Patents

Literature

32results about How to "Accurate and efficient assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

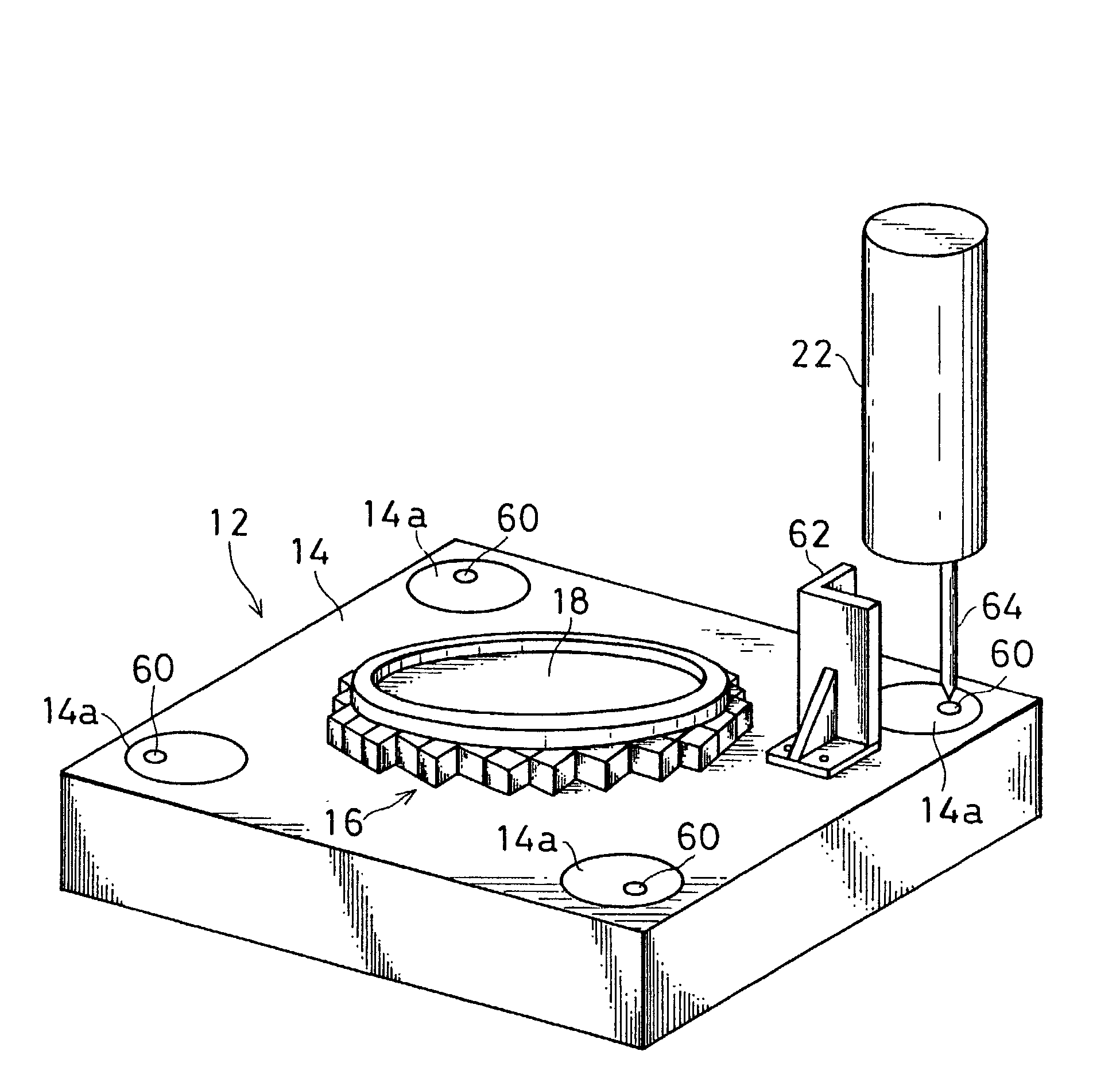

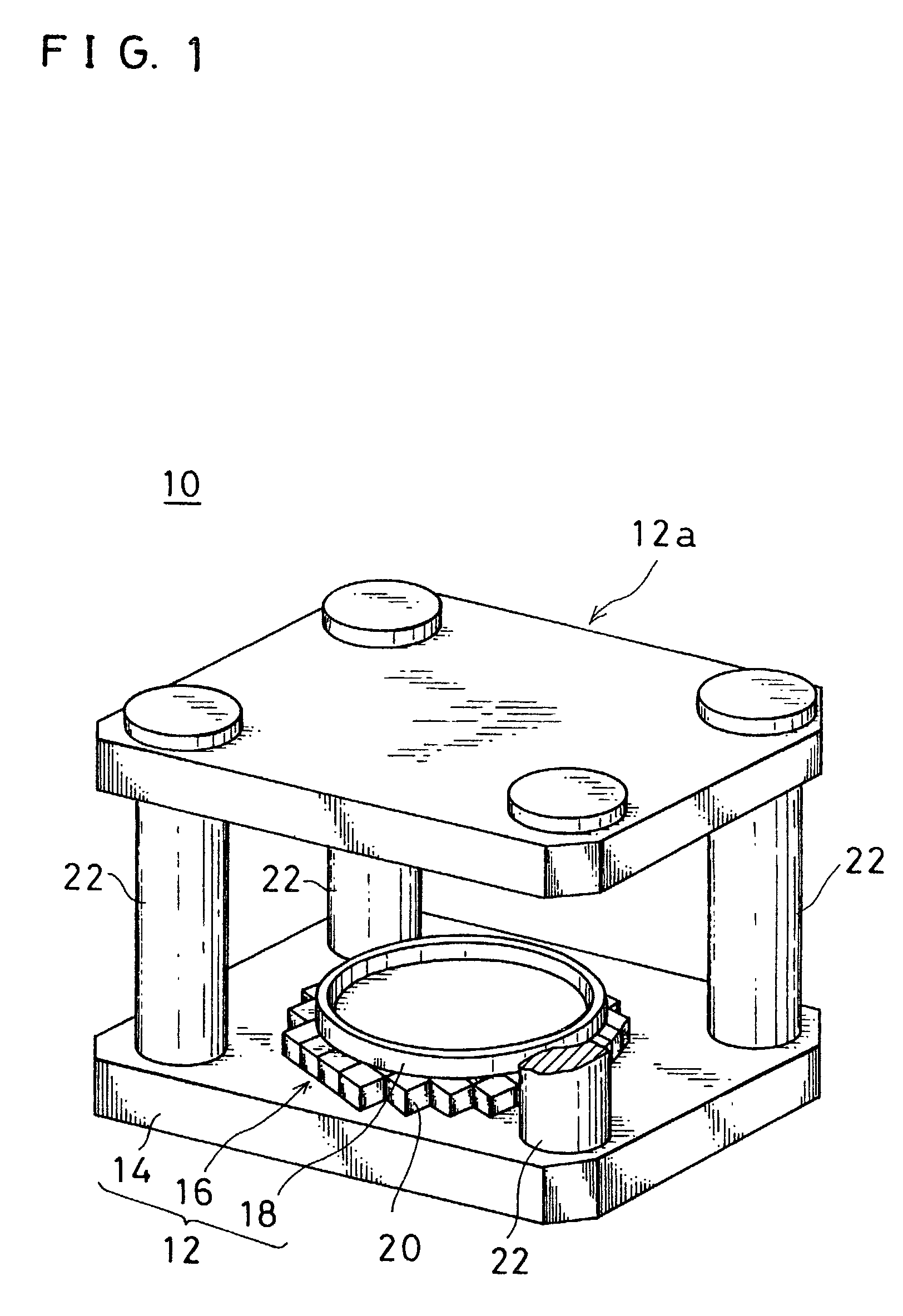

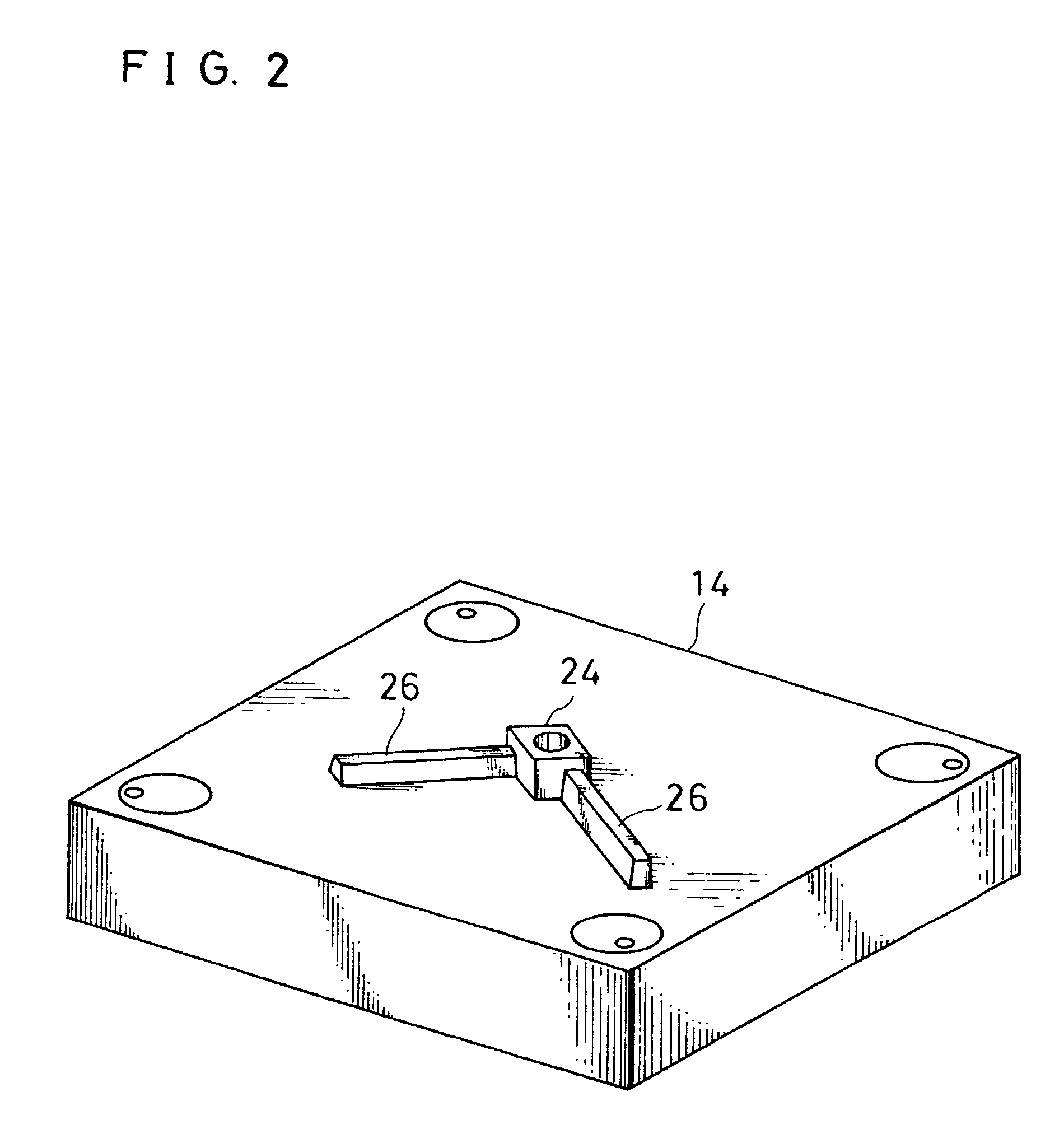

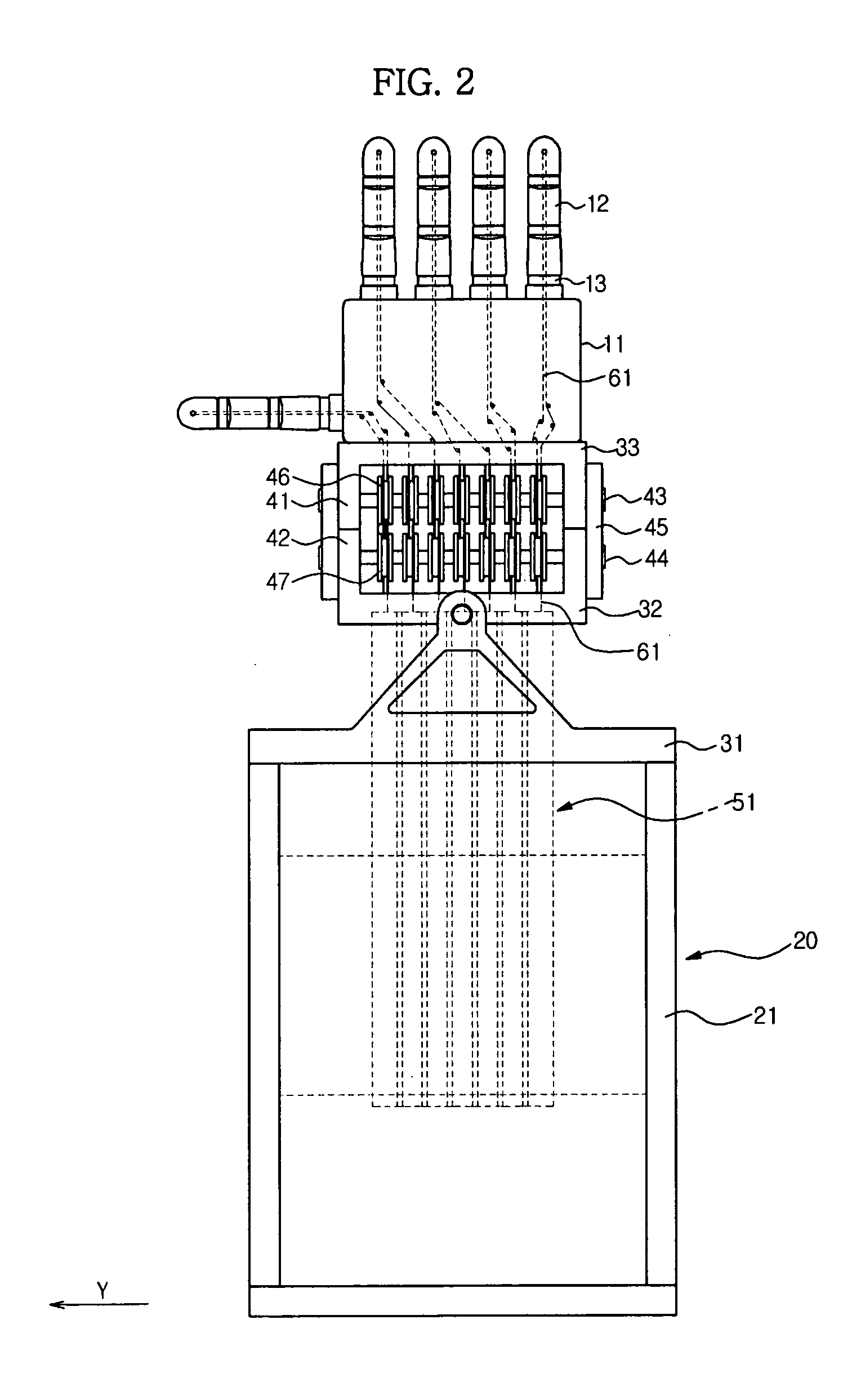

Method for assembling a magnetic field generator for MRI

InactiveUS7065860B2Efficient assemblyAccurate and efficient assemblyWave amplification devicesDiagnostic recording/measuringEngineeringMagnet

A plate yoke has an upper surface formed with a projection and a guiding rail. A new magnet block is transported by sliding on the upper surface of the plate yoke, and is bonded side by side with the projection or a magnet block which is already fixed. During the above operation, a magnetic member is held above the plate yoke. Preferably, the new magnet block is transported toward a corner portion, with side surfaces of the magnet block held parallel to a side surface of the projection and a side surface of the guiding rail respectively. When the magnet unit and the column yoke is connected, the column yoke or the magnet unit is lowered so that a guiding rod attached to an end face of the column yoke is inserted into a hole formed in the magnetic unit. Further, the column yoke is guided by a guiding member disposed between a permanent magnet on the plate yoke and a position where the column yoke is to be connected on the plate yoke.

