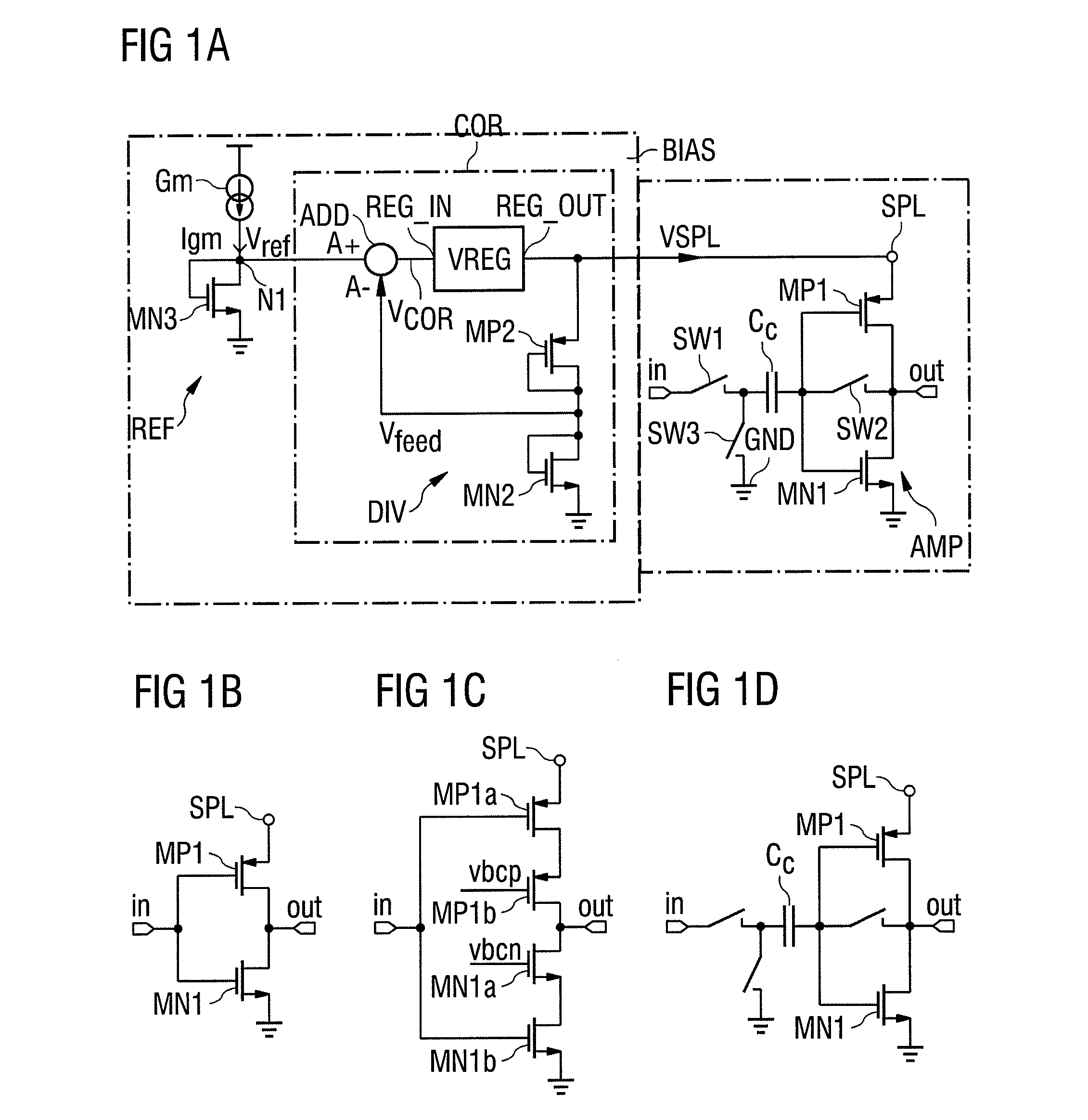

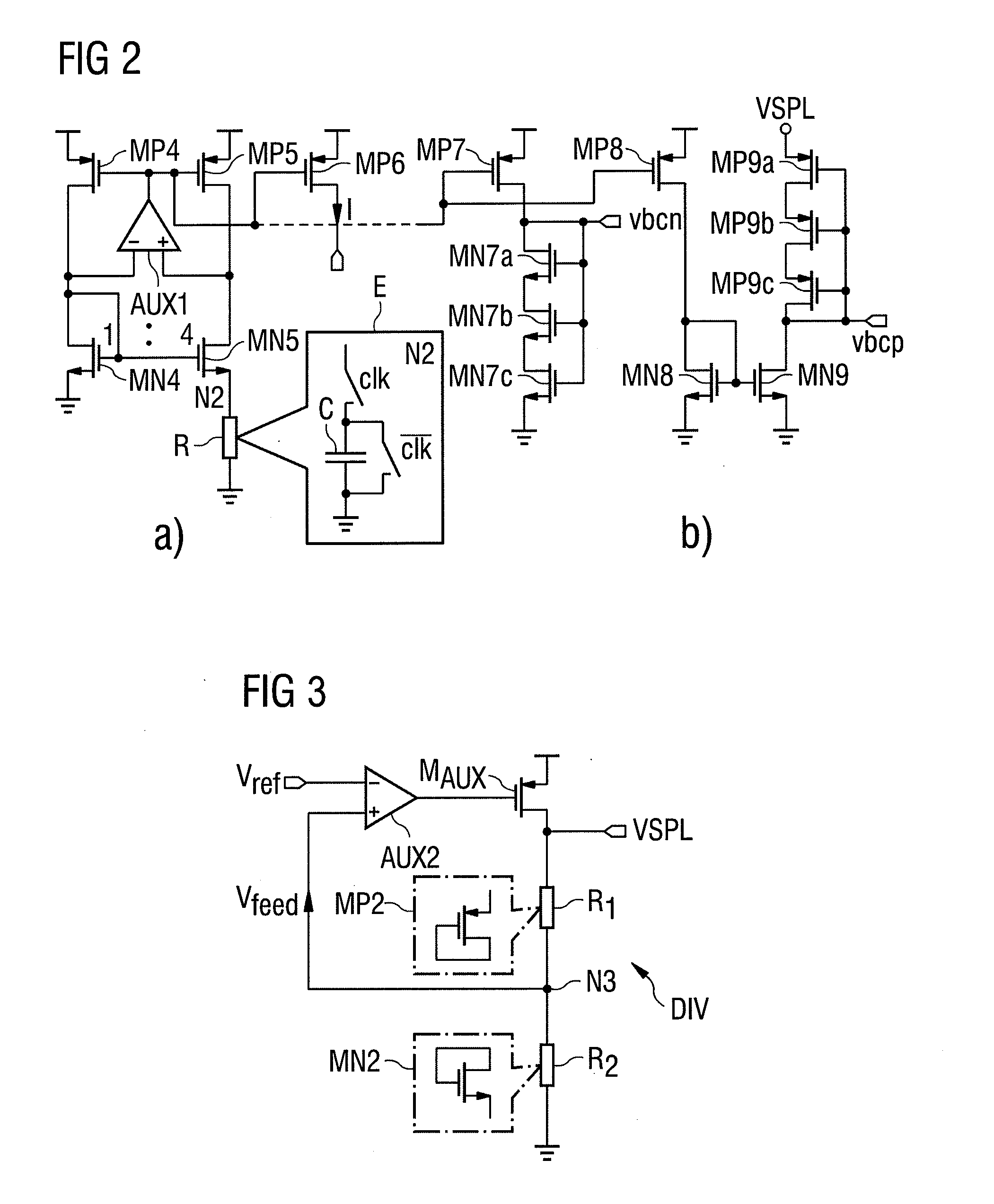

Amplifier Arrangement and Method for Operating an Amplifier Arrangement

ActiveUS20120268212A1Precise adjustmentEasy to adjustAmplifiers using switched capacitorsPositive-feedback-circuit arrangementsEngineeringOperating point

Owner:AMS AG

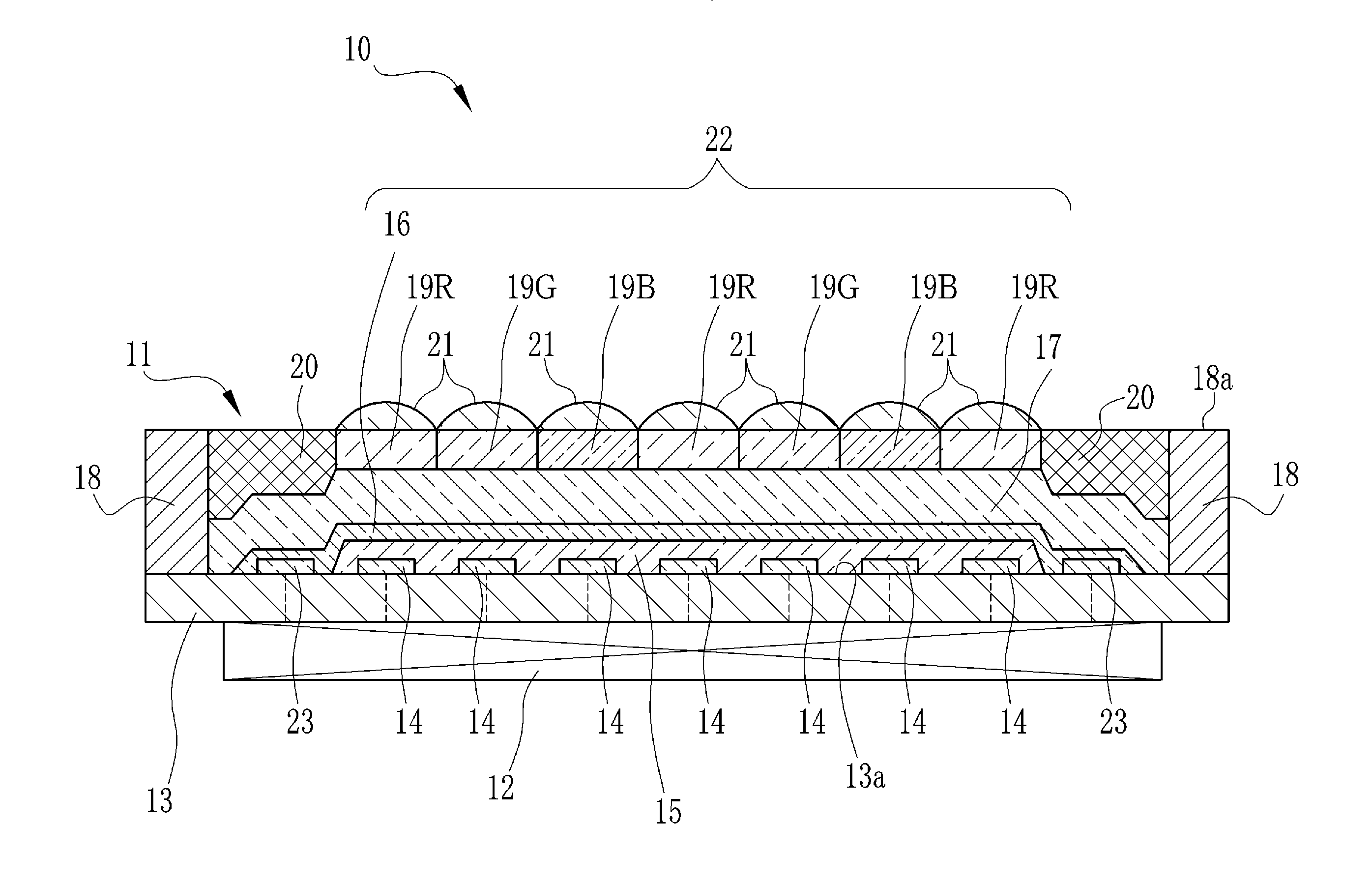

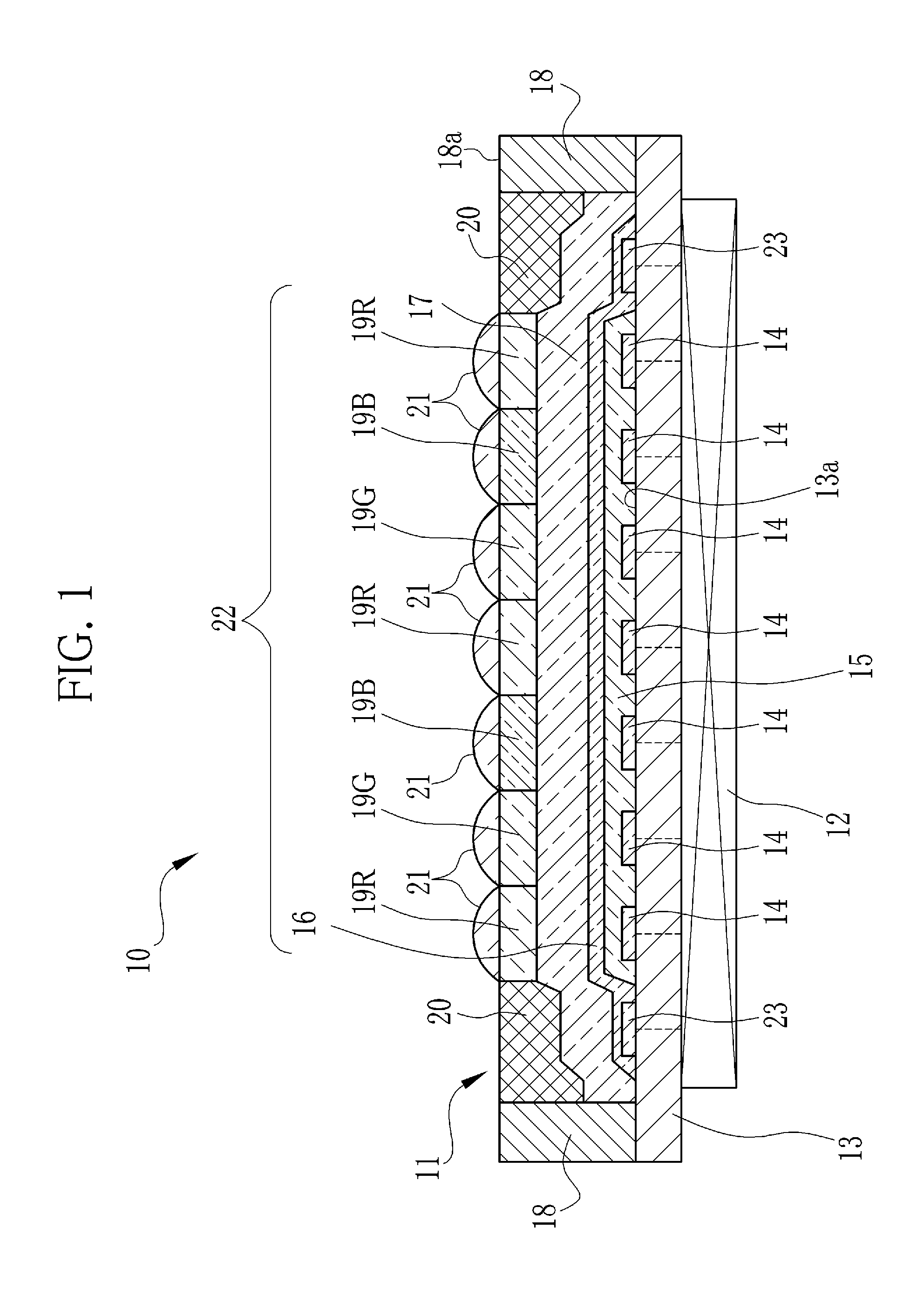

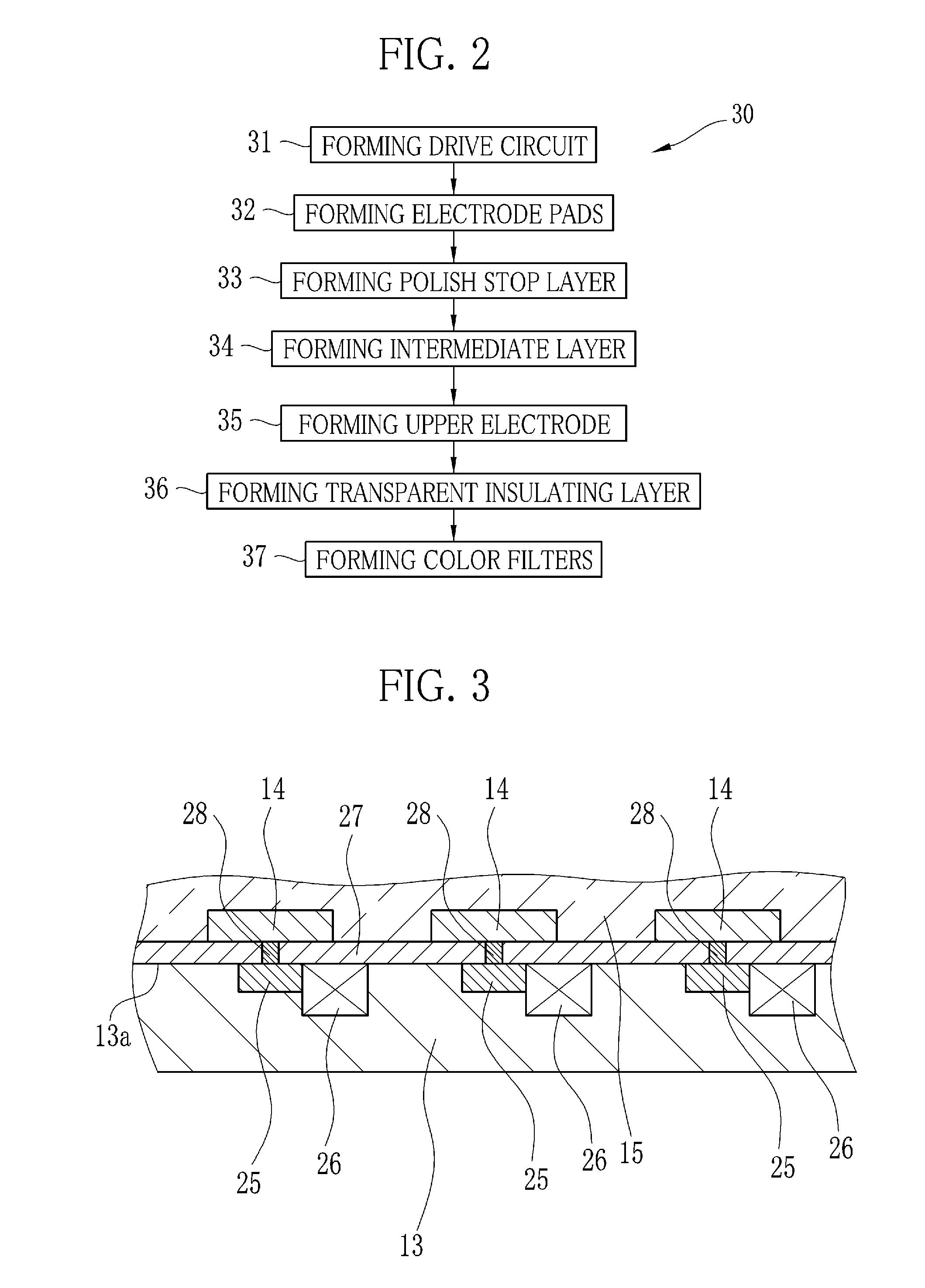

Light/electric power converter and solid state imaging device

InactiveUS20100194941A1Precise adjustmentImprove productionTelevision system detailsTelevision system scanning detailsSolid-stateEngineering

A semiconductor substrate has an active pixel area comprising a stack of lower electrodes, an intermediate layer of an organic photoelectric conversion material, an upper electrode, a transparent insulating layer and first to third color layers. Disposed outside the active pixel area is a polish stop layer having a high resistance to polishing. In planarizing the first to third color layers, the polishing operation is ended upon reaching the polish stop layer.

