Precision adjusting device and method for ball screw assembly

A ball screw and adjusting device technology, which is applied in the direction of manufacturing tools, manipulators, etc., can solve the problems of increasing labor costs, inability to ensure the installation accuracy of ball screw components, and time-consuming problems, so as to improve accuracy and efficiency, and improve accuracy and the efficiency of measurement, the effect of easy replacement and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments, but the implementation of the present invention is not limited thereto.

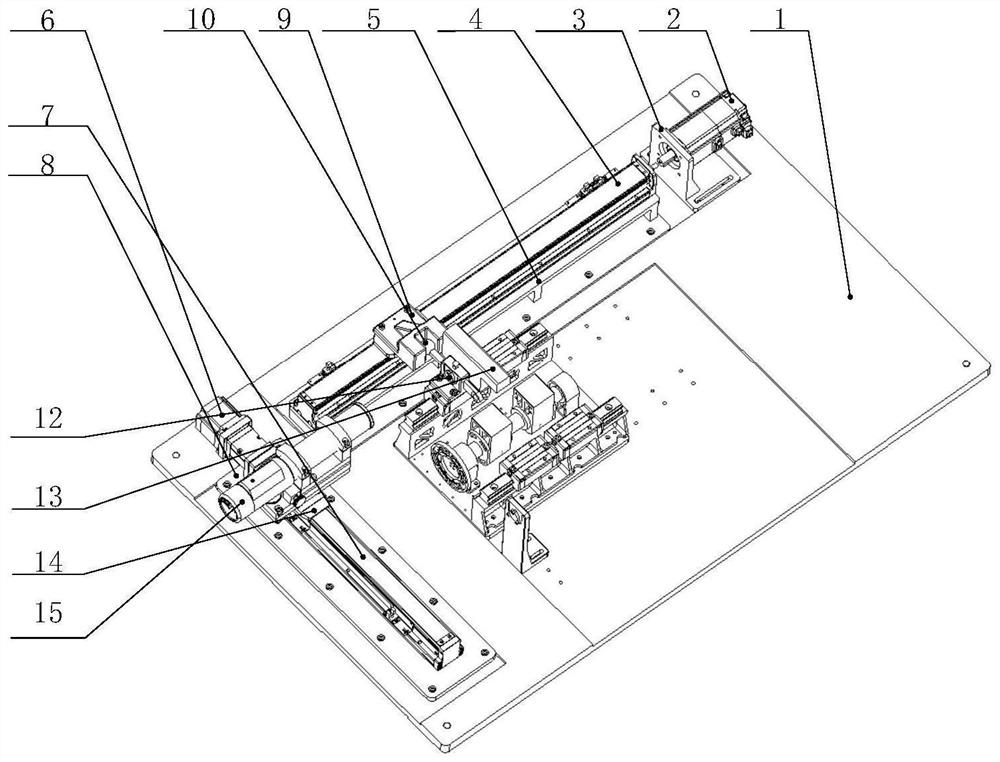

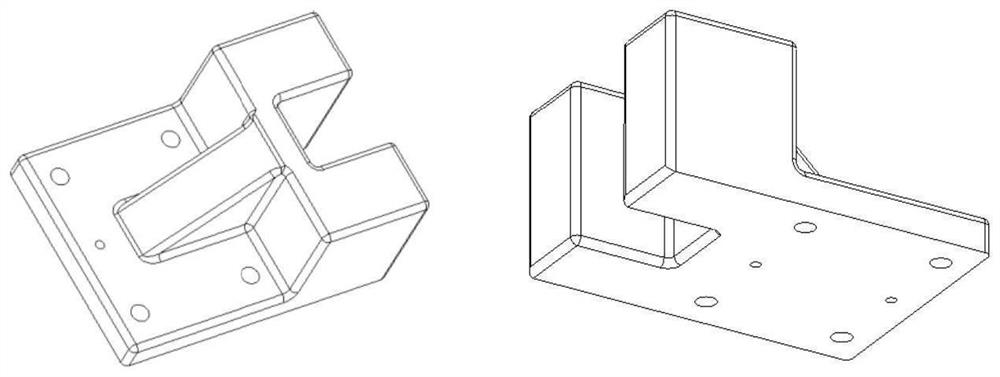

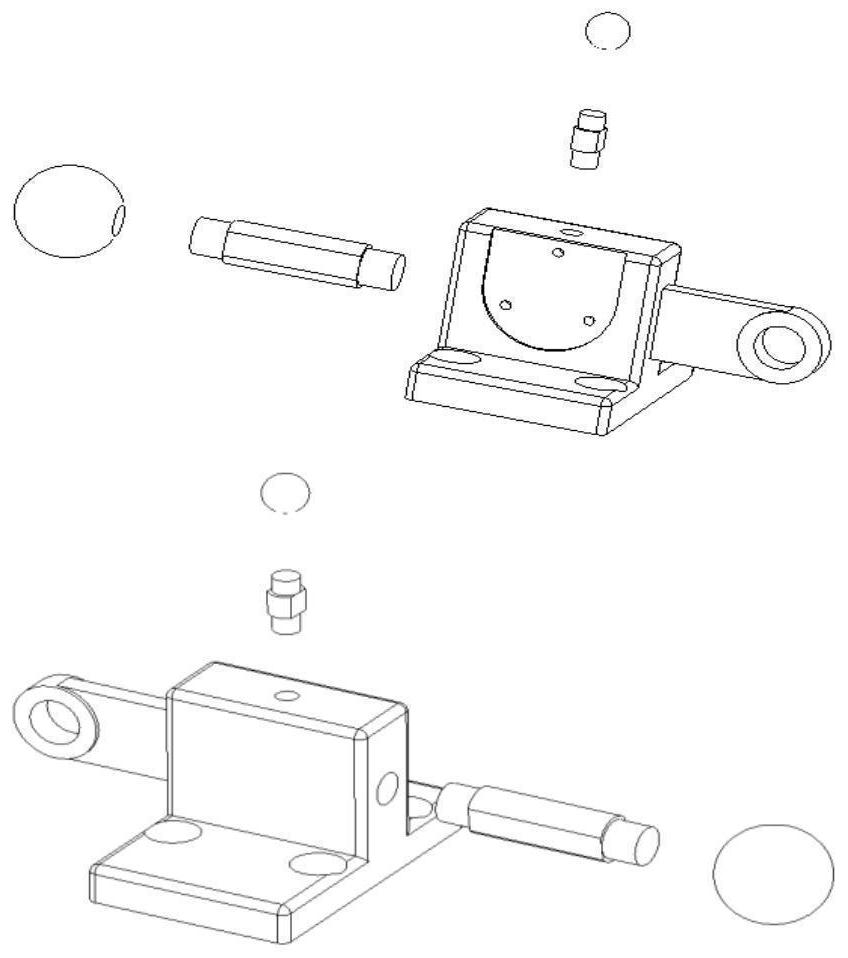

[0049] combine figure 1 , Figure 4 and Figure 9 As shown, the present invention proposes a device for precision adjustment of ball screw assemblies, which is characterized in that it includes a basic motion module, an adjustment precision guarantee module and a control module, wherein:

[0050] The basic motion module is used for the matching and adjustment of the ball screw assembly. It has the function of linear motion, and provides an installation environment for the assembly and adjustment accuracy assurance module. The four corners of the basic motion module are installed with eye screws, which are convenient for lifting and moving. The basic motion module consists of a positioning base plate 1, a servo motor assembly and an optical translation assembly; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com