Owner:SUMITOMO SPECIAL METAL CO LTD

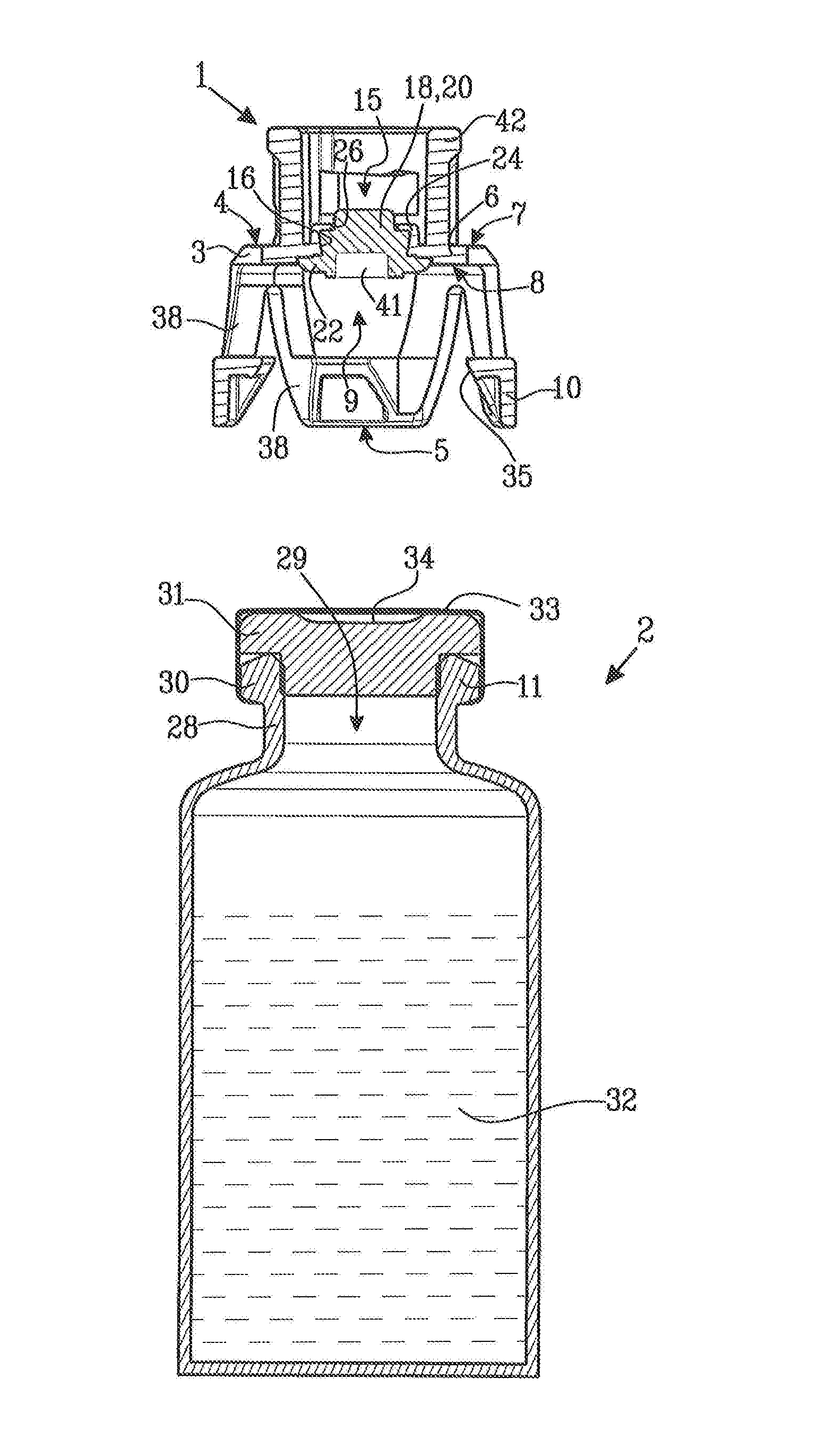

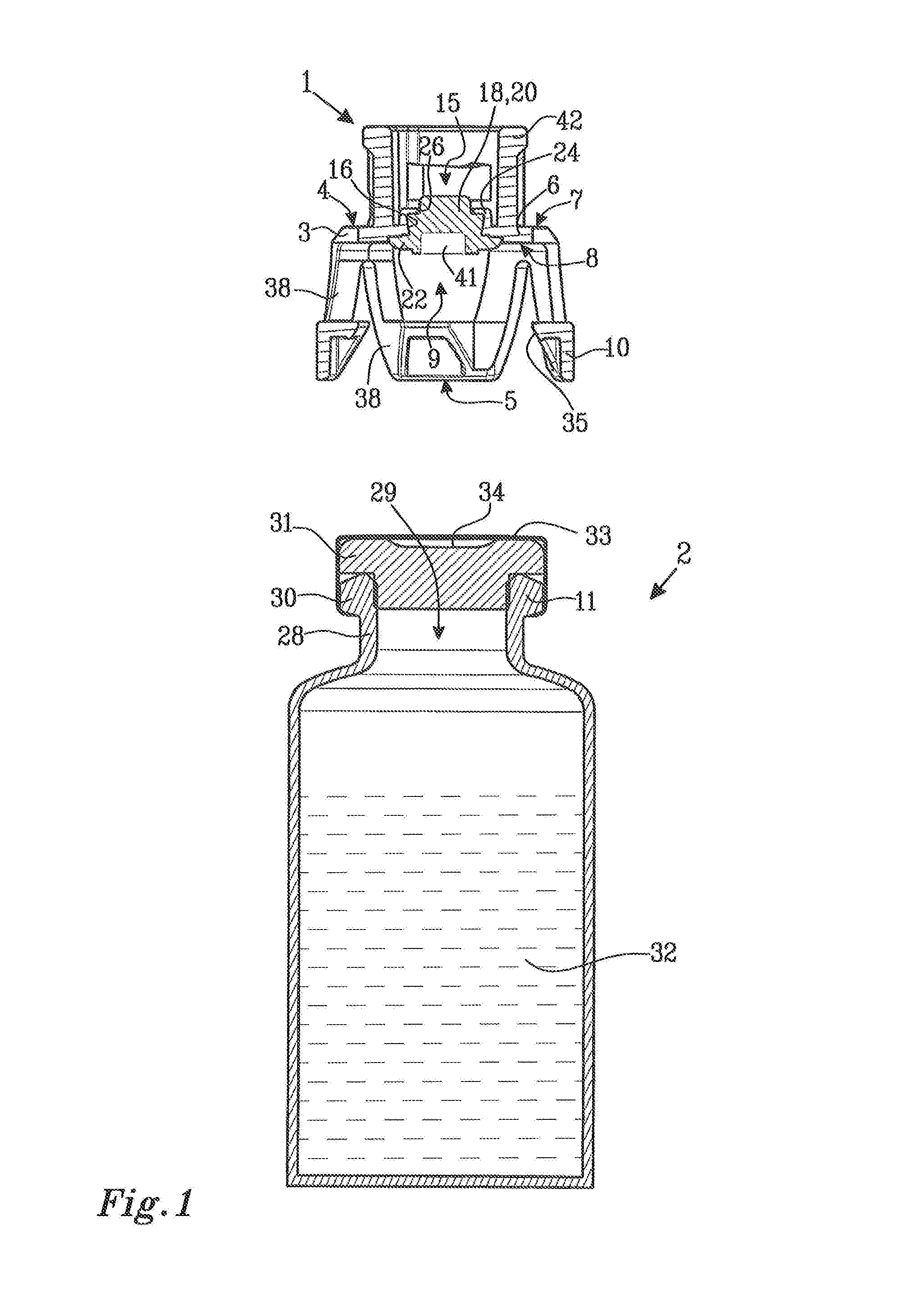

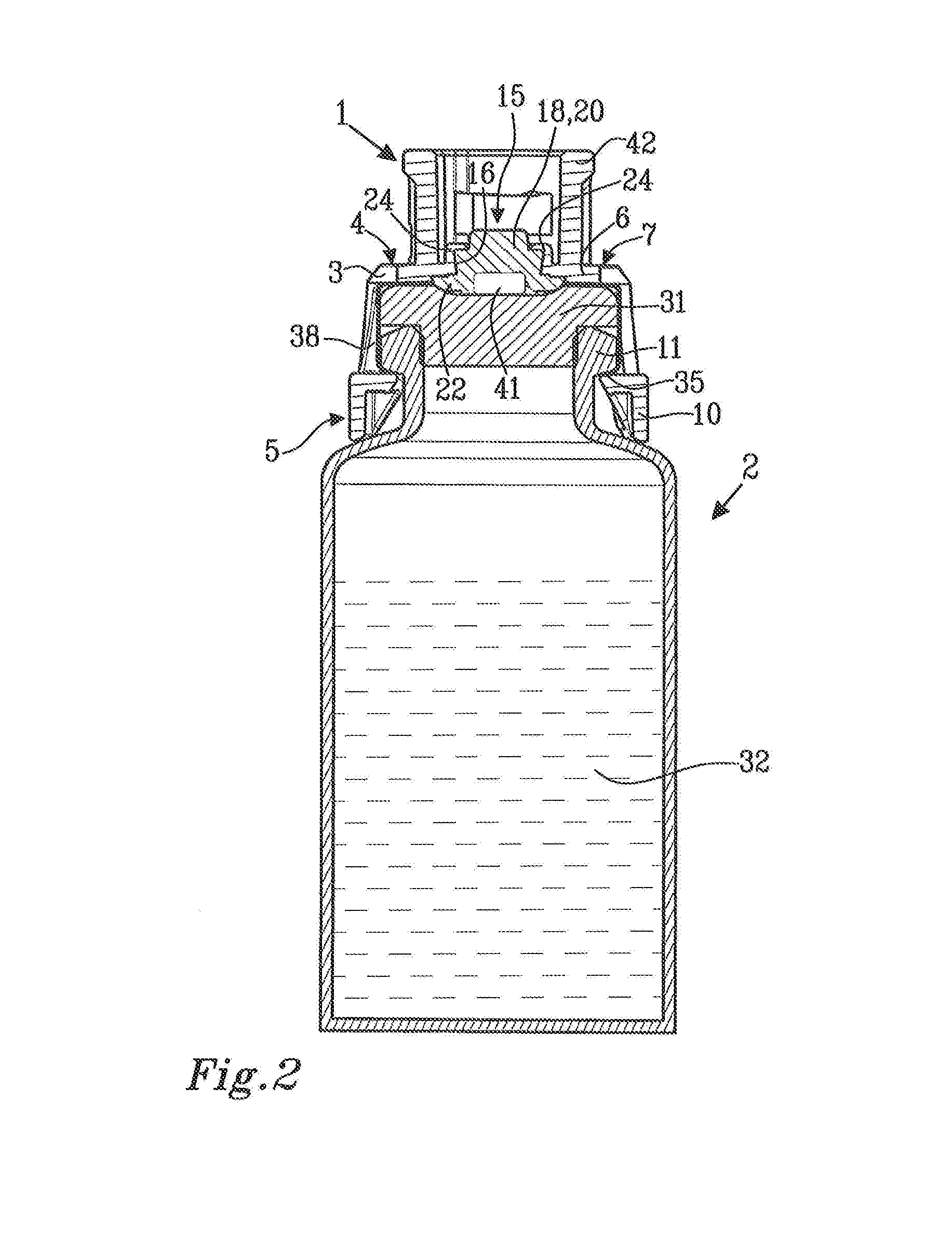

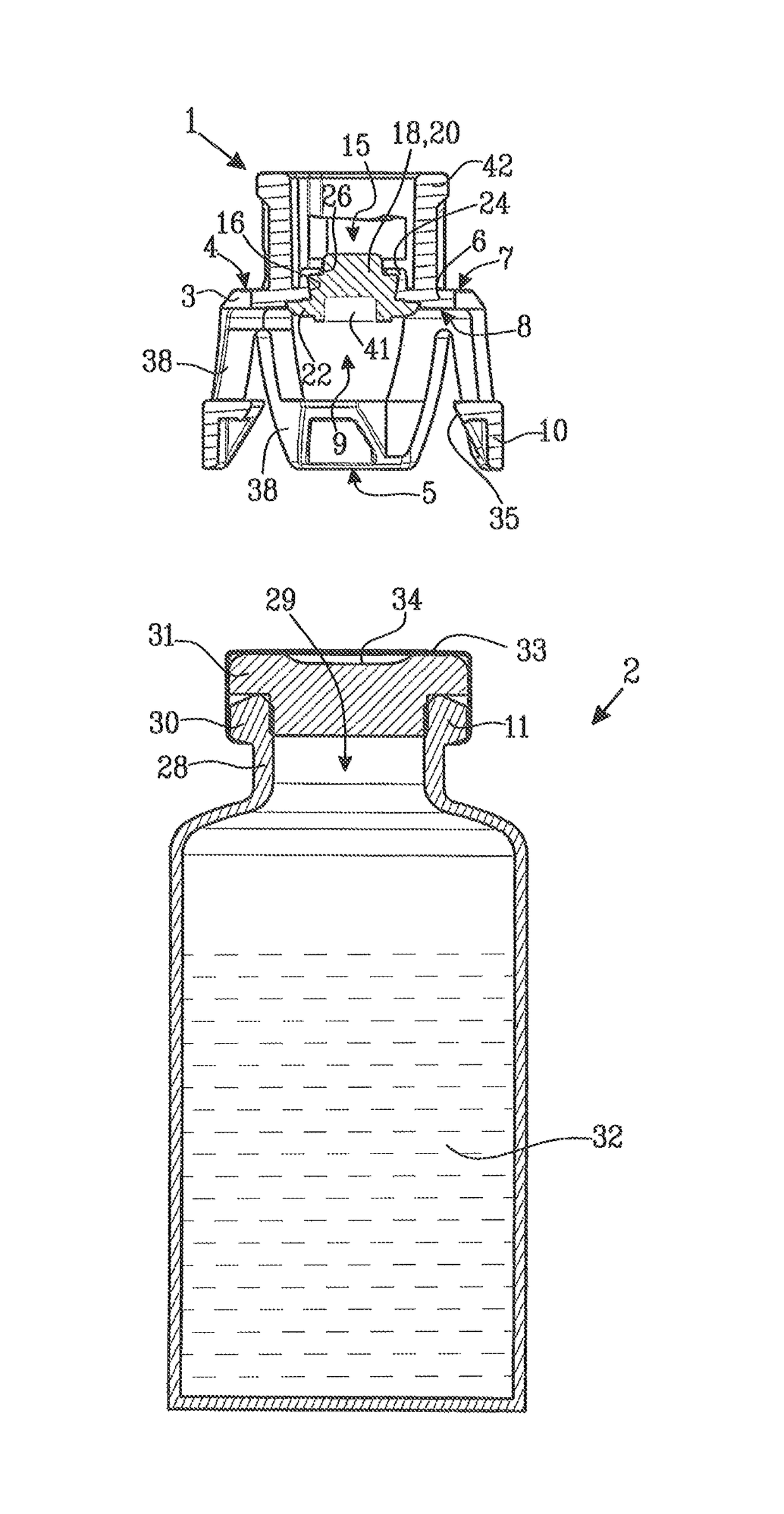

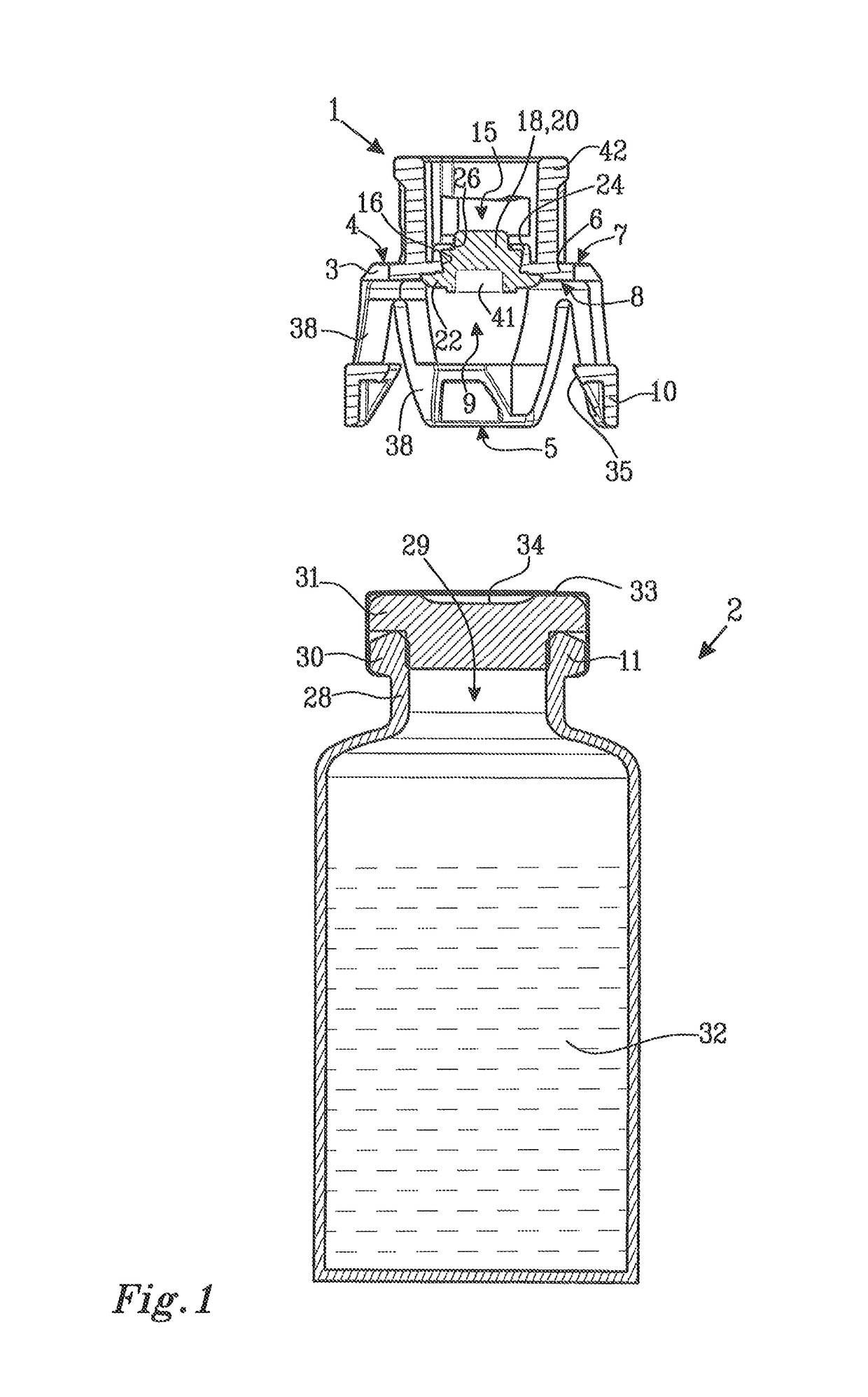

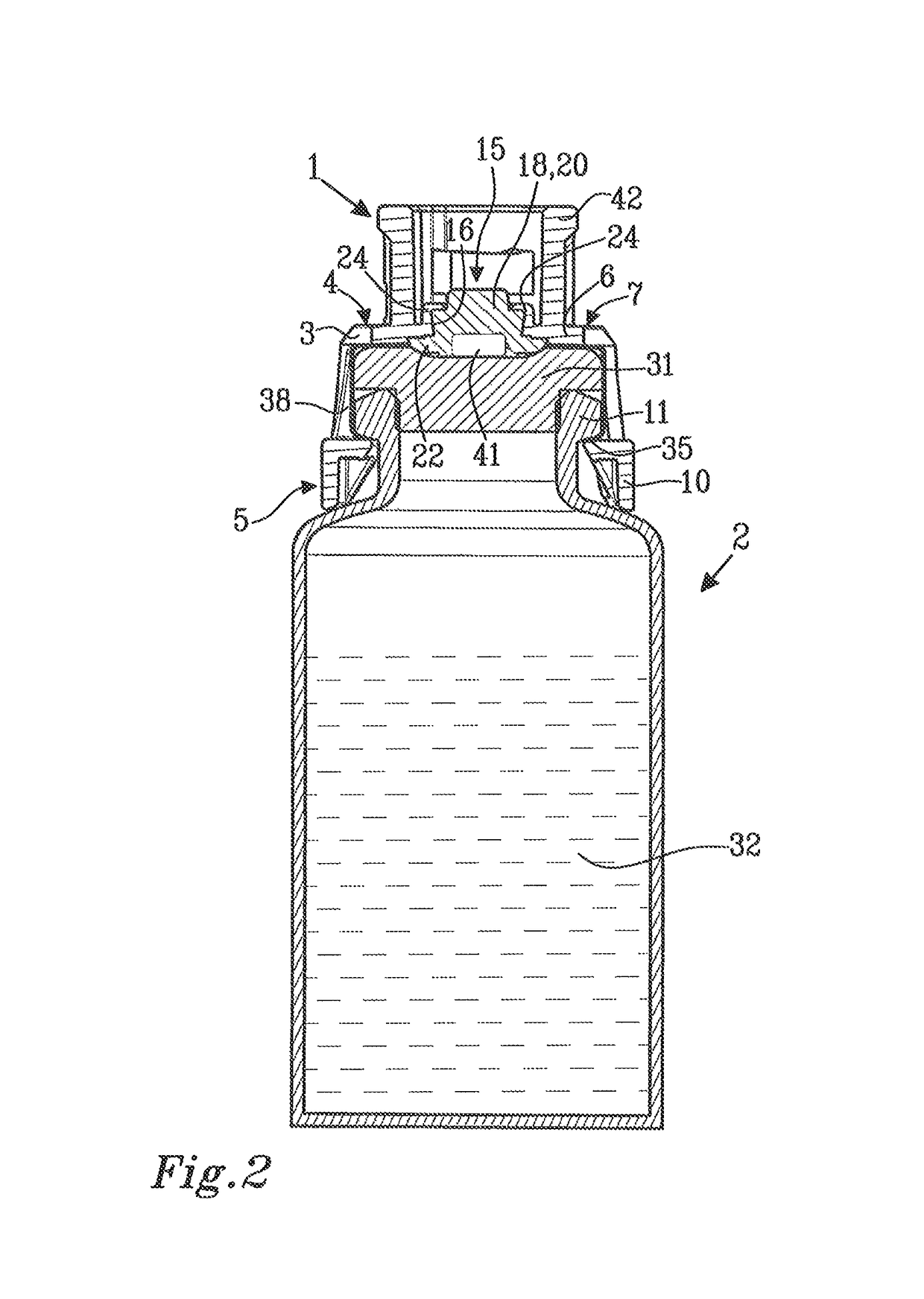

Protective Cap

ActiveUS20160038373A1Produced cost efficientlyCost efficientCapsClosure using stoppersMedical deviceBiomedical engineering

A protective cap (1) for application on a medical device such as a medical vial (2) comprising a membrane holder (3) in which a resilient membrane (18) is mounted. The protective cap (1) is provided with connection means (10) for connecting the cap (1) to the medical device (2). The resilient membrane (18) comprises a piercing portion (20) and a sealing portion (22) and is mechanically and / or adhesively held in the protective cap (1) and is arranged to be brought into seailng contact with a receiving portion of the medical device (2) when the protective cap (1) is applied on the medical device (2).