Owner:FUJIFILM CORP

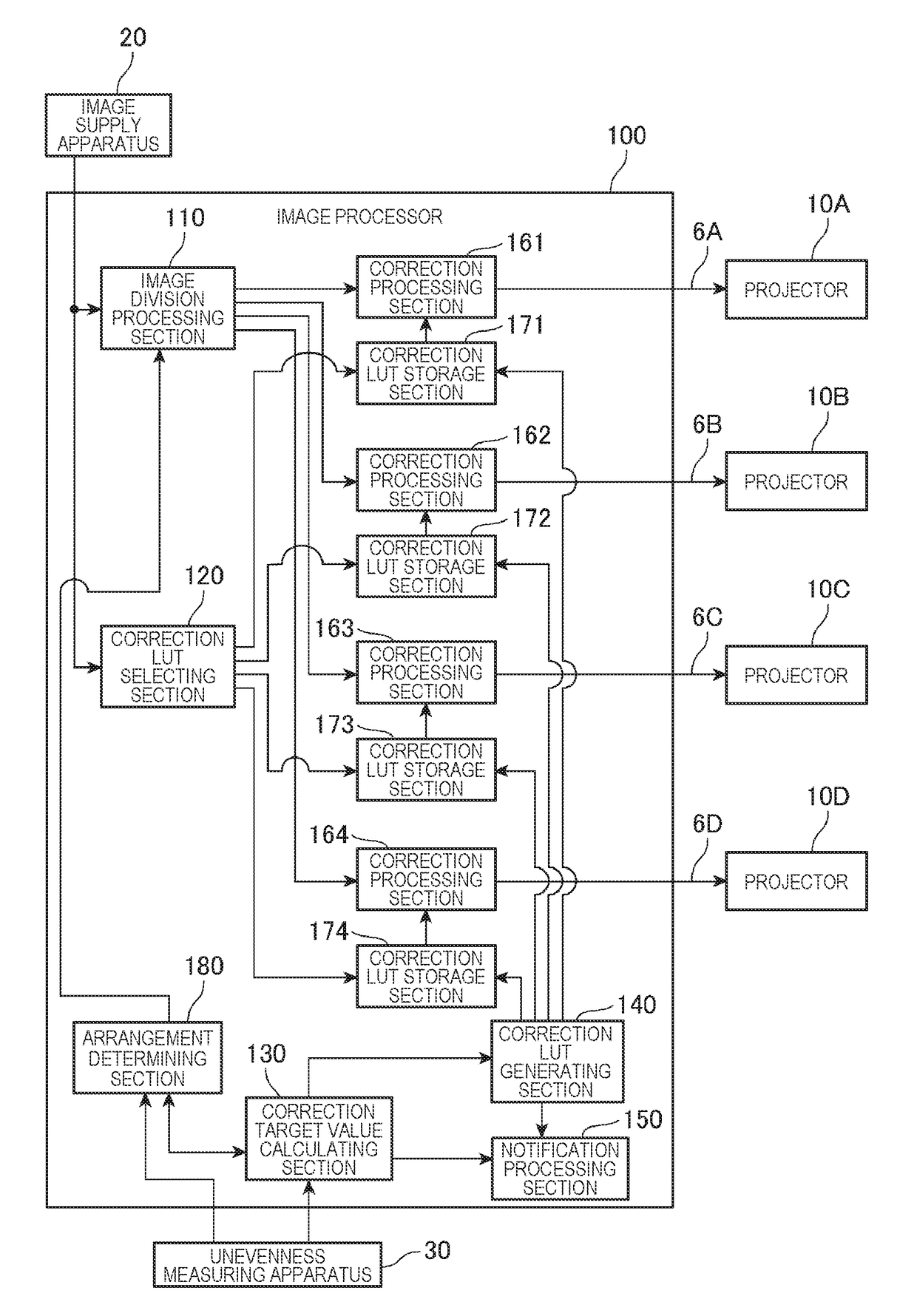

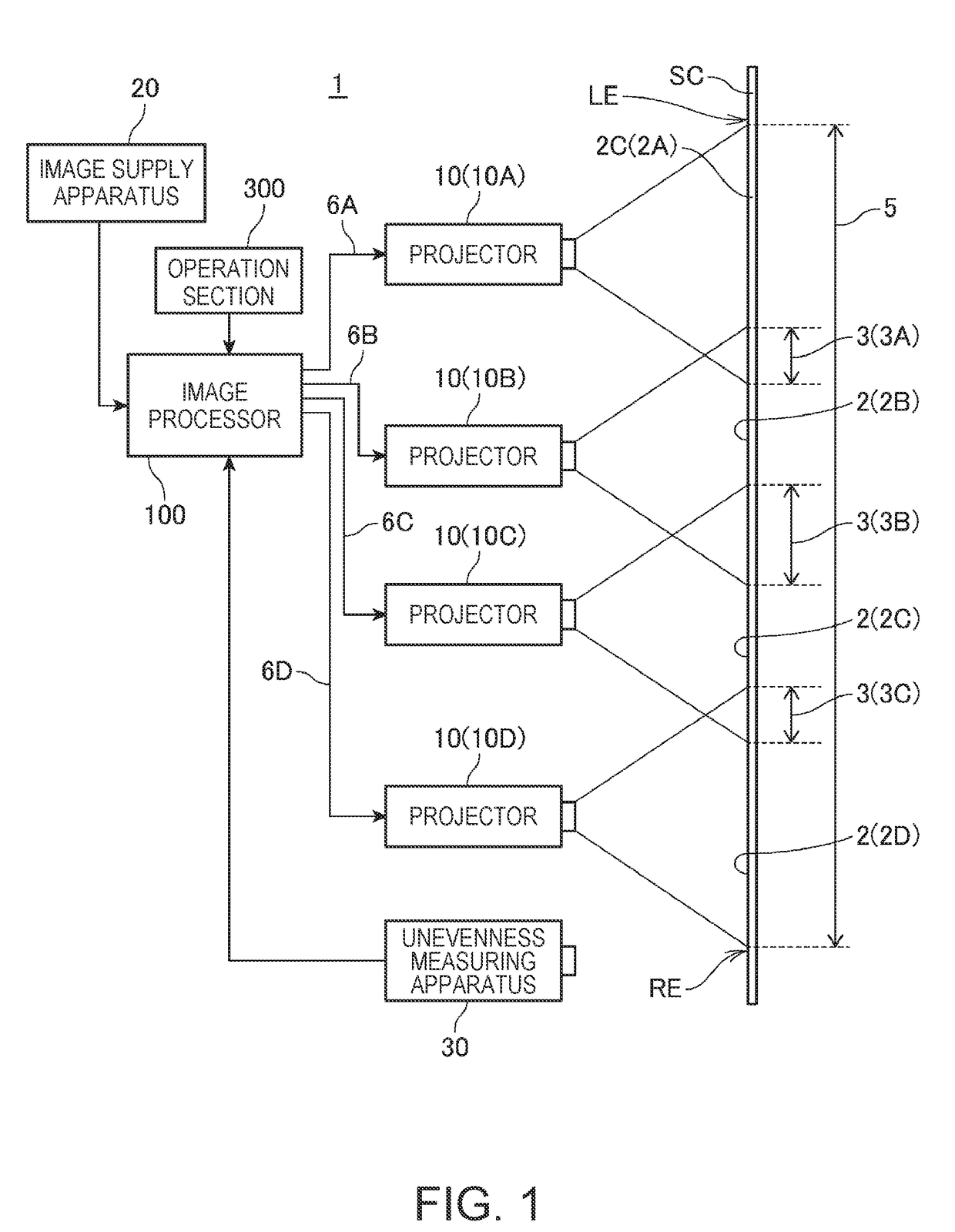

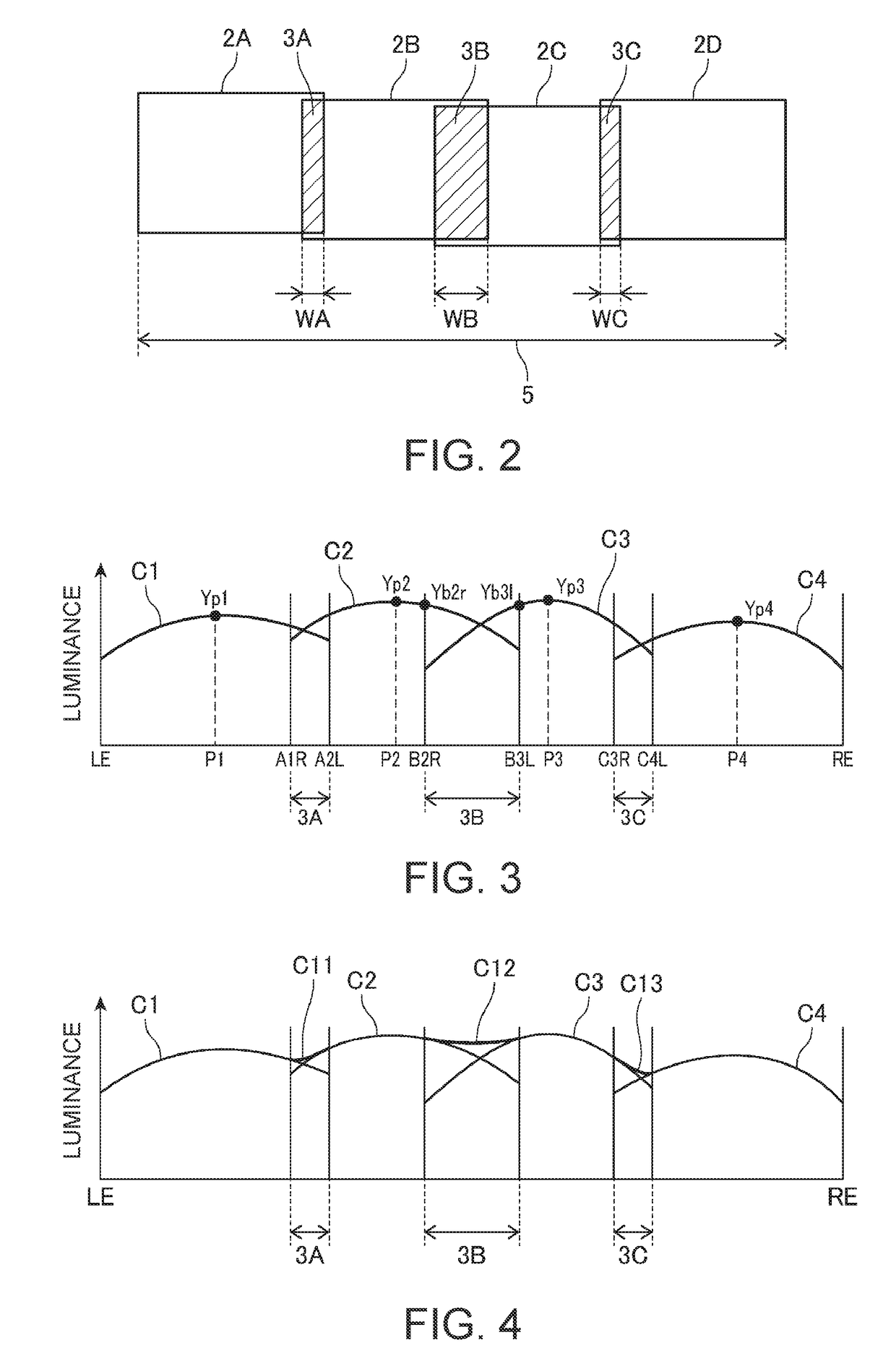

Projection system and method for adjusting projection system

ActiveUS20180013995A1Precise adjustmentImage unevennessProjectorsPicture reproducers using projection devicesProjection imageProjection system

A projection system includes three or more projectors. Each of the projectors includes a projection section that projects image light to form a projection image on a screen. The projectors are so arranged that the three or more projection images projected by the projectors form a tiled image. The projection image projected by any of the projectors and the projection image projected by an adjacent projector form an overlapping area where the projection images overlap with each other, and one of the overlapping areas differs from the other overlapping areas in terms of size.

Owner:SEIKO EPSON CORP

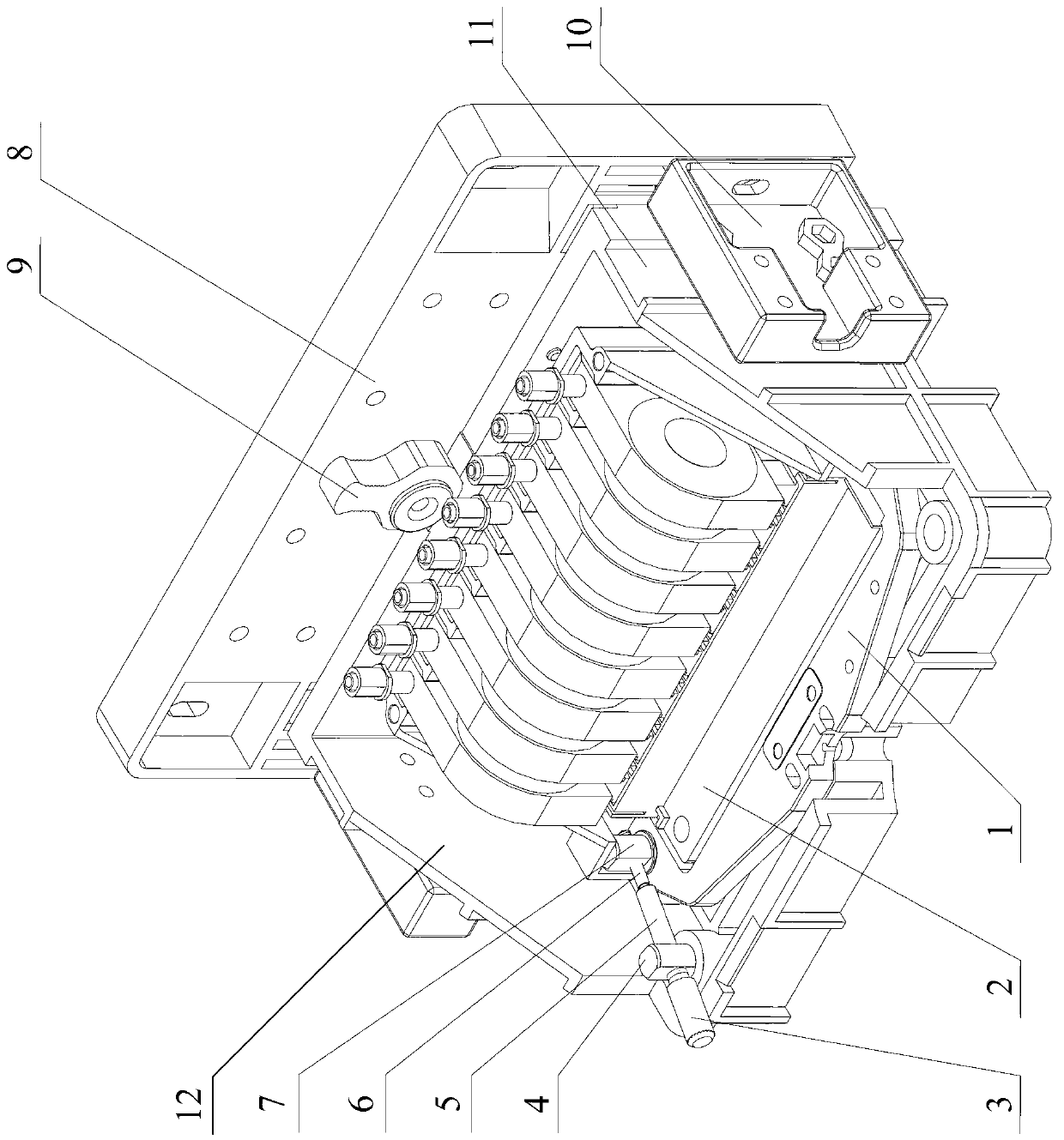

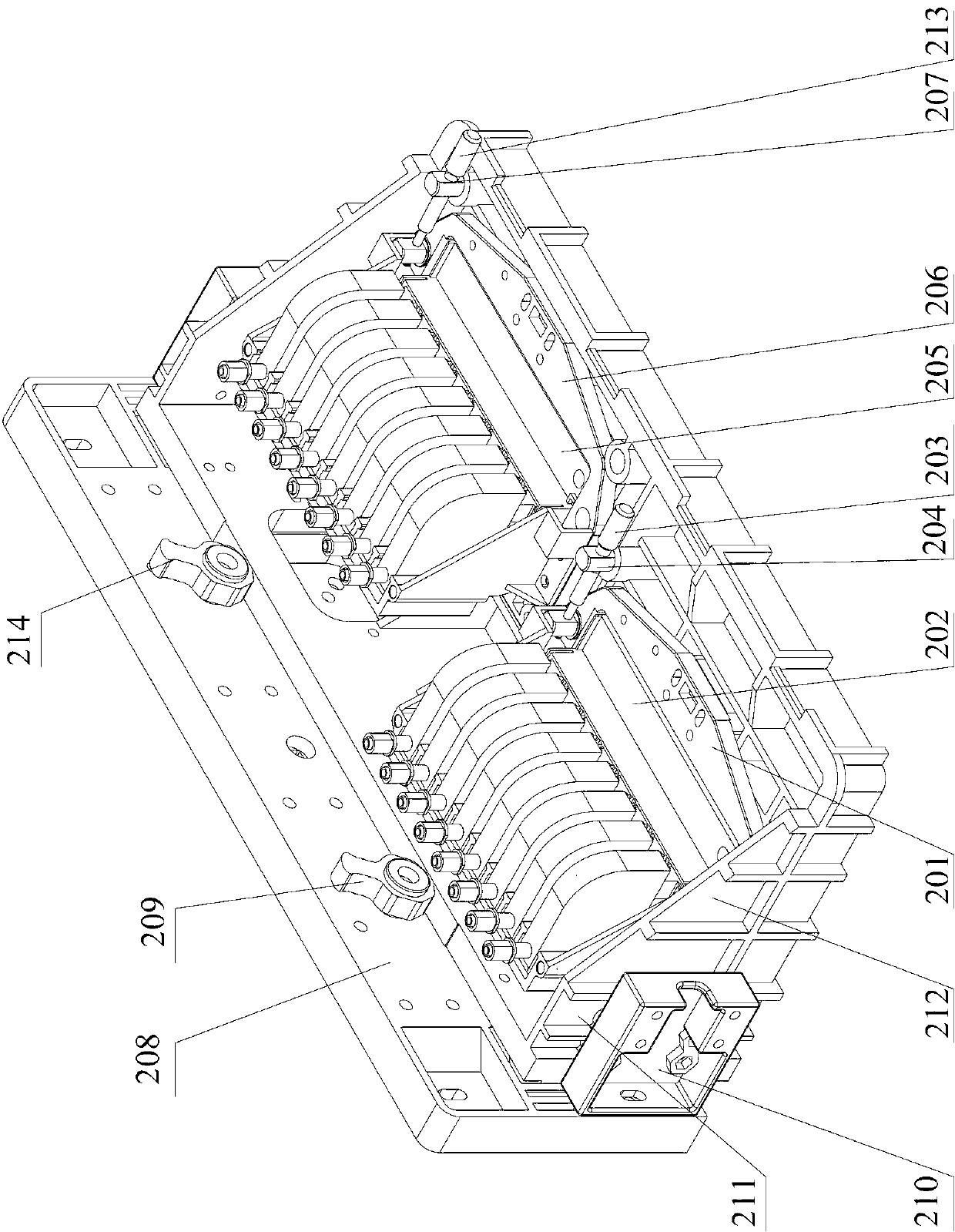

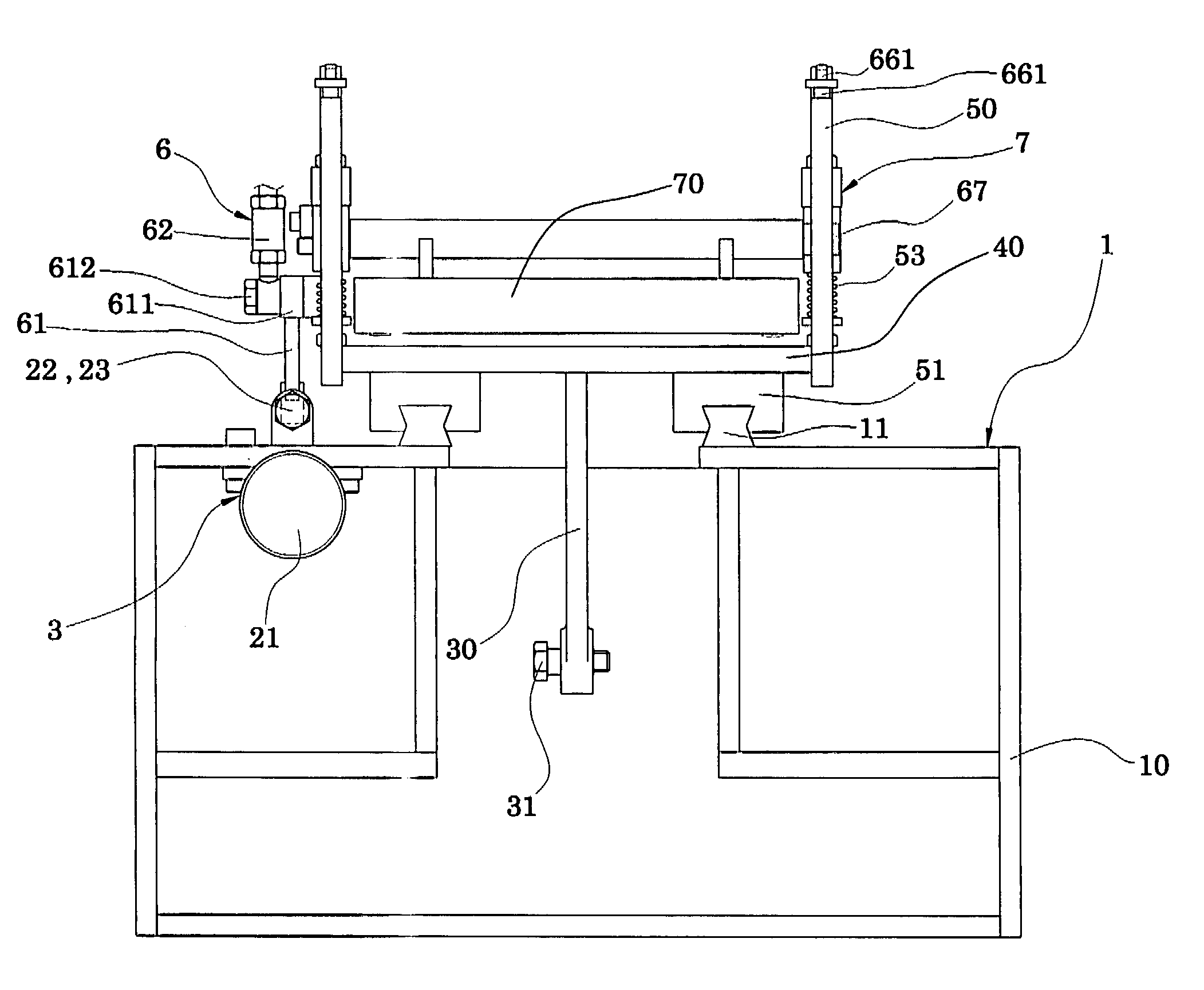

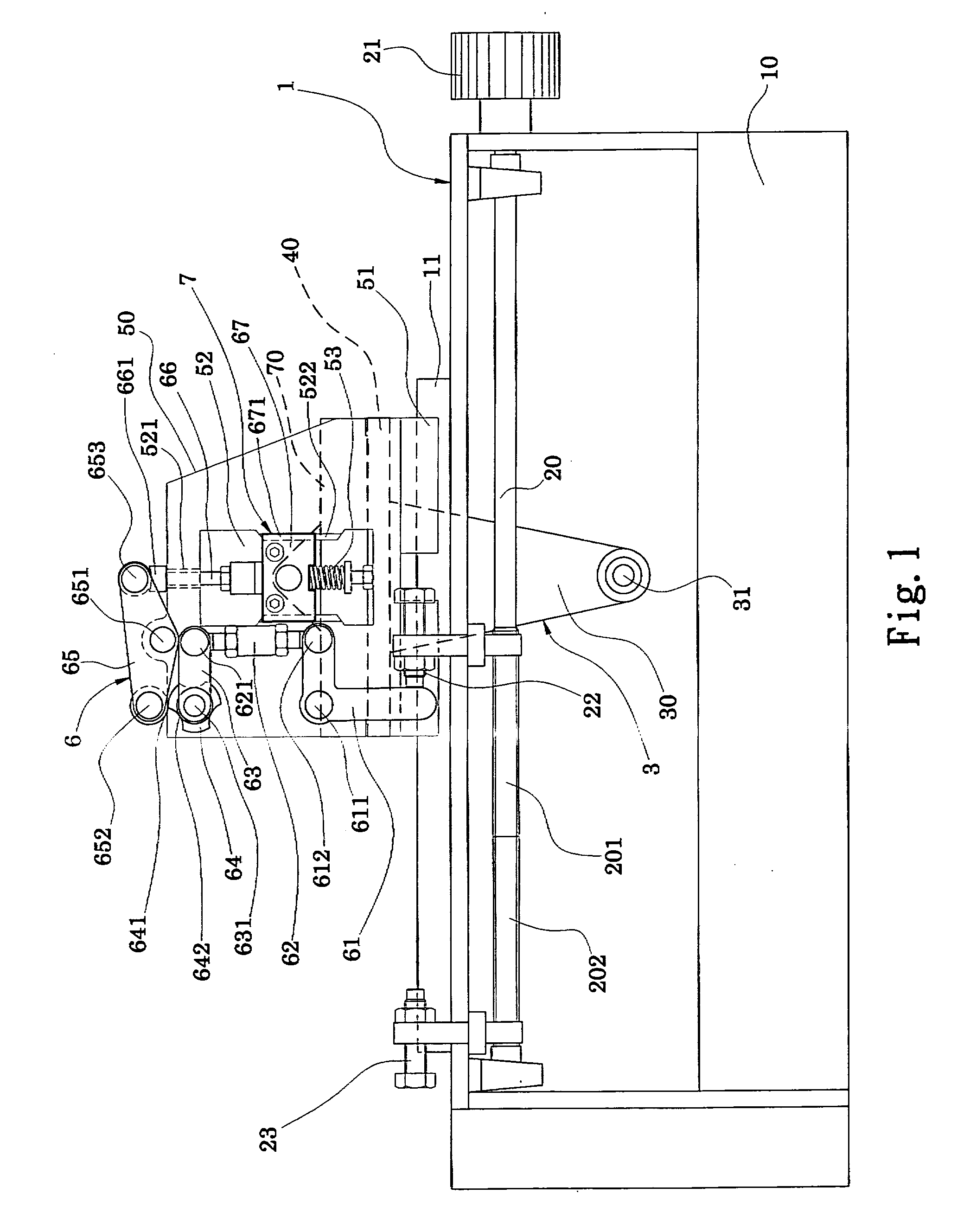

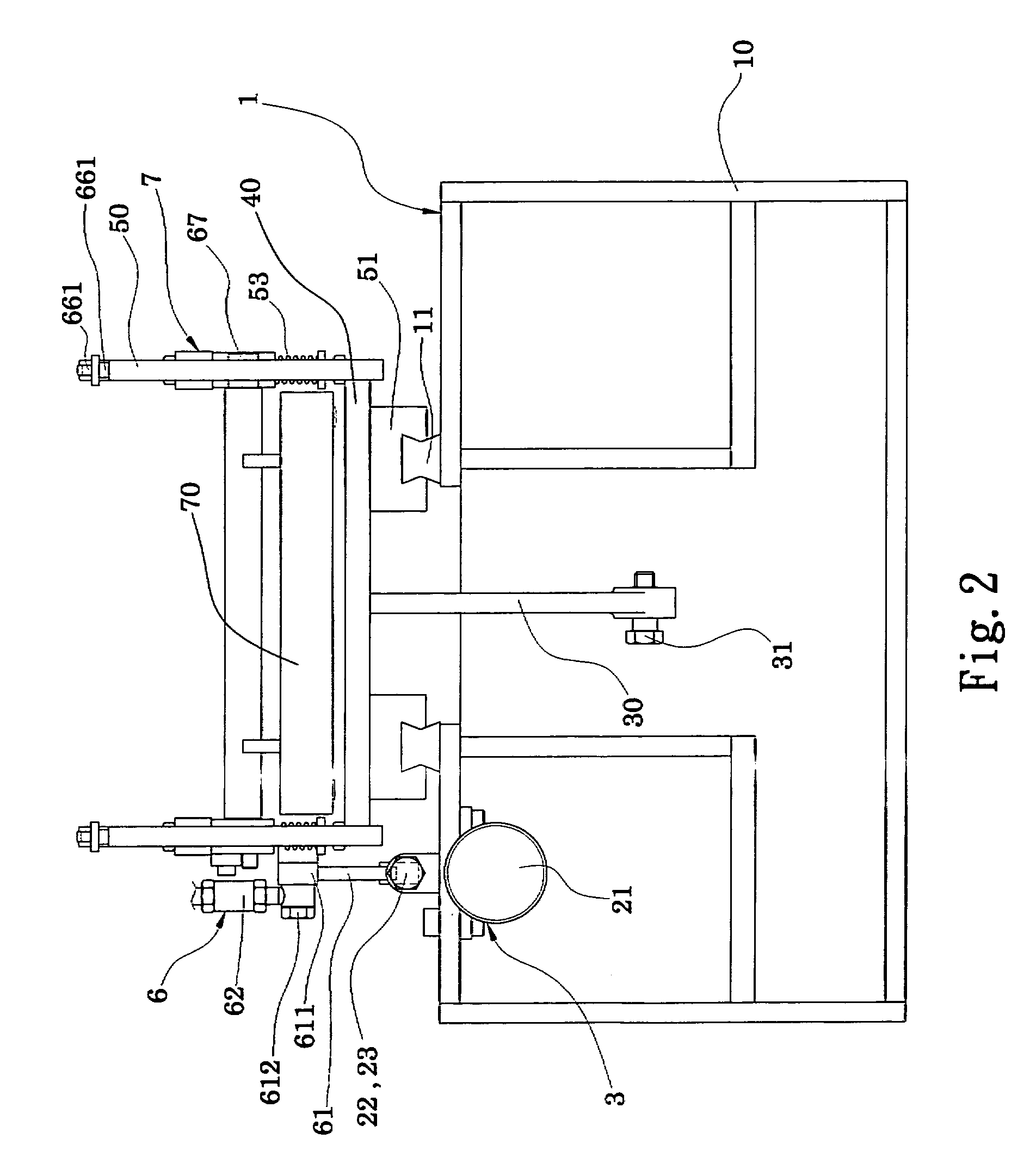

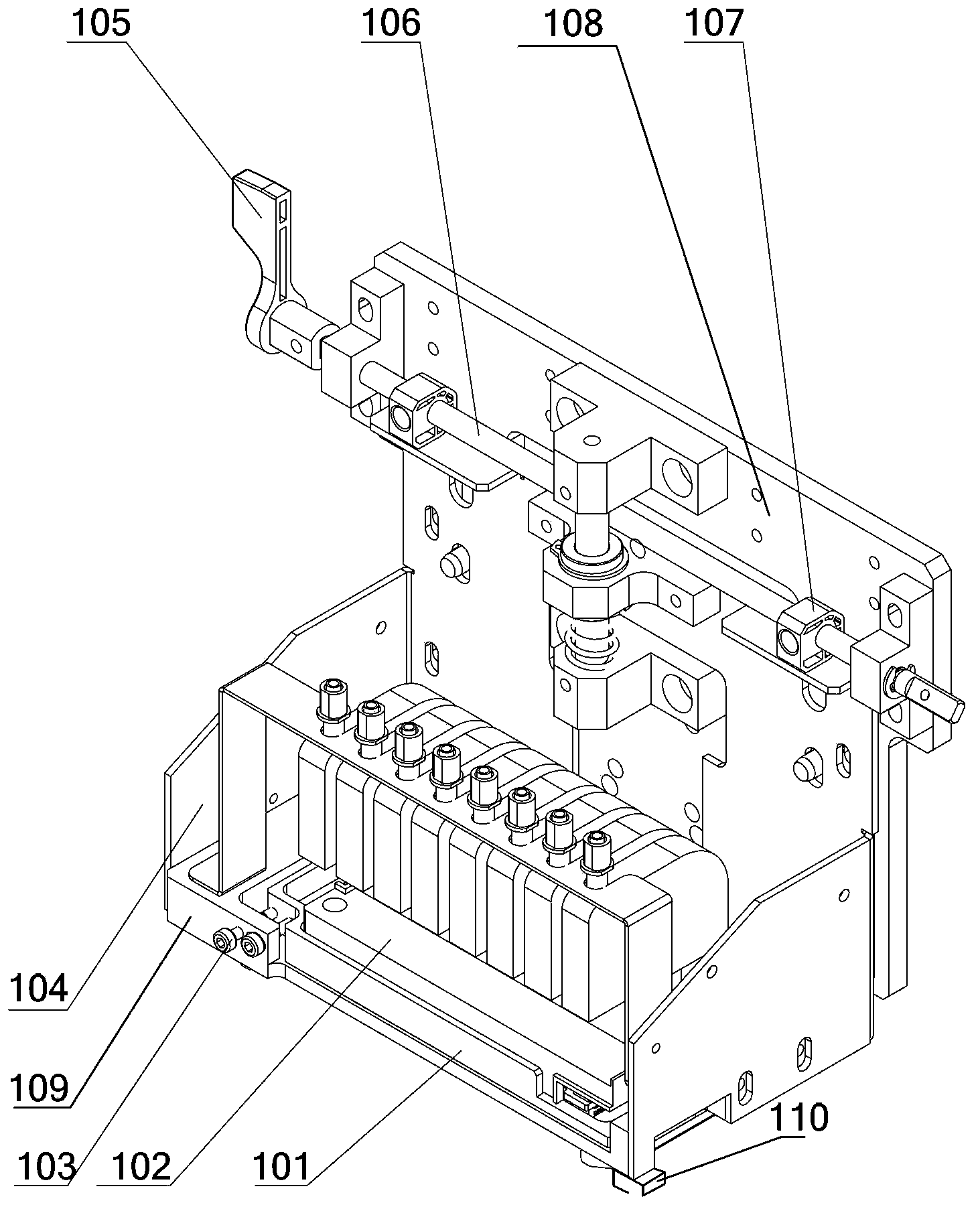

Sprayer regulating device and sprayer regulating method

The invention discloses a sprayer regulating device. The sprayer regulating device comprises a sprayer regulating board used for regulating a printer and a regulating rod parallel to a sprayer sliding board. The regulating rod is sequentially provided with a first screw thread and a second screw thread. The screw pitch of the first screw thread is bigger that the screws pitch of the second screw thread. A rotating handle is arranged on one end of the regulating rod. The end of the regulating rod is close to the first screw thread. The sprayer regulating device further comprises a first regulating nut block matched with the first screw thread in use and a second regulating nut block matched with the second screw thread in use. The first regulating nut block is fixed on a sprayer support of the printer. The second regulating nut block is fixed on the sprayer regulating board. The sprayer regulating device has the advantages that major movement fine adjustment is achieved, even twisting of the regulating rod is too much, angle of the sprayer cannot be regulated too much, regulating mode becomes more accurate, and regulating accuracy is improved. The invention further provides a sprayer regulating method.

Owner:WENZHOU ACPASS DISPLAY EQUIP

Compressed Chinese medicine decoction pieces and preparation method thereof

InactiveCN106852940AReduce volumeEasy to adjustPharmaceutical product form changePlant ingredientsPharmacologyRaw material

The present invention proposes a compressed Chinese herbal decoction piece and its preparation method. The compressed Chinese herbal decoction piece is made of traditional Chinese medicine decoction piece or crude drug. The shape itself, the properties of the Chinese herbal decoction pieces or the crude drug in the compressed Chinese herbal decoction pieces remain unchanged. The compressed Chinese medicine decoction pieces of the present invention are small in size, which is beneficial for storage, packaging, storage and transportation; the compressed decoction pieces increase the stability of the Chinese medicine components and reduce the divergence of volatile components; The compressed decoction pieces are convenient for formula adjustment of traditional Chinese medicine, which makes the formula adjustment more accurate and the adjustment efficiency higher; the preparation method is simple, the cost is low, and it is suitable for industrial production.

Owner:韩丰河

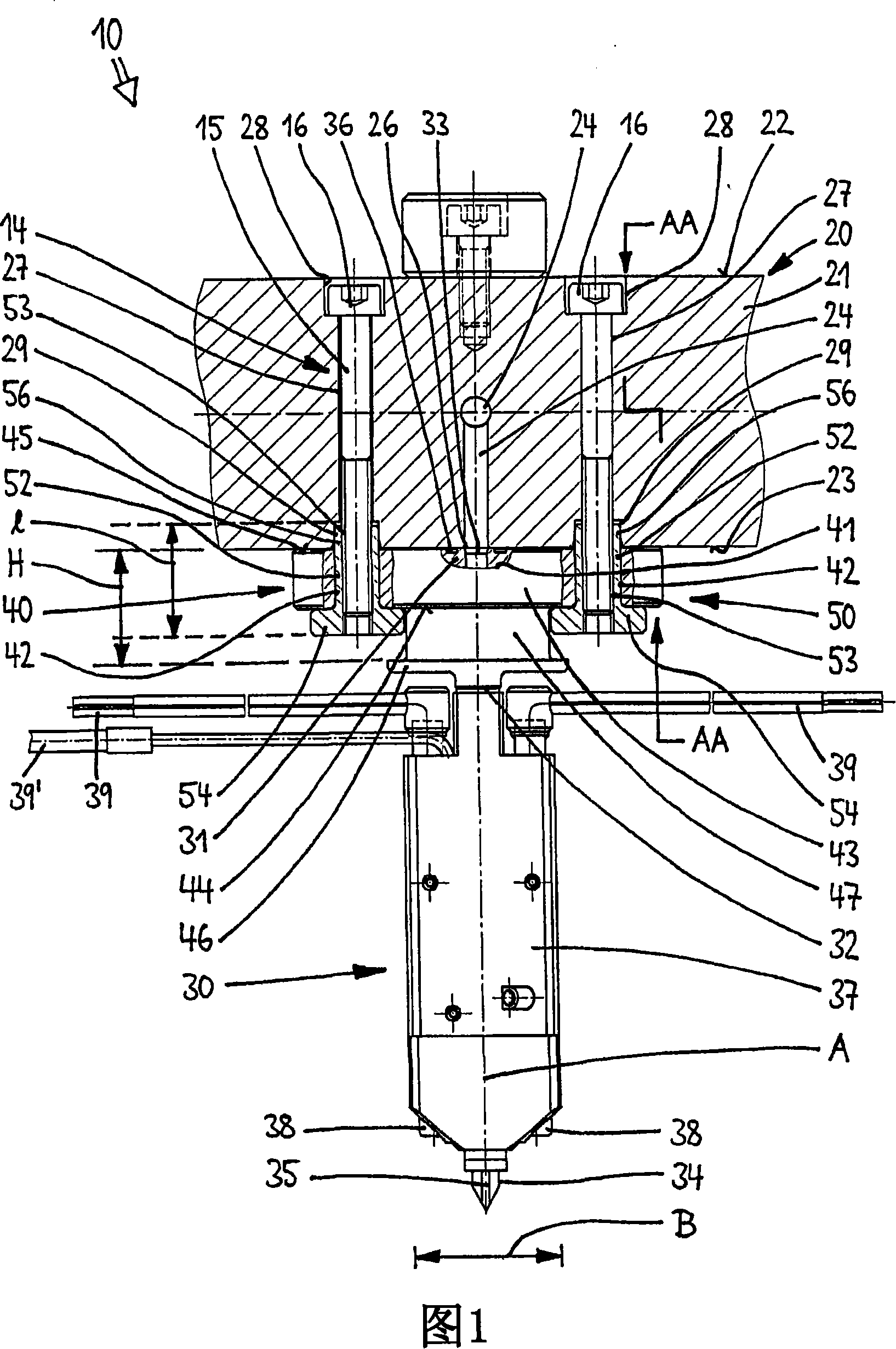

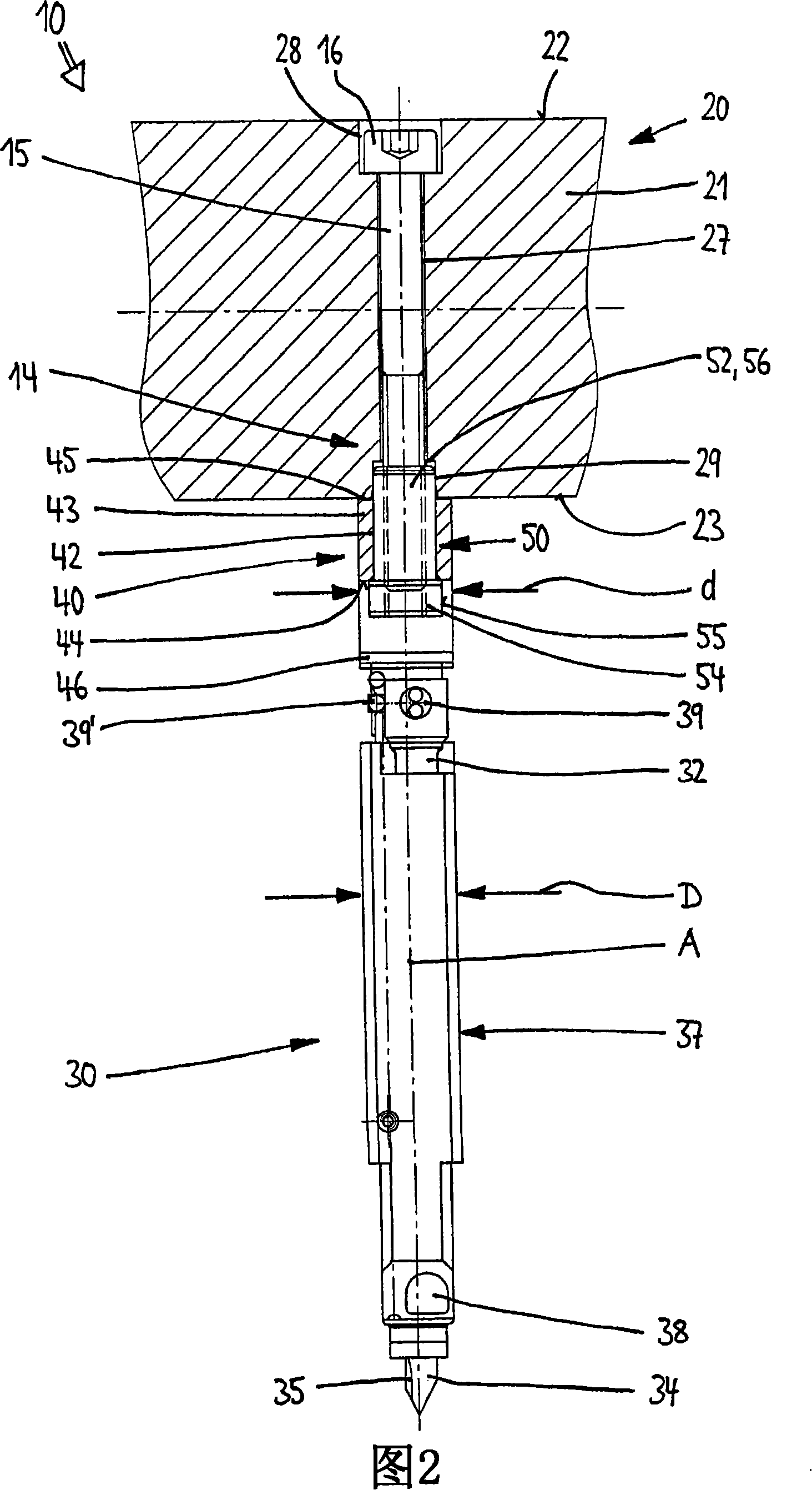

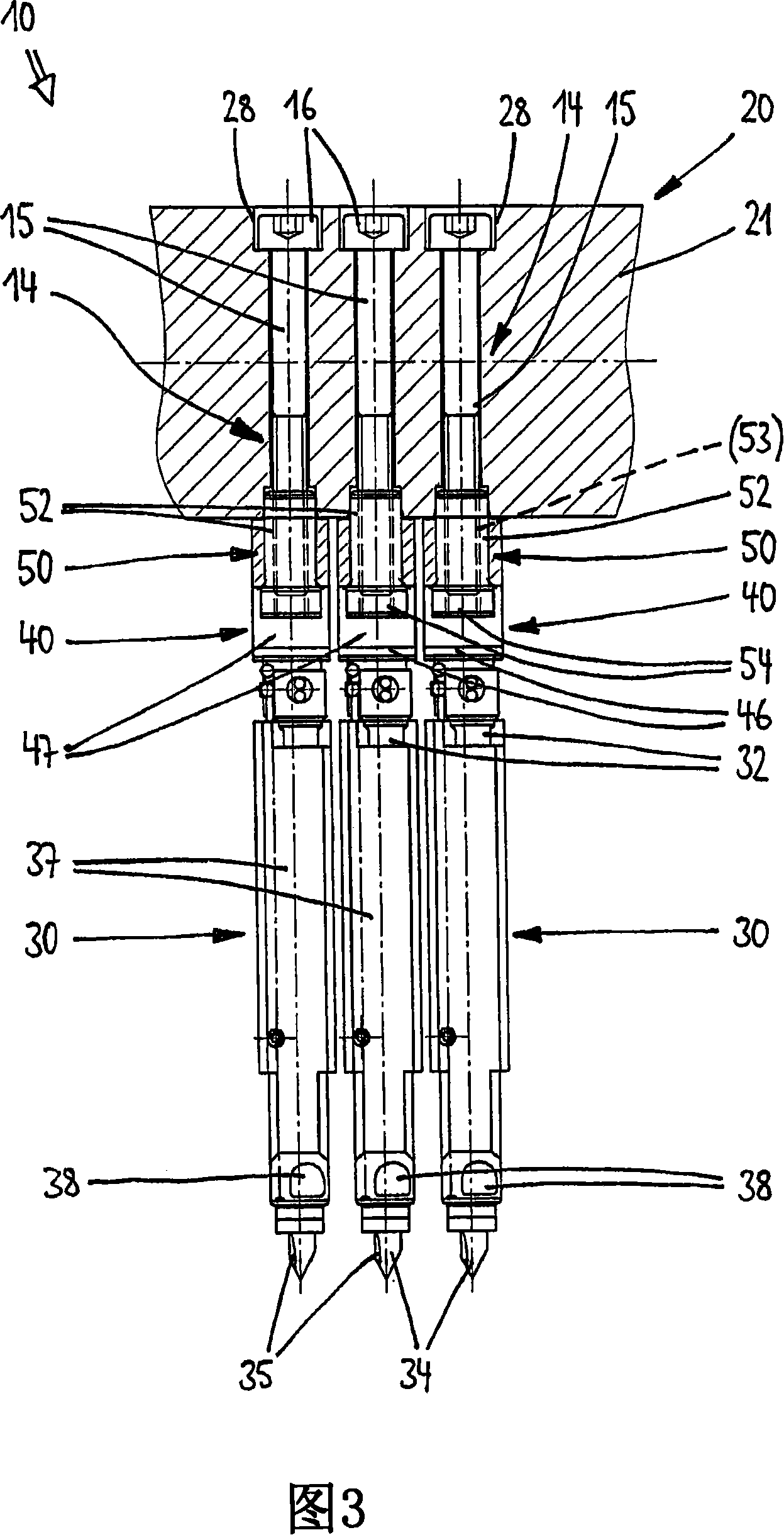

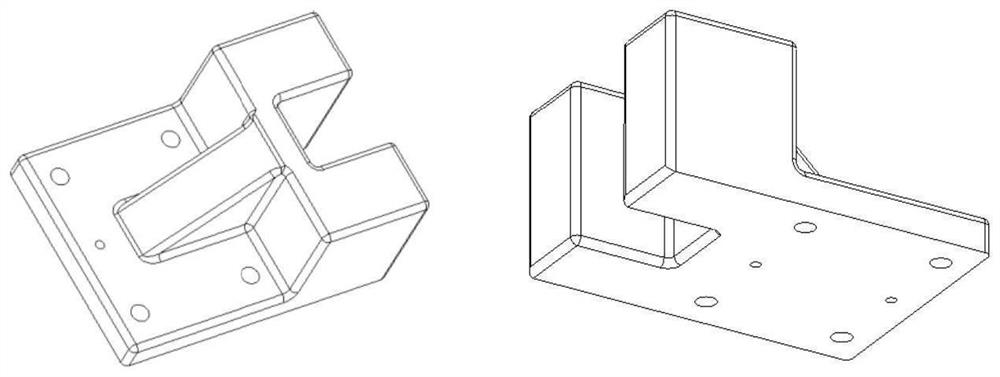

Injection moulding device

InactiveCN101115602AUnimpeded inflowQuick and comfortable positioning and fixingEngineeringInjection moulding

The invention relates to an injection moulding device (10) comprising at least one distributor (20) and at least one injection mould nozzle (30) wherein each nozzle (30) is fixed to the distributor (20) by means of a holding element (40). In order to carry out a rapid mounting and ensure a long lasting sealing of all distributor nozzles, the holding element (40) is provided with at least one centring and / or fixing element (50) which is longitudinally displaceably arranged and is connectable to the distributor (20) in a final assembly position in such a way that the distributor (20) and the nozzle (30) are fixed to each other. The holding element (40) comprises at least one recess (41) for receiving the nozzle (30) and at least one other recess (42) for receiving the fixing element (50), which is longitudinally displaceably arranged therein. In the preferred embodiment, the fixing element (50) is embodied in the form of a fixing element for the holding device (40), in particular, a screw connection part (14).