Owner:CARMEL PHARMA

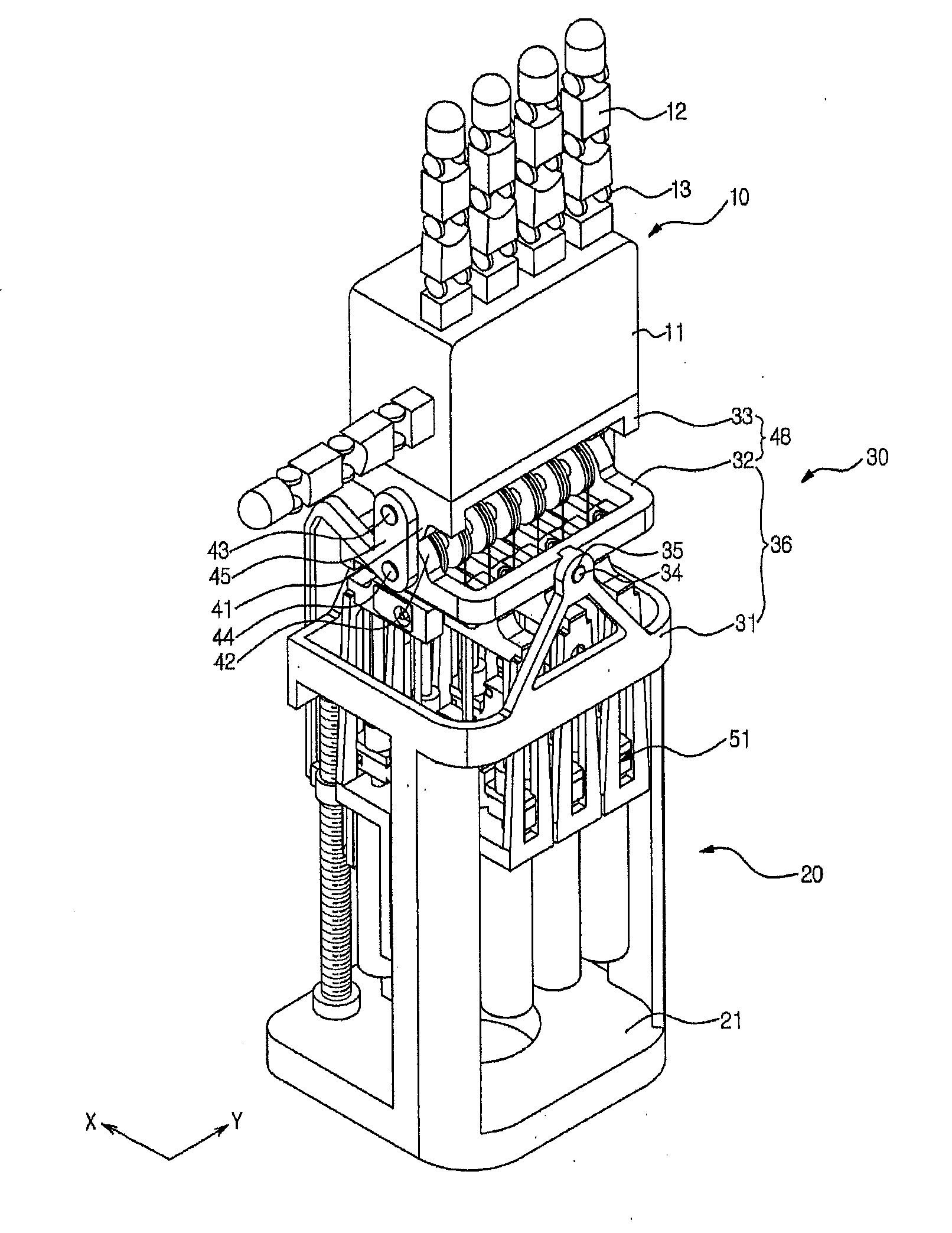

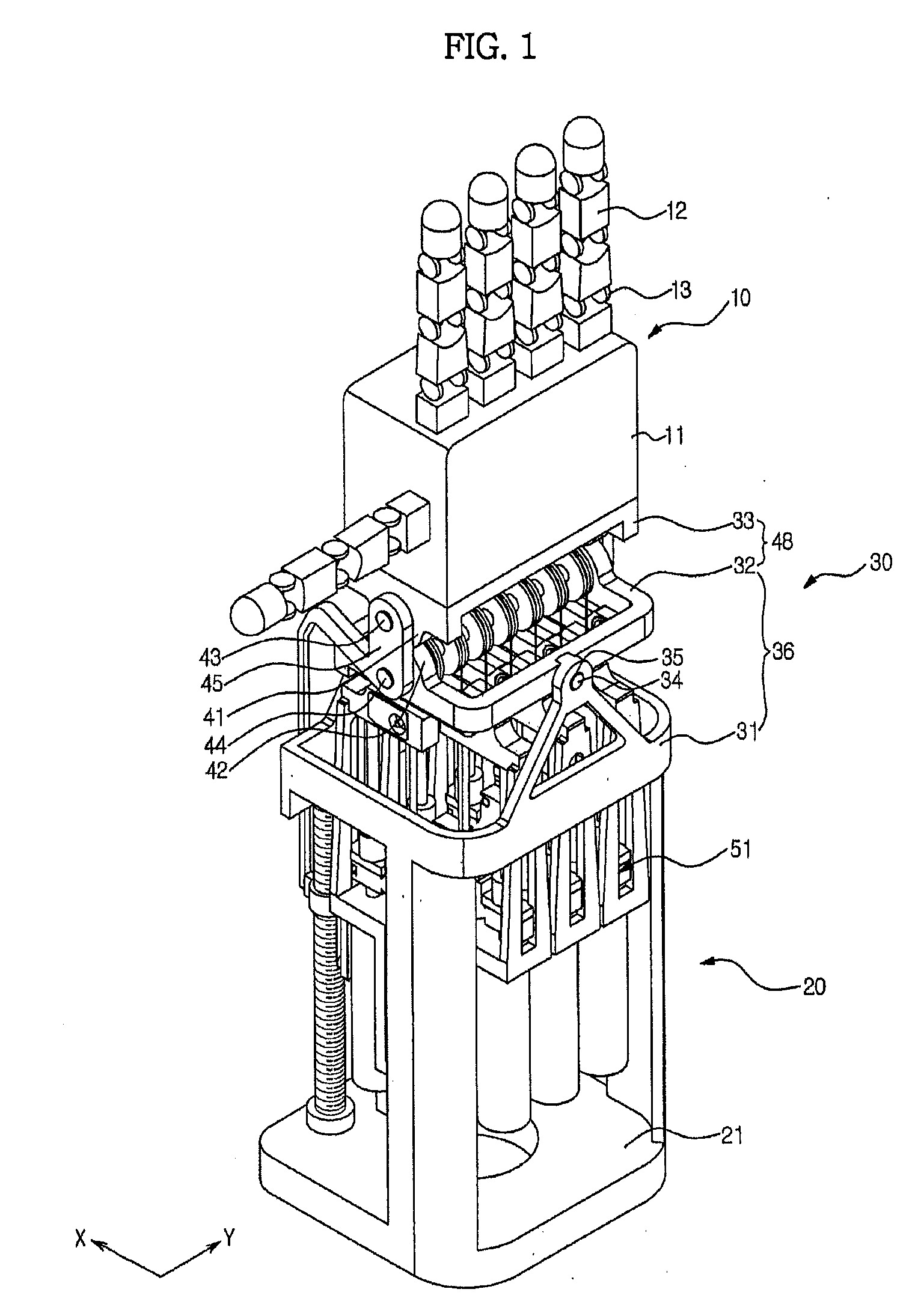

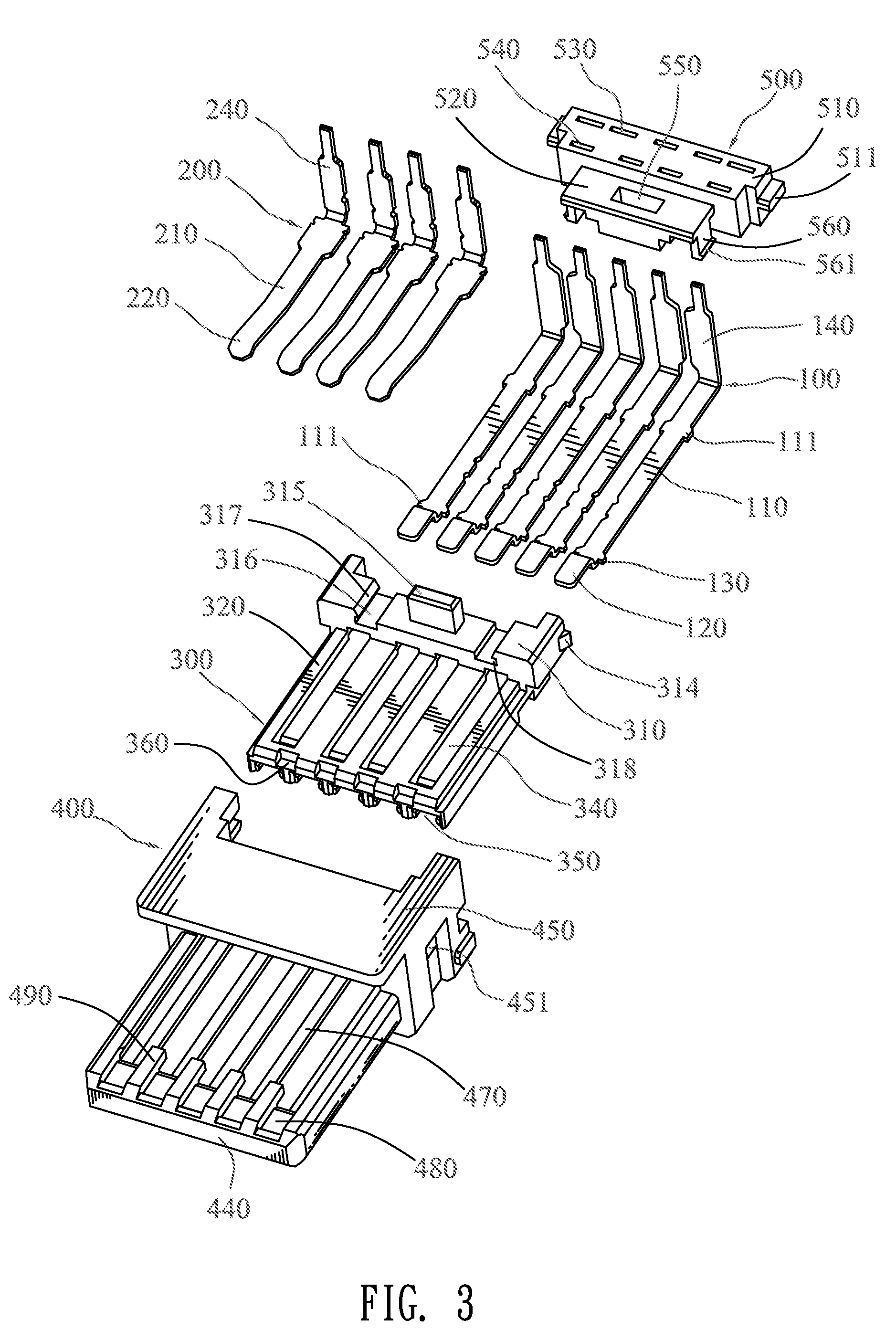

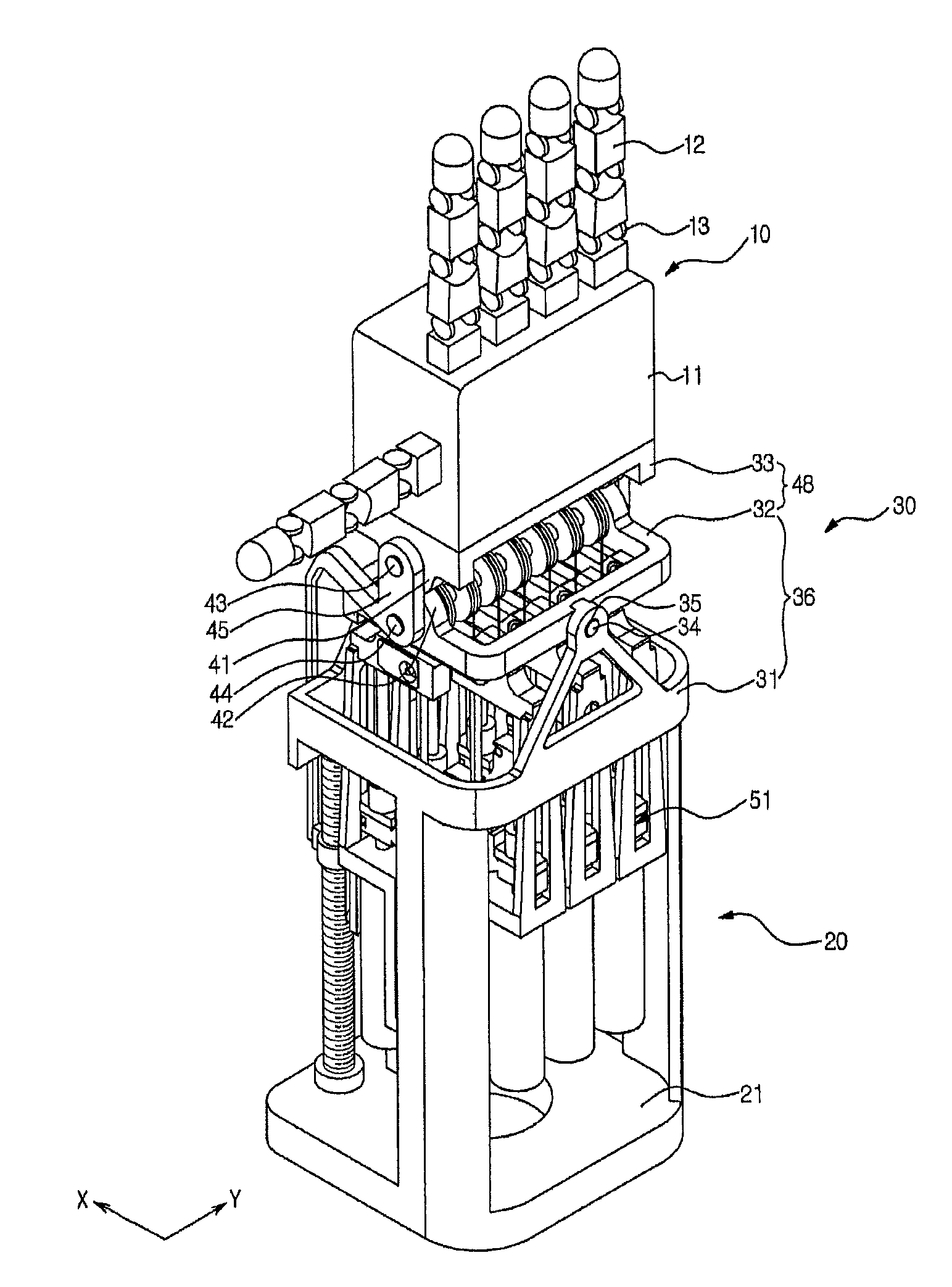

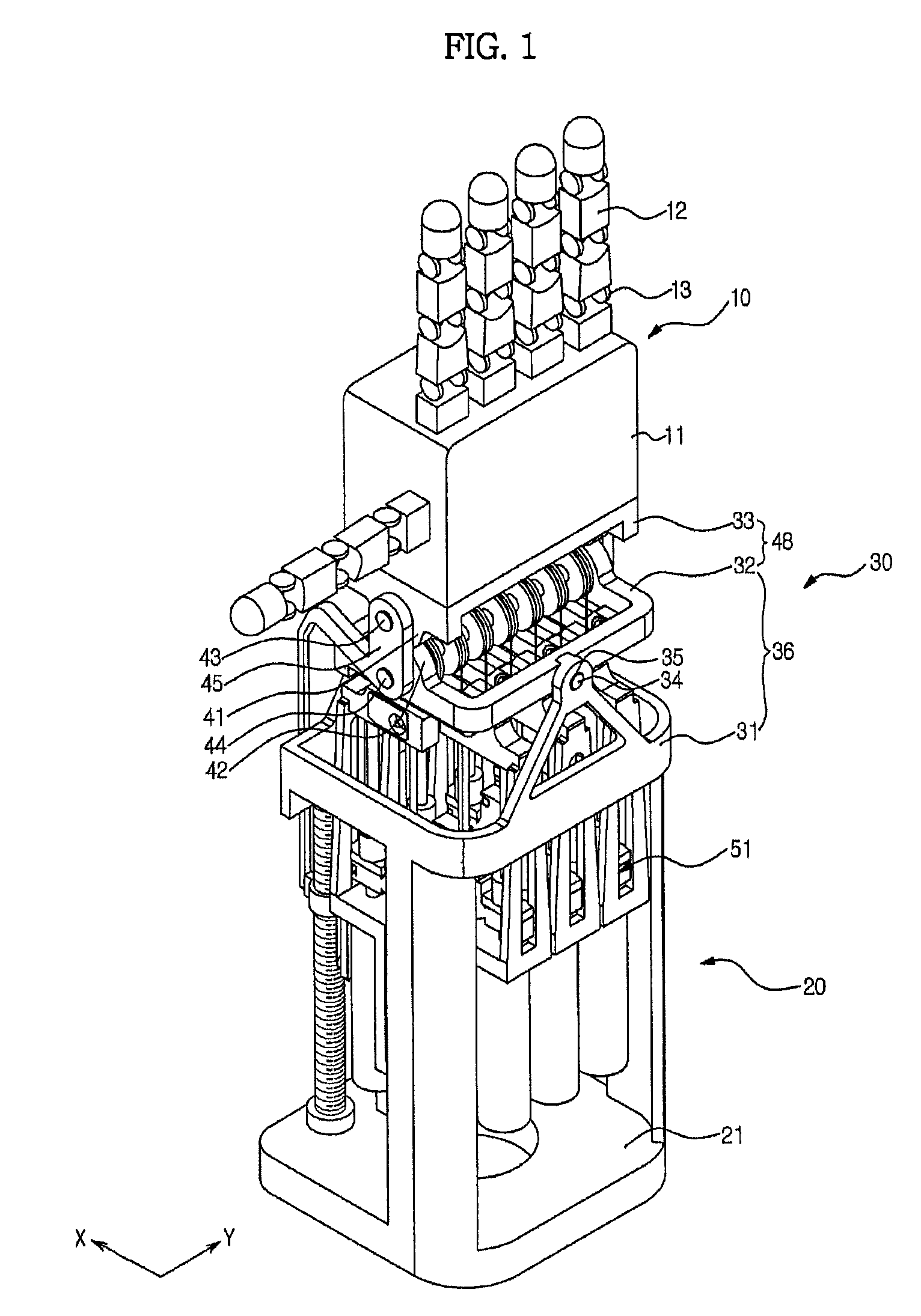

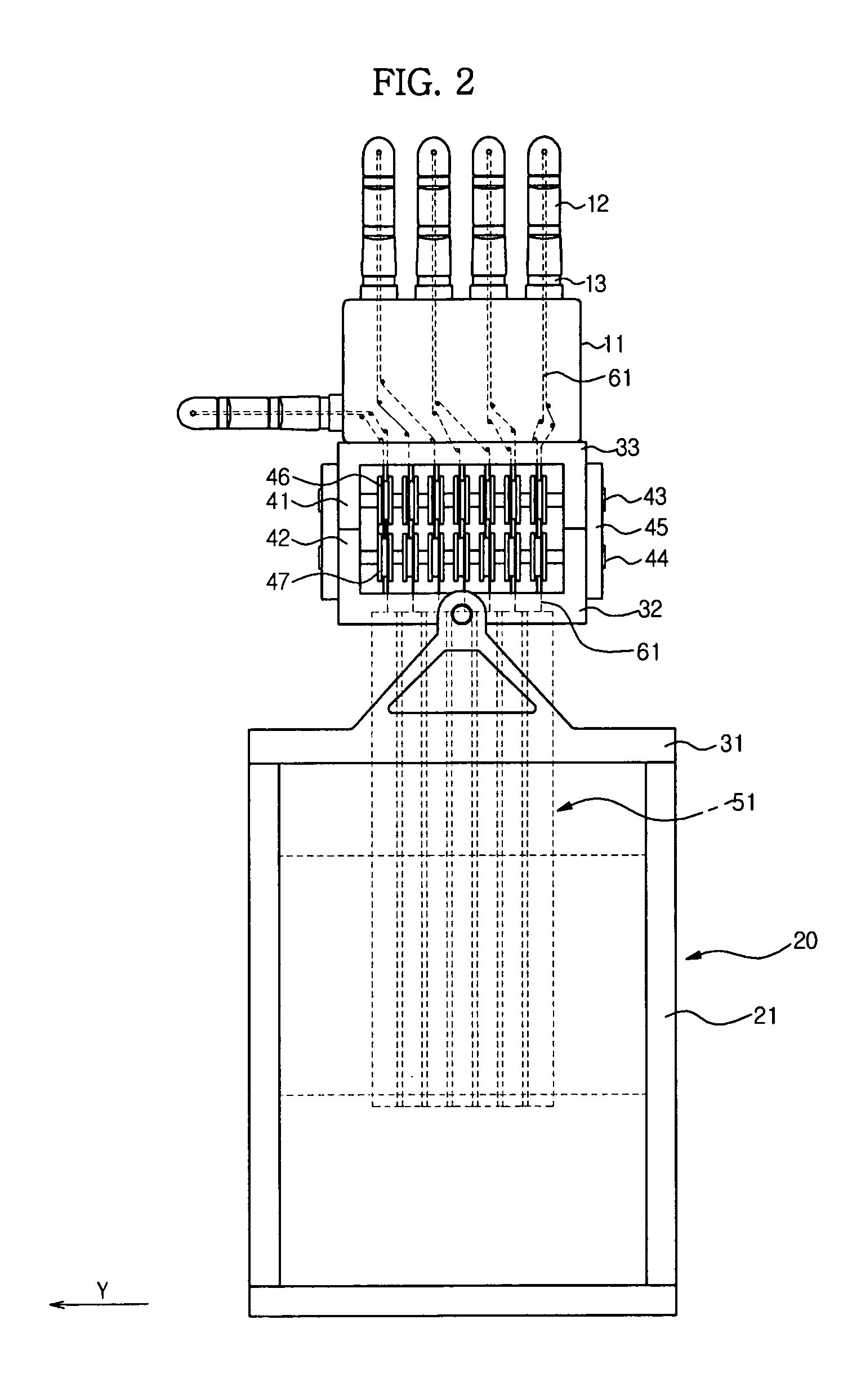

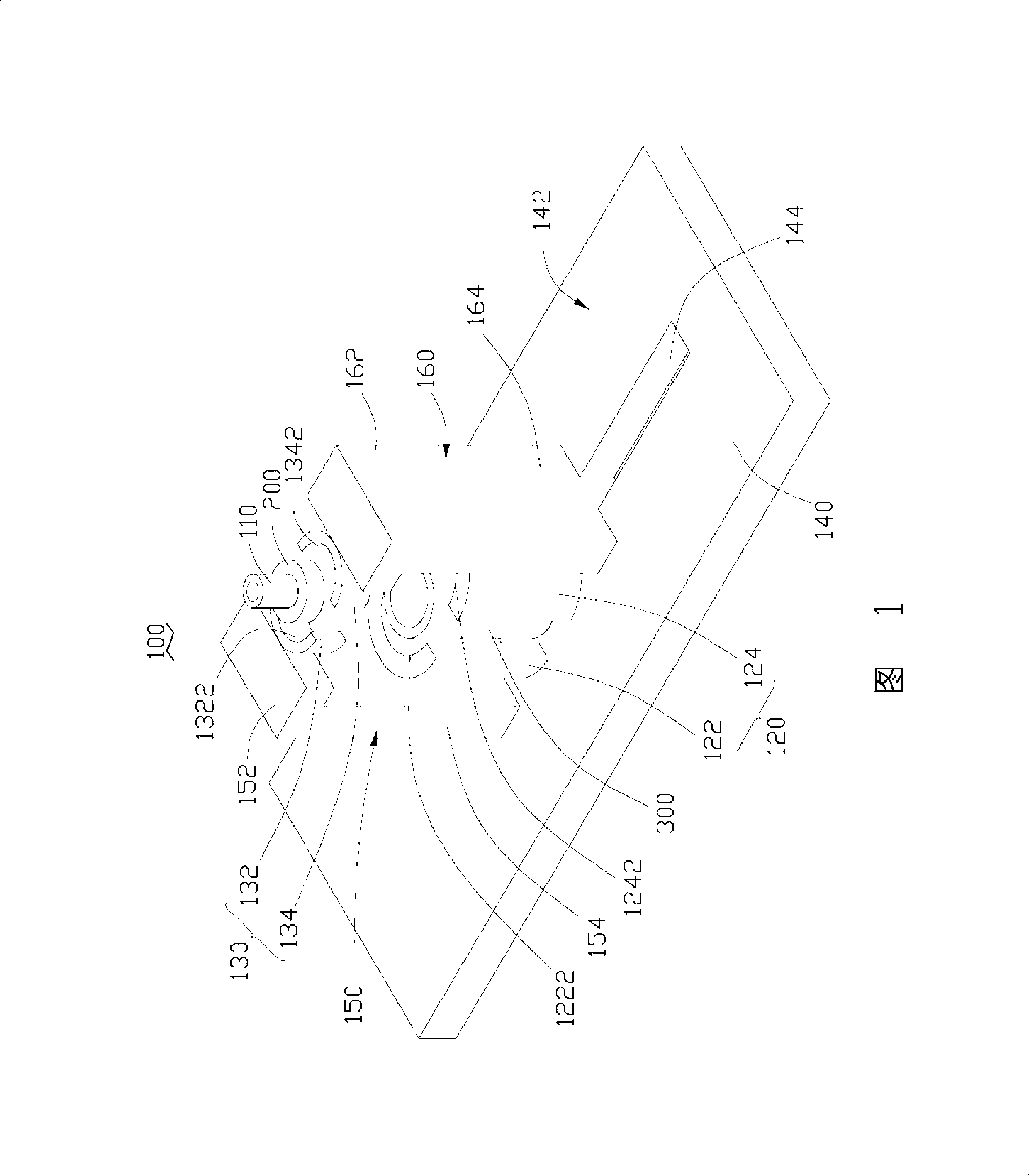

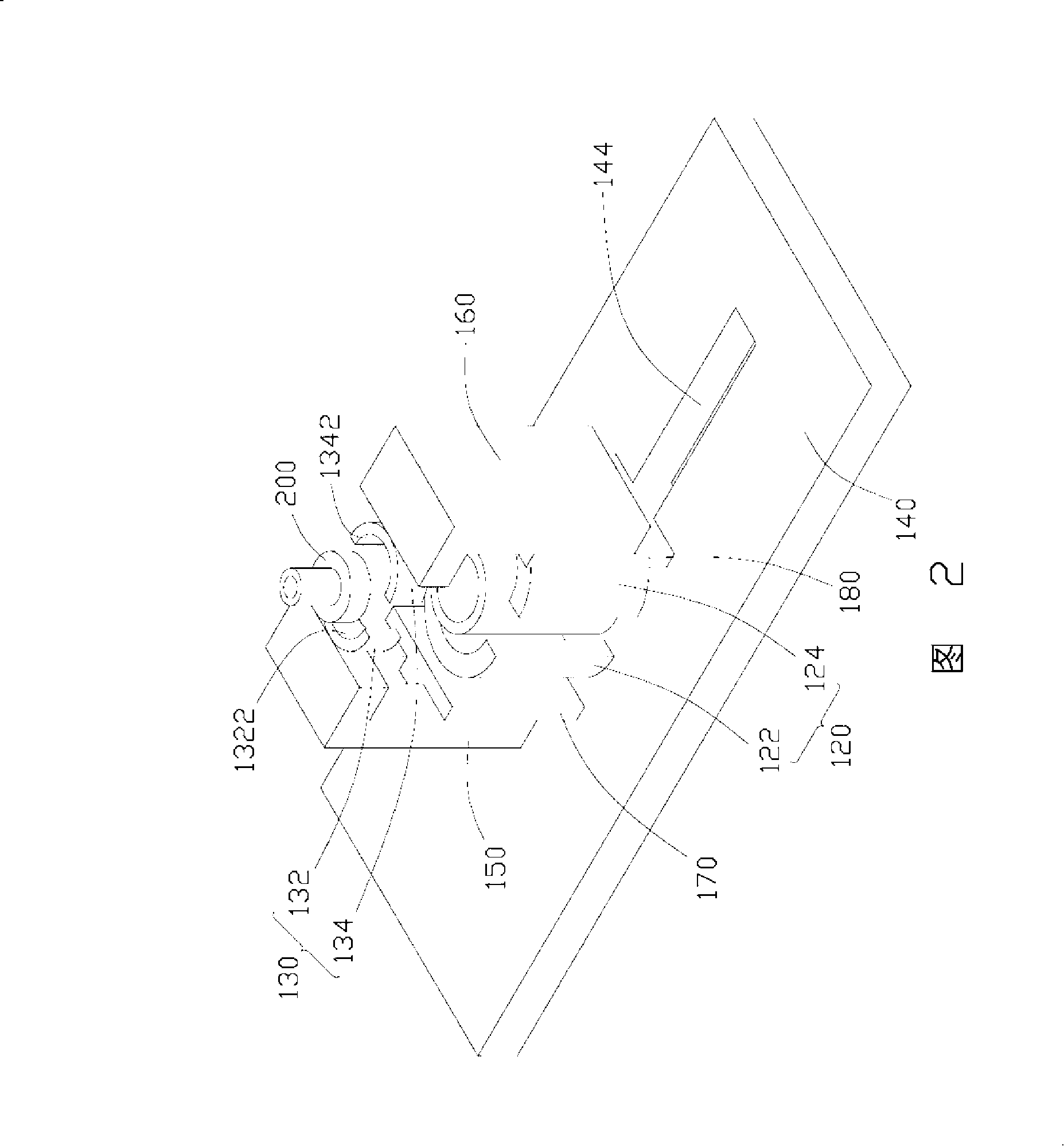

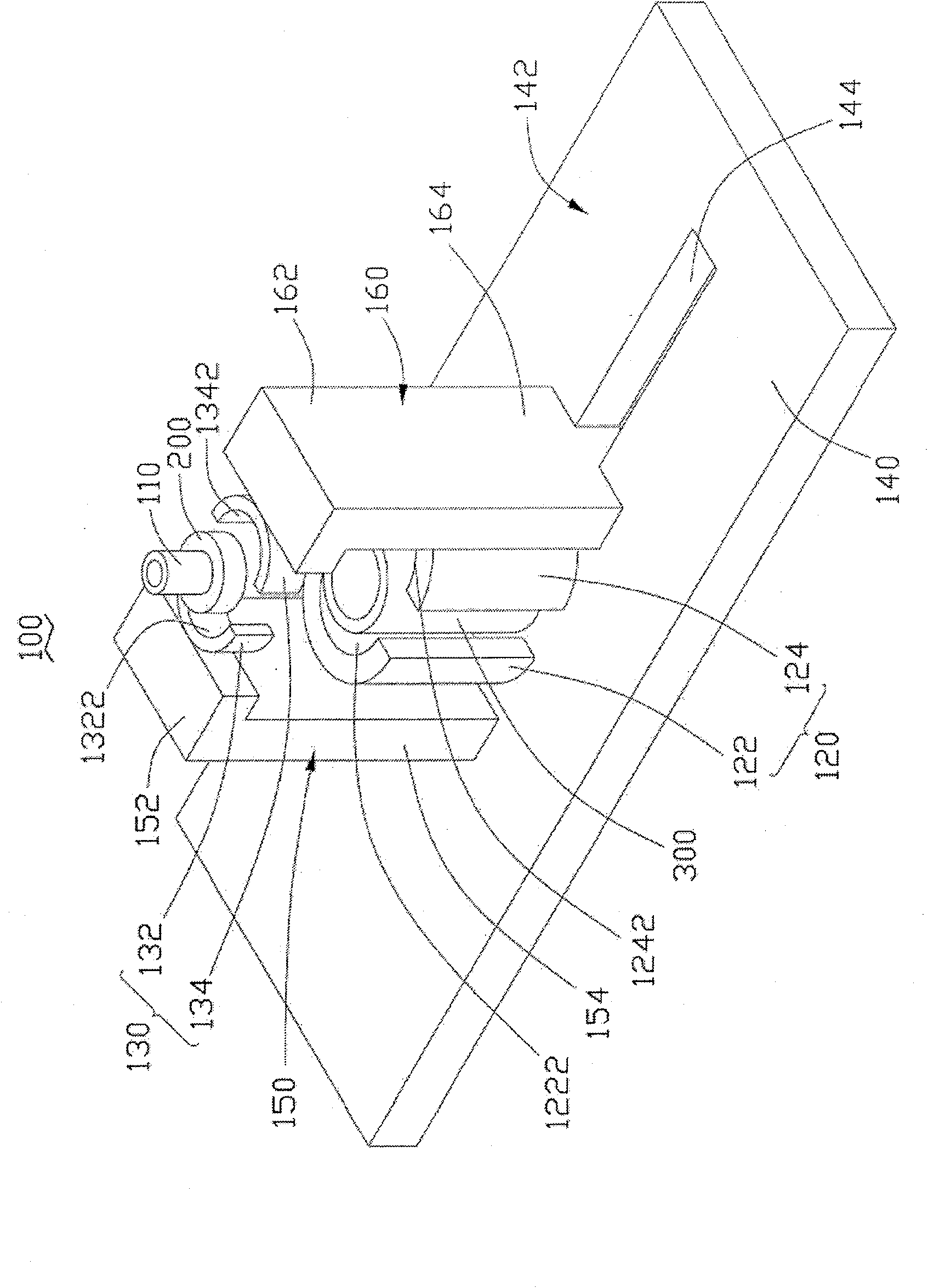

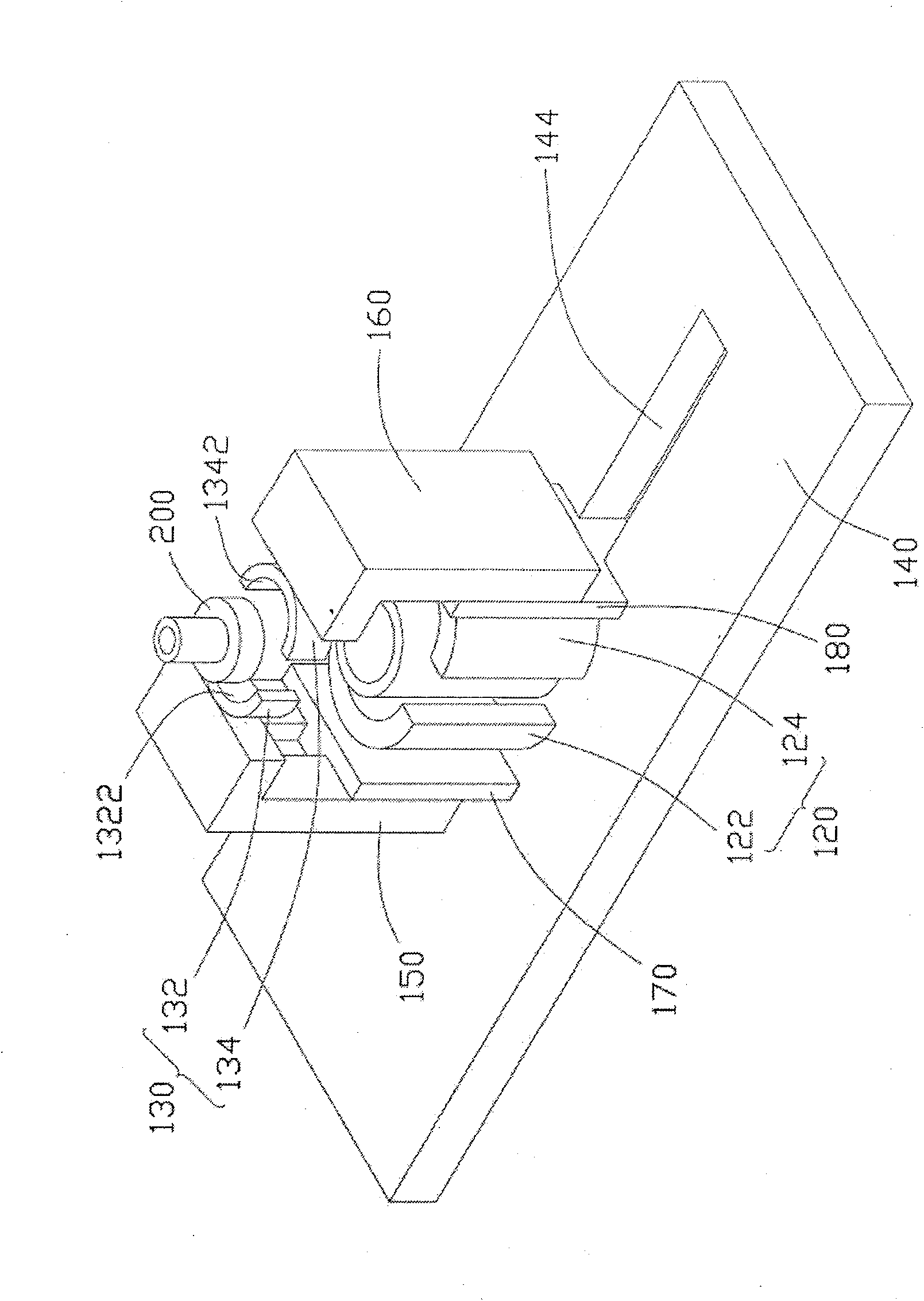

Robot actuator and humanoid robot having the same

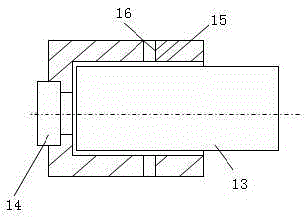

ActiveUS20110067518A1Effective reflectionAccurate and efficient assemblyProgramme-controlled manipulatorJointsHumanoid robot naoBall screw

Disclosed herein are a robot actuator and a humanoid robot having the same. The robot actuator includes a rotation driving source, a ball screw member including a ball screw part connected to the rotation driving source and a nut part connected to the ball screw part, a guide member separated in parallel from the ball screw part, a slider member movably supported by the guide member, and a connection member connecting the slider member and the nut part to move the slider member in connection with movement of the nut part, and the connection member is relatively movably connected to at least one of the nut part and the slider member. Therefore, efficiency in force reflection and back-drivability of the actuator is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

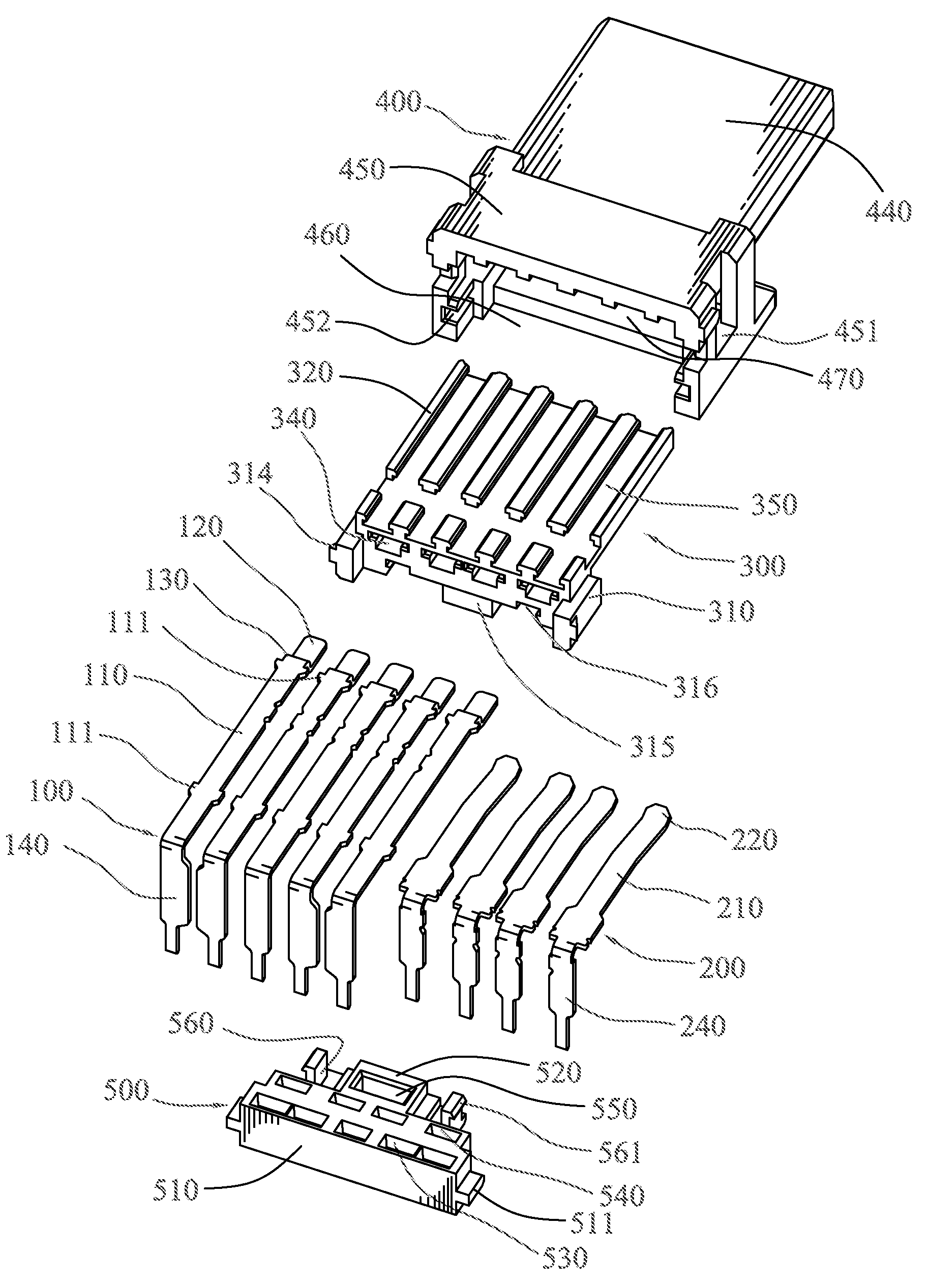

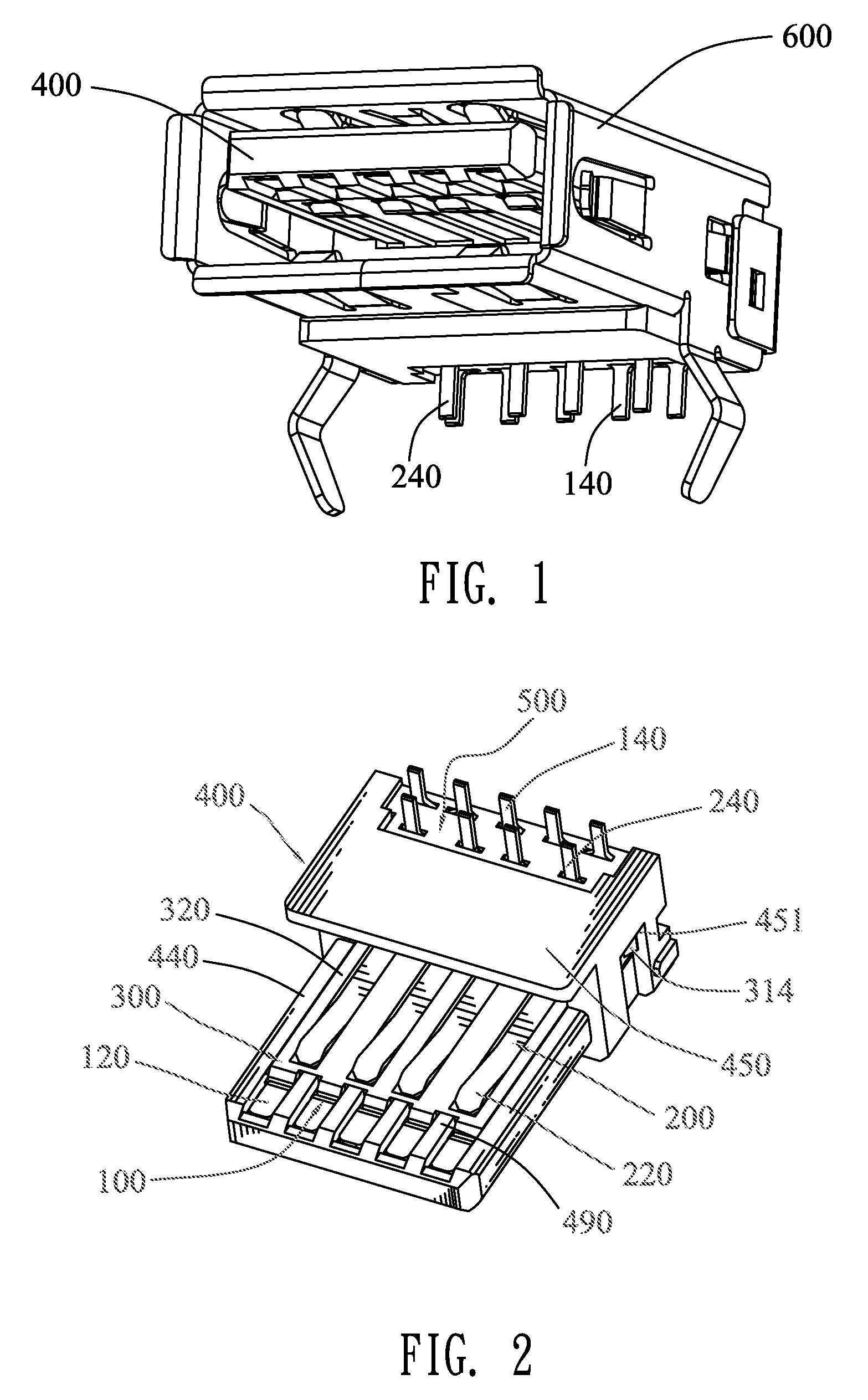

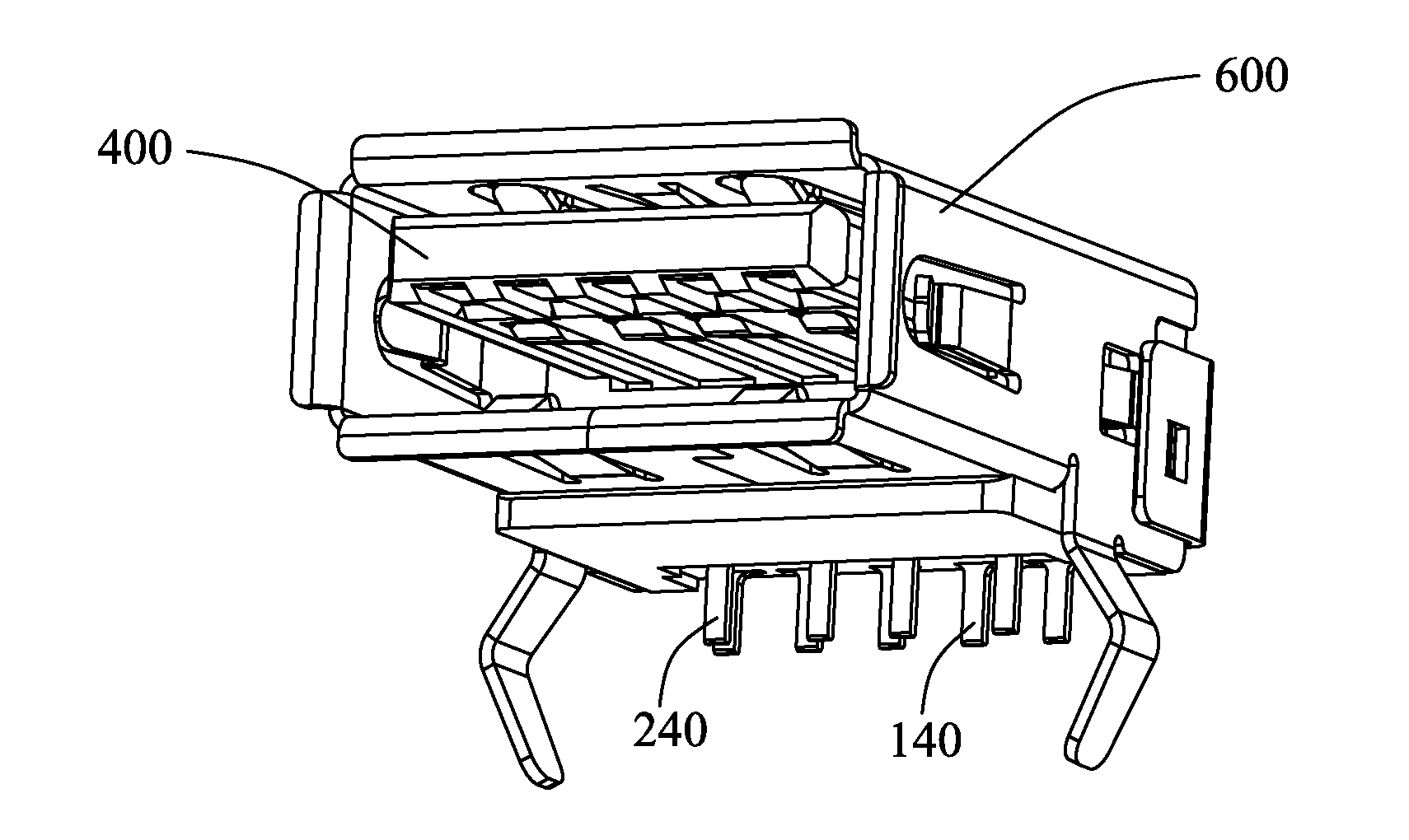

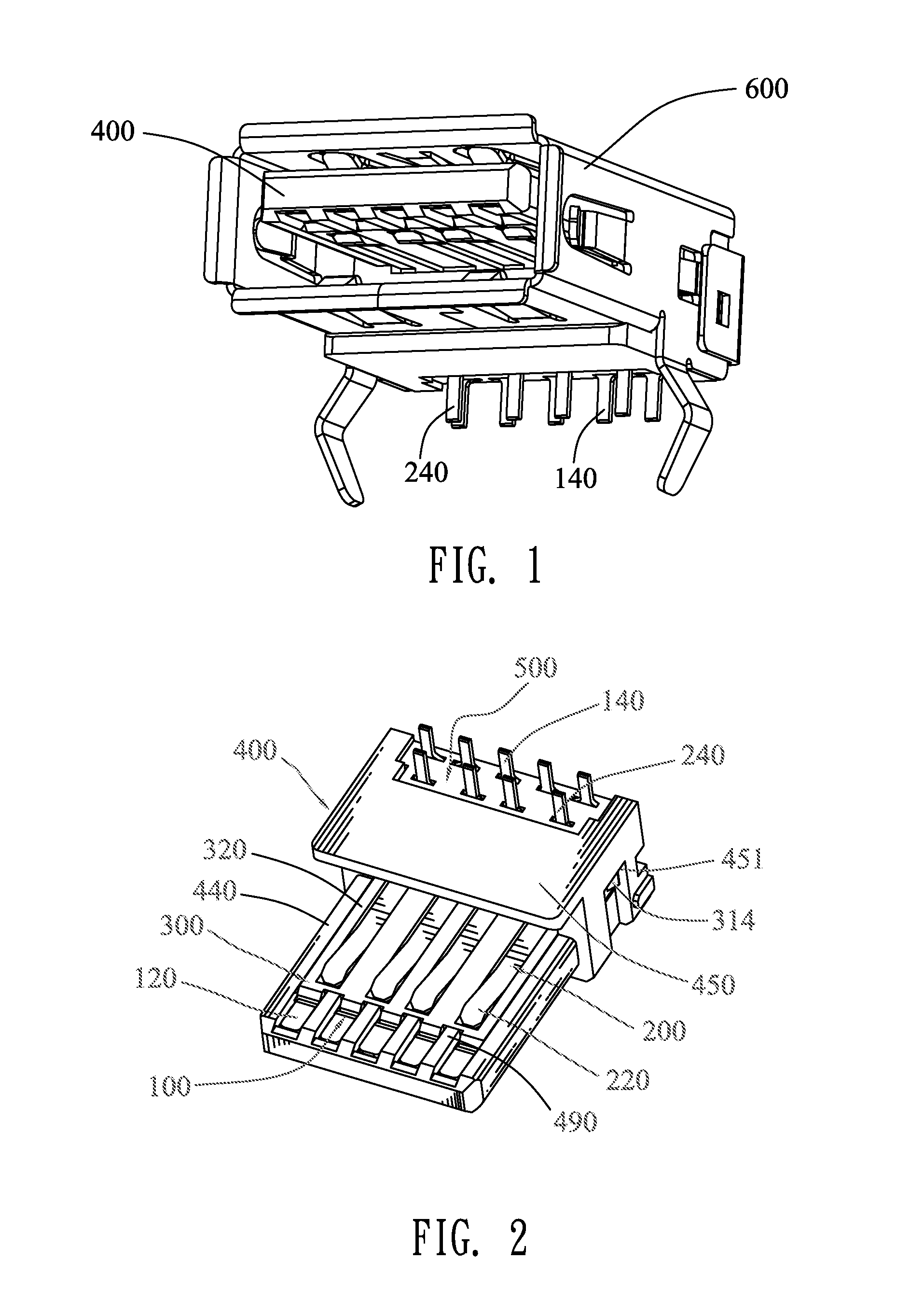

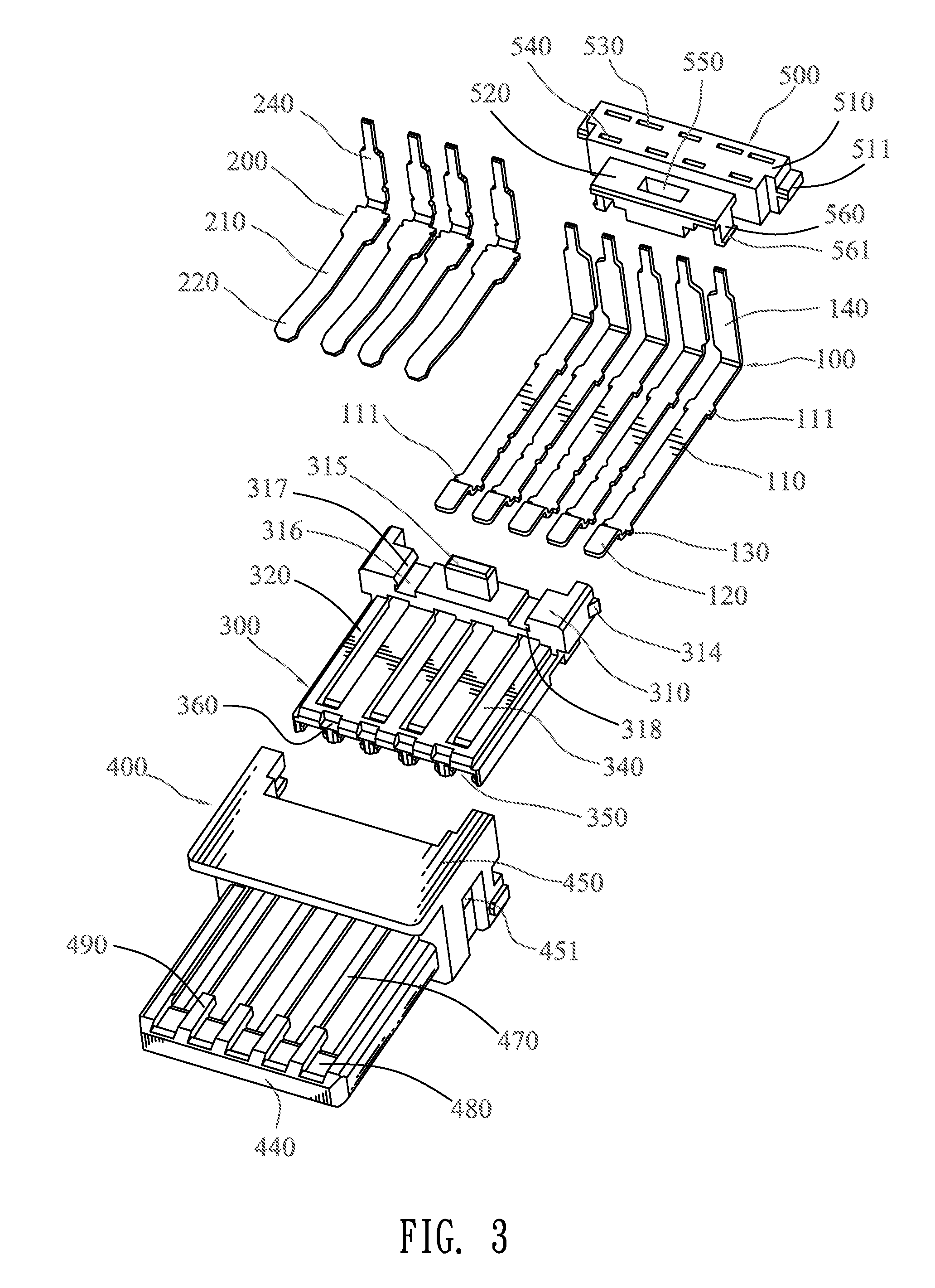

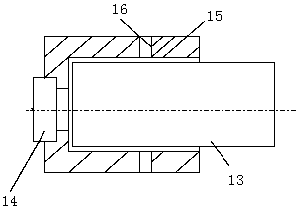

Electrical connector

InactiveUS8147276B2Avoid deformationAccurate and efficient assemblyElectric discharge tubesTwo-part coupling devicesEngineeringElectrical connector

An electrical connector includes an insulating body having a base portion and a tongue portion extending forward from the base portion, a plurality of terminals disposed in two opposite surfaces of the tongue portion and each having a soldering tail which stretches behind the base portion and further projects upward beyond a top of the base portion, and a lid having a positioning body and a fastening portion protruding forward from the positioning body. The positioning body defines a plurality of positioning apertures spaced from one another and each extending vertically to penetrate through the positioning body. The fastening portion is mounted to the top of the base portion to make the positioning body locate behind the base portion. The soldering tails are inserted in the positioning apertures to be positioned and strengthened by the positioning body, with free ends thereof projecting beyond a top of the positioning body.

Owner:CHENG UEI PRECISION IND CO LTD

Electrical connector

InactiveUS20120052739A1Avoid deformationAccurate and efficient assemblyElectric discharge tubesTwo-part coupling devicesEngineeringSoldering

An electrical connector includes an insulating body having a base portion and a tongue portion extending forward from the base portion, a plurality of terminals disposed in two opposite surfaces of the tongue portion and each having a soldering tail which stretches behind the base portion and further projects upward beyond a top of the base portion, and a lid having a positioning body and a fastening portion protruding forward from the positioning body. The positioning body defines a plurality of positioning apertures spaced from one another and each extending vertically to penetrate through the positioning body. The fastening portion is mounted to the top of the base portion to make the positioning body locate behind the base portion. The soldering tails are inserted in the positioning apertures to be positioned and strengthened by the positioning body, with free ends thereof projecting beyond a top of the positioning body.

Owner:CHENG UEI PRECISION IND CO LTD

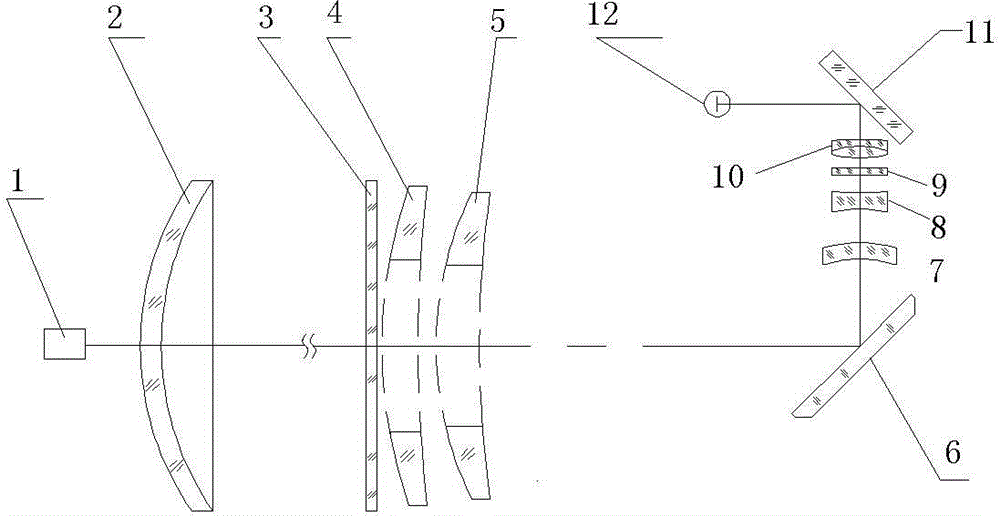

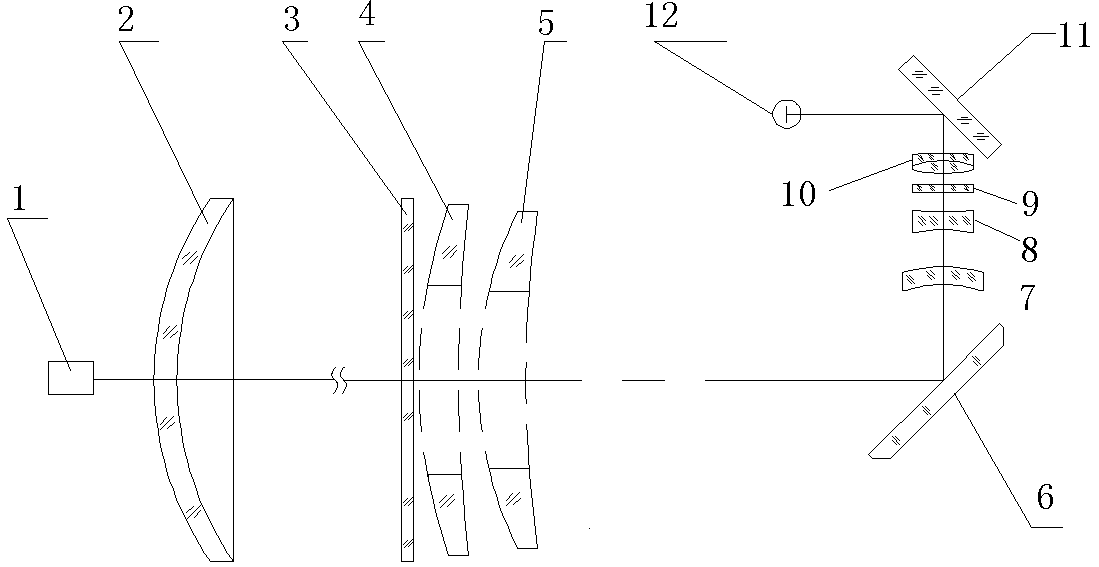

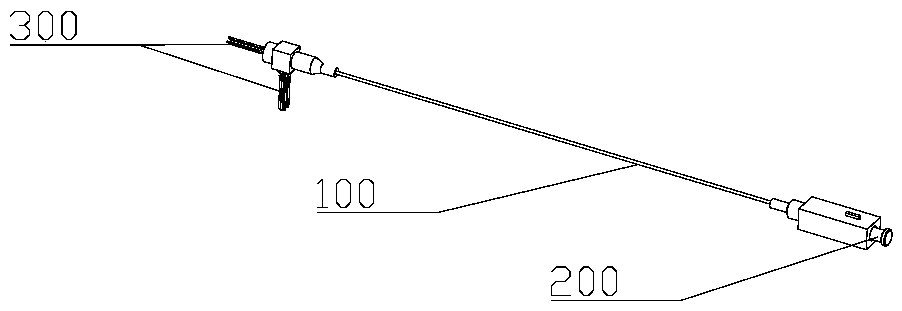

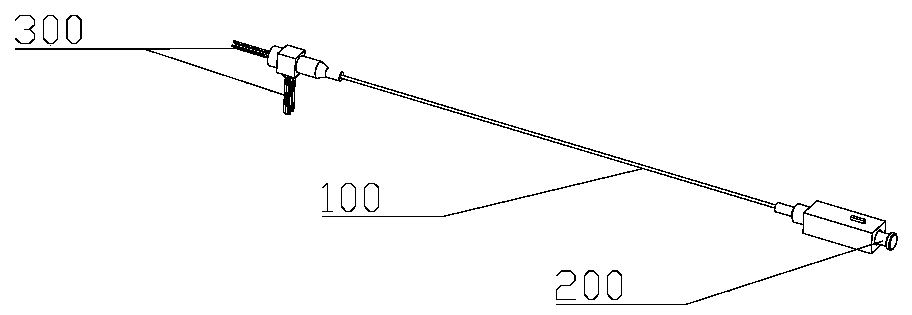

Laser reception debugging method and apparatus

ActiveCN105301578AEasy to operateLow skill level and experience requirements for workersWave based measurement systemsOptical pathLaser ranging

The invention relates to the optical adjusting field of a laser range finding machine, and specifically relates to a laser reception debugging method and apparatus. The laser reception debugging method comprises adjusting a reception light path; performing convergence and at least two-level replication for a laser echo signal generated after reflection of the signal emitted from the laser range finding machine through a detection object, and converging the laser echo signal at the photosensitive surface position of the detector eventually; setting an endoscope which can convert the invisible light into visible light, at the position of the photosensitive surface of the detector; and then adjusting the detector. The laser reception debugging method and apparatus can utilize the endoscope to display the invisible light as the visible light so that visual adjusting of a laser optical axis can be realized and accurate adjusting of the light path can be realized. The laser reception debugging method and apparatus can solve the problem about offset of the optical axis because of blind adjusting of laser optical axis, optical component machining error and adjusting error of an assembling staff, and has the advantages of being simple in operation, having no requirement for the skill level and the experience of workers, reducing the adjusting time, effectively improving the adjusting accuracy, and being able to realize accurate and effective adjusting of the laser optical axis.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