Owner:GUENTHER HEISSKANALTECHNIK GMBH

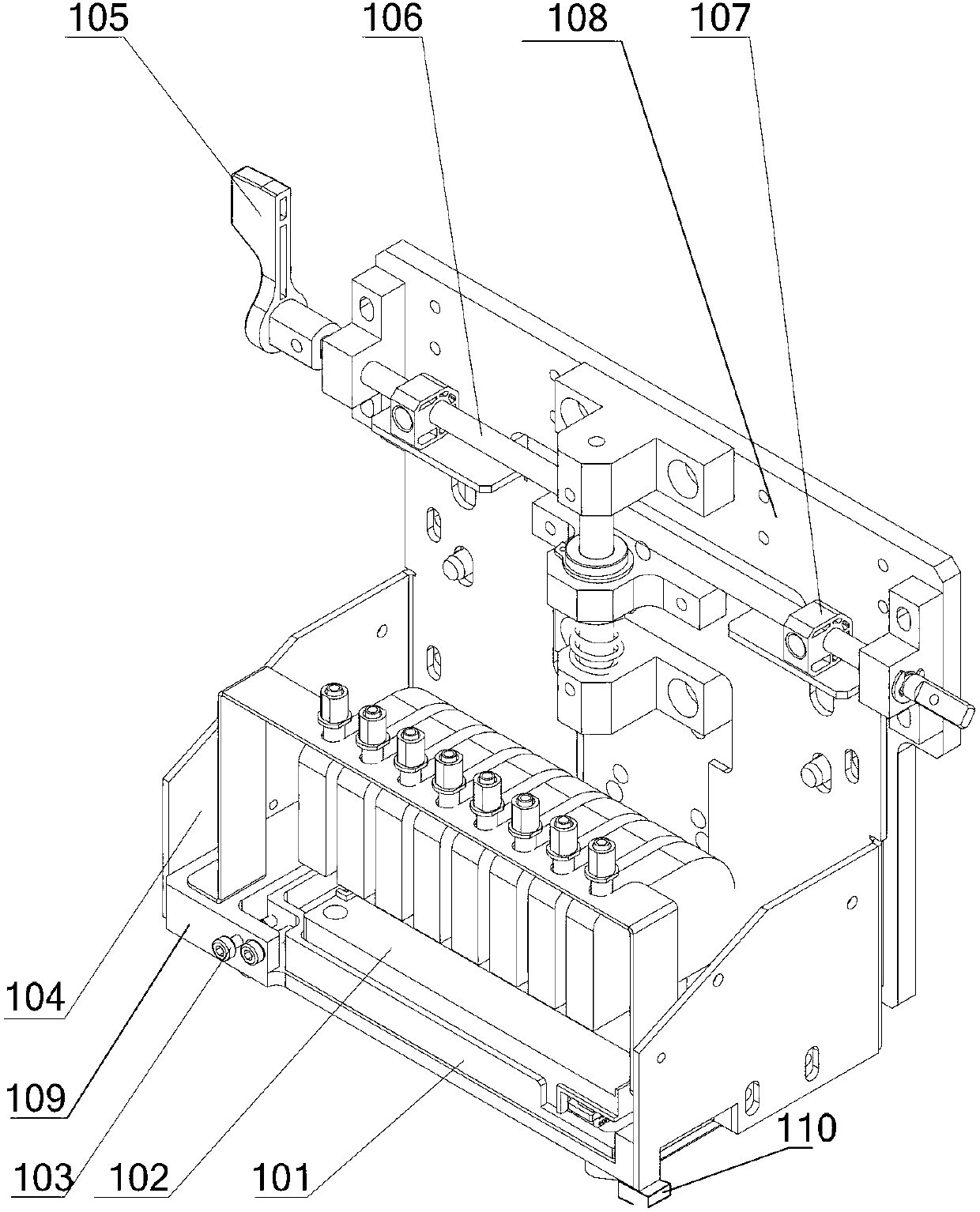

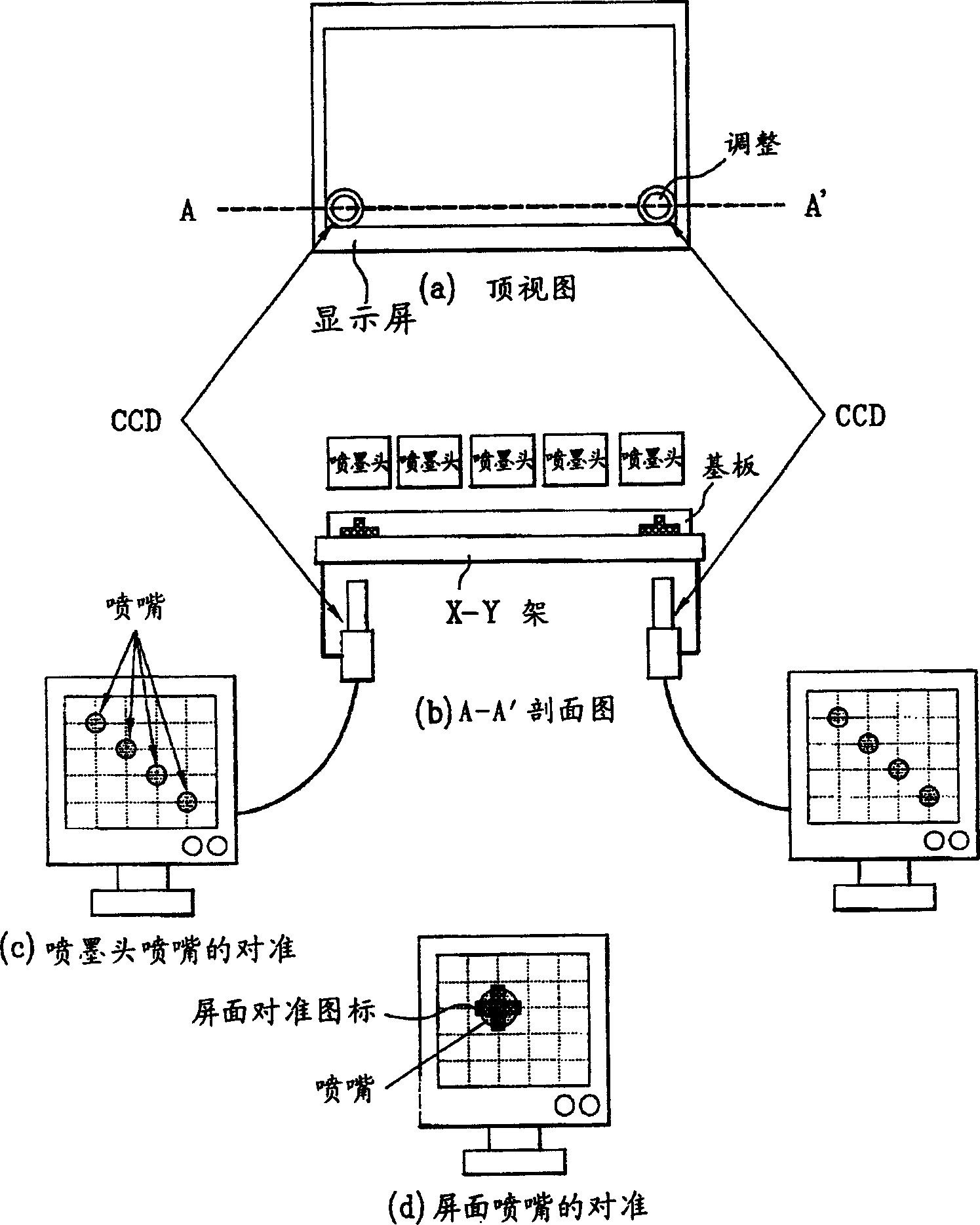

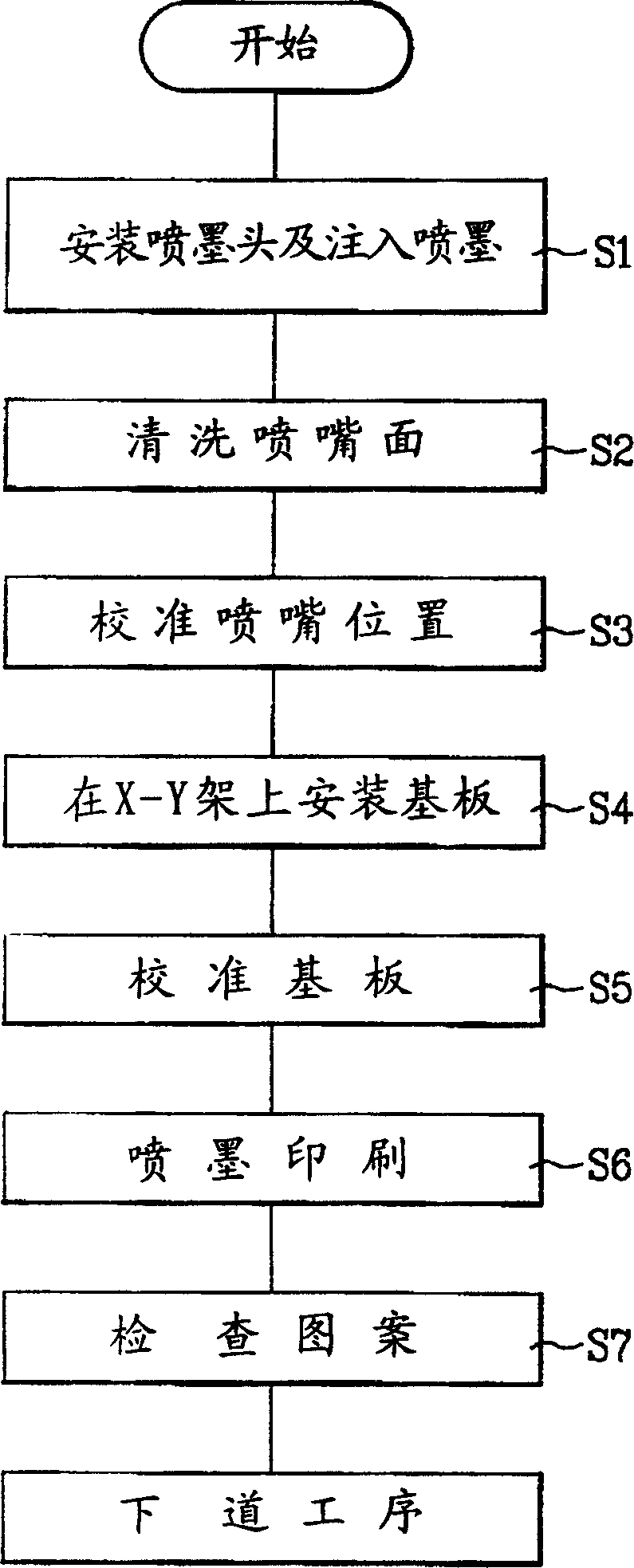

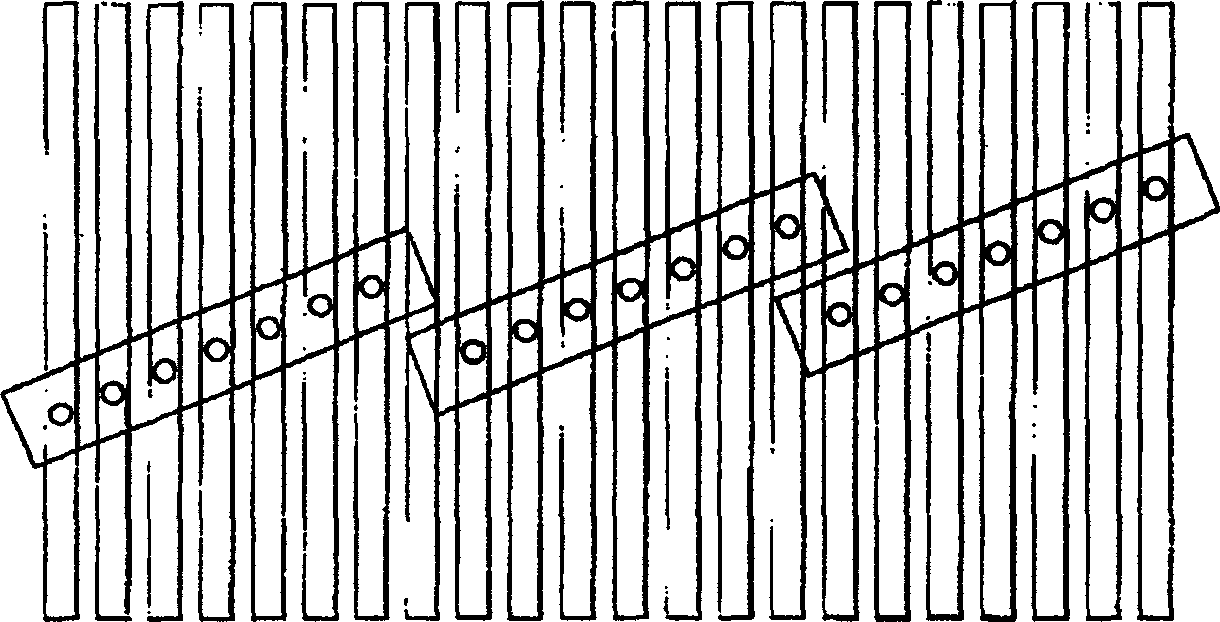

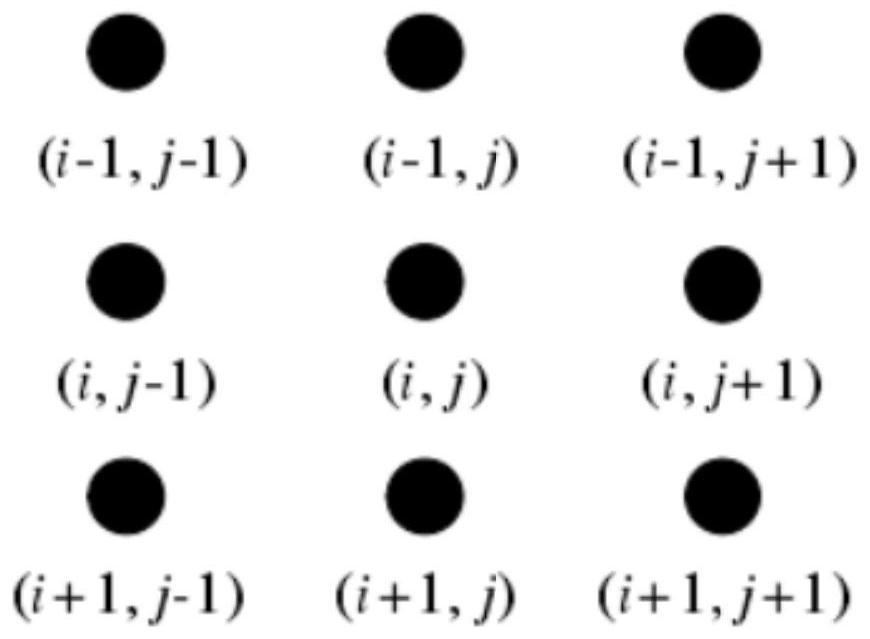

Ink jet position regulator for making display screen

The ink jet position regulator for making display screen consists of several position regulating ink jetting heads capable of aligning the jet position and several CCD cameras capable of regulating ink jetting heads to make nozzles of the ink jetting heads align to image pixel pitch formed lattice. The present invention has no demerits in traditional technology, and has simple making process, low cost, high efficiency, accurate position regulation, no double ghost in the displayed image and high product quality.

Owner:LEIJIN ELECTRONIC SHENYANG CO LTD

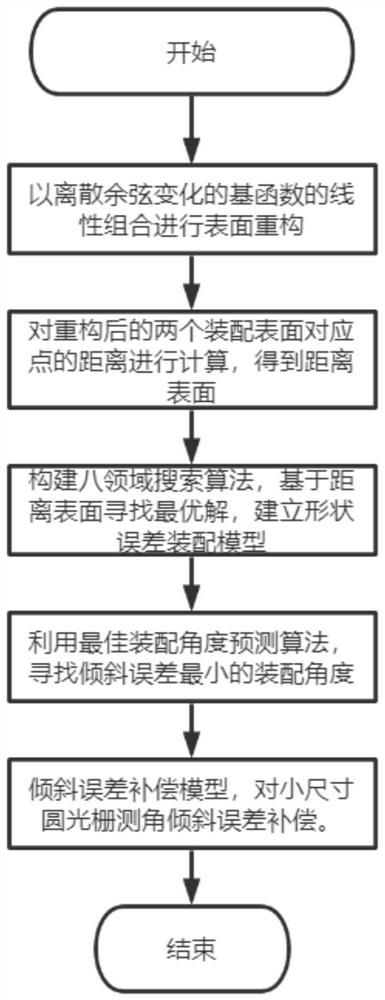

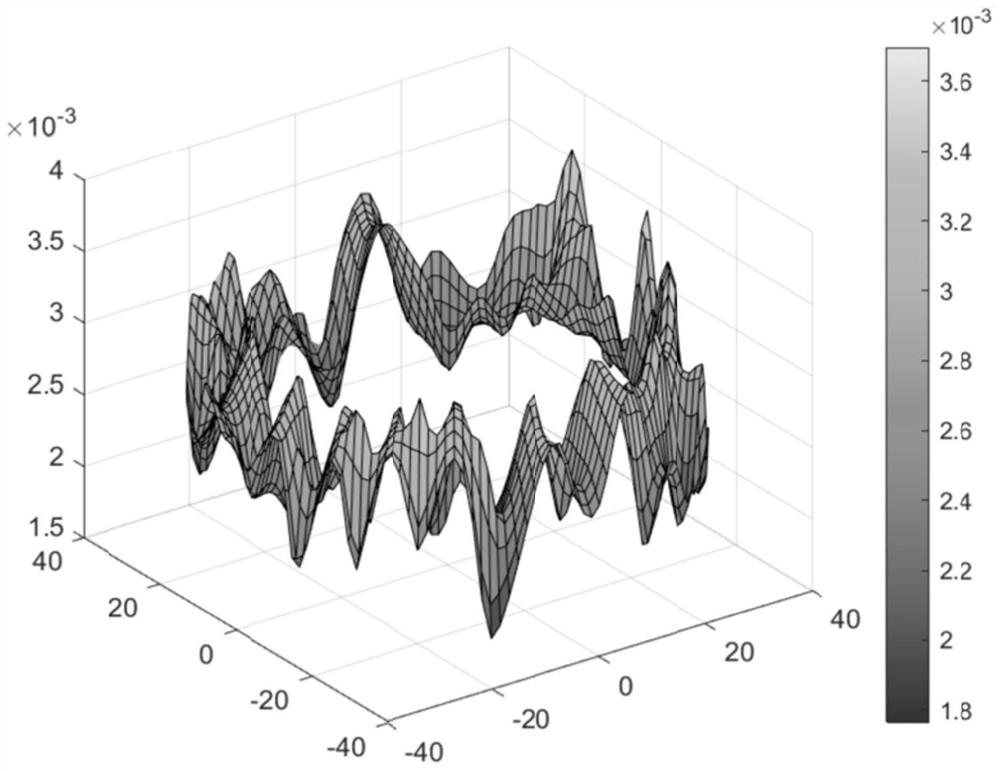

Method and system for optimizing assembly tilt error of circular grating encoder

PendingCN114417532ARealize precise adjustmentImprove measurement efficiencyGeometric CADUsing optical meansGratingAngular degrees

The invention discloses a circular grating encoder assembly inclination error optimization method and system, and the method comprises the steps: building an assembly model based on the geometric shape error of a bearing part of a circular grating encoder, calculating the inclination deviation of assembly, taking an initial assembly position as a reference, enabling a coded disc installation hub to rotate for a circle when the coded disc installation hub rotates for 30 degrees relative to a central spindle, and enabling the coded disc installation hub to rotate for a circle; analyzing the assembly inclination deviation at each position, establishing an optimal assembly angle model, finding an optimal assembly angle, analyzing and modeling the assembly angle of the circular grating encoder, and establishing an assembly model by sampling the shape error of the assembly surface, so that the measurement efficiency and the measurement precision are improved; the installation of a circular grating bearing part is guided according to the model, so that the installation inclination deviation is reduced, the influence of the installation inclination deviation on the angle measurement precision of the circular grating encoder is reduced, the angle measurement precision is improved, and the method has a remarkable effect and important significance for a precise angle measurement system of the circular grating encoder.