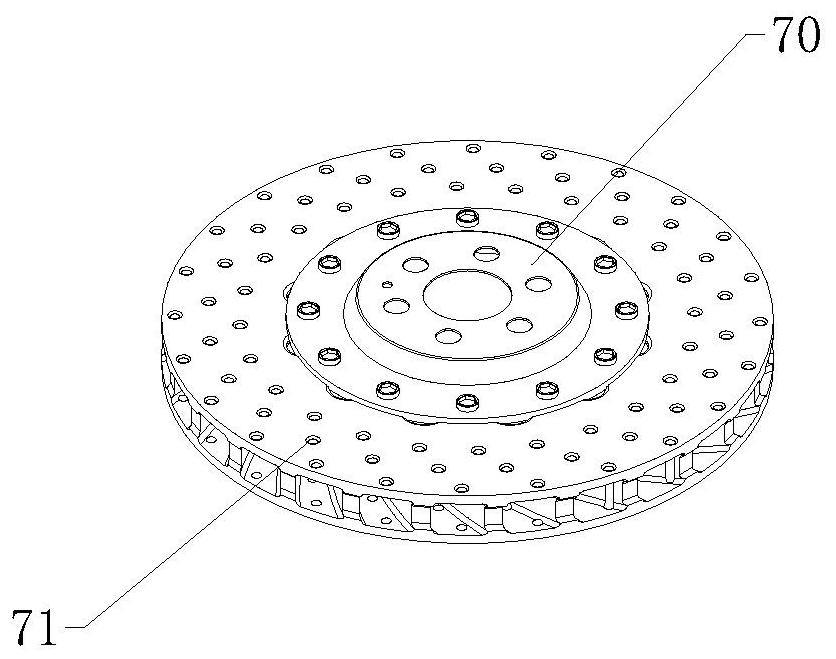

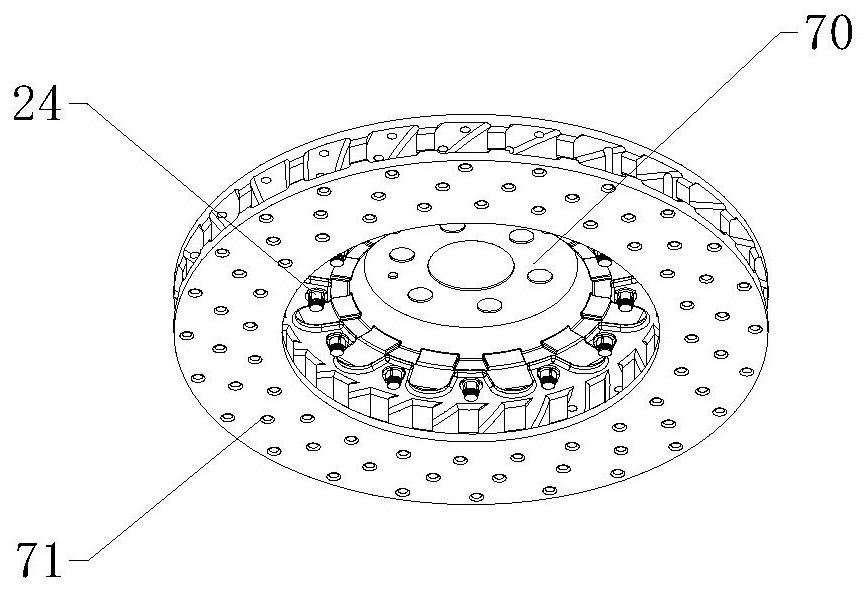

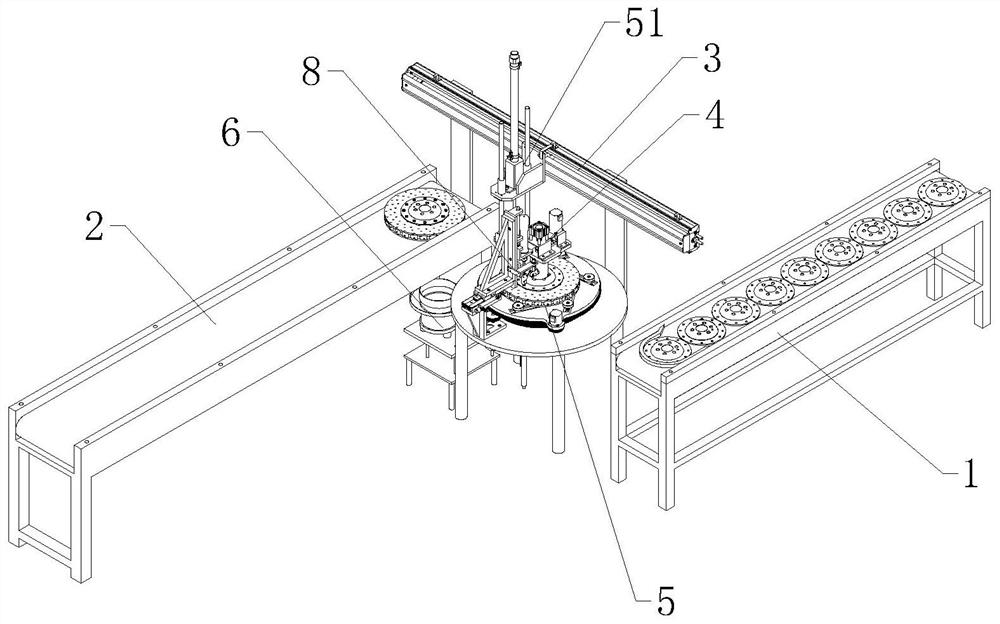

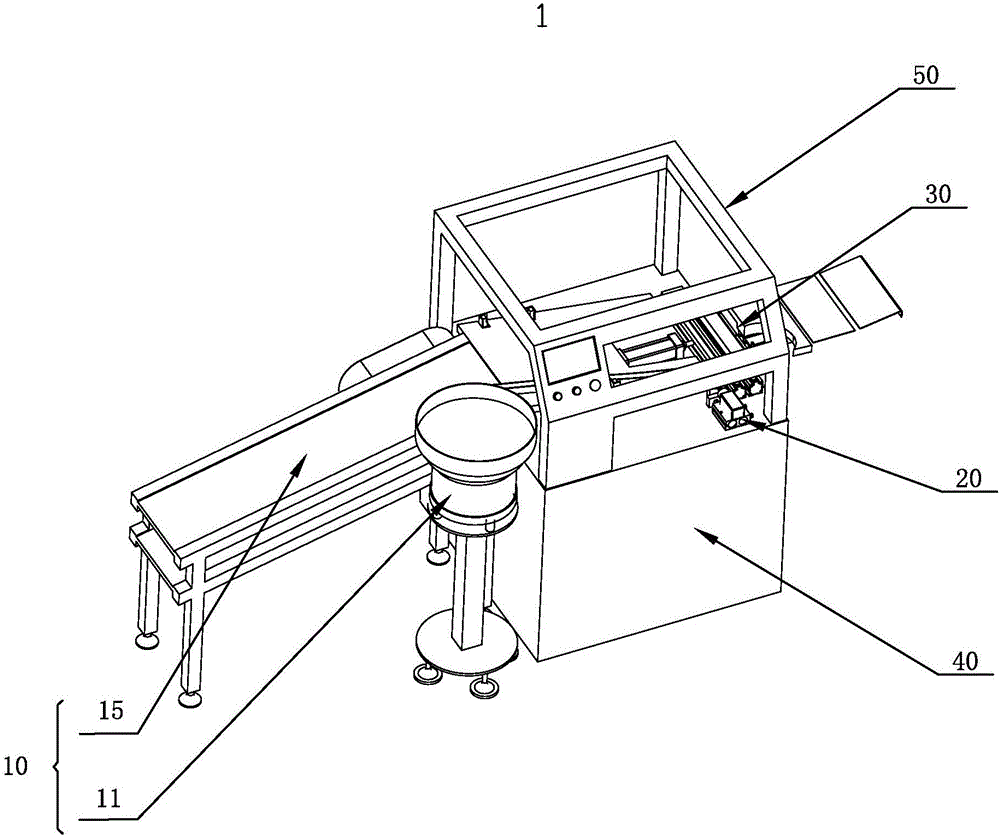

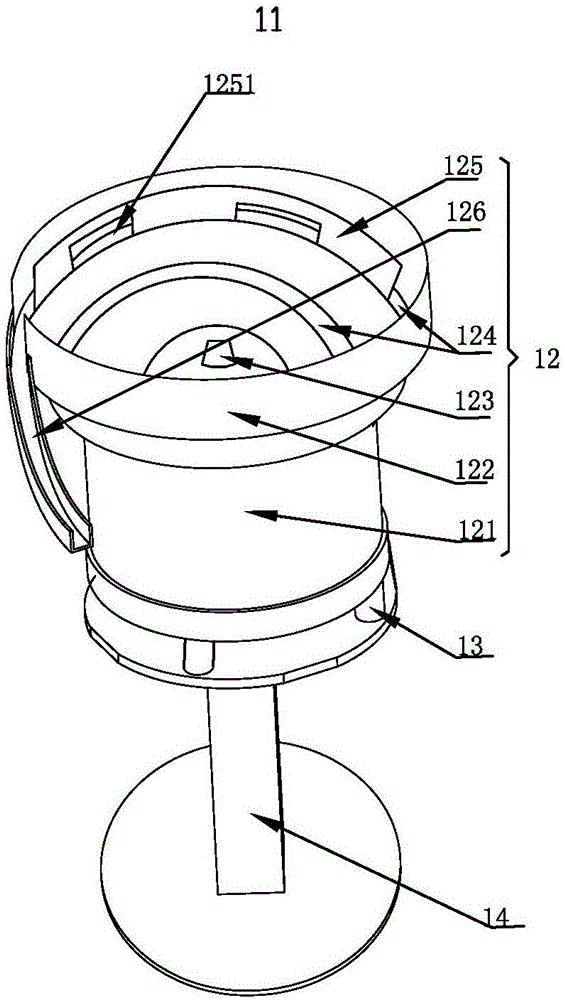

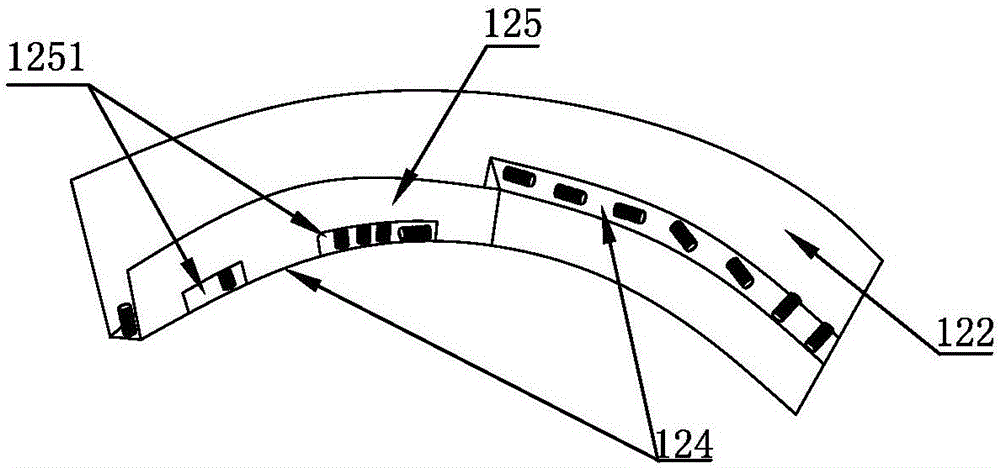

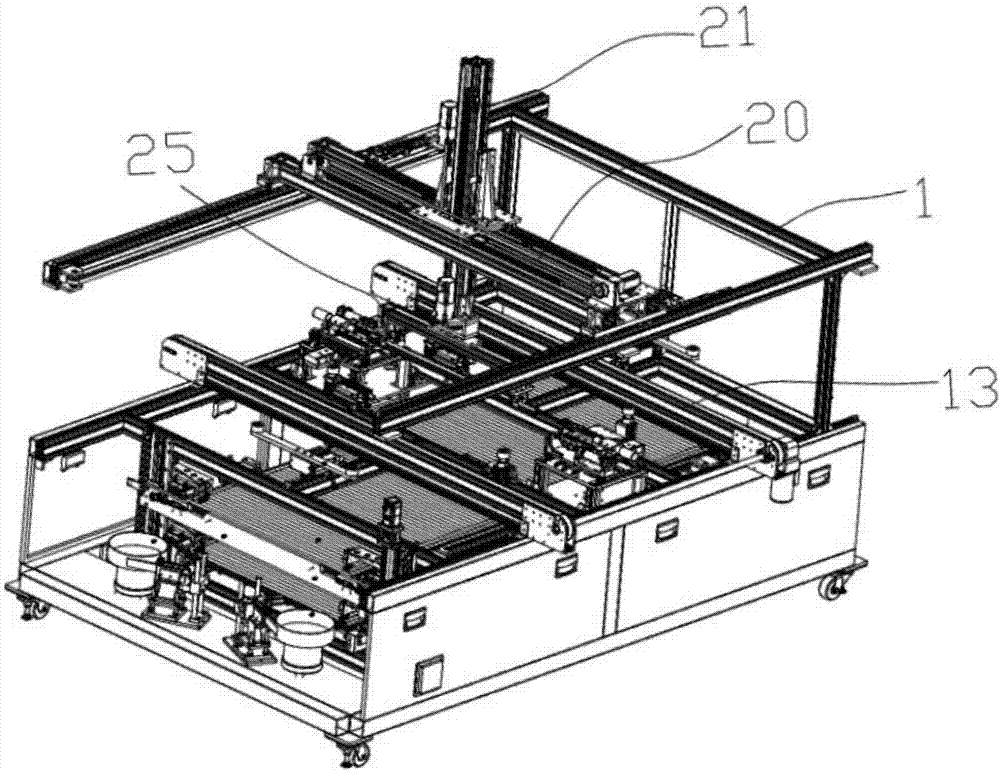

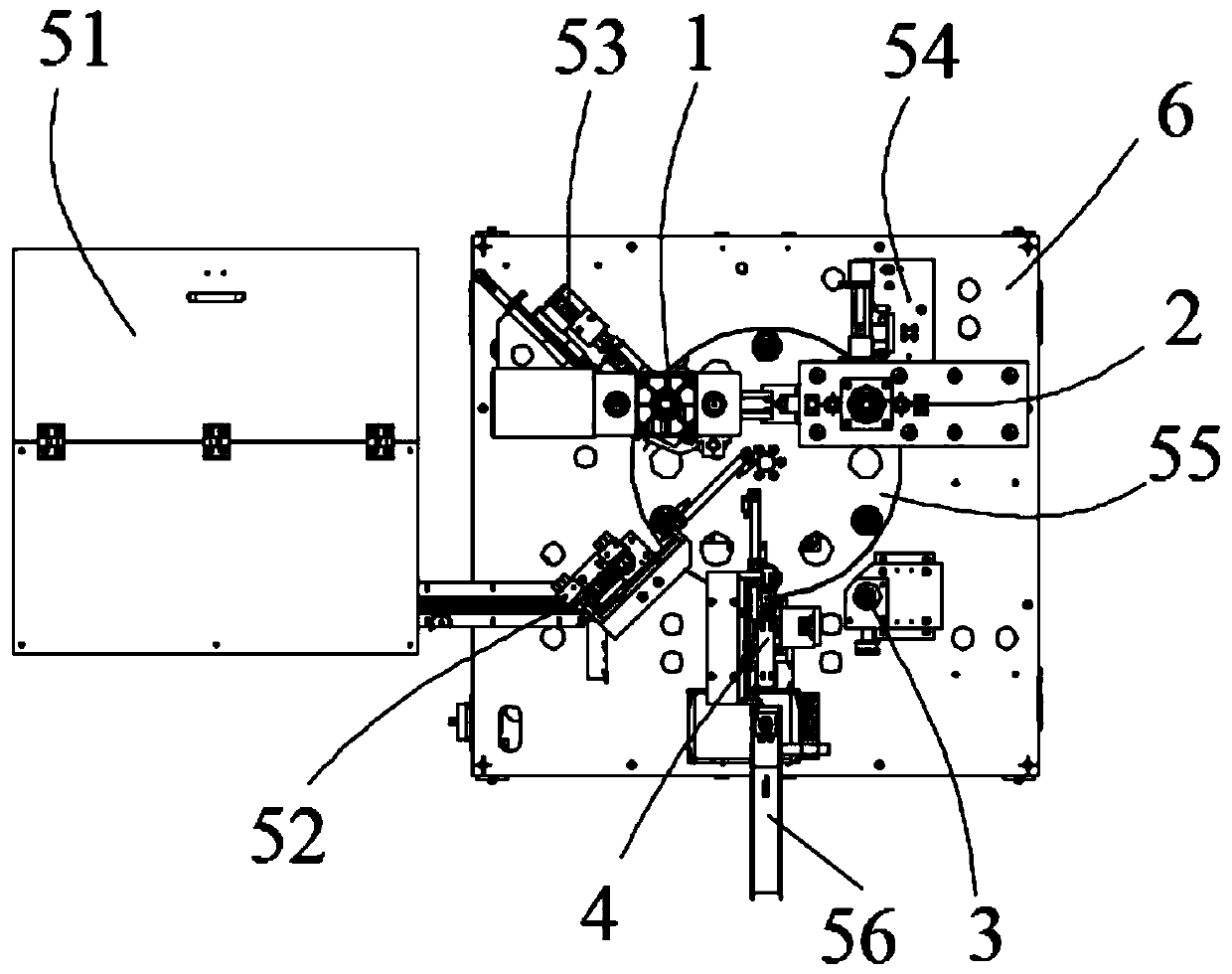

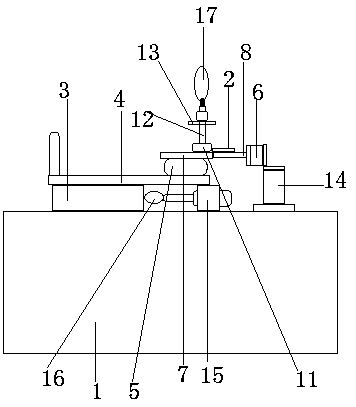

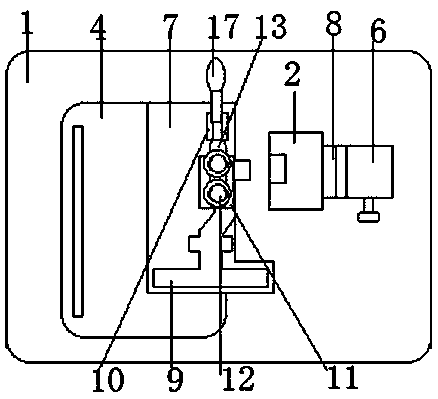

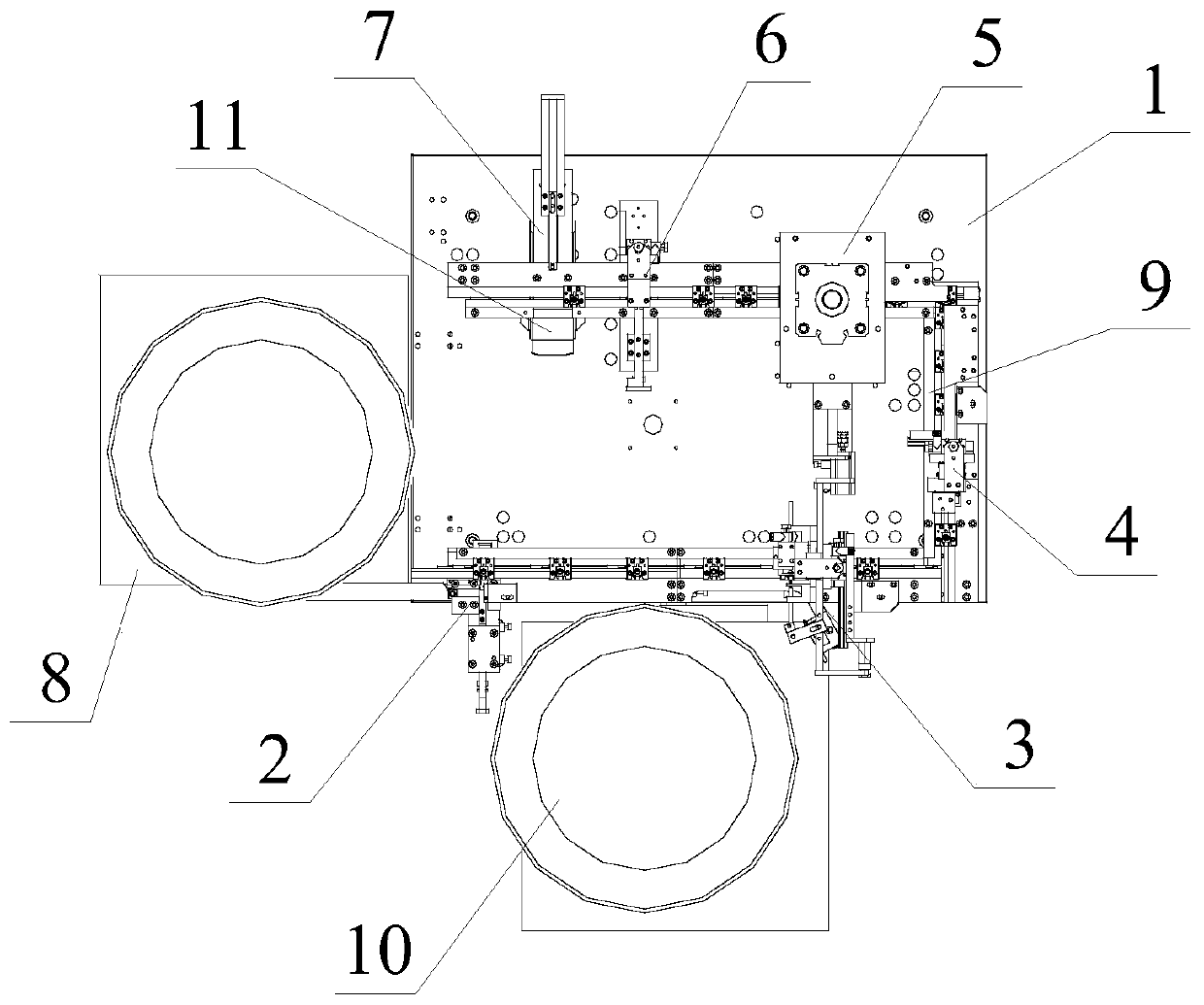

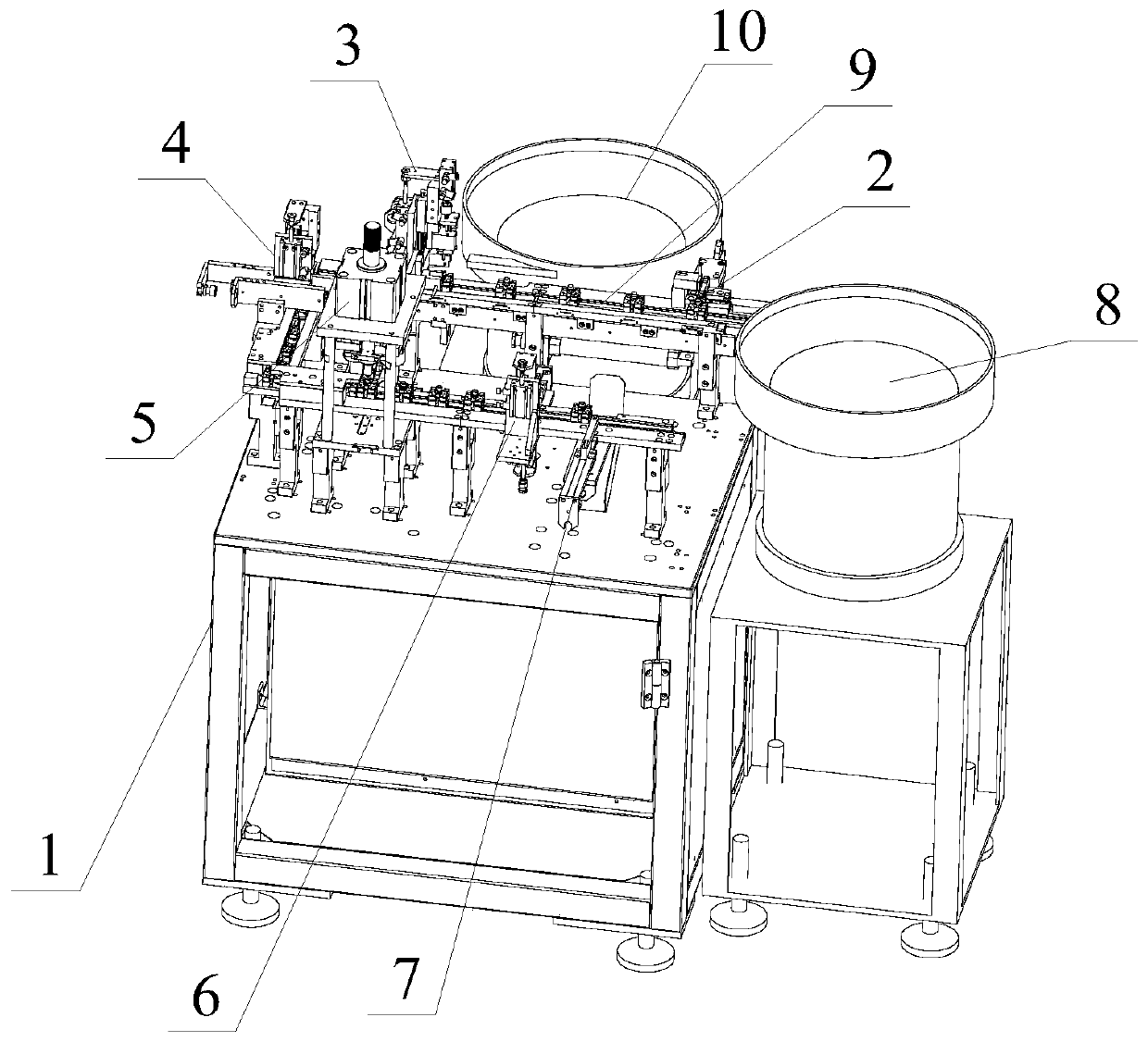

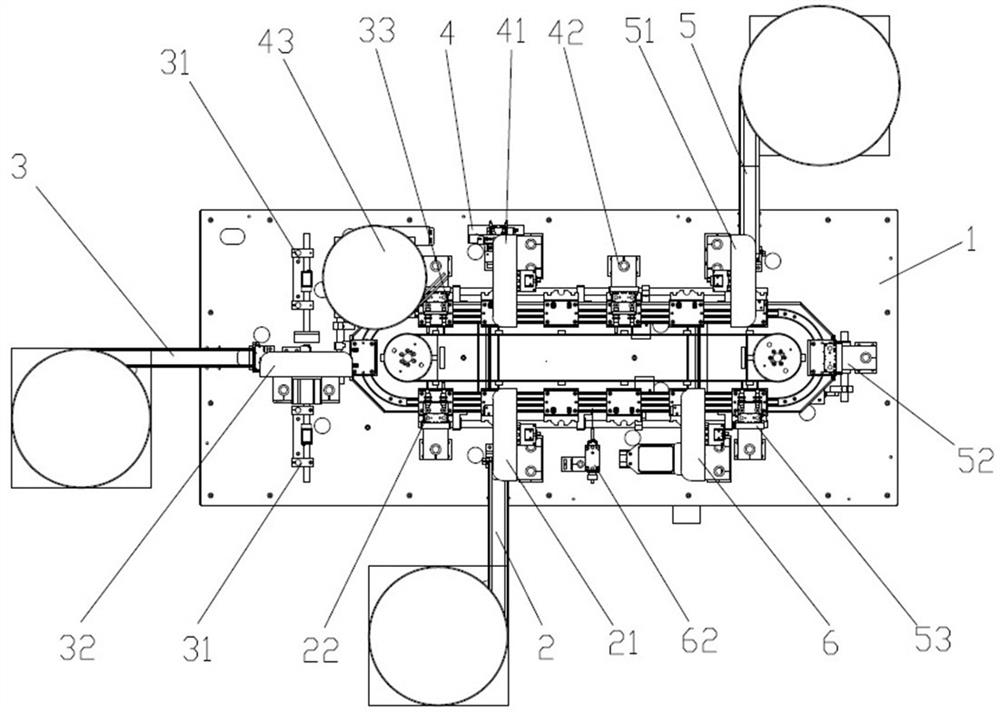

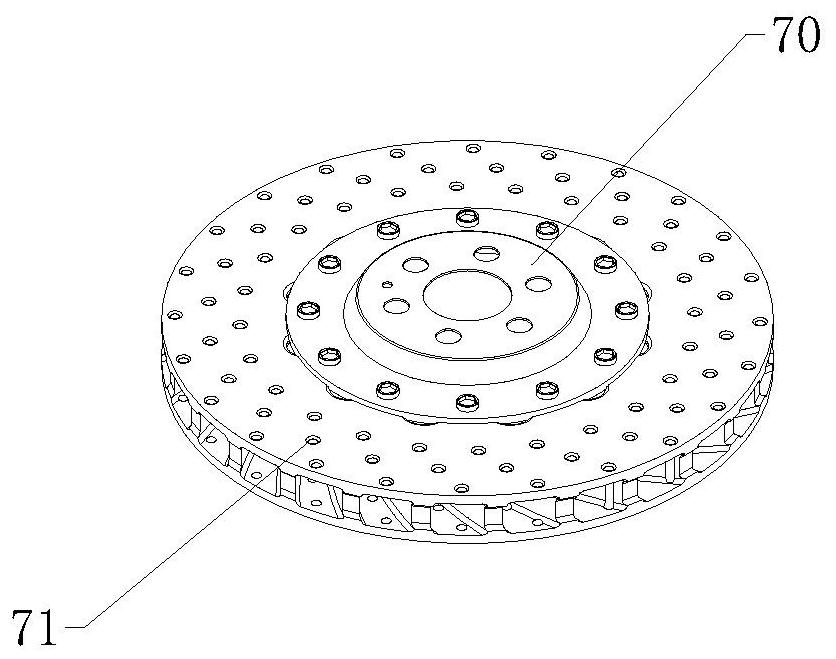

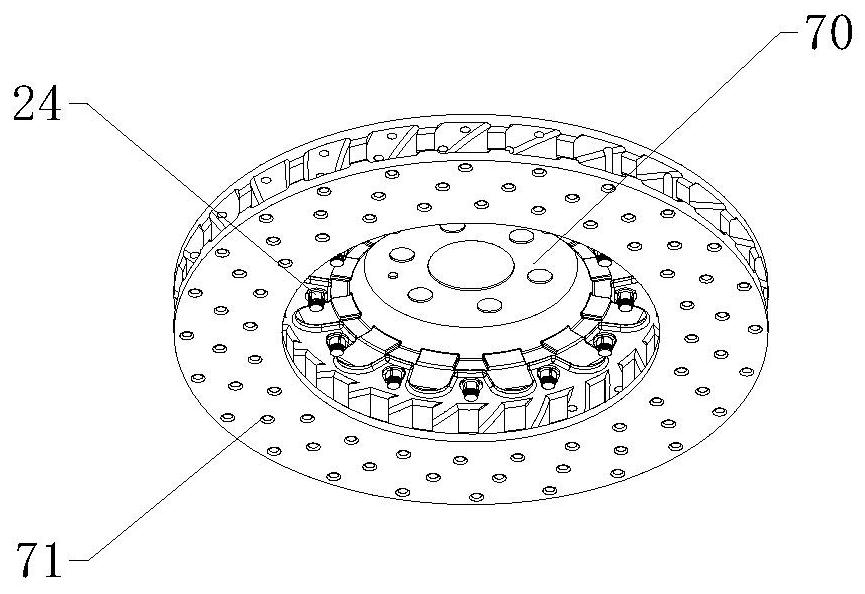

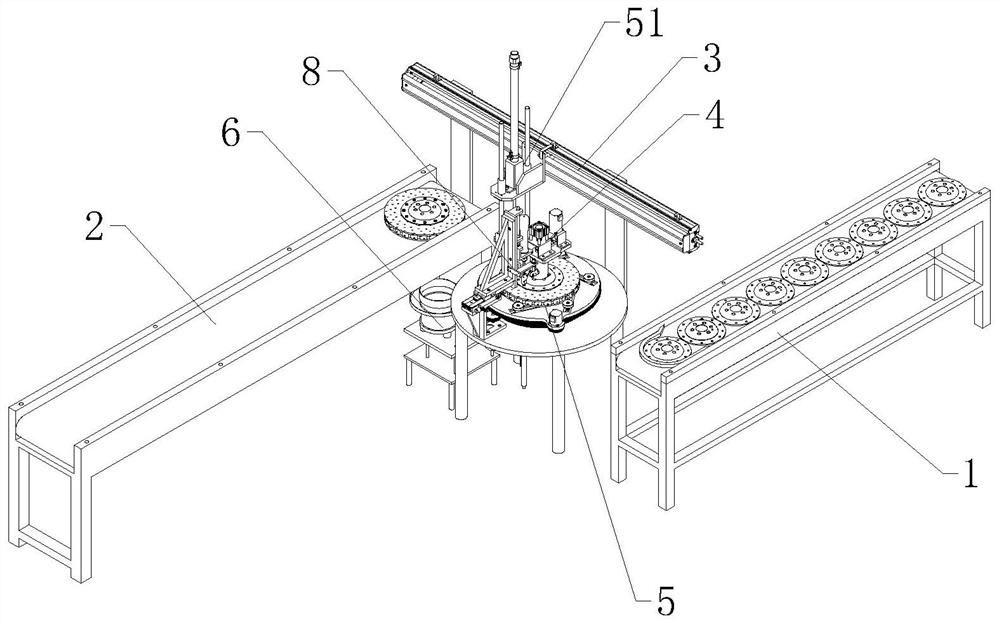

Automatic hole-aligning assembly equipment for split brake disc

The invention relates to the field of split brake assembly, in particular to automatic hole-aligning assembly equipment for a split brake disc. The automatic hole-aligning assembly equipment for the split brake disc comprises a first conveyor belt, a second conveyor belt, a material moving mechanism, a clamping mechanism, a clamping worktable, a nut feeding mechanism, a nut positioning and liftingmechanism, a screw locking mechanism and a laser rangefinder, wherein the clamping worktable is arranged between the first conveyor belt and the second conveyor belt, the material moving mechanism ispositioned beside the clamping worktable, the clamping mechanism is arranged on an output end of the material moving mechanism, the nut feeding mechanism is arranged below the clamping worktable, thenut positioning and lifting mechanism is fixedly arranged at the bottom of the clamping worktable, and the center of the clamping worktable is provided with an avoidance hole penetrating up and down;according to the invention, the automatic hole-aligning assembly equipment can complete the screw hole alignment between a joint head and a disc body through the laser rangefinder and a controller calibration algorithm when the joint head and the disc body are assembled, and then the assembly process of the split brake disc can be carried out accurately and efficiently.

Owner:江苏惠博汽车部件制造有限公司

Protective cap

ActiveUS9956138B2Prevent escapeMade accurately and efficientlyClosuresPharmaceutical containersMedical deviceBiomedical engineering

Owner:CARMEL PHARMA

Robot actuator and humanoid robot having the same

ActiveUS8579343B2Effective reflectionAccurate and efficient assemblyProgramme-controlled manipulatorGripping headsHumanoid robot naoBall screw

Disclosed herein are a robot actuator and a humanoid robot having the same. The robot actuator includes a rotation driving source, a ball screw member including a ball screw part connected to the rotation driving source and a nut part connected to the ball screw part, a guide member separated in parallel from the ball screw part, a slider member movably supported by the guide member, and a connection member connecting the slider member and the nut part to move the slider member in connection with movement of the nut part, and the connection member is relatively movably connected to at least one of the nut part and the slider member. Therefore, efficiency in force reflection and back-drivability of the actuator is improved.

Owner:SAMSUNG ELECTRONICS CO LTD

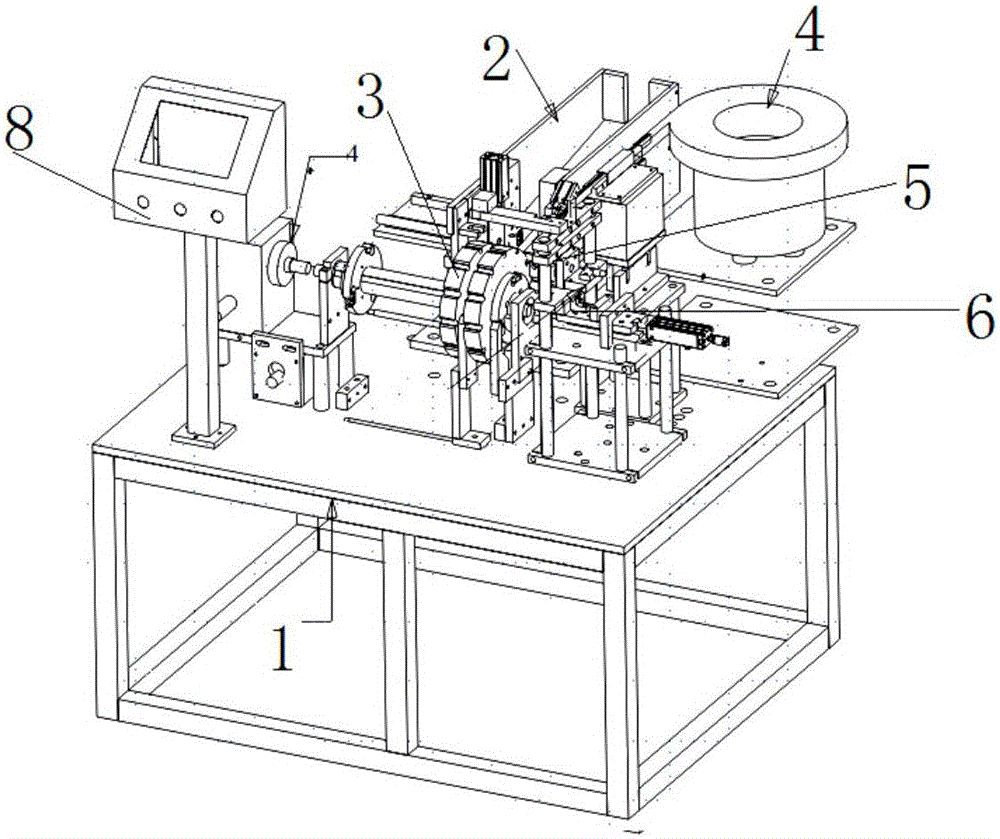

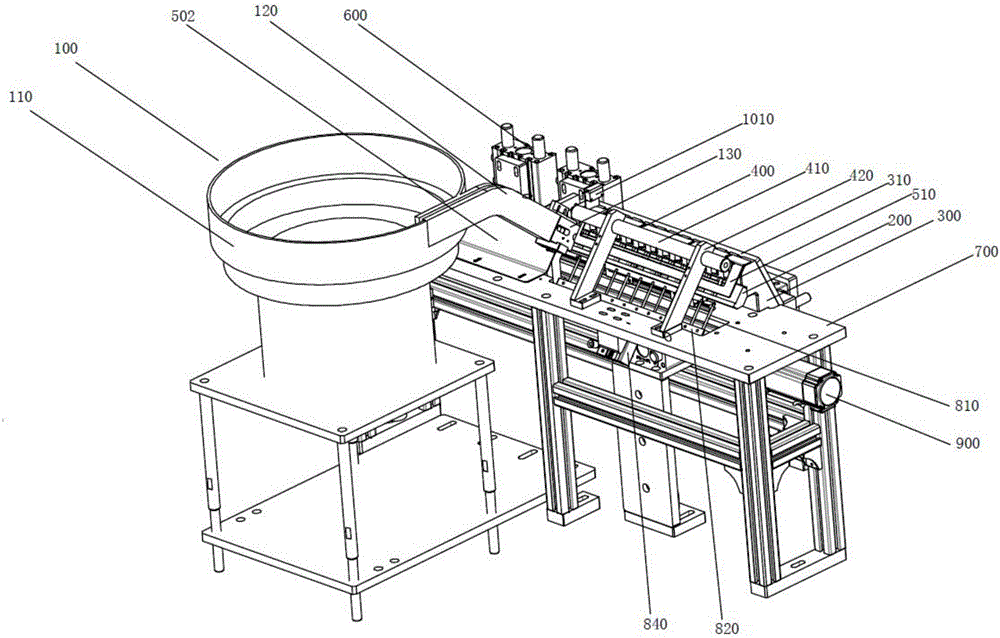

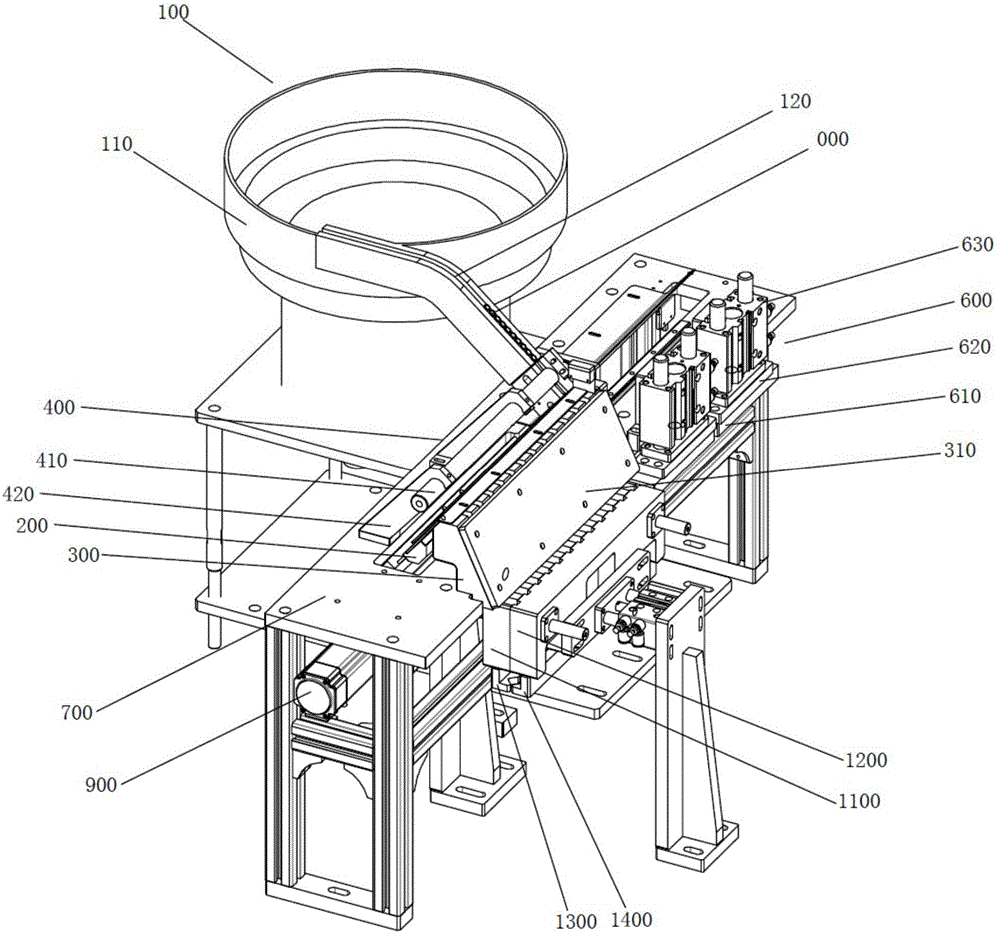

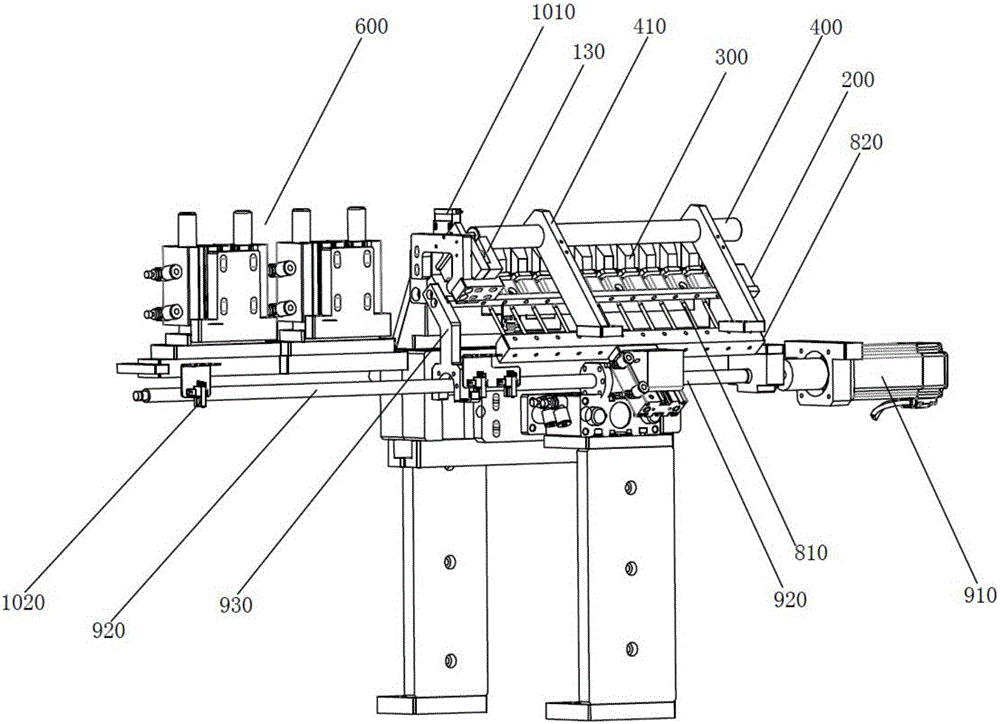

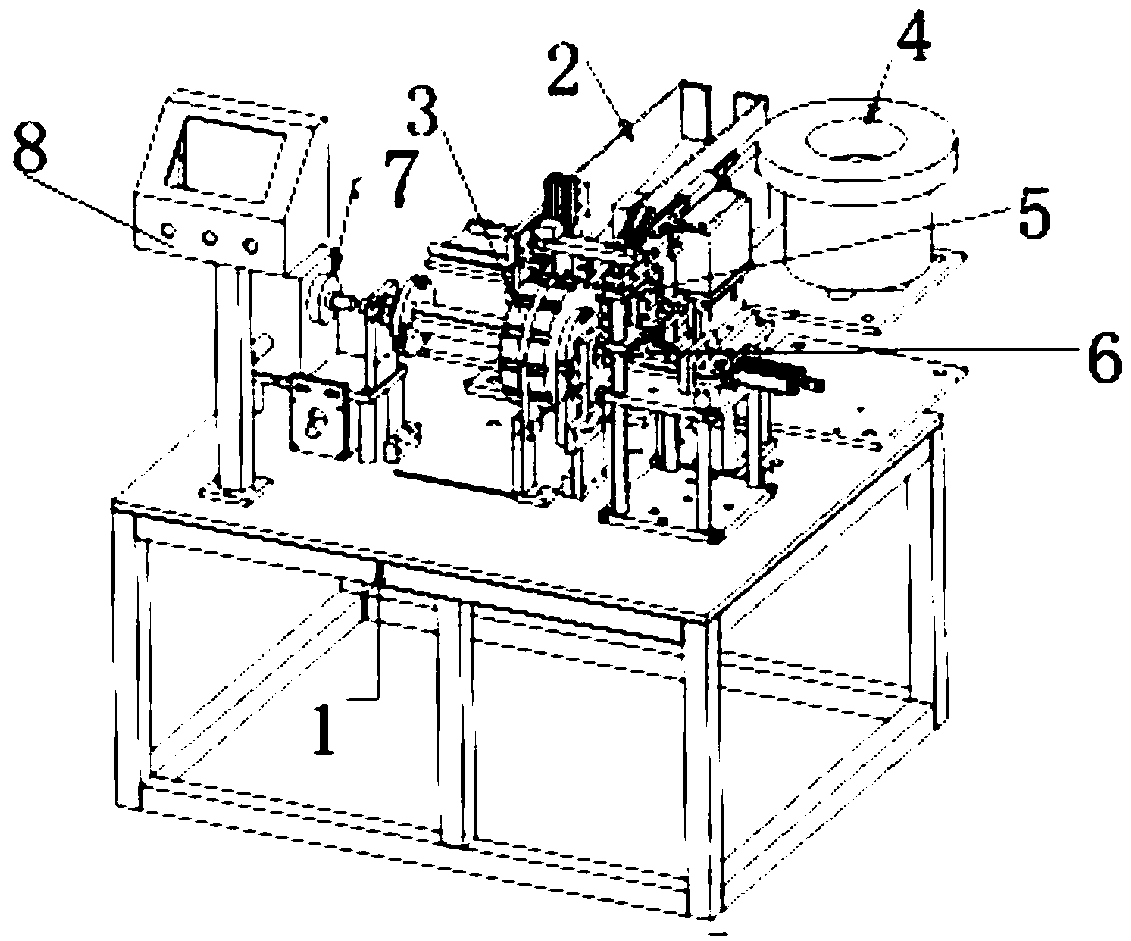

Full-automatic threaded fitting assembling device and process

InactiveCN106425431AAccurate and efficient assemblyImprove detection efficiencyMetal working apparatusThreaded pipePipe fitting

The invention relates to a full-automatic threaded fitting assembling device. The full-automatic threaded fitting assembling device is used for completing the automatic fitting process of a threaded pipe fitting and connectors to form a fitting element. The full-automatic threaded fitting assembling device comprises a feeding mechanism, an assembling mechanism and a control mechanism. The control mechanism is electrically connected with the feeding mechanism and the assembling mechanism so as to control the automatic fitting process. The feeding mechanism comprises a first transfer assembly and a second transfer assembly. The first transfer assembly is used for transferring the connectors to the assembling position in the assembling mechanism in order. The second transfer assembly is used for transferring the pipe fitting to the assembling position. The assembling mechanism is used for enabling the connectors to rotate relative to the pipe fitting to complete the automatic fitting process. The invention further provides a full-automatic threaded fitting assembling process adopting the full-automatic threaded fitting assembling device. By adoption of the full-automatic threaded fitting assembling device and process, the working efficiency in the automatic fitting process of the pipe fitting and the connectors is improved.

Owner:深圳兴通成机电技术有限公司

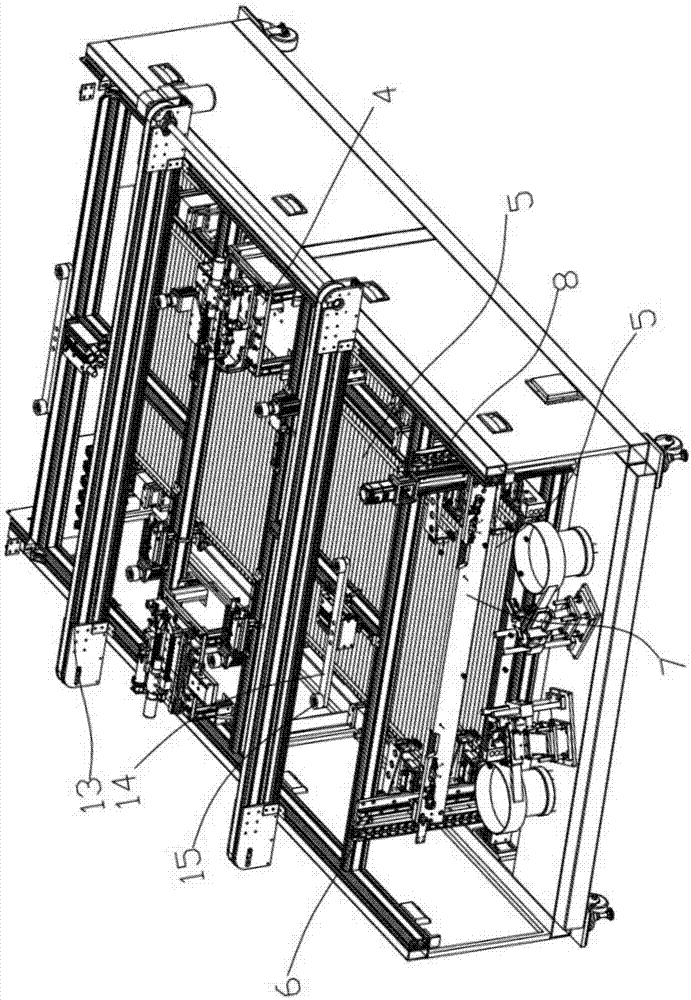

Piston rod sleeve snap spring processing equipment and method

ActiveCN106217016AIncrease productivityImprove product qualityMetal working apparatusBiochemical engineeringElectrical control

The invention discloses a piston rod sleeve snap spring processing equipment and method, belonging to the technical field of piston rod assembly. The equipment comprises a rack, a piston rod automatic feeding mechanism, a piston rod automatic sequencing and putting mechanism, a snap ring automatic feeding mechanism, a snap ring automatic grabbing and putting mechanism, a piston rod and snap ring automatic assembly mechanism, a product discharging mechanism and an electrical control system, wherein the piston rod automatic feeding mechanism feeds piston rods to the piston rod automatic sequencing and putting mechanism; the snap ring automatic feeding mechanism feeds snap rings to the snap ring automatic grabbing and putting mechanism; the snap ring automatic grabbing and putting mechanism conveys the snap rings to the piston rod and snap ring automatic assembly mechanism; the piston rod automatic sequencing and putting mechanism conveys the piston rods to the piston rod and snap ring automatic assembly mechanism; the piston rod and snap ring automatic assembly mechanism assemblies the snap rings and the piston rods; and the product discharging mechanism conveys out the assembled piston rods sleeved with the snap rings. The equipment and the method have the effects of improving the production efficiency and ensuring the product quality after installation.

Owner:ANHUI LAITE GAS SPRING CO LTD

Automatic cross rod clamping and screw locking machine

PendingCN107127563ANo human intervention requiredHigh degree of automationMetal working apparatusEngineeringMachine

The invention provides an automatic cross rod clamping and screw locking machine. The automatic cross rod clamping and screw locking machine comprises a rack. The rack is provided with a cross rod conveying mechanism, a plate body conveying mechanism, a material taking mechanism and at least one screw locking mechanism. The plate body conveying mechanism is located on the upper portion of the cross rod conveying mechanism. The material taking mechanism is movably connected to the upper portion of the rack and points to the plate body conveying mechanism. According to the automatic cross rod clamping and screw locking machine, matching work can be conducted through the cross rod conveying mechanism and the plate body conveying mechanism; after a plate body where a cross rod needs to be fixed is accurately conveyed through a conveying belt, the cross rod is grabbed through clamping jaws of the material taking mechanism and placed in the corresponding position; the screw locking mechanisms are started, and screws are automatically screwed and locked; manual intervention is not needed in the whole process; the automation degree is high; and assembling is accurate and efficient.

Owner:KUNSHAN MENGTEZHAN PRECISION ELECTROMECHANICAL CO LTD

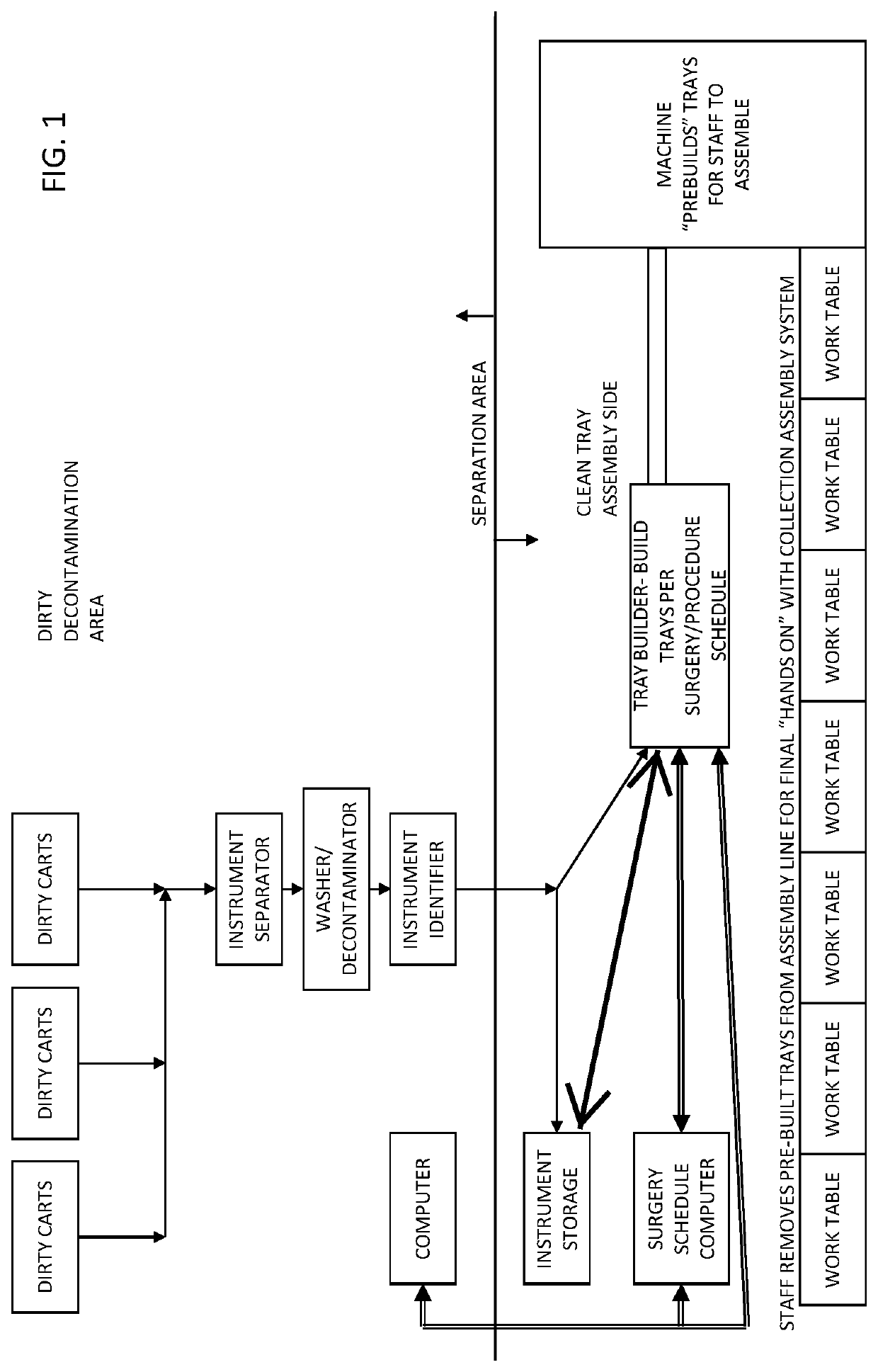

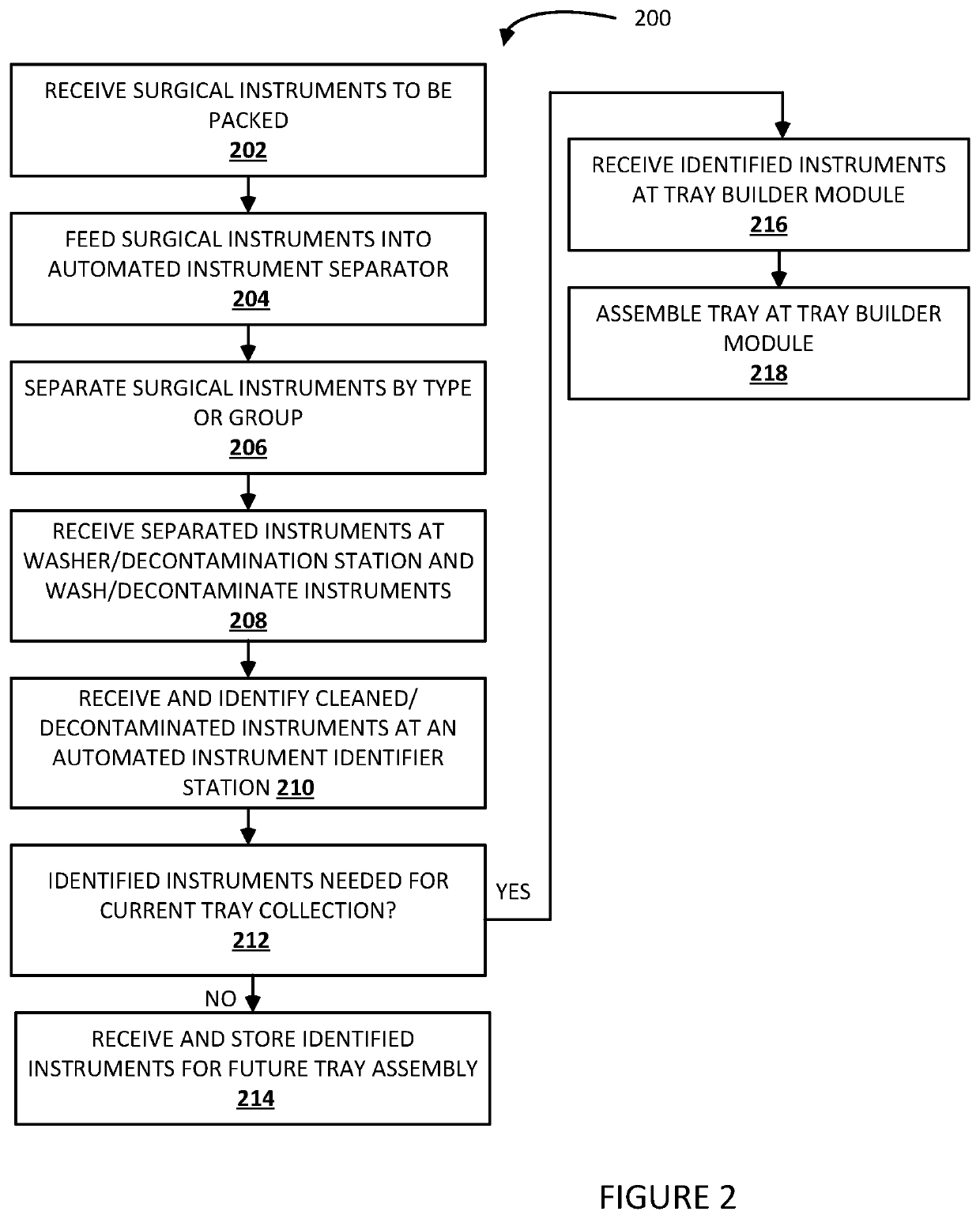

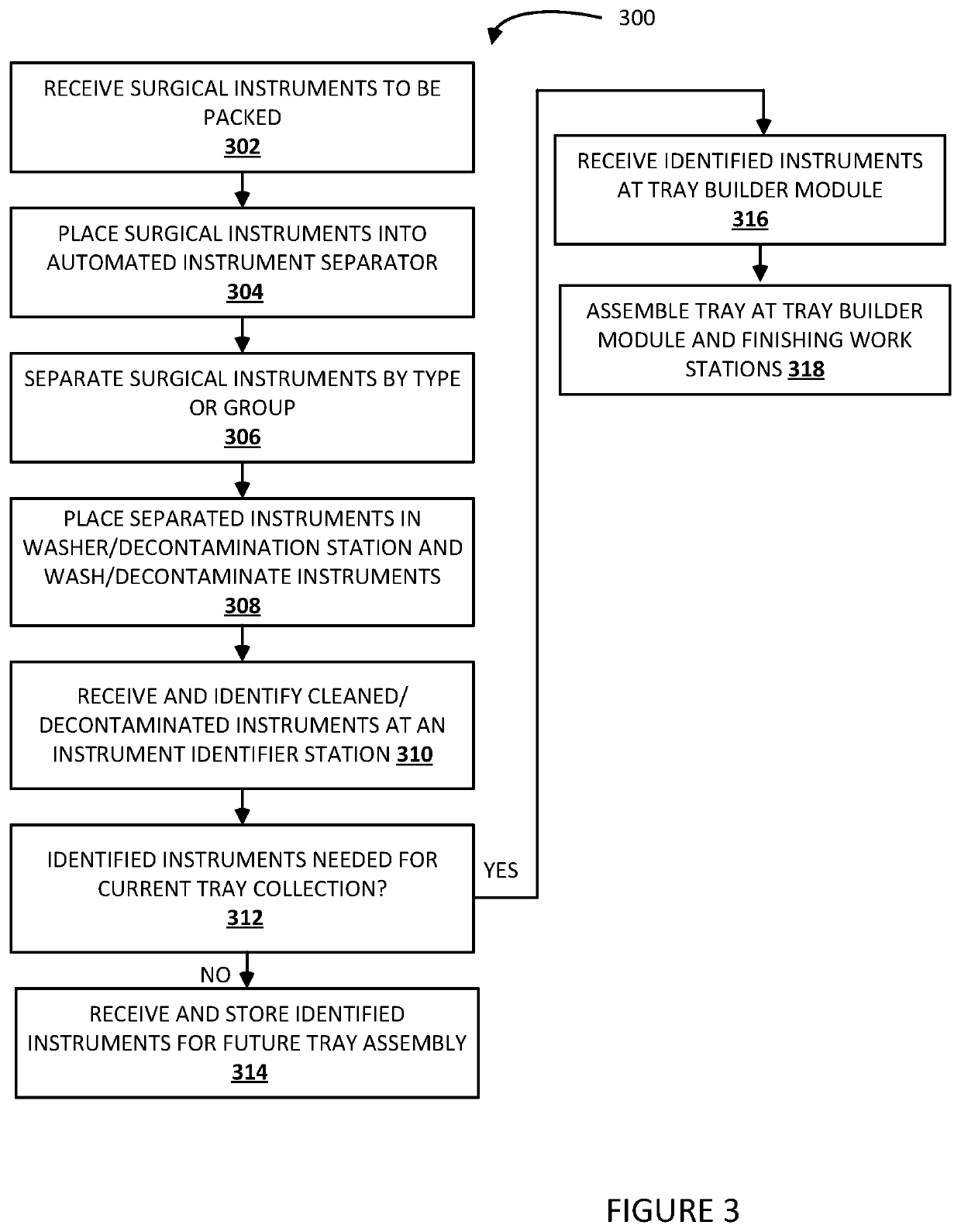

Method and system for assembling and completing a collection of individual disparate-shaped components with identification via electronic images

PendingUS20200143195A1Efficient and accurateAccurate and efficient assemblyDiagnosticsSurgeryEngineeringSurgical department

The instant disclosure relates to camera-based and image-based methods and systems for accurately and efficiently assembling and completing stocked or arranged disparate-shaped components of a collection using electronic images for identification. In one implementation, for example, methods and system are provided for accurately and efficiently assembling and assisting assembly of and completing stocked and / or arranged surgical instrument trays. These services are, for the most part, provided by Sterile Processing Departments (SPD) of any hospital or surgical center. SPD service facilities are common to hospital and surgery centers throughout the world.

Owner:MONTANO ROBERT A

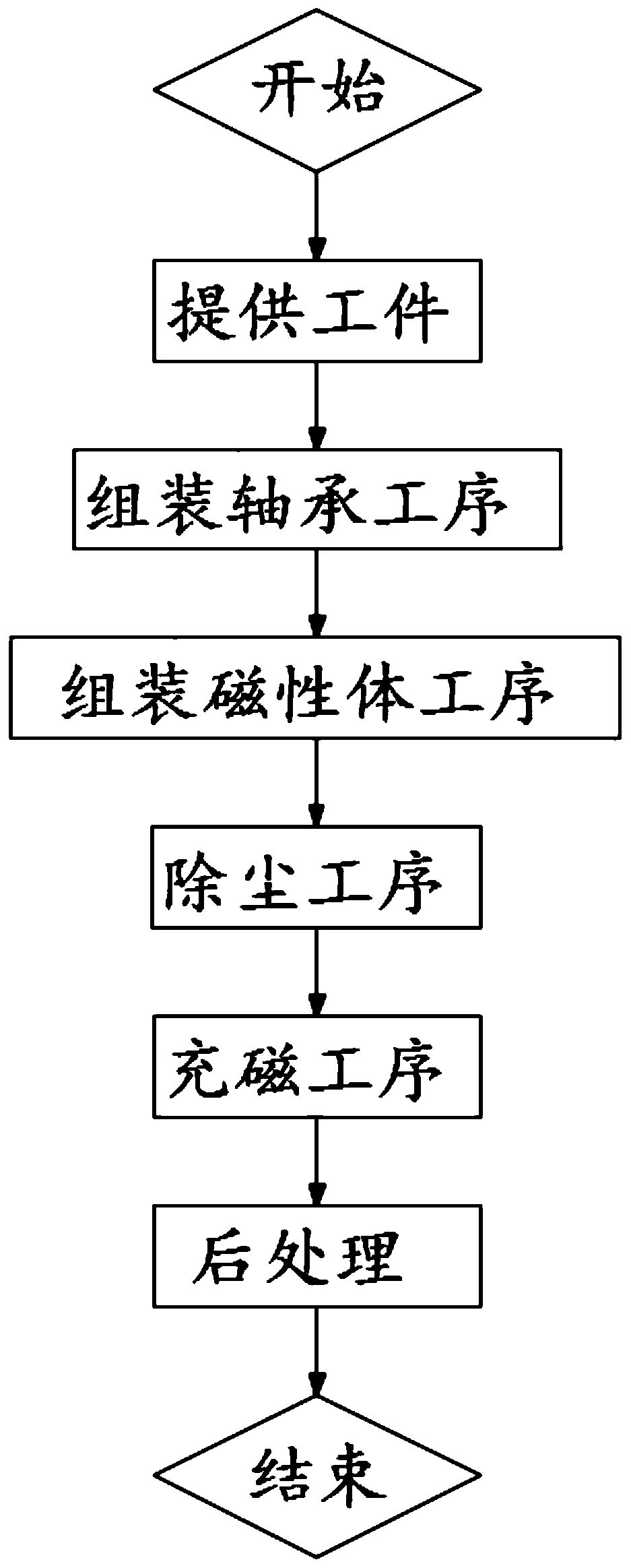

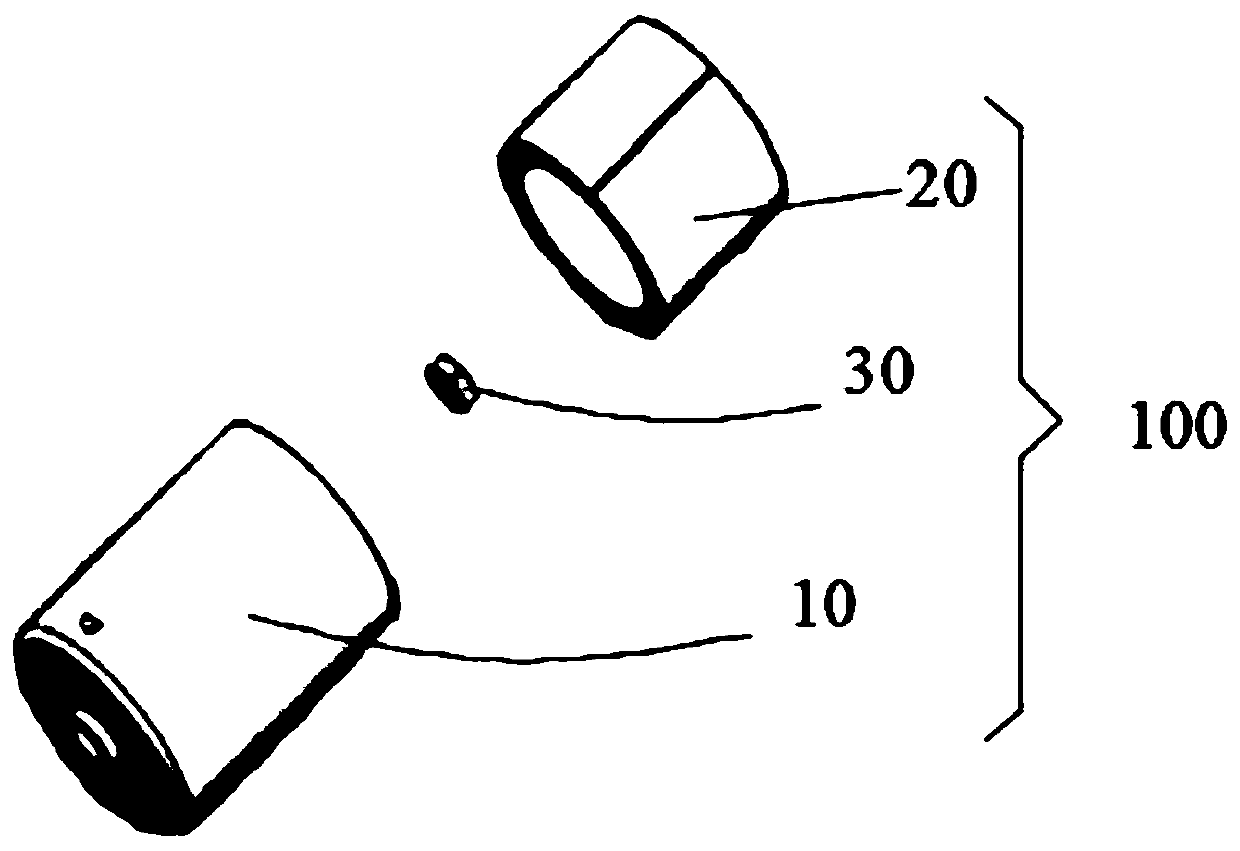

Automatic assembling process and device for motor shell

ActiveCN111463980AQuick and accurate installationSimple processManufacturing dynamo-electric machinesDust controlStructural engineering

The invention discloses an automatic assembly process and device for a motor shell, and relates to the field of motor assembly. The method comprises the steps of providing a workpiece, wherein the workpiece comprises a barrel shell, a bearing and a magnetic body, and an inner cavity is formed in the barrel shell; assembling a bearing, conveying the barrel shell to an axial pressing mechanism, pressing the bearing into the barrel shell, and enabling the bearing to be fixed in a bearing groove; assembling the magnetic body, conveying the barrel shell in which the bearing is pressed to a magneticbody installing mechanism, and installing the magnetic body in the inner cavity; conducting a dust removal process for performing dust removal treatment; conducting a magnetizing step for magnetizingthe magnetic body; and conducting post-processing for detecting and processing the magnetized shell assembly. According to the invention, the process is simple, the cylinder shell, the bearing and the magnetic body can be rapidly and accurately installed in the barrel shell, the working efficiency is improved, rapid assembling of the motor shell is achieved through the axial pressing mechanism, the magnetic body installing mechanism, a dust collection mechanism, the magnetizing mechanism and other mechanisms, the device space occupation ratio is small, accurate and efficient assembling of themotor shell is achieved, the labor cost is reduced, and the working space is saved.