Owner:XI AN JIAOTONG UNIV

Continuous feeder

InactiveUS20080156620A1Precise adjustmentEasy to adjustConveyorsMetal-working feeding devicesEngineeringHardness

The present invention is a continuous feeder which, through a power source, can continuously drive a fixing clip to move back and forth equidistantly and also a mobile clip at the top of the fixing clip, so that when the fixing clip arrives the return point, the material can be downwardly clipped or upwardly released for achieving a continuous feeding. The present invention not only can precisely adjust the moving distance of material in processing for continuously and accurately driving the material to the operation tool, but also can change the driving method for the material to be pull or push in response to the hardness degree of the material.

Owner:SUN YIEH IND

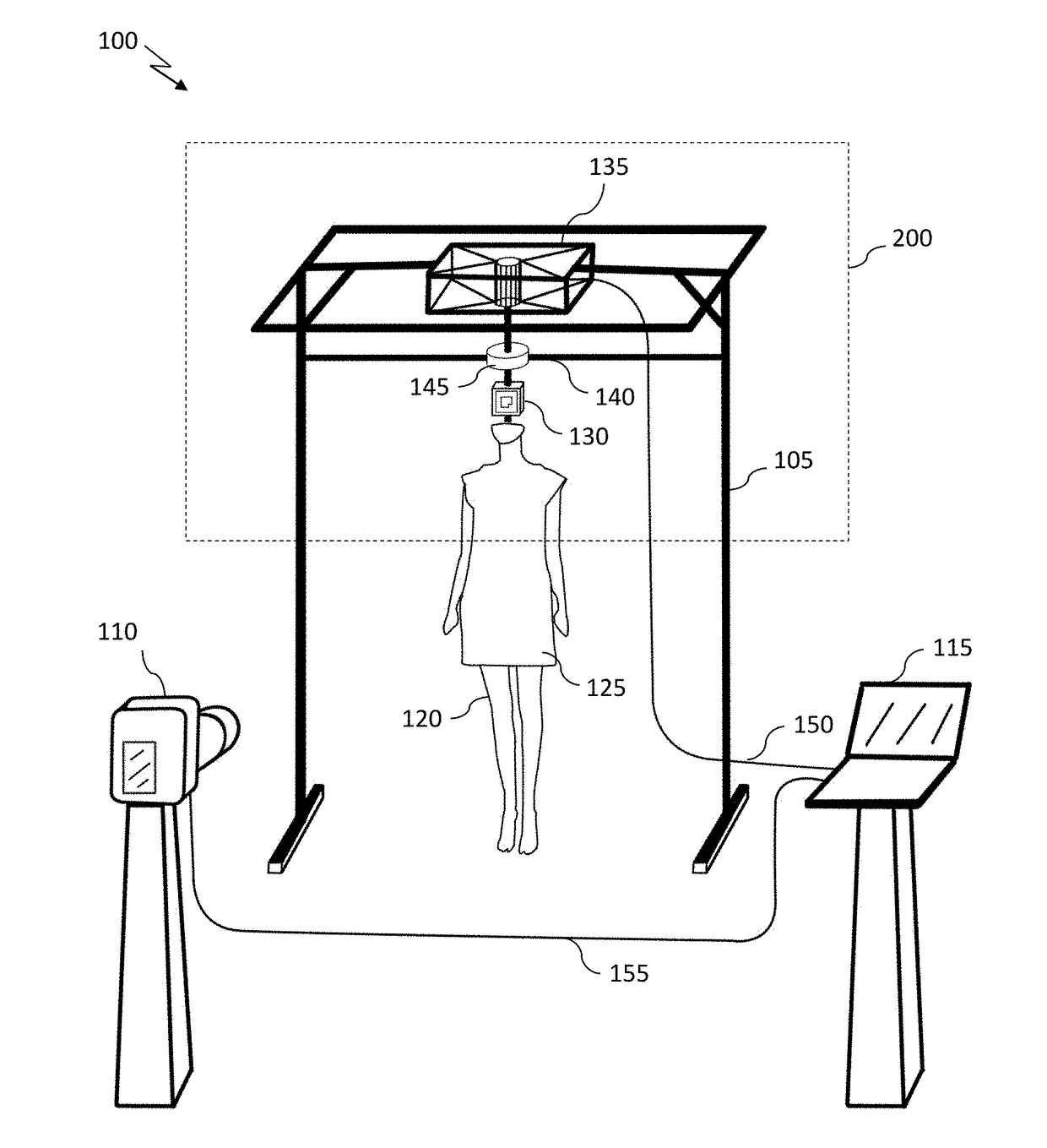

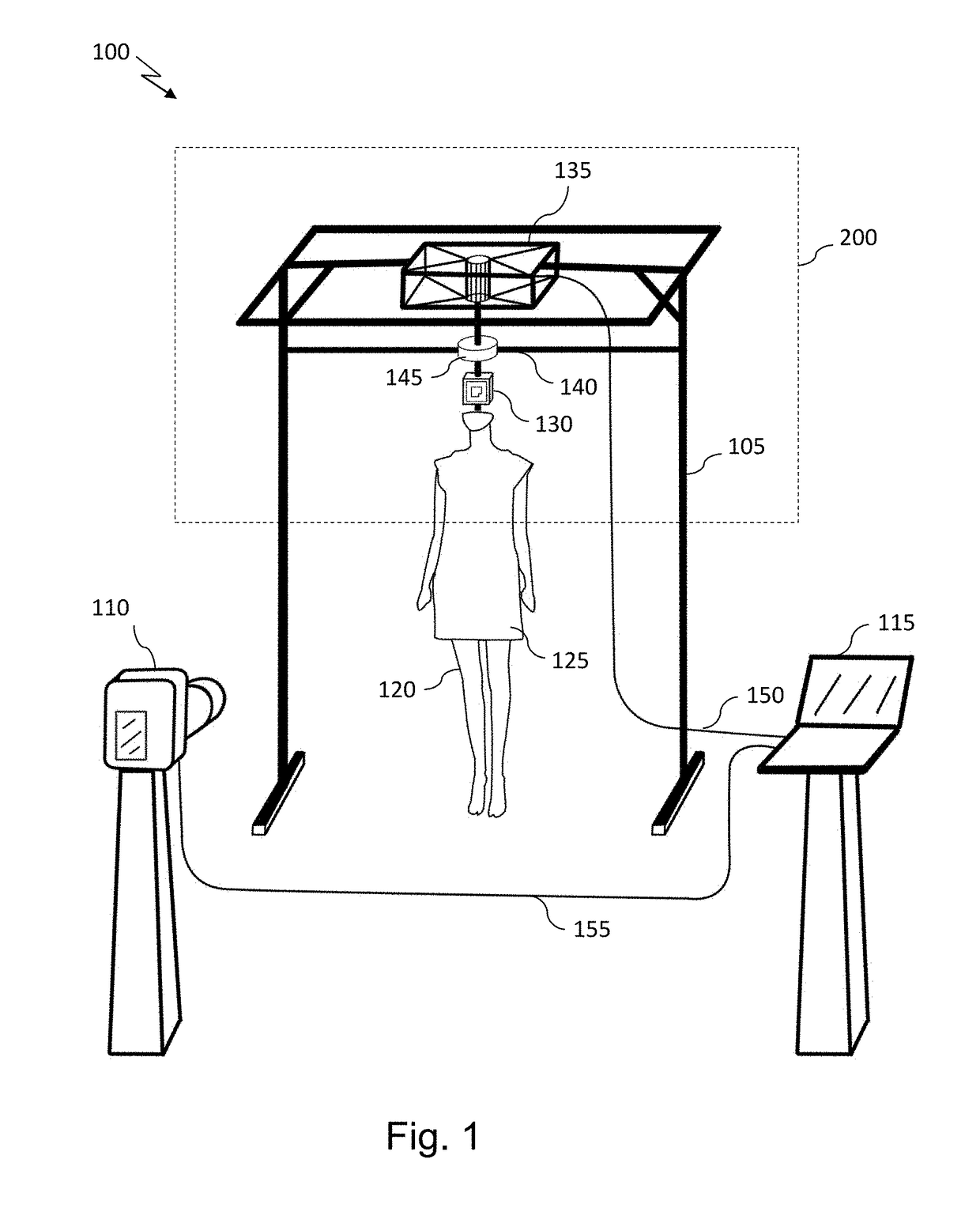

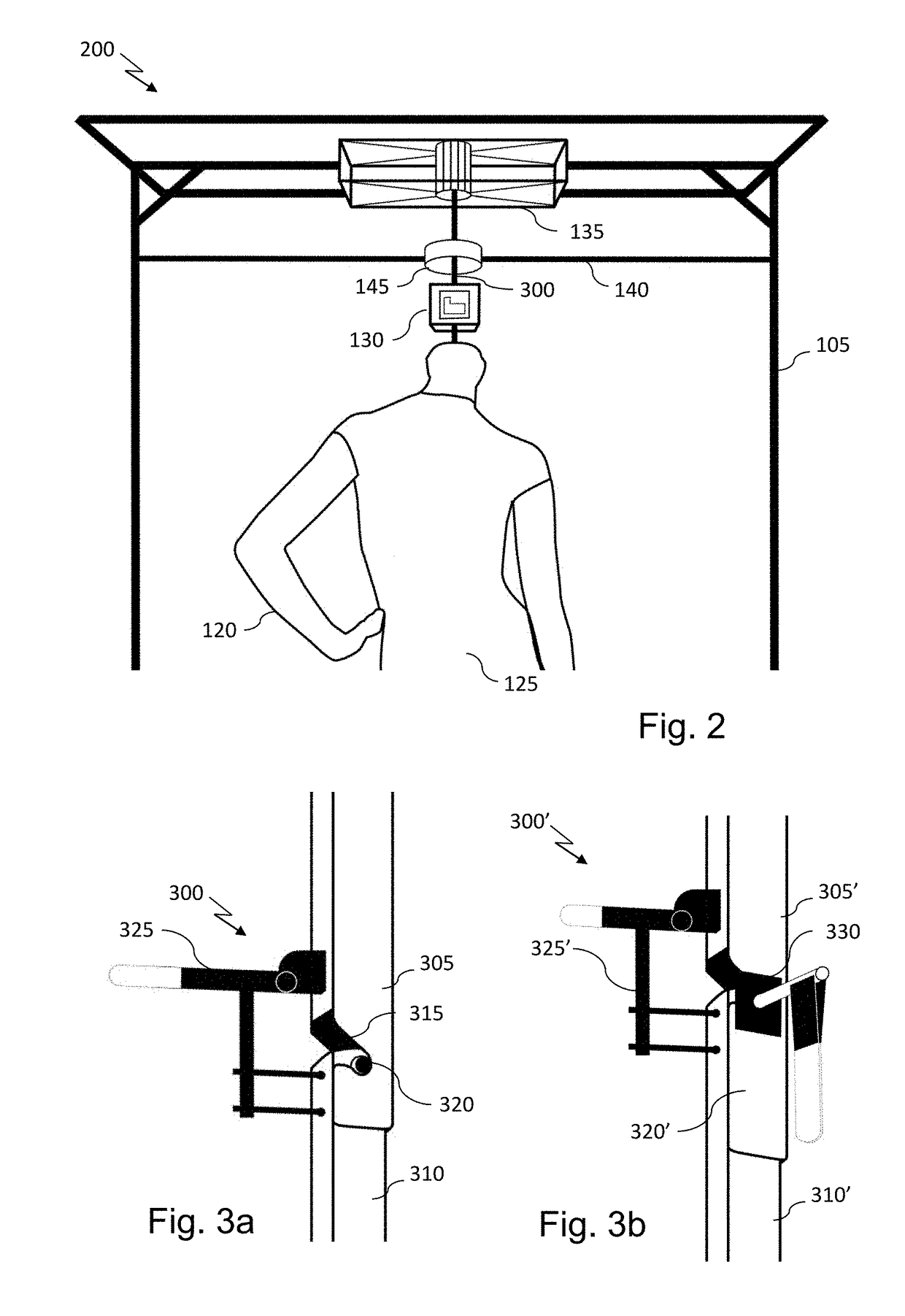

Set and method for assisting in the shooting of images of objects presented on a mobile removable support

ActiveUS20170228911A1Save timePrecise adjustmentImage analysisCharacter and pattern recognitionComputer visionComputer graphics (images)

Disclosed is a set for assisting in the shooting of images of an object including a mobile removable support (120) configured to receive the object, a unit (135) for modifying the pose of a member, including a unit for rigid fastening by suspension of the support, making it possible to modify the pose of the support, image shooting unit (110) enabling images to be obtained representing the support and the object placed on the support as well as computing unit (115) for receiving images from the image shooting unit, analyzing the images received and, in response to an analysis of those images and predetermined position information, controlling the unit for modifying the pose of a member.

Owner:ALLURE SYSTEMS RESEARCH FRANCE

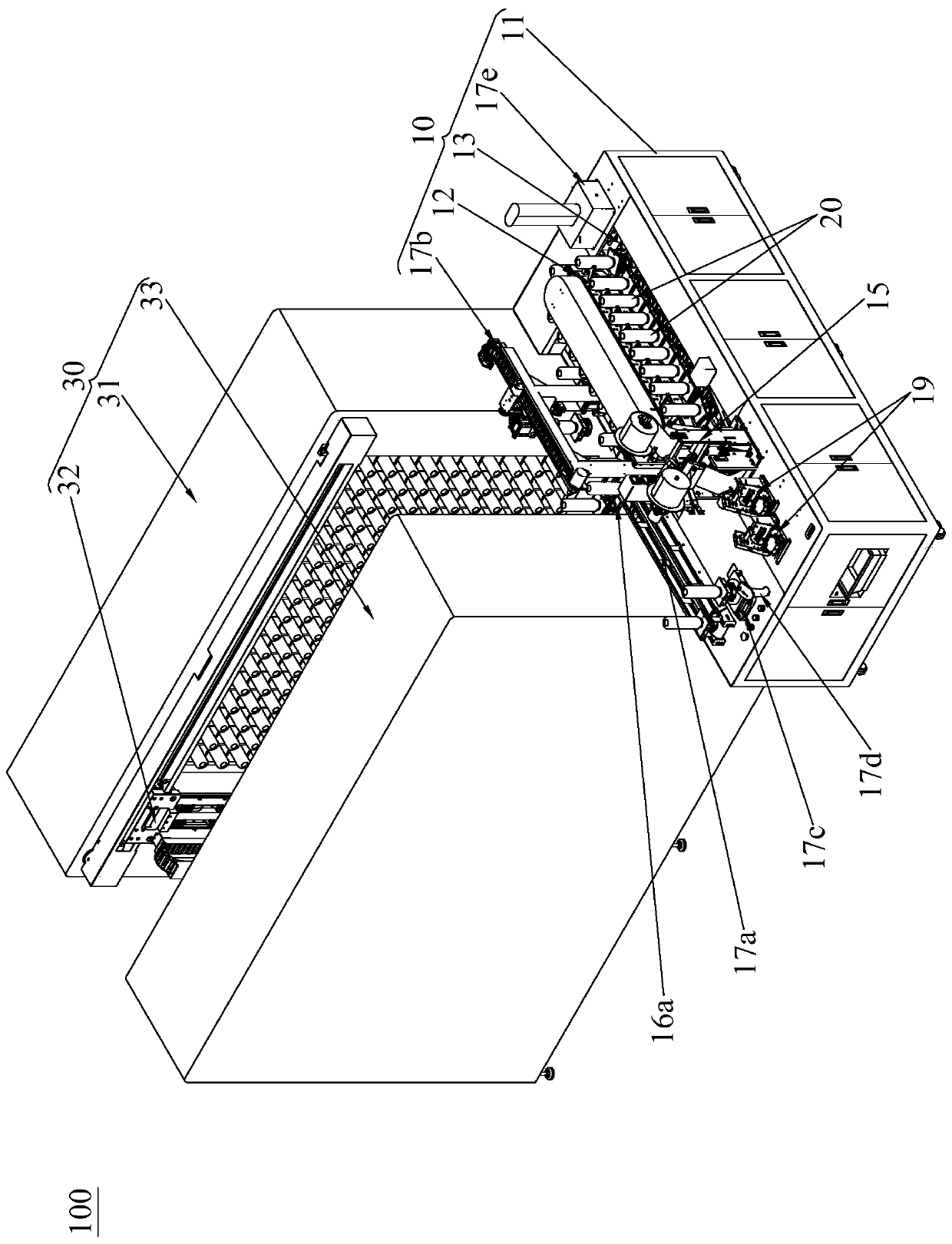

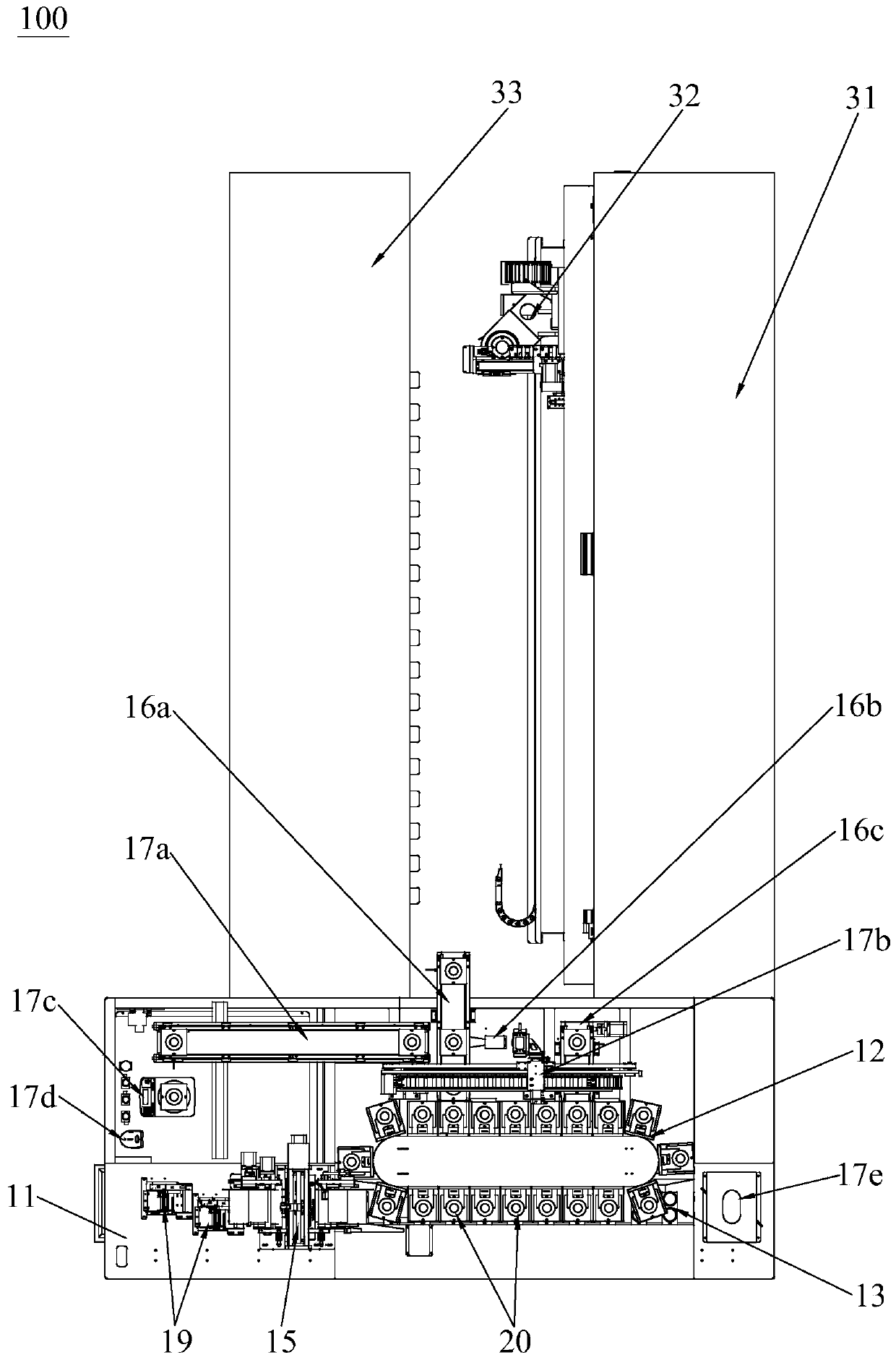

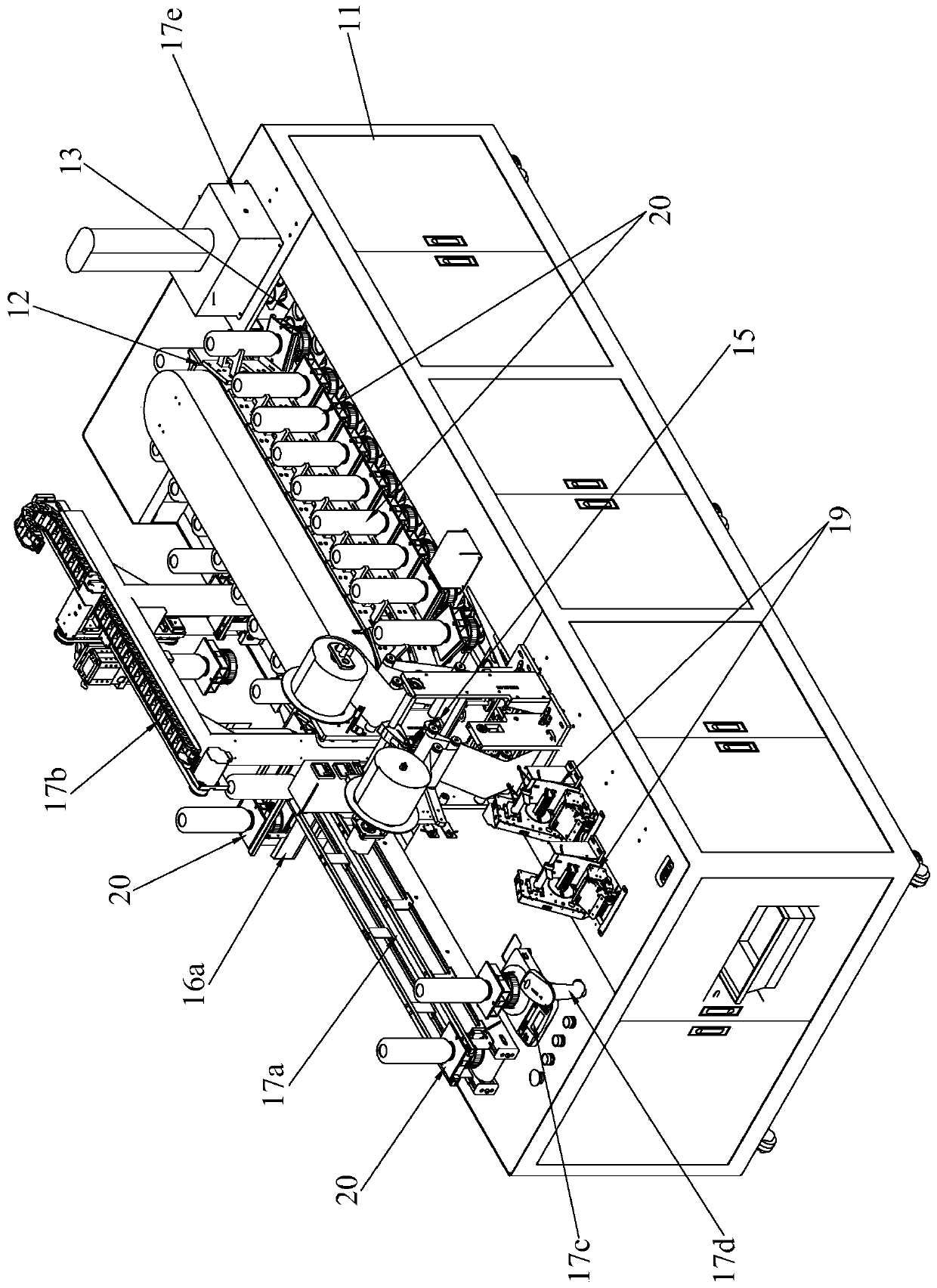

Automatic dispensing equipment

PendingCN111232267APrevent hardeningSimple structural designWrapper twisting/gatheringSolid materialDrugProcess engineering