Owner:SHIXING STANDARD MOTOR CO LTD

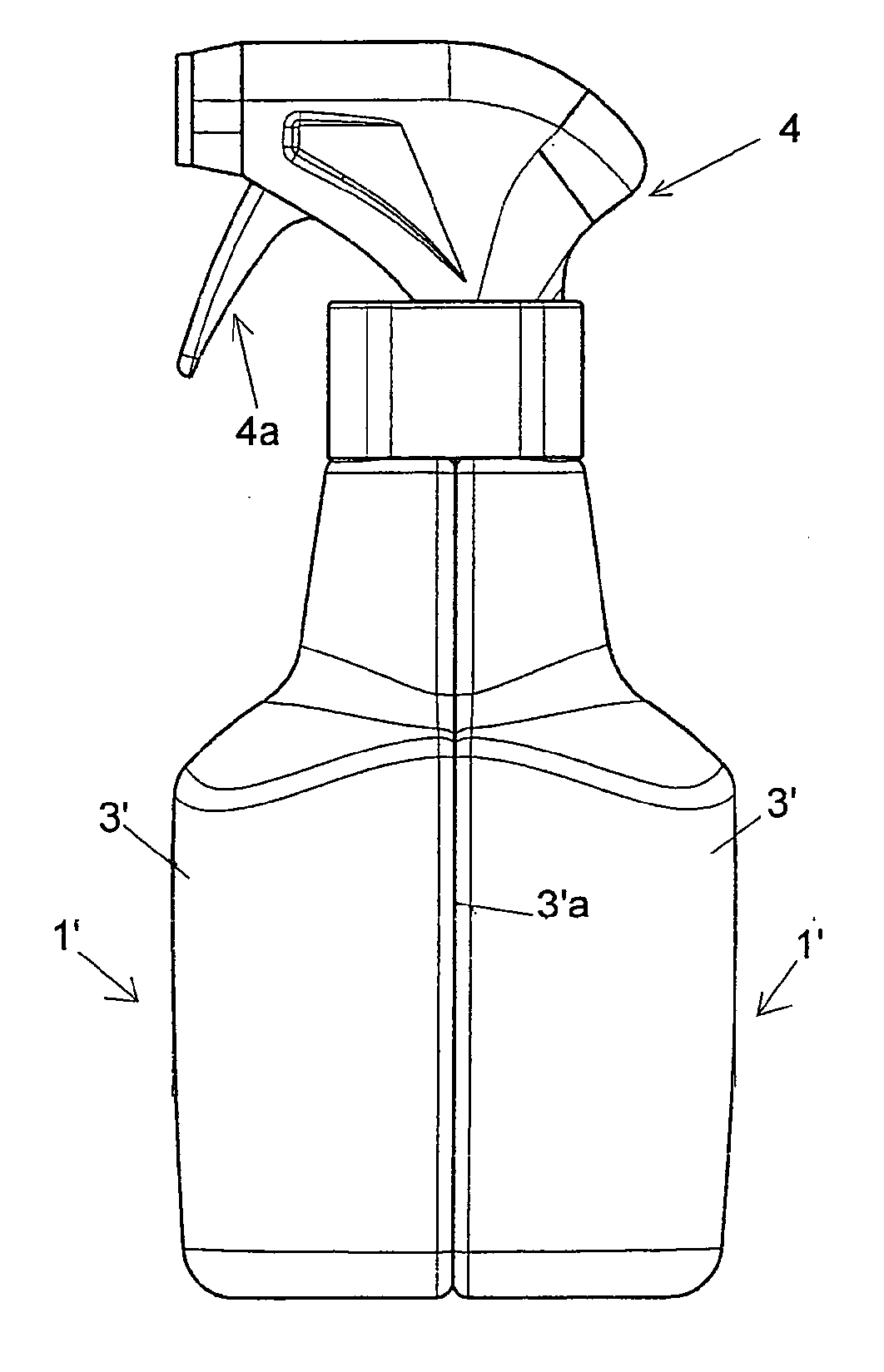

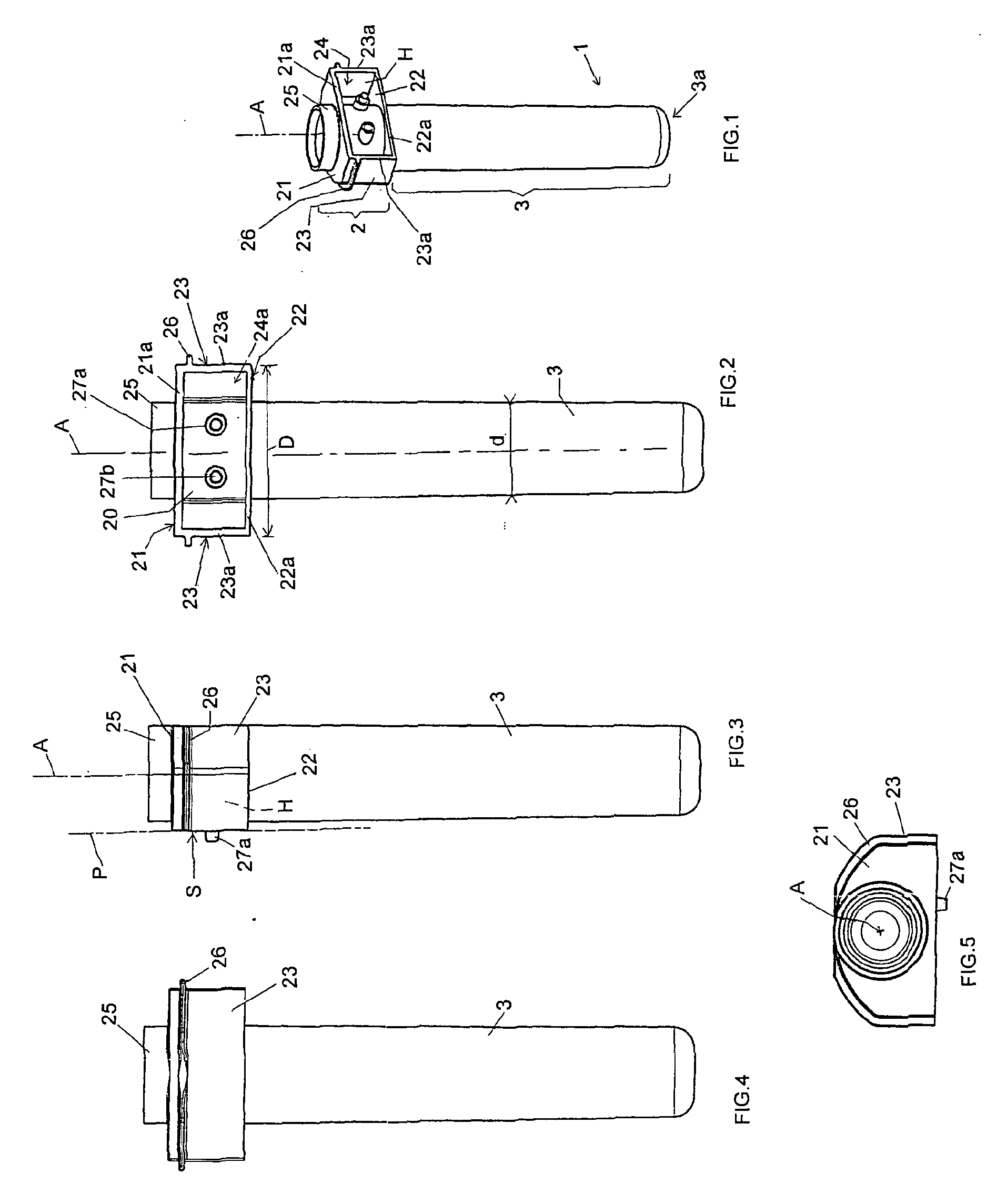

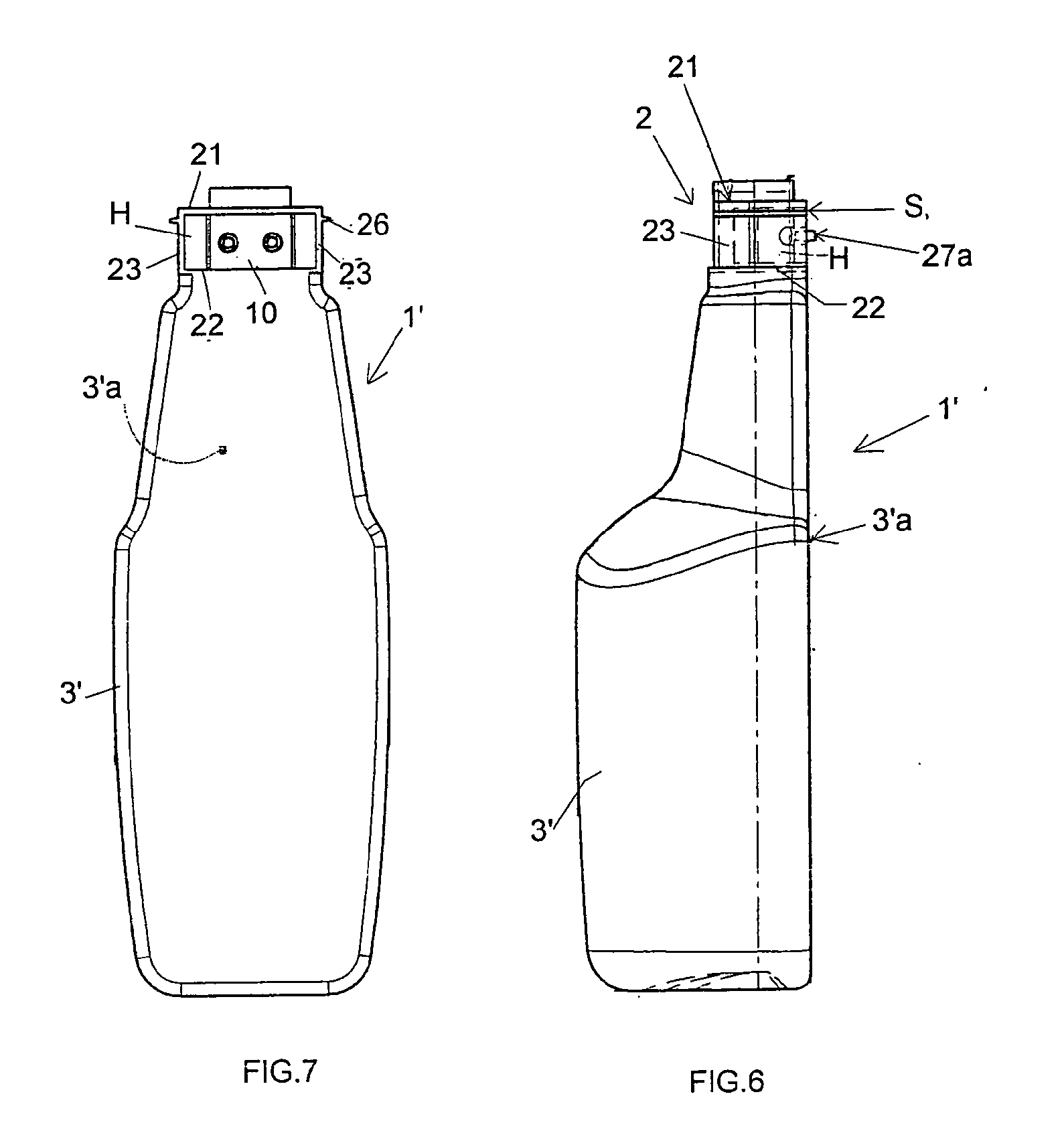

Plastic Preform and Single Container for Making a Dual-Container Dispenser

ActiveUS20110057054A1Easily and advantageously manufacturedAssembly precisionBottlesSynthetic resin layered productsEngineeringMechanical engineering

The rigid plastic container (V) is designed for being assembled with another rigid plastic container (V) and forming a dual-container dispenser. The container (V) comprises a neck finish (2) and a stretched body (3′) closed at its bottom end. The neck finish (2) comprises a tubular part (20), an upper wall (21), a lower wall (22) and a side wall (23). The side wall (23) extends between the upper (21) and lower (22) walls and said side wall (23), upper wall (21) and lower wall (22) form a housing (H) for the tubular part (20). The housing (H) comprises an assembly surface (S) formed by the edges of the side wall (23), upper wall (21 and lower wall (22). The tubular part (20) is opened at both ends and forms a path through the upper wall (21), within the housing (H) and through the lower wall (22), for filling the stretched body (31).

Owner:PLASTIPAK BAWT S A R L

Lens module assembled apparatus and method

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Assembling equipment for sheaths and bottle inserting needles

PendingCN106041497AStable outputEfficient dischargeMetal working apparatusBottleBiomedical engineering

The invention provides assembling equipment for sheaths and bottle inserting needles. The assembling equipment comprises a sheath discharging device, a sheath pushing device and an assembling device for the sheaths and the bottle inserting needles, wherein the sheath discharging device comprises a sheath conveying device and a sheath receiving device; the sheath pushing device comprises a sheath lifting device and a sheath guiding device; the assembling device for the sheaths and the bottle inserting needles comprises a sheath locating device used for simultaneously locating a plurality of sheaths and a bottle inserting needle locating and clamping device used for clamping and fixing a plurality of bottle inserting needles; the sheath conveying device is used for conveying the sheaths onto the sheath receiving device, and the sheath lifting device is used for lifting the sheaths located on the sheath receiving device into the sheath guiding device; and the sheaths in the sheath guiding device are nested on the bottle inserting needles clamped and fixed in the bottle inserting needle locating and clamping device along the sheath locating device. The assembling equipment is simple in structure and great in performance and ensures that the discharging and pushing of the sheaths and the assembly of the sheaths and the bottle inserting needles are accurate, efficient and timely.