The invention provides automatic dispensing equipment. The equipment comprises a dispensing and subpackaging cabinet and a plurality of drug storage and distribution assemblies; the drug storage and distribution assemblies are used for storing and quantitatively distributing formula granules to be dispensed, and the dispensing and subpackaging cabinet comprises a rack as well as a dispensing conveyer, a drug cup conveyer, a dispensing and distribution drive device and a packaging device which are arranged on the rack; a plurality of distribution stations are distributed on a drug bottle conveying line, a cup receiving station, drug receiving stations located below the distribution stations in a one-to-one correspondence manner, a packaging station and a discharging station are sequentiallydistributed on the drug cup conveying line; the dispensing conveyer receives and conveys the drug storage and distribution assemblies along the drug bottle conveying line, the drug cup conveyer is arranged at the cup receiving station to receive drug cups and sequentially conveys the drug cups to the drug receiving stations, the packaging station and the discharging station along a drug cup conveying line, the dispensing and distribution drive device drives the drug storage and distribution assemblies conveyed to the distribution stations to quantitatively distribute the formula granules to fall into the drug cups conveyed to the corresponding drug receiving stations, and the packaging device performs sealing packaging on the drug cups conveyed to the packaging station.

Owner:SHENZHEN COLIBRI TECH

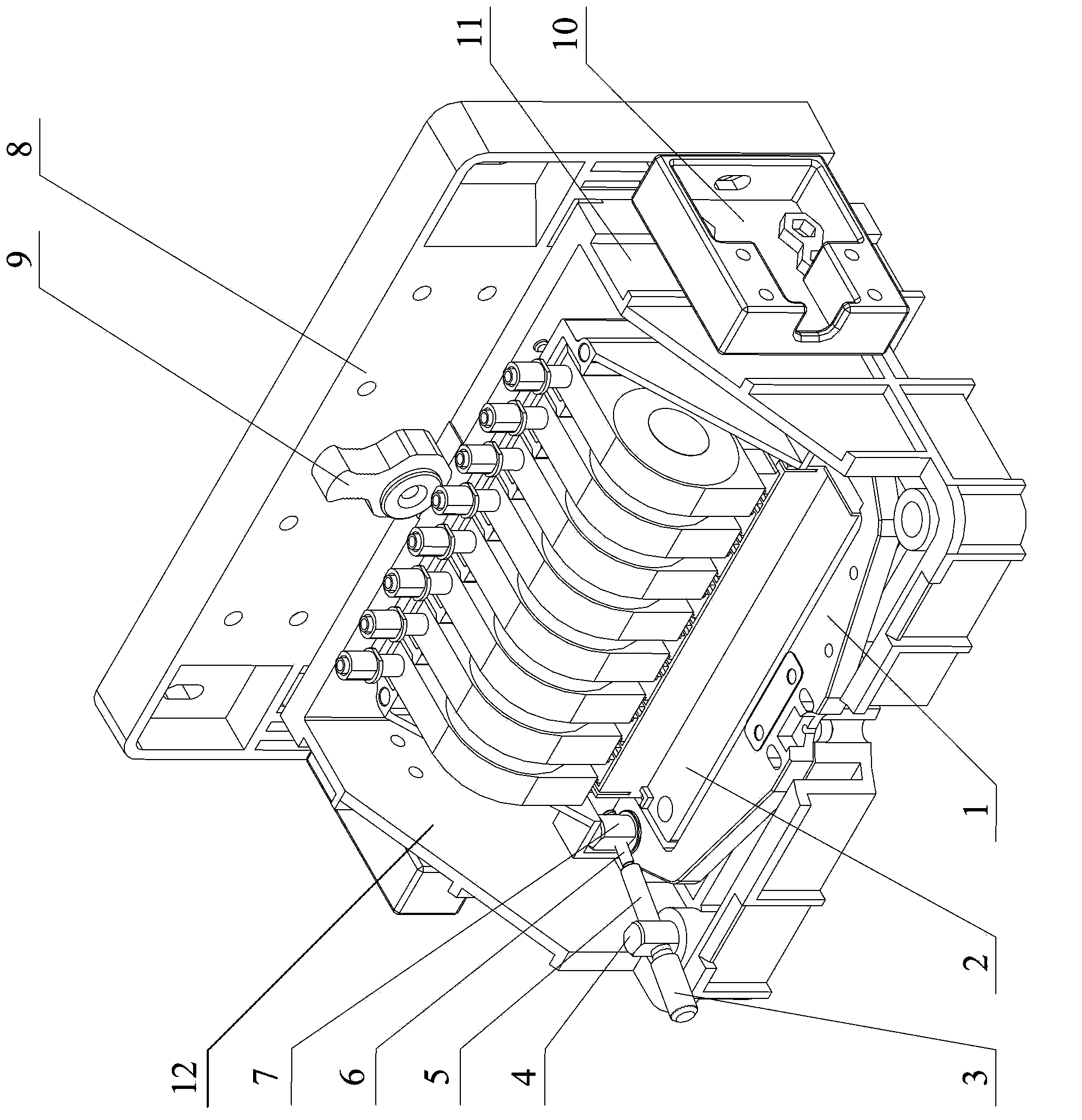

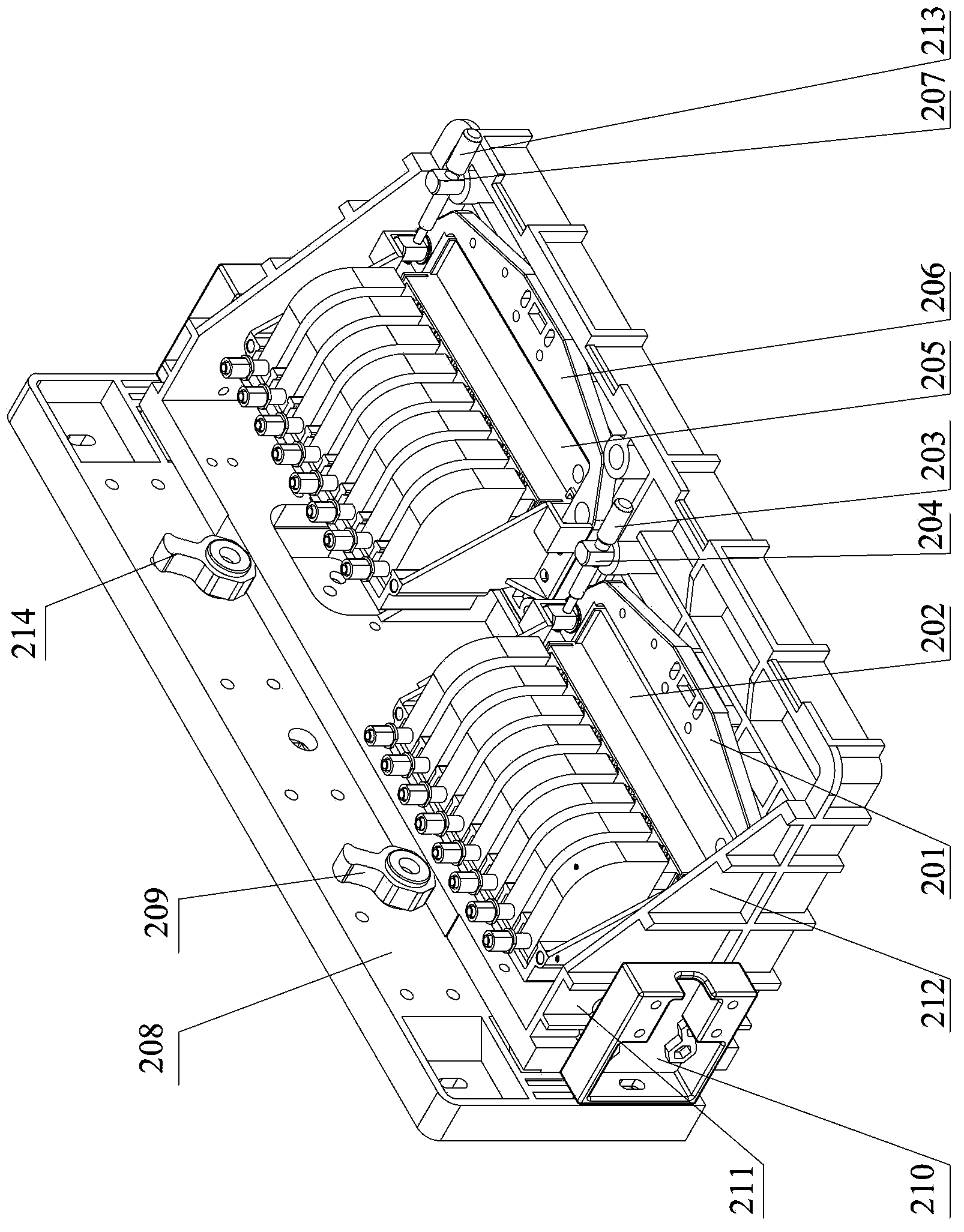

A nozzle adjustment device and a nozzle adjustment method

ActiveCN103101306BRealize micro-adjustment of large movementsPrecise adjustmentPrintingSprayerEngineering

The invention discloses a sprayer regulating device. The sprayer regulating device comprises a sprayer regulating board used for regulating a printer and a regulating rod parallel to a sprayer sliding board. The regulating rod is sequentially provided with a first screw thread and a second screw thread. The screw pitch of the first screw thread is bigger that the screws pitch of the second screw thread. A rotating handle is arranged on one end of the regulating rod. The end of the regulating rod is close to the first screw thread. The sprayer regulating device further comprises a first regulating nut block matched with the first screw thread in use and a second regulating nut block matched with the second screw thread in use. The first regulating nut block is fixed on a sprayer support of the printer. The second regulating nut block is fixed on the sprayer regulating board. The sprayer regulating device has the advantages that major movement fine adjustment is achieved, even twisting of the regulating rod is too much, angle of the sprayer cannot be regulated too much, regulating mode becomes more accurate, and regulating accuracy is improved. The invention further provides a sprayer regulating method.

Owner:WENZHOU ACPASS DISPLAY EQUIP

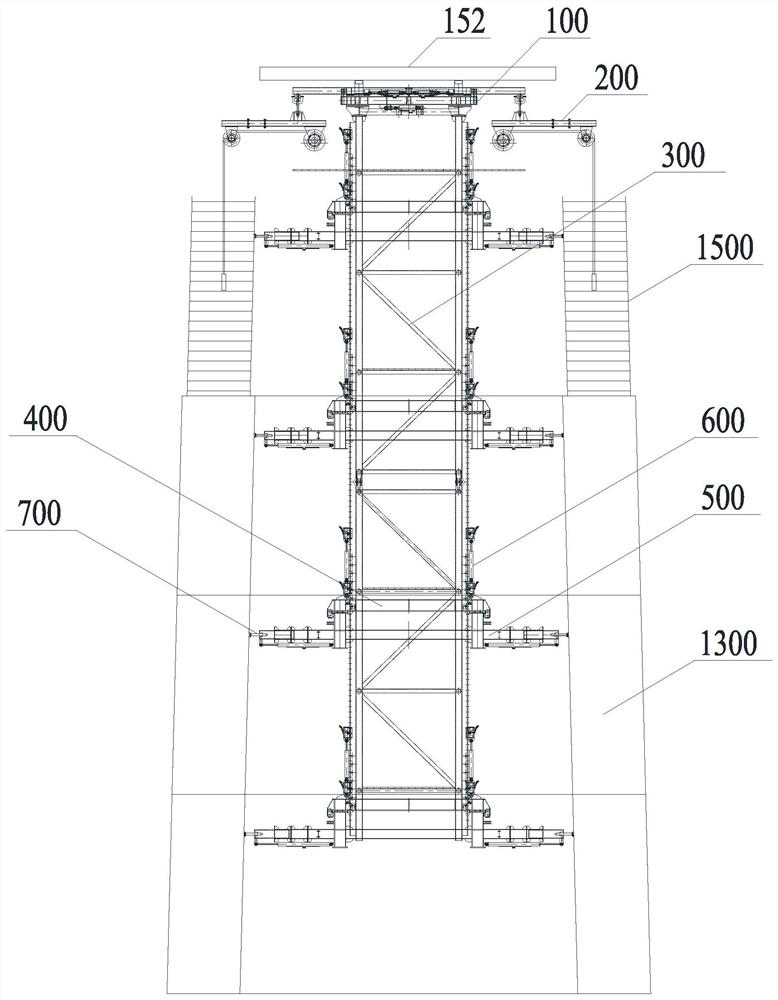

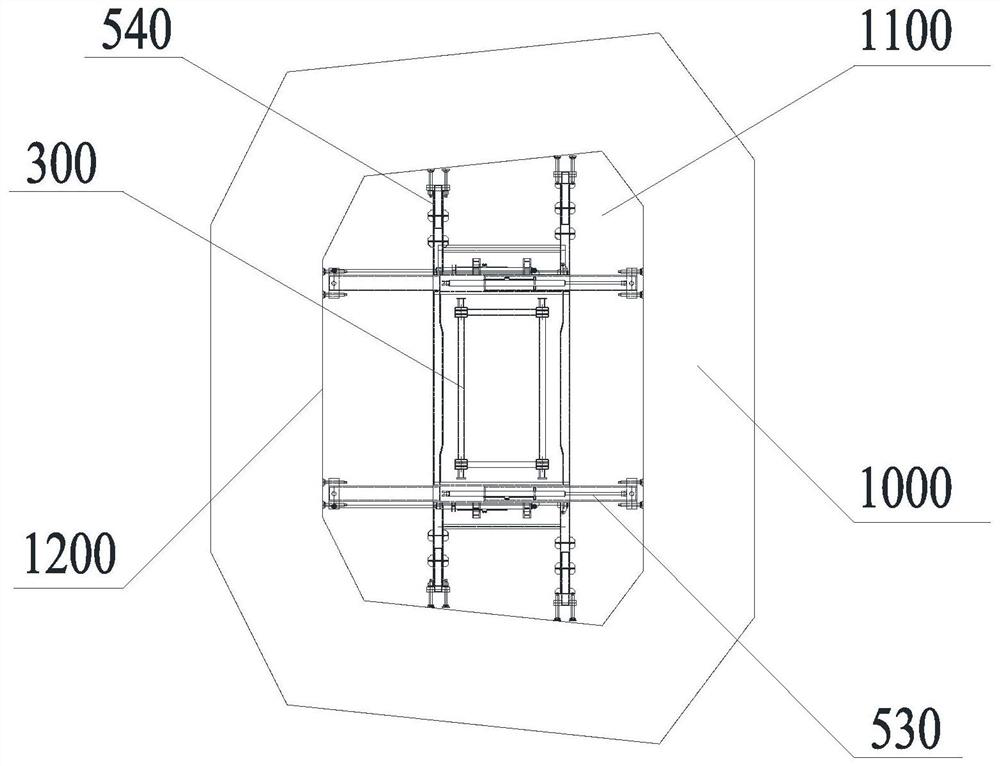

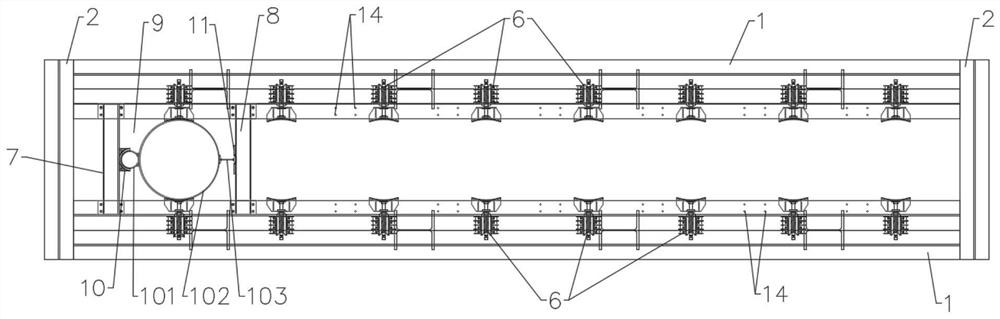

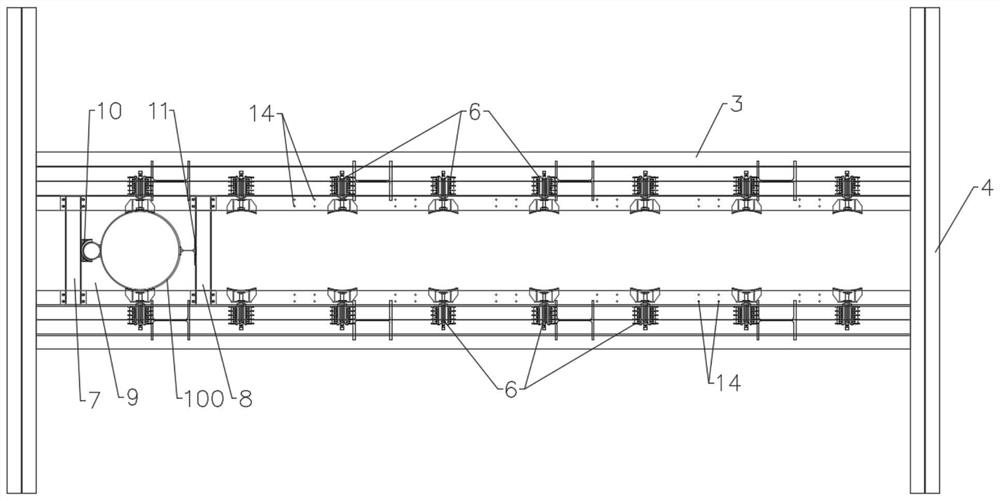

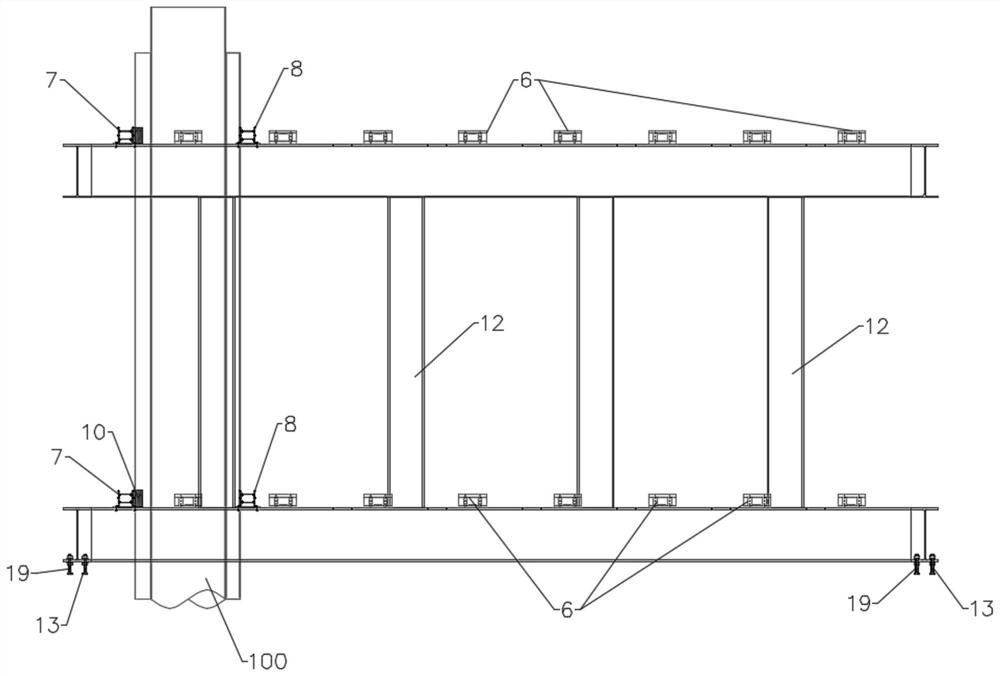

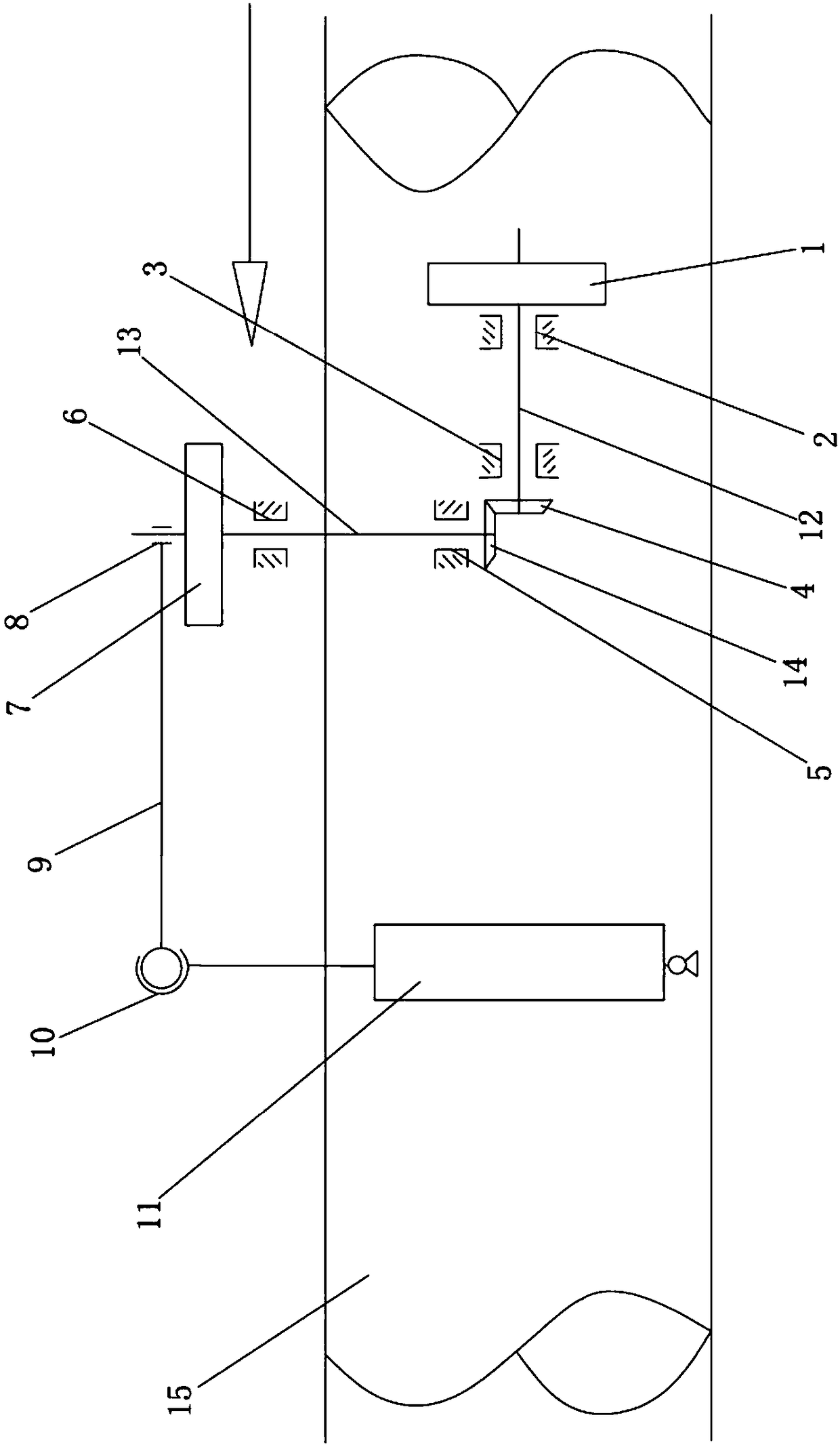

Concrete cavity multifunctional construction platform and its construction method

ActiveCN110644374BImprove construction efficiencyAccurate adjustment positionBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses a multifunctional construction platform with a concrete inner cavity, which comprises an inner mold bracket located in the inner cavity of a leaning tower column. A traversing platform and a load-carrying platform are sheathed on the outer side of the bracket, and the upper end of the traversing platform is hinged with a climbing device that pushes and slides alternately with the climbing track. The present invention also provides a construction method based on the multifunctional construction platform of the concrete inner cavity, which mainly includes: 1) installing the multifunctional construction platform; 2) pouring the concrete segment to be poured; 3) climbing the load-bearing platform; 4) supporting the inner mold Climbing; 5) Installation and positioning of the reinforcement cage; 6) Climbing of the inner mold. The entire multi-functional platform integrates multiple functions such as internal formwork climbing, steel cage installation and positioning, precise vibration, and internal formwork support automatic climbing, which greatly improves the efficiency of concrete inner cavity construction of inclined tower columns; and the positioning device and vibration The positioning accuracy of the device is high.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

Adjustment of scanning performance of lidar sensor

PendingCN114325660ACrosstalk probability minimizationCompensate for phase jitterElectromagnetic wave reradiationMedicineEngineering

The invention relates to a method for adjusting the scanning performance of at least one lidar sensor by means of a control device, in which measurement data of the lidar sensor are received and at least one parameter is ascertained, and the scanning performance of the lidar sensor is adjusted on the basis of the ascertained parameter or in a time-dependent manner. In addition, the invention also discloses a control device.

Owner:ROBERT BOSCH GMBH

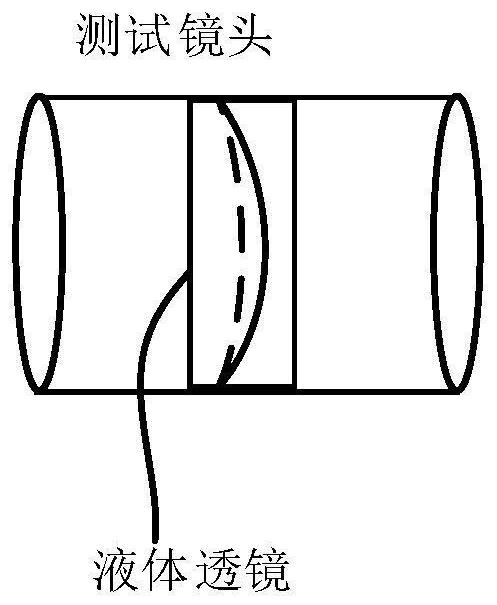

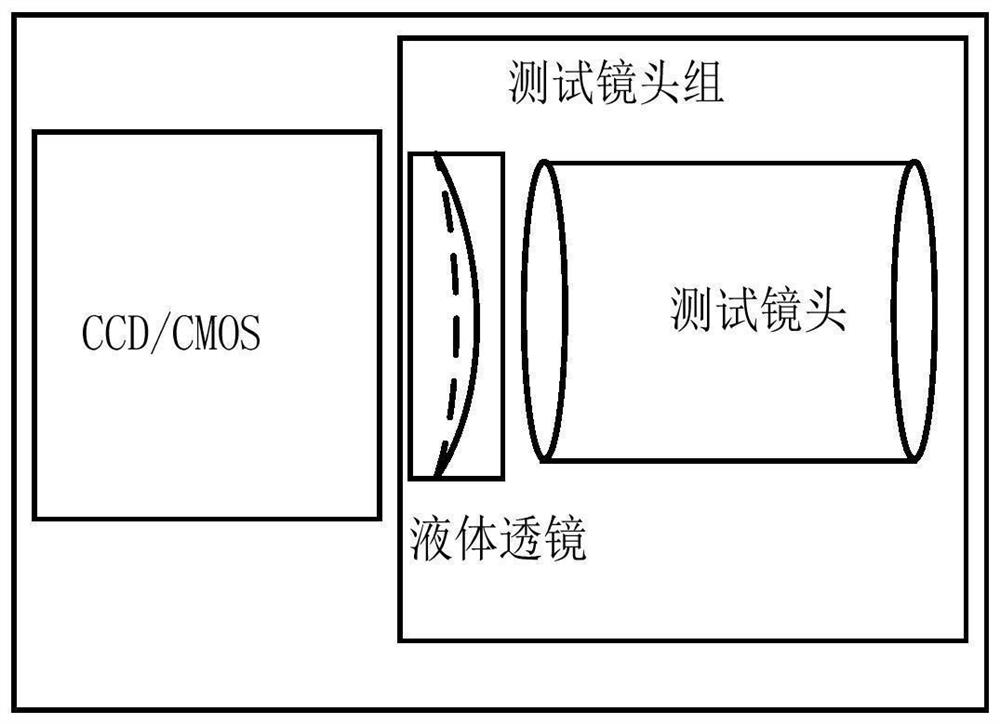

Vision testing device and method of near-to-eye display system and storage medium

PendingCN114427954AEasy to operatePrecise adjustment and controlTesting optical propertiesOphthalmologyNear eye display

The invention discloses a diopter testing device and method of a near-to-eye display system and a storage medium. The device comprises a testing lens group comprising a liquid lens, a sensor, a control system and a testing system, the to-be-tested near-to-eye display system is arranged at a preset position in front of the test lens group to display a test image; the sensor is arranged behind the test lens group for imaging; the control system is used for changing the focal power of the liquid lens; and the test system is connected with the sensor and is used for acquiring the imaging image corresponding to each focal power, determining the focal power corresponding to the imaging image with the highest definition according to the definitions of different imaging images, and determining the diopter of the near-to-eye display system to be tested according to the focal power corresponding to the imaging image with the highest definition. According to the near-to-eye display system, the display images of the near-to-eye display system to be tested under different diopters can be acquired through the sensor while the accuracy and stability of diopter adjustment are ensured, and finally the quality of the near-to-eye display system to be tested is evaluated from multiple aspects.

Owner:BEIJING NEDPLUSAR DISPLAY TECH CO LTD

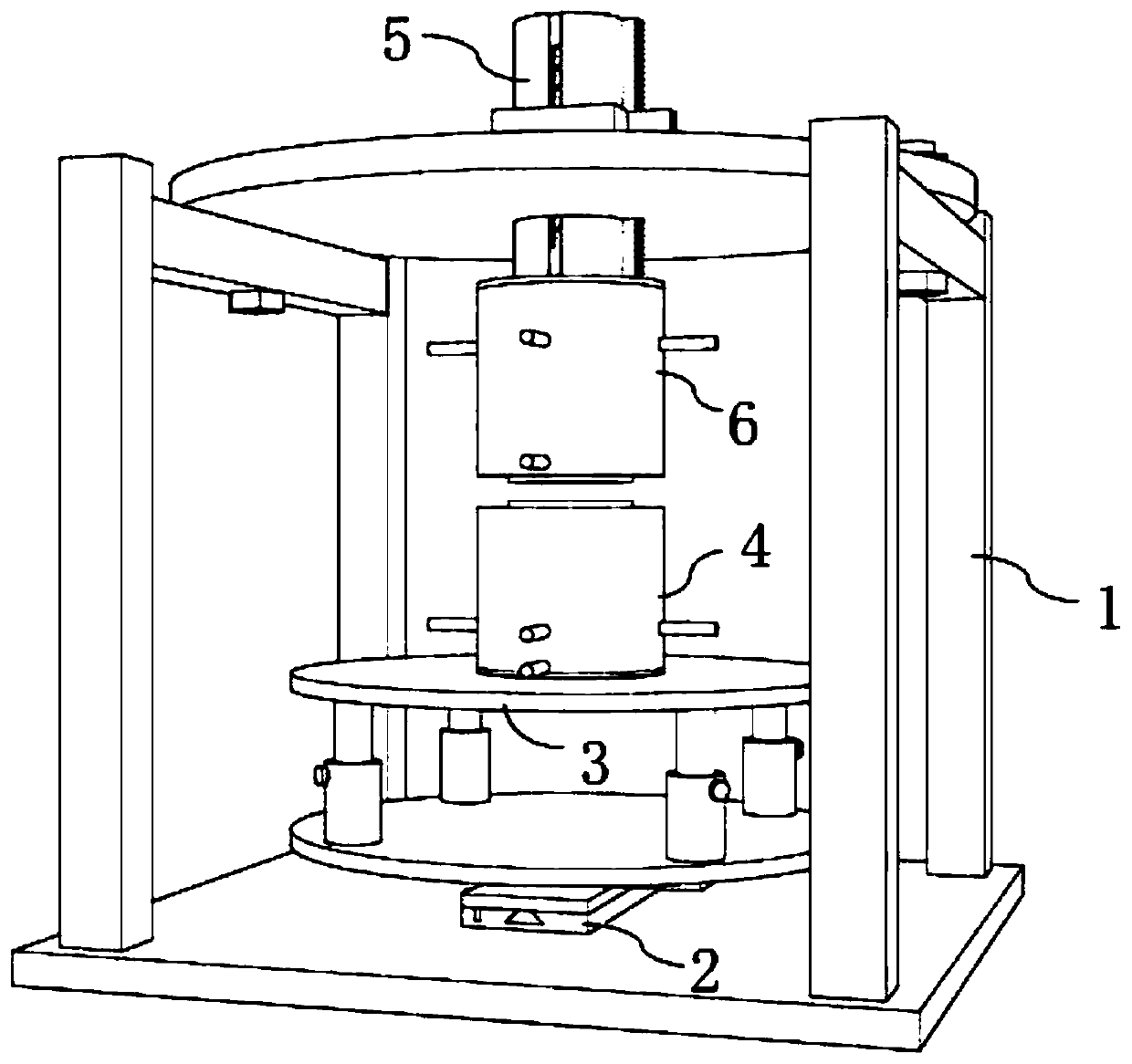

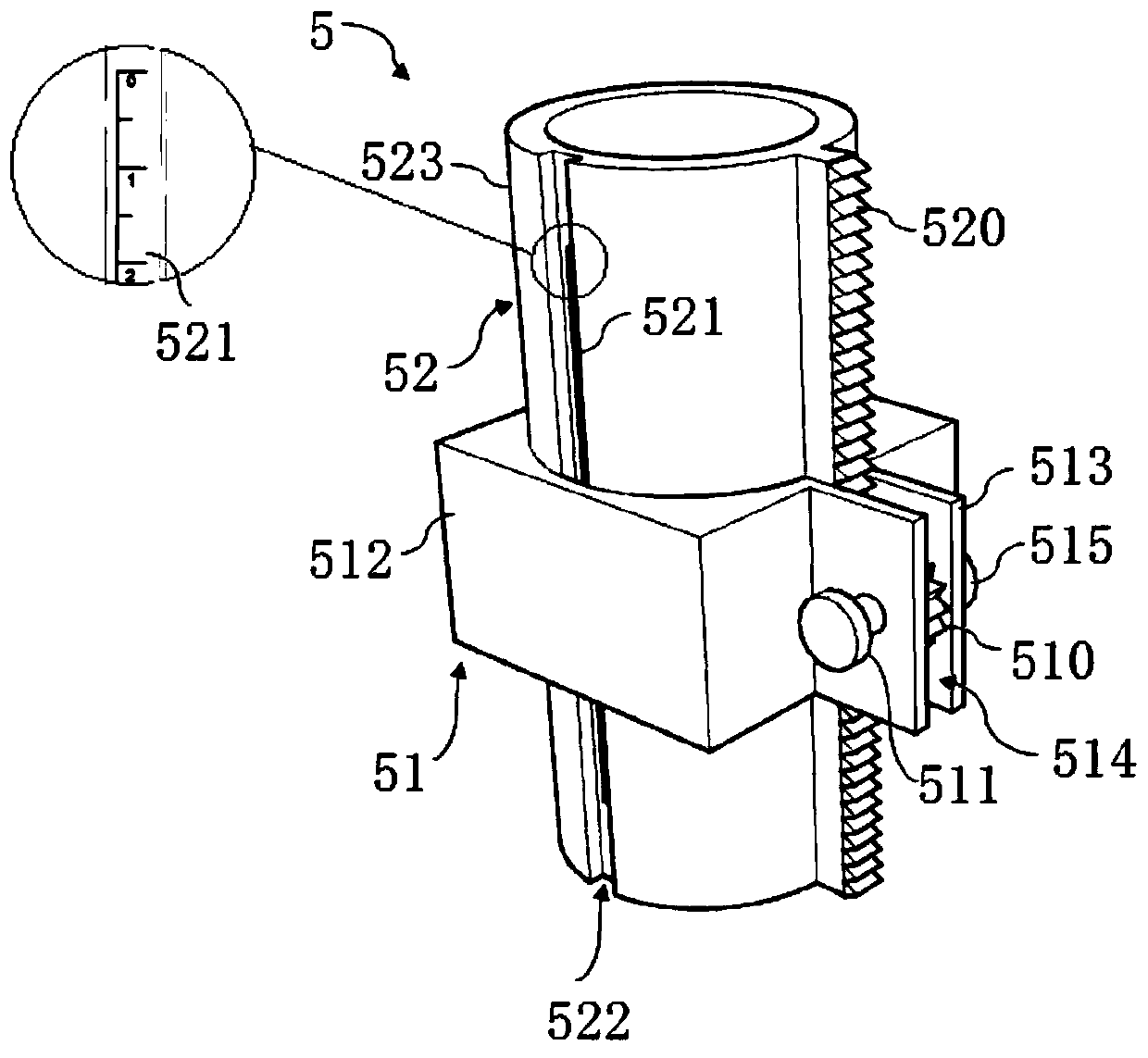

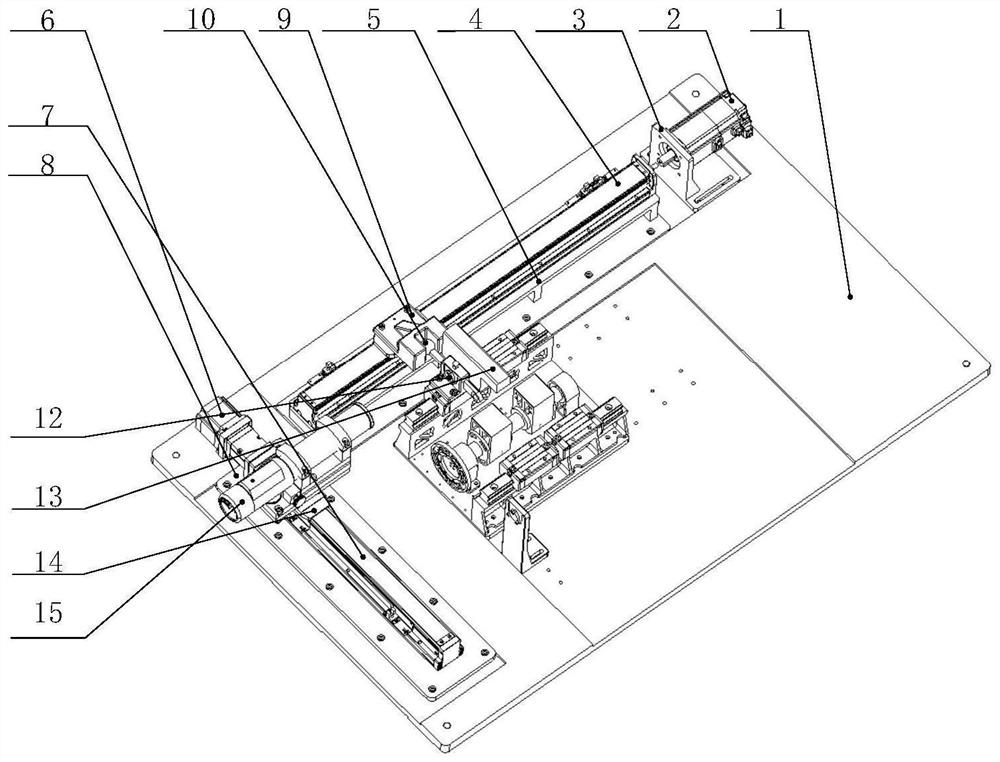

Counter-flow flame test table capable of accurately adjusting burner nozzles

PendingCN110542740ARealize up and down adjustmentSolve the problem that cannot be adjusted continuouslyChemical analysis using combustionGaseous fuel burnerCombustorCounter flow

The invention discloses a counter-flow flame test table capable of accurately adjusting burner nozzles, and belongs to the field of counter-flow flame test devices. The counter-flow flame test table comprises a mounting rack, a horizontal adjusting platform arranged on a bottom plate of the mounting rack, a lower burner supporting device arranged on the horizontal adjusting platform, a lower counter-flow burner arranged on the lower burner supporting device, an upper burner adjusting device that penetrates through a top plate of the mounting rack, and an upper counter-flow burner arranged at the lower end of the upper burner adjusting device, wherein the nozzle of the lower counter-flow burner is opposite to the nozzle of the upper counter-flow burner. The counter-flow flame test table canaccurately adjust the distance between the nozzle of the upper counter-flow burner and the nozzle of the lower counter-flow burner, and can align the nozzle of the upper counter-flow burner with thenozzle of the lower counter-flow burner, so that the problem of inconvenient and inaccurate adjustment of a traditional test table is effectively solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

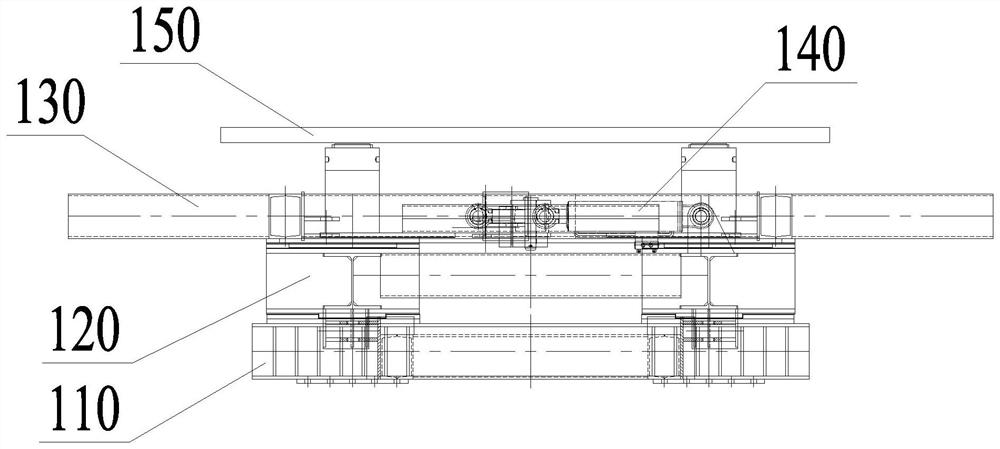

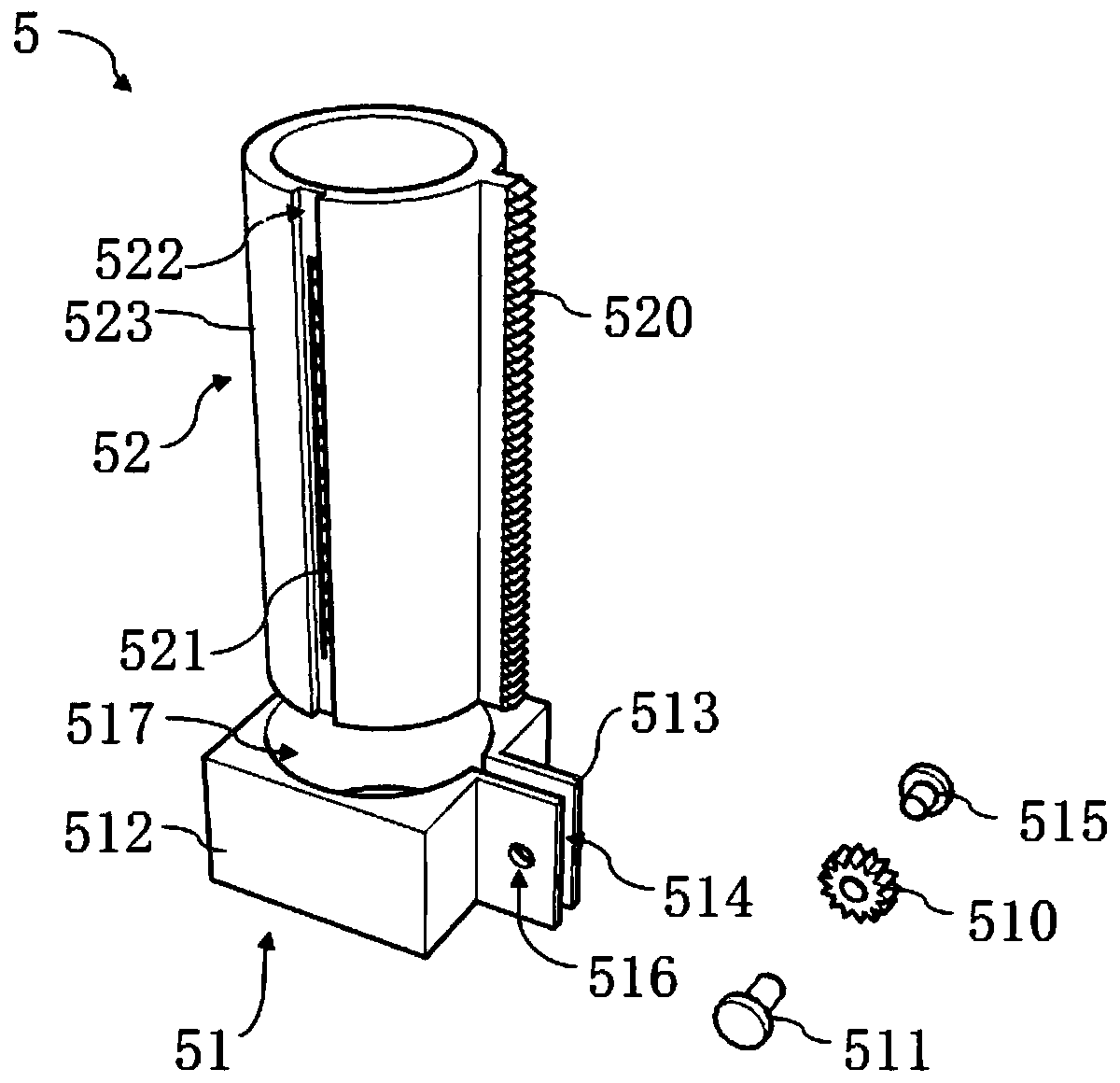

Precision adjusting device and method for ball screw assembly

ActiveCN114670245ASolve the accuracy problemSolve efficiency problemsTotal factory controlManipulatorGraphicsBall screw

The invention discloses a precision adjusting device and method for a ball screw assembly, and the device and method achieve the precision adjustment of the ball screw assembly with a visual pattern through a laser autocollimator, an inclinometer and other electronic measurement devices. The precision adjusting device is mainly composed of a basic movement module, an installation and adjustment precision guaranteeing module and a control module. The basic movement module is used for matched installation and adjustment of the ball screw assembly, has a linear movement function and provides an installation environment for the installation and adjustment precision guarantee module. And the assembly and adjustment precision guarantee module is used for accurate measurement of form and location tolerance of matched assembly and adjustment of each component and high-precision assembly and adjustment guarantee of each component. And the control module is used for realizing the driving control and information measurement functions of electromechanical components in the ball screw assembly assembling and adjusting process. The precision adjusting method solves the problems of low precision, low efficiency and boring work of manual adjustment of the ball screw assembly, assists manual adjustment to be rapid and accurate, and improves the precision and efficiency of manual adjustment.

Owner:BEIHANG UNIV

Ultra-long lock catch steel pipe pile guiding and positioning support and using method thereof

PendingCN114753368AGuaranteed positioning accuracyAvoid lateral twisting and lateral displacement deviationsBulkheads/pilesSteel tubePipe

According to the super-long lock catch steel pipe pile guiding and positioning support and the using method thereof, an upper-layer guiding frame positioning system and a lower-layer guiding frame positioning system are formed by correspondingly arranging a top guiding frame and a bottom guiding frame, and an arranged vertical position adjusting mechanism can accurately adjust the position of the whole guiding frame in the vertical direction; the lock catch steel pipe pile, especially a super-long lock catch steel pipe pile, is ensured to be in a precision controllable and adjustable state in the driving process, when the lock catch steel pipe pile is guided and positioned, the first positioning piece and the second positioning piece are matched with the C-shaped lock catch and the T-shaped lock catch on the corresponding sides of the lock catch steel pipe pile respectively, the positioning precision of the lock catch steel pipe pile is ensured, and the positioning accuracy of the lock catch steel pipe pile is improved. According to the steel cofferdam, lateral distortion and lateral displacement deviation are avoided, the rubber cushion blocks are installed on the inner sides of the first positioning pieces, the buffering and protecting effects are achieved in the sinking process of the steel cofferdam, deformation of a main body structure of the steel cofferdam is avoided, in addition, an assembled structure is adopted, production and installation are convenient, and replacement can be conducted according to different steel cofferdam structural forms.

Owner:CCCC SECOND HARBOR ENG +1

Automatic deviation-adjustment device and deviation-adjustment method for rubber belt at circle forming section of tubular belt conveyor

PendingCN108609347ARealize automatic deviation correctionMake sure to runConveyorsFailure rateCircular disc

The invention discloses an automatic deviation-adjustment device and a deviation-adjustment method for a rubber belt at a circle forming section of a tubular belt conveyor. The automatic deviation-adjustment device comprises a carrier roller, a first horizontal bearing, a second horizontal bearing, a first longitudinal bearing and a second longitudinal bearing. A horizontal rotary shaft is connected between the first horizontal bearing and the second horizontal bearing; a driving bevel gear wheel and a driving circular disc are connected to the left end and the right end of the horizontal rotary shaft; a longitudinal rotary shaft is connected between the first longitudinal bearing and the second longitudinal bearing; a driven circular disc and a driven bevel gear wheel are connected to theupper end and the lower end of the longitudinal rotary shaft; the driven bevel gear wheel meshes with the driving bevel gear wheel; the carrier roller is connected with a connecting rod through a spherical pair; the connecting rod is eccentrically arranged on the driven circular disc; and when the circle forming section of the rubber belt deviates toward one side, the deviation of the circle forming section of the rubber belt promotes the rotation of the driving circular disc, and the carrier roller automatically produces a corresponding inclination angle through the device, so that the deviated circle forming section of the rubber belt is automatically adjusted. The automatic deviation-adjustment device provided by the invention is ingenious in structure, low in cost, low in failure rate, time and labor saving, and high in deviation-adjustment efficiency.

Owner:SANMING UNIV

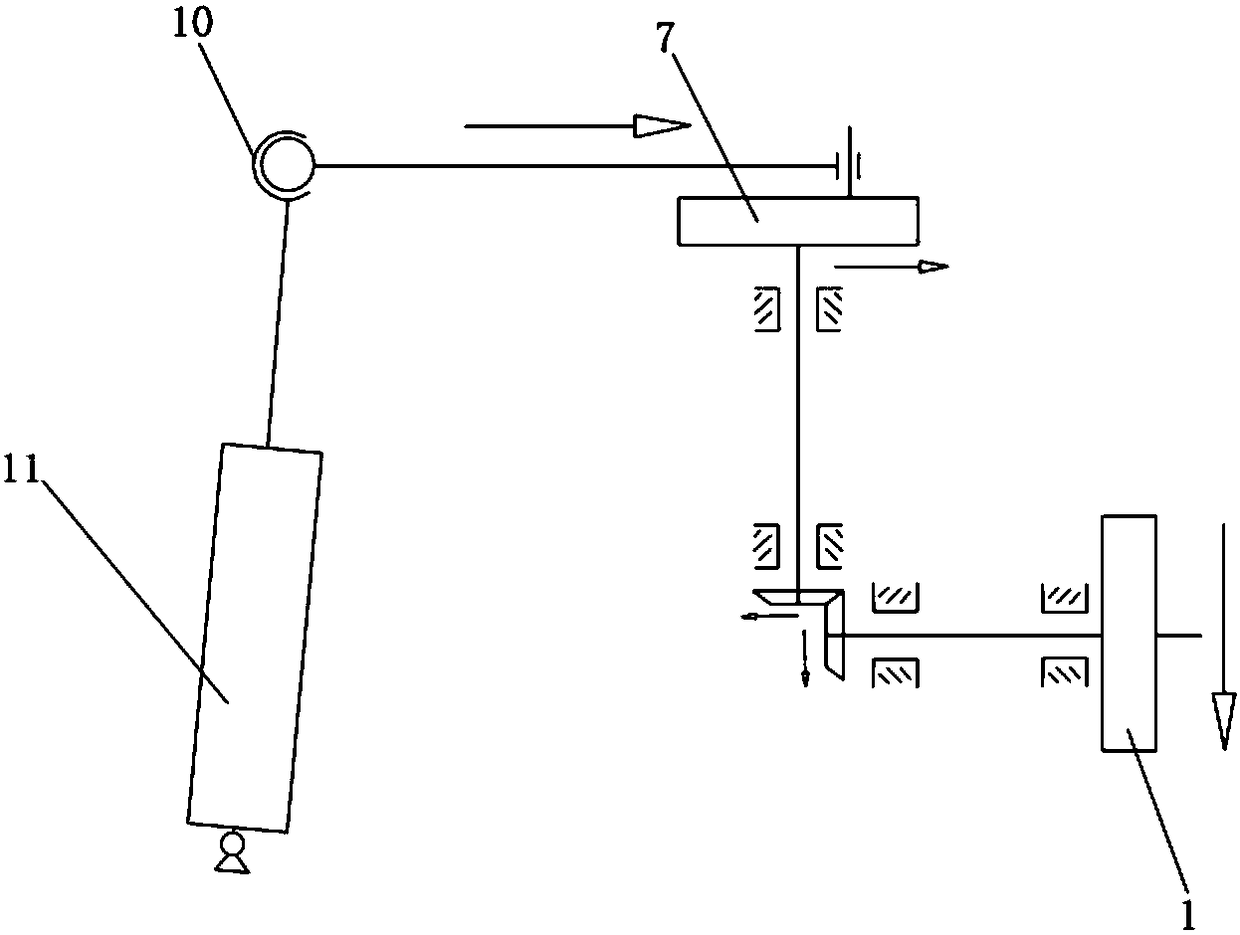

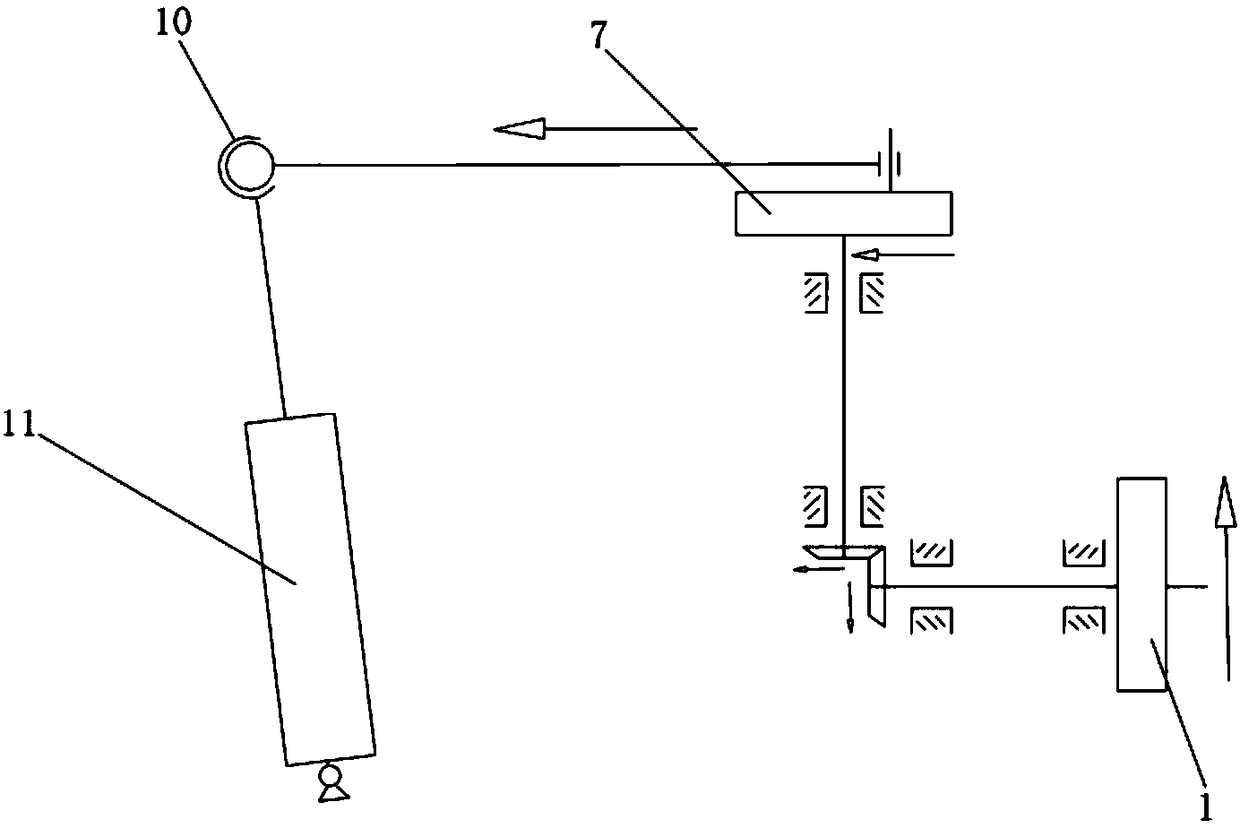

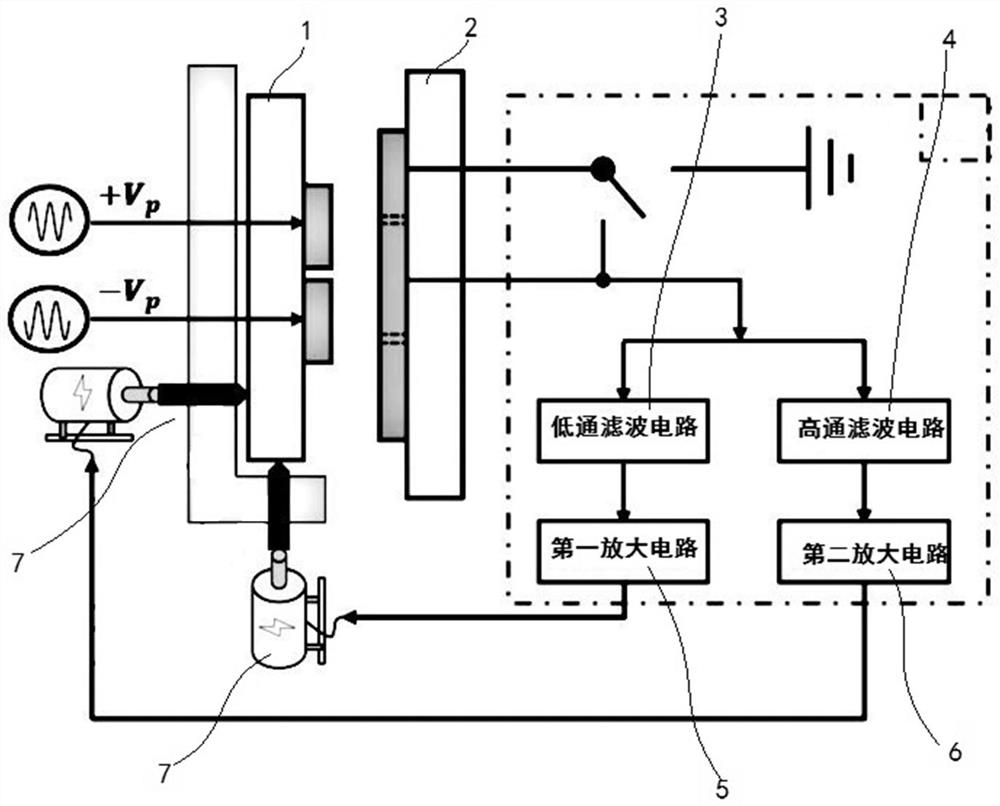

A capacitor plate adjustment device and method

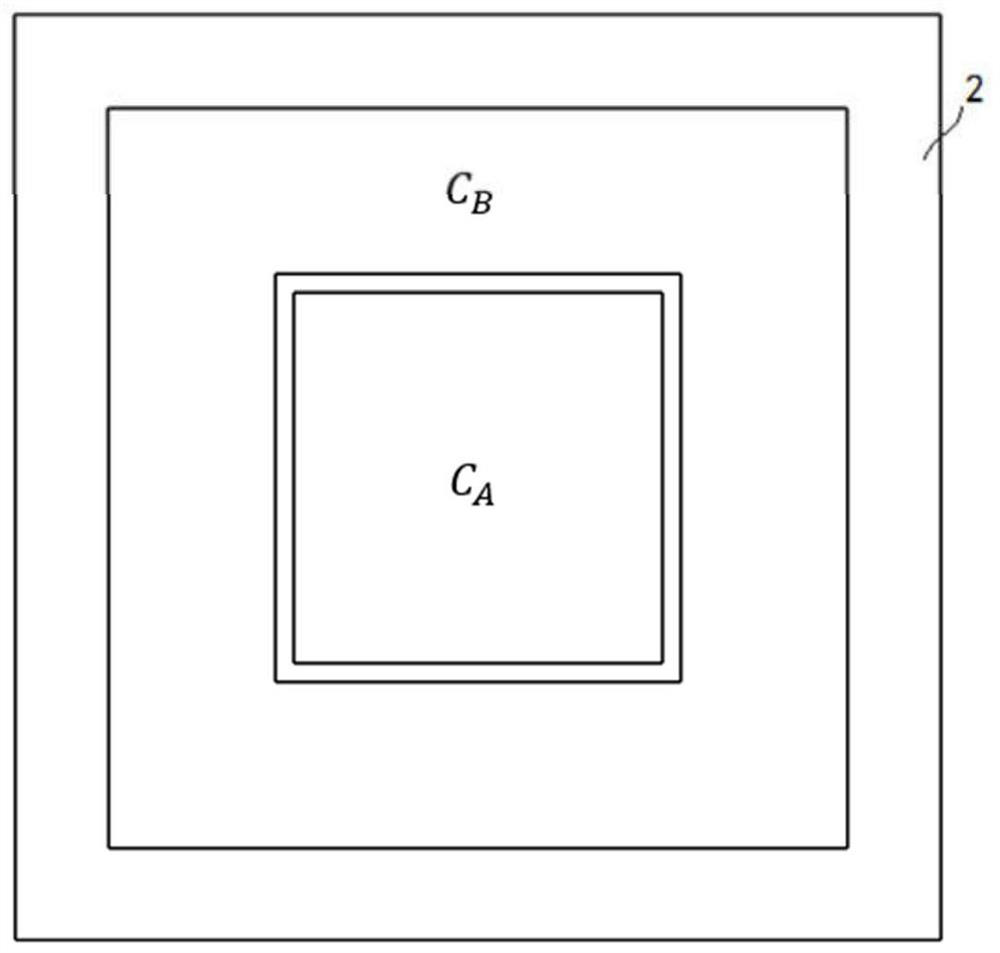

ActiveCN111412830BRealize automatic adjustmentPrecise adjustmentUsing electrical meansEngineeringComputational physics

The invention discloses a capacitor plate adjustment device and method, which are applied to adjust the parallelism and coaxiality between capacitor plates in a capacitive displacement sensing device, including a capacitor plate unit, a capacitance test unit, a moving adjustment unit; the capacitive plate unit includes a first capacitive plate and a second capacitive plate oppositely placed; the first capacitive plate includes four capacitive detection areas, and the second capacitive plate includes two capacitive detection areas, when the two When the two capacitance detection areas are electrically connected, they form four independent capacitances with equal area and unequal spacing with the four capacitance detection areas of the first capacitance plate. Real-time testing of the capacitance test unit and real-time adjustment of the mobile adjustment unit realize the capacitance plate The parallelism between them is adjusted; when one capacitance detection area of the second capacitance plate is grounded, the other capacitance detection area and the four capacitance detection areas of the first capacitance plate form four independent capacitances with equal intervals and different areas. Realize the adjustment of the coaxiality between the capacitor plates.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com