Owner:梁启明

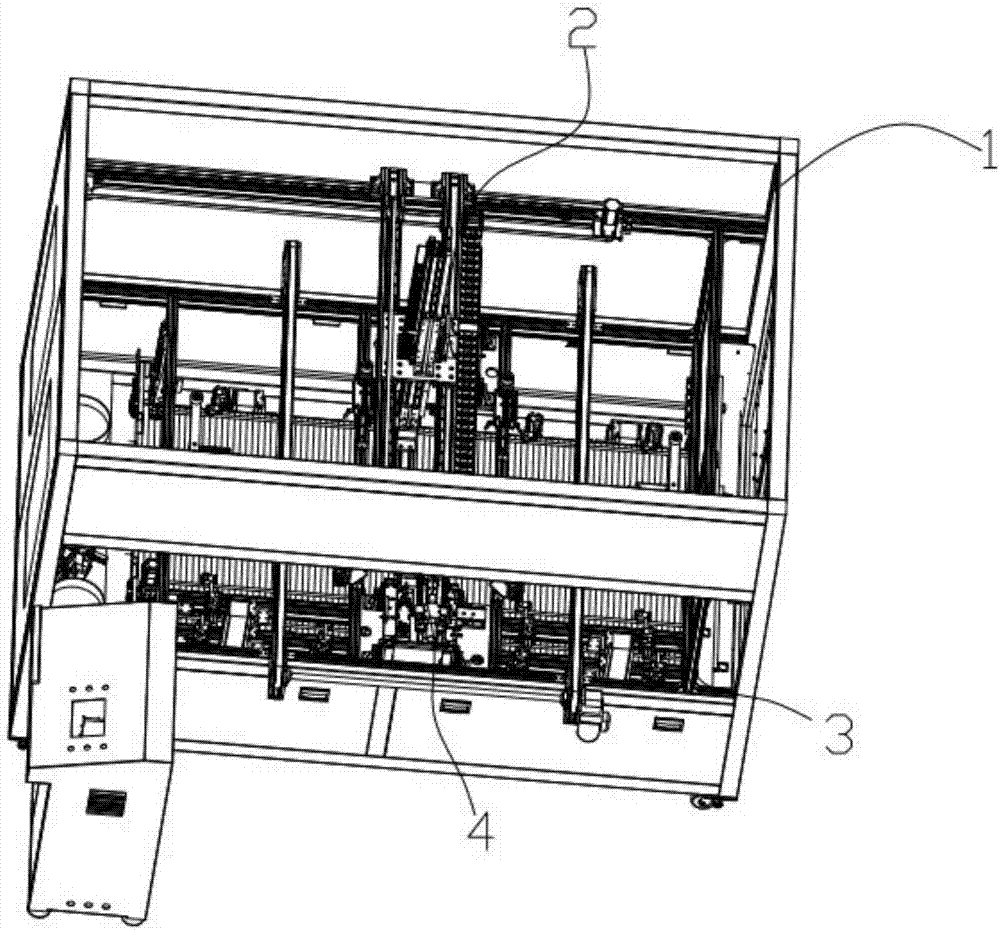

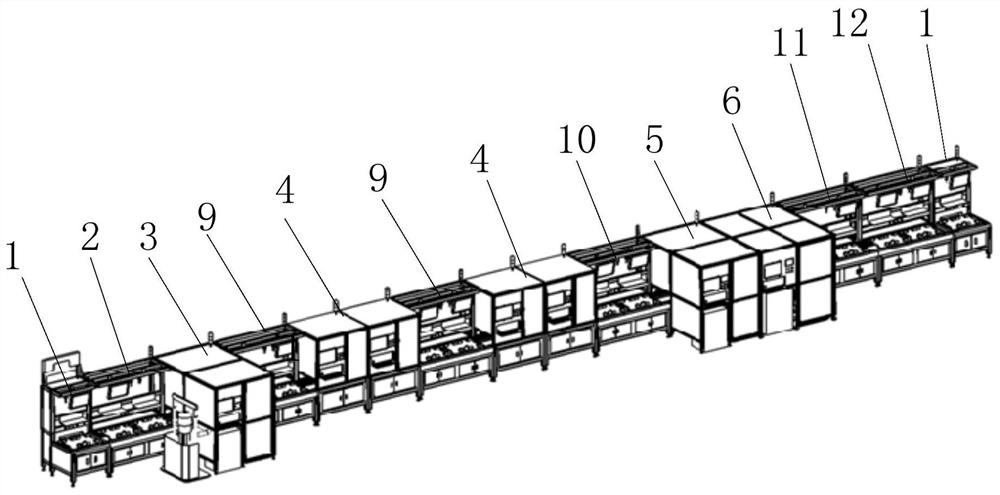

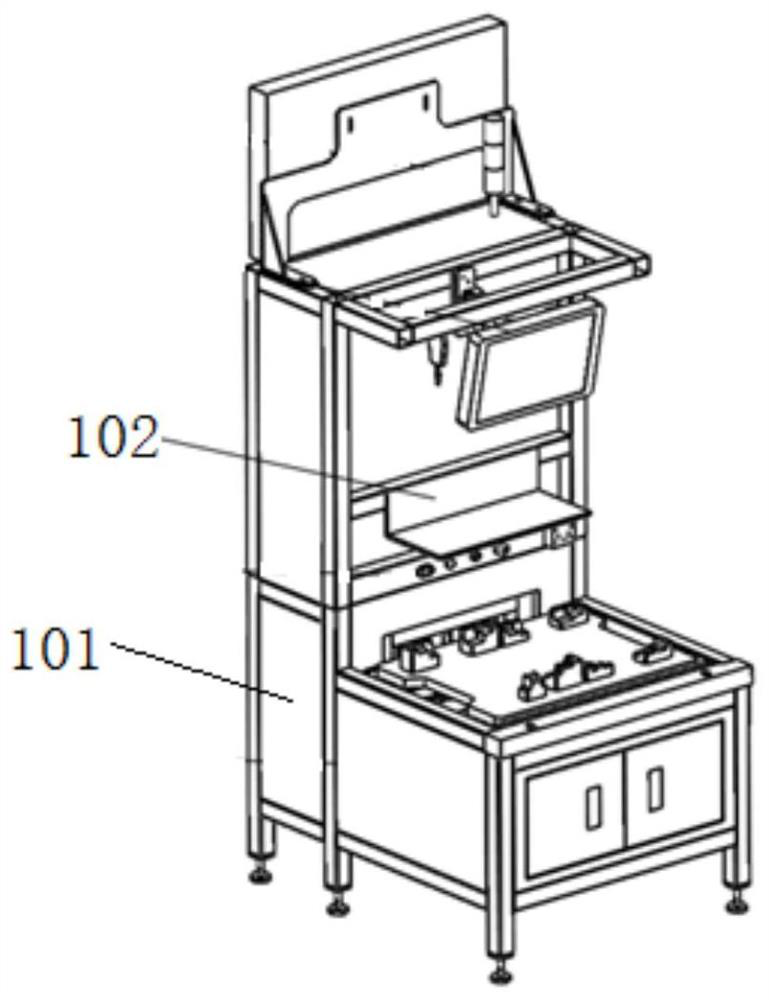

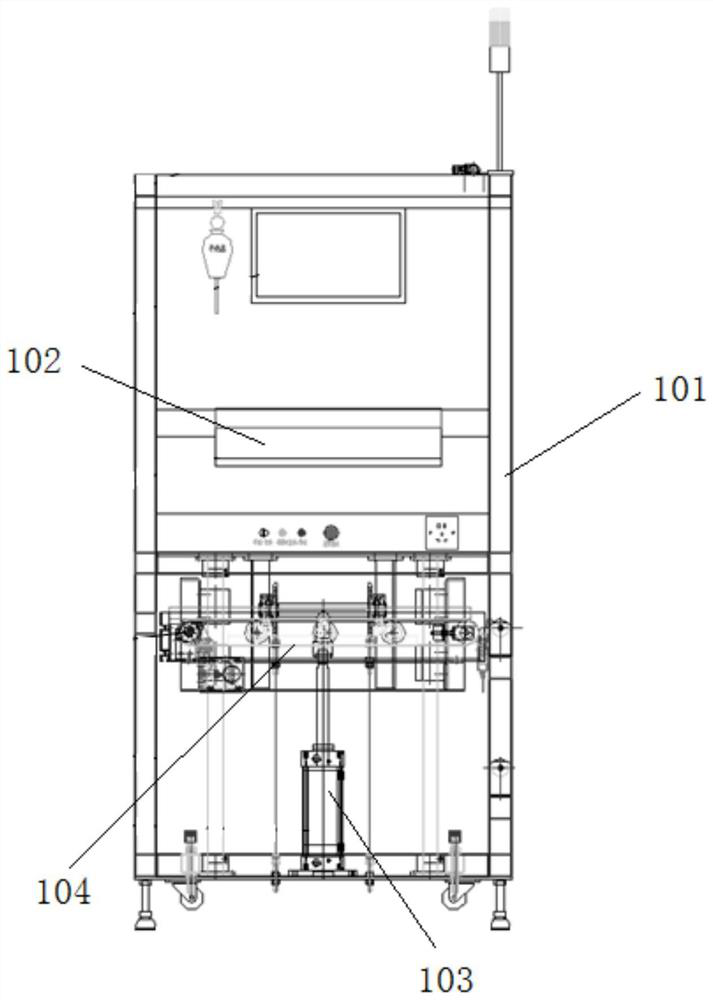

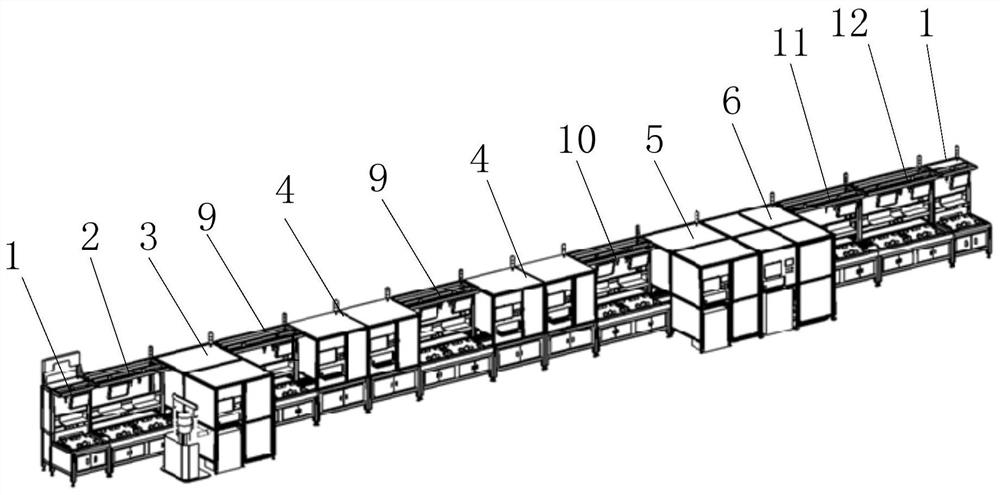

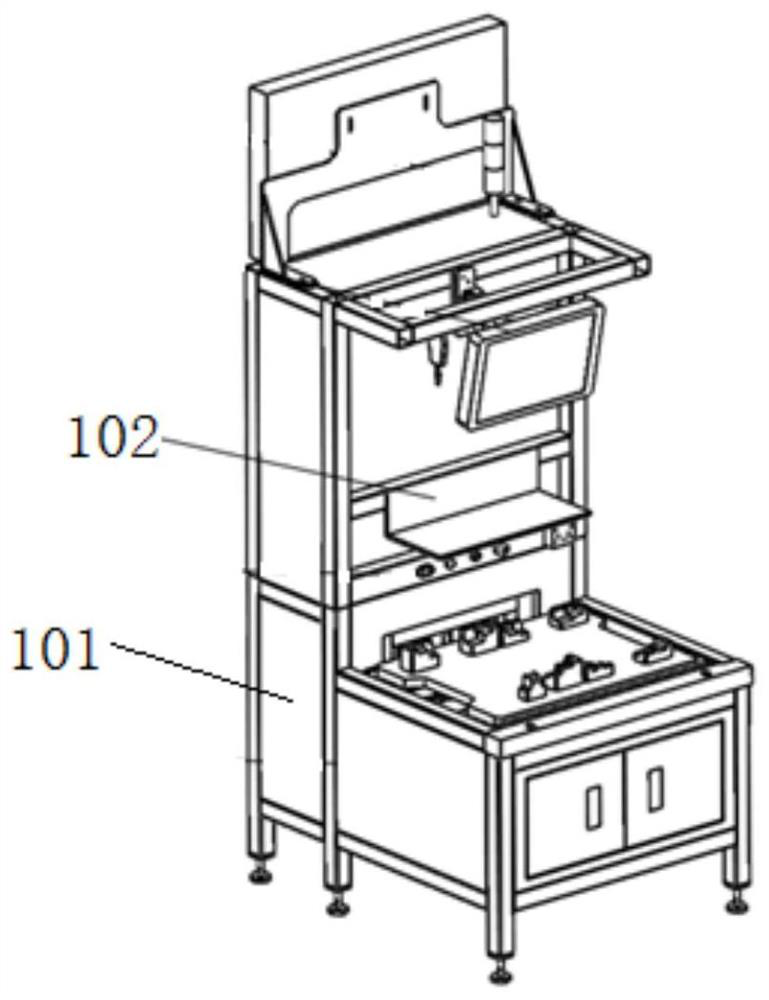

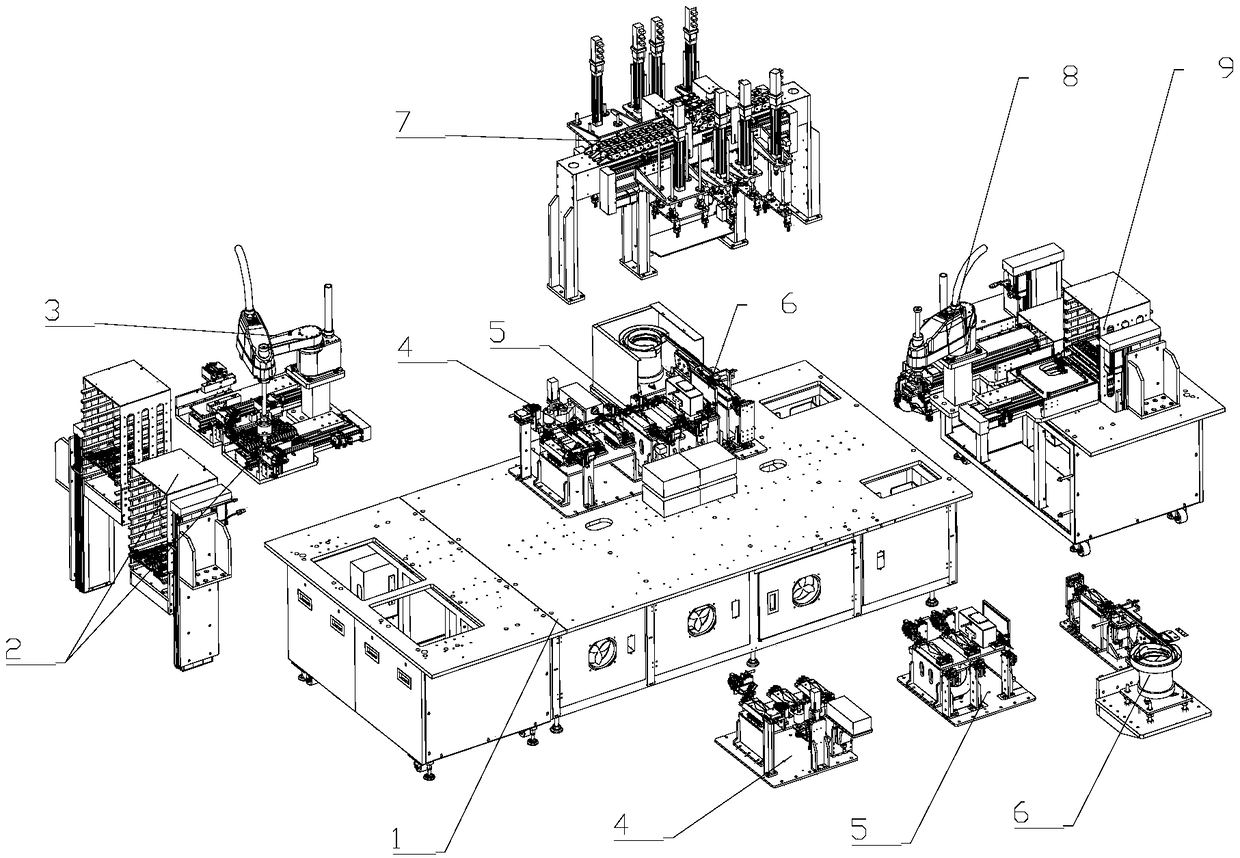

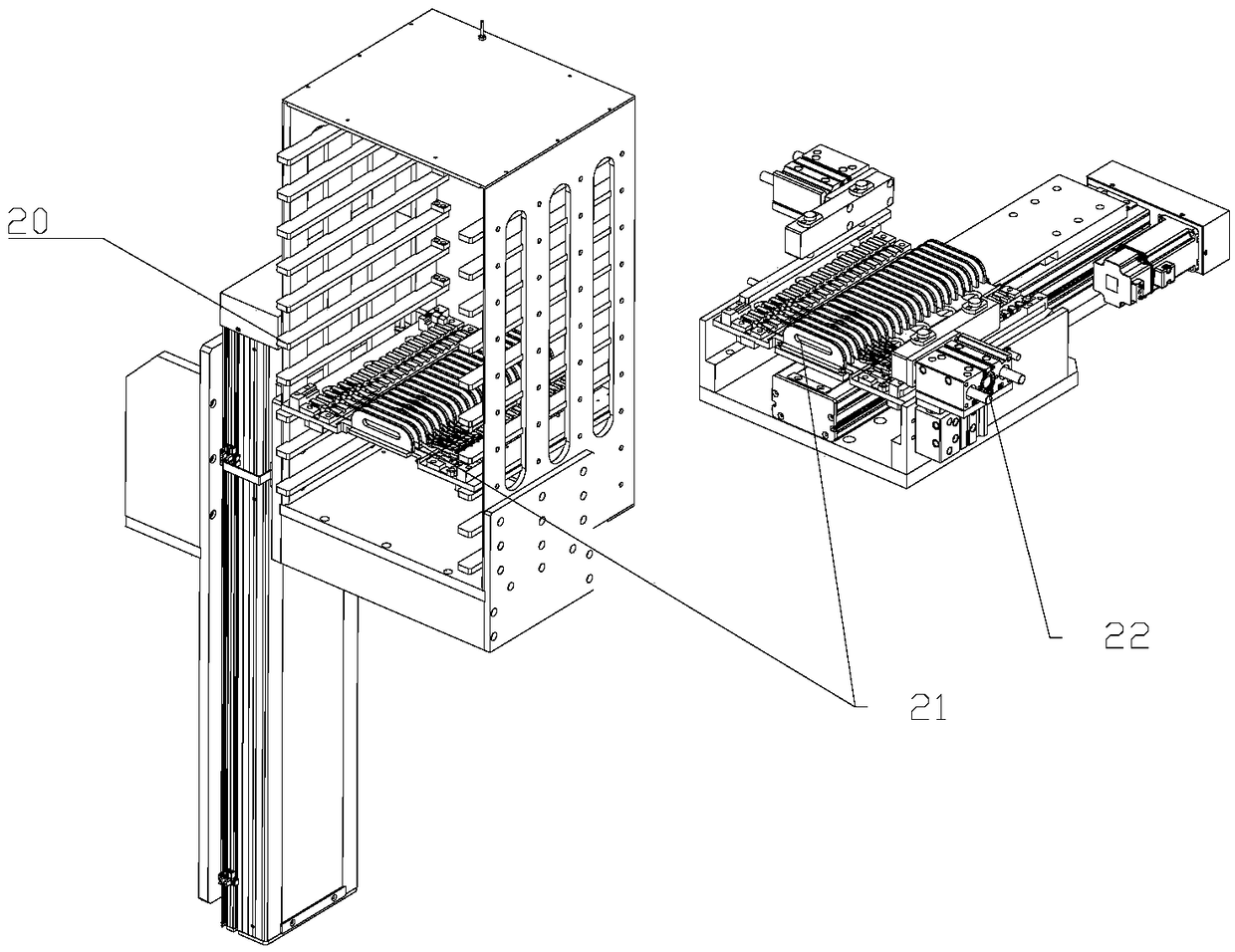

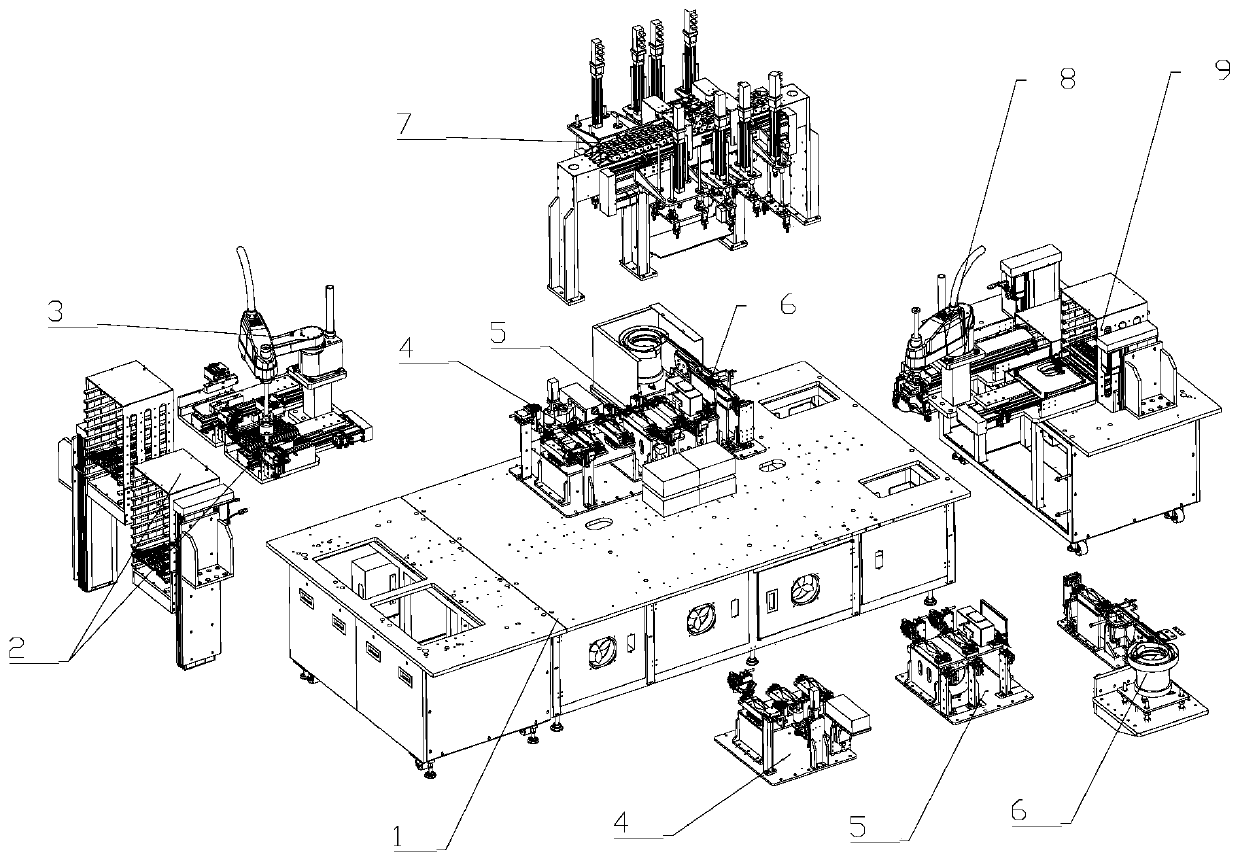

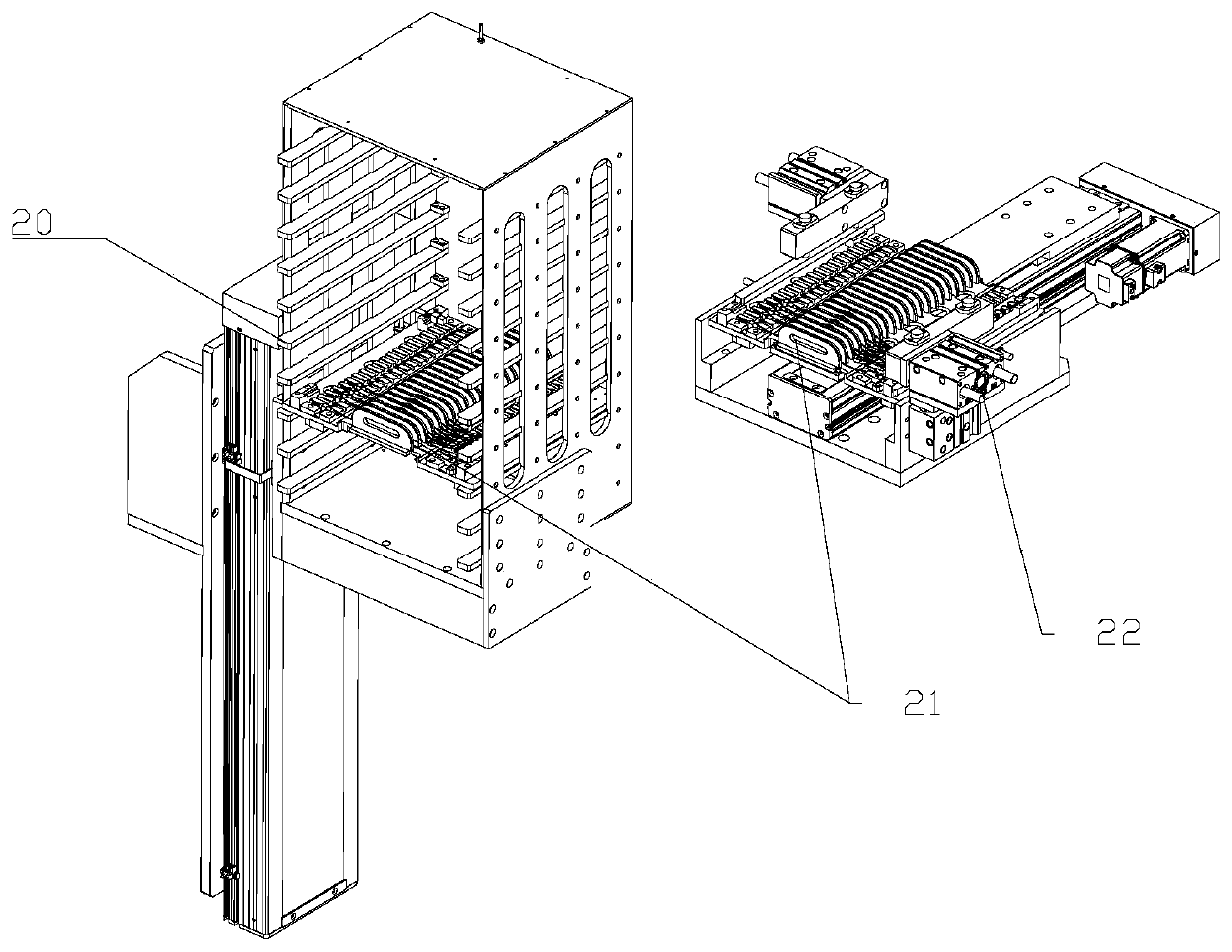

A kind of RRU product assembly equipment and assembly method based on modular design

ActiveCN112475828BEasy to manageImprove assembly yieldLiquid surface applicatorsImage analysisAssembly cellsModularity

The invention relates to RRU product assembly equipment and an assembly method. In order to solve the existing RRU product assembly, due to the lack of large-scale equipment covering the entire assembly process and the excessive intervention of manual operations, the assembly efficiency is low, the assembly site management is difficult, and the assembly yield is low. To solve the technical problem, provide a RRU product assembly equipment and assembly method based on modular design, covering the entire process of RRU product assembly, two lifting units, which are installed through the first assembly unit, the dispensing unit, and the second assembly unit. , the screwing unit, the third assembly unit, the detection unit, the jumper mounting unit, the first conveyor and the second conveyor of the fourth assembly unit and the fifth assembly unit, can form a recyclable assembly line, through Automation and manual cooperation are used to complete the assembly processes such as electrical component insertion, dispensing, circuit board fixing, testing confirmation, jumper installation, information input confirmation and cover closing.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

RRU product assembling device and assembling method based on modular design

ActiveCN112475828AEasy to manageImprove assembly yieldLiquid surface applicatorsImage analysisProduction lineSoftware engineering

The invention relates to an RRU product assembly device and assembly method, and in order to solve the technical problems of low assembly efficiency, difficulty in assembly field management and low assembly yield caused by lack of large devices covering the whole assembly process and excessive manual operation intervention in existing RRU product assembly, provides an RRU product assembly device and assembly method based on modular design. The whole process of RRU product assembling is covered, and two lifting units are matched with a first conveyor and a second conveyor which are installed ona first assembling unit, a glue dispensing unit, a second assembling unit, a screw driving unit, a third assembling unit, a detecting unit, a bridging piece installing unit, a fourth assembling unitand a fifth assembling unit in a penetrating mode, and a recyclable assembling production line can be formed. Due to automation and manual cooperation, assembling procedures such as electrical elementplugging connection, glue dispensing, circuit board fixing, detection confirmation, bridging piece installation, information input confirmation and cover closing are completed.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Lens module assembled apparatus and method

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

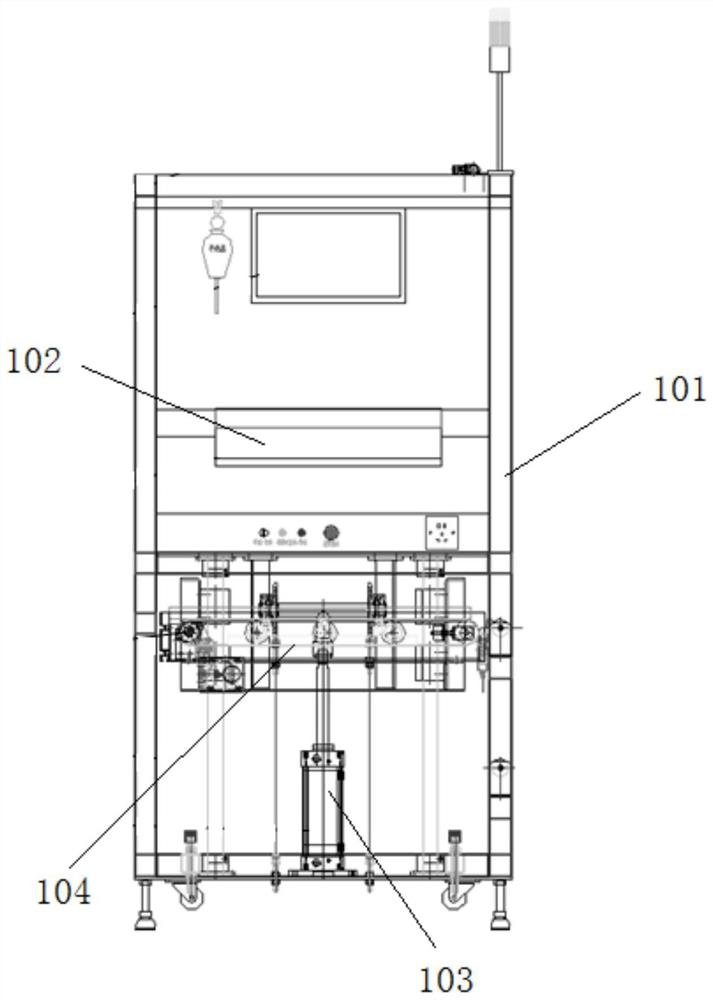

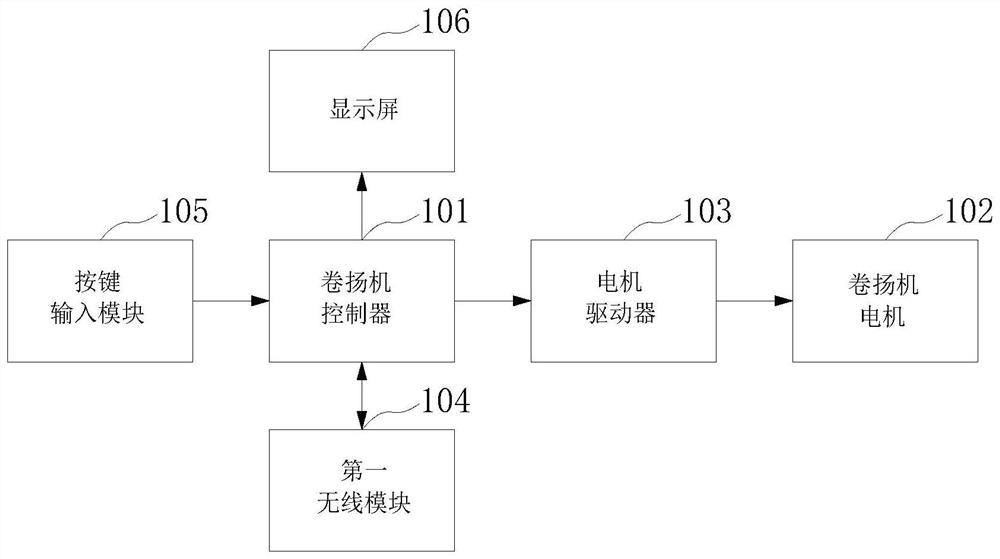

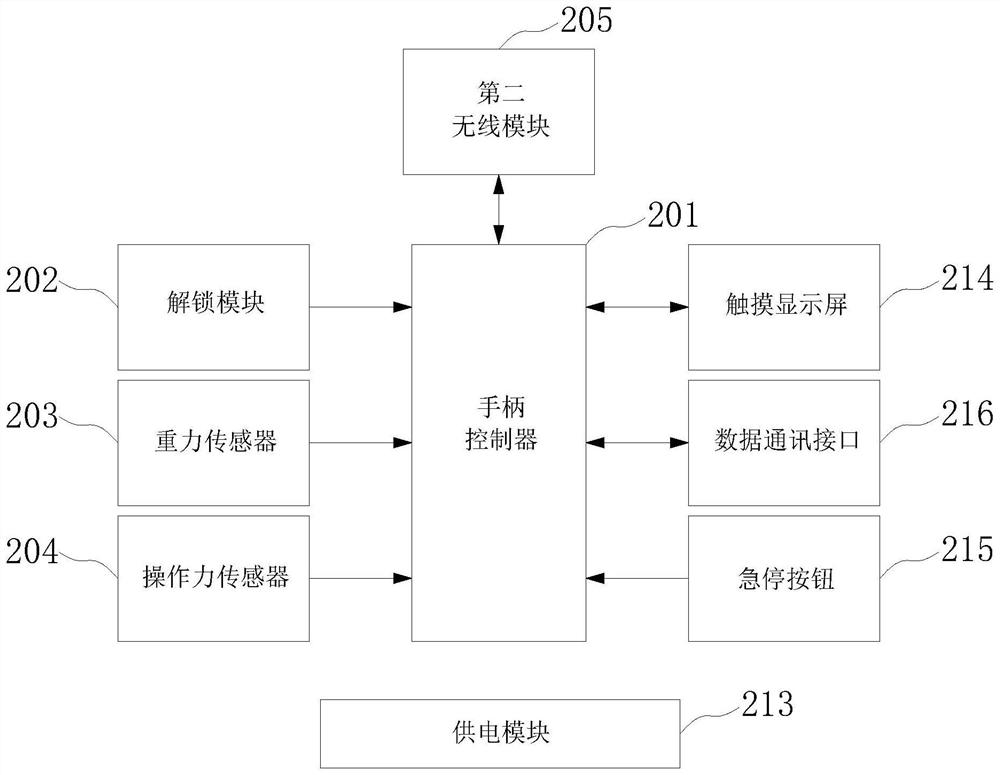

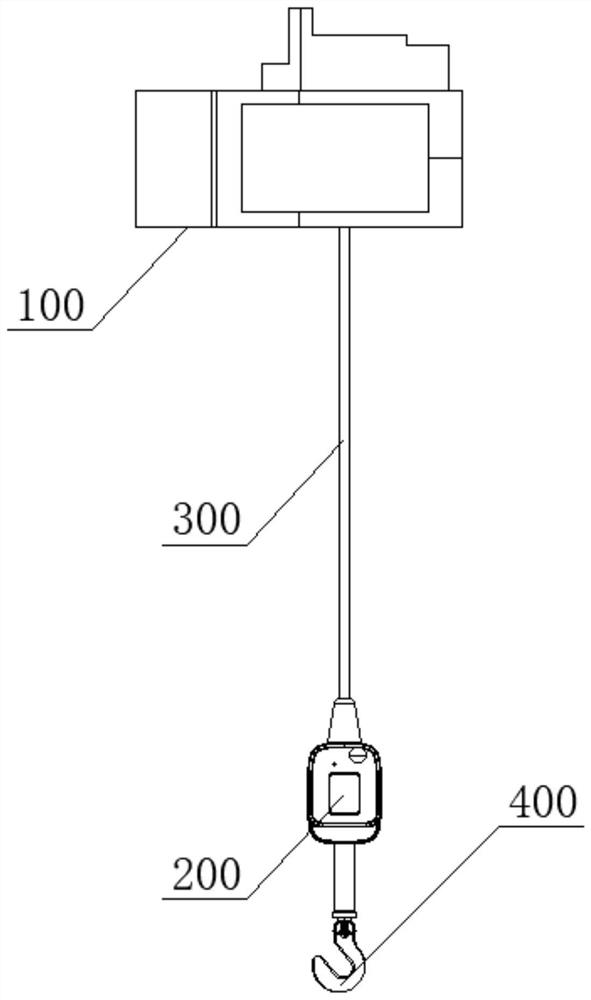

Force sensing lifting equipment and control method

PendingCN114835043AImprove battery lifeImprove operational convenienceWinding mechanismsElectric machineControl engineering

The invention discloses force sensing lifting equipment and a control method, the lifting equipment comprises a winch assembly, a force sensing handle assembly and a cable, the two ends of the cable are connected with the winch assembly and the force sensing handle assembly respectively, and a hanging assembly is connected to the force sensing handle assembly; the winch assembly comprises a winch controller, a winch motor, a motor driver and a first wireless module, the winch controller is electrically connected with the motor driver and the first wireless module, and the motor driver is electrically connected with the winch motor; the force sensing handle assembly comprises a handle controller, an unlocking module, a gravity sensor, an operating force sensor and a second wireless module, the handle controller is electrically connected with the unlocking module, the gravity sensor, the operating force sensor and the second wireless module, and the first wireless module and the second wireless module are in communication connection. According to the invention, the motion trend of the heavy object is consistent with the operation intention under low power consumption, a redundancy control method is considered, and the operation convenience of the lifting equipment is improved.

Owner:杭州微感科技有限公司

Assembling test fixture for flexible PCBA

PendingCN109283455AAccurate and efficient assemblyImprove assembly efficiencyPrinted circuit testingEngineeringTest fixture

The invention discloses an assembling test fixture for flexible PCBA, which comprises a base, a test single chip, an access plate, a damping device, a sliding rail, a movable platform, a lifting frame, a translation frame, a first platform deck, a second platform deck, a limiting groove and a fixing device. Through the manner, the assembling test fixture for flexible PCBA in the invention can assemble the access plate and the circuit board more accurately and efficiently, thereby improving the assembling efficiency of the operation staff and reducing the assembling difficulty; moreover, jointsare not easy to be damaged and collided with; and the rejection rate and management cost due to manual assembly are reduced.

Owner:FLEXTRONICS ELECTRONICS TECH SUZHOU

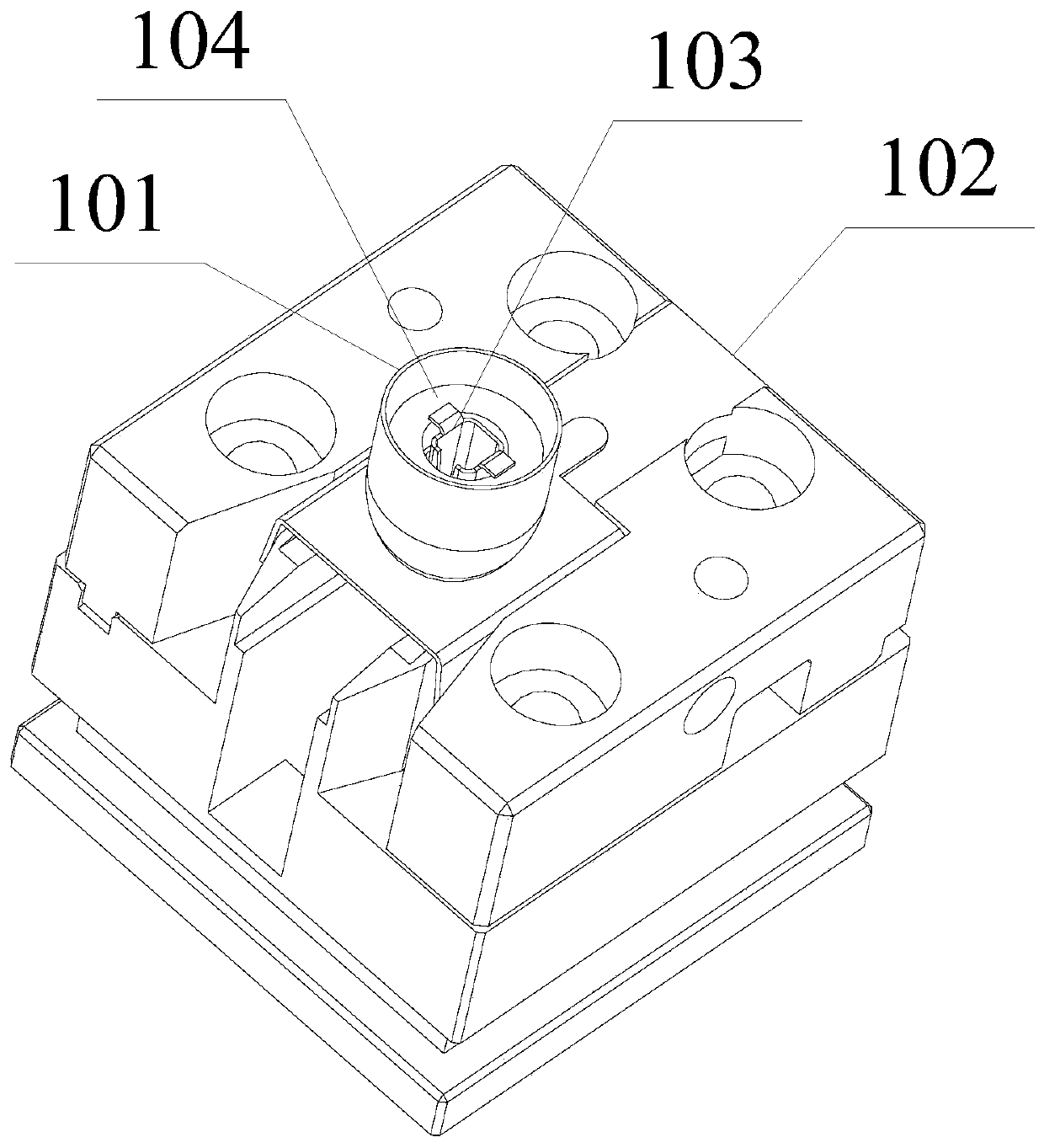

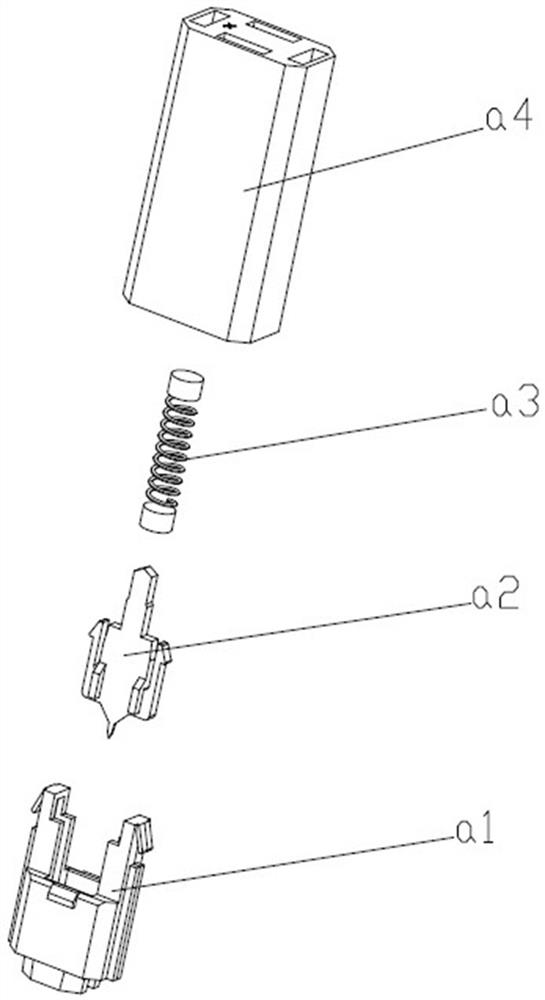

A kind of interface automatic assembly equipment

ActiveCN108173104BAccurate and efficient assemblyAssembly precisionContact member assembly/disassemblyAssembly lineEngineering

The invention provides an automatic interface assembling device which comprises a case and an assembly line, a terminal shell fixing mechanism for fixing the terminal shell and the base arranged on the assembly line and obtaining the terminal shell fixing piece, a terminal-in rubber core fixing mechanism for putting the terminal-in rubber core into the terminal shell of the terminal shell fixing piece and obtaining the terminal-in rubber core fixing piece, a rubber core press-in fixing mechanism for pressing in and integrating the rubber core of the terminal-in rubber core in the terminal-in rubber core fixing piece, a rubber sleeve pressing-in fixing mechanism for pressing and integrating the rubber sleeve in the terminal-in rubber core fixing piece, and an interface fixing mechanism anda discharging mechanism used for integrally pressing and integrating the terminal-in rubber core fixing piece. The interface automatic assembling device is high in automation degree, the safety and the accuracy are improved, and the service life of the machine is long, the production cost is reduced, and the high-efficiency and high-quality interface self-assembly work is further achieved.

Owner:南通吉程机械有限公司

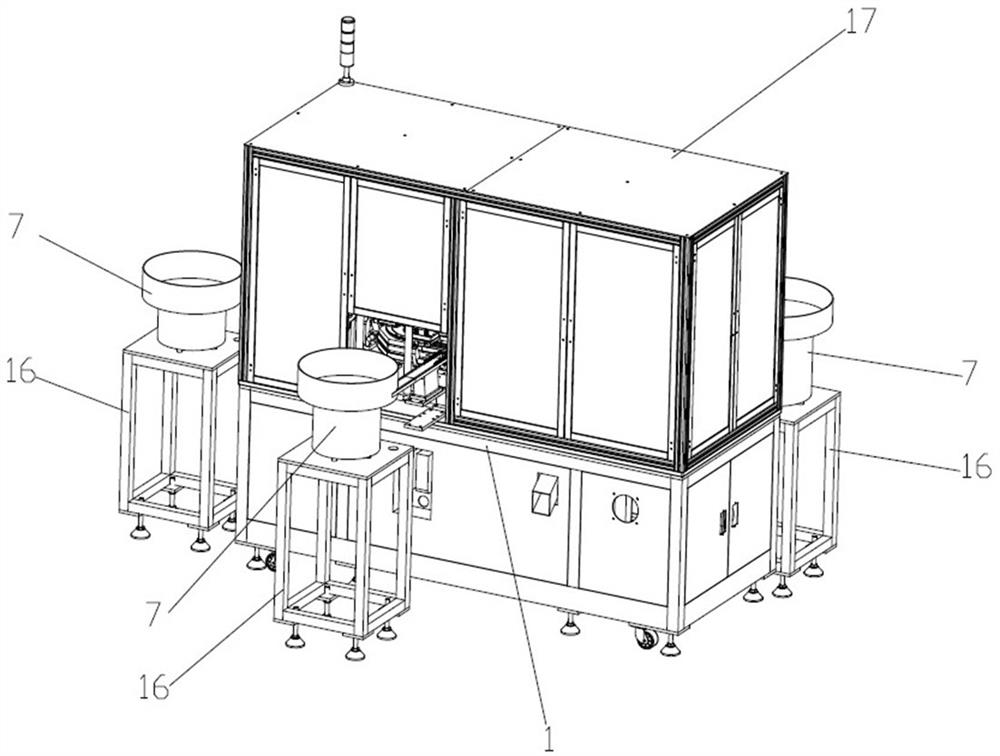

Automatic blood taking needle assembling equipment and assembling method thereof

PendingCN111922714AAccurate and efficient assemblyEasy maintenanceAssembly machinesMetal working apparatusElectric machineryEngineering

The invention provides automatic blood taking needle assembling equipment which comprises a table. A closed track is arranged on the table, a plurality of placing blocks are arranged on the closed track, a plurality of placing grooves for placing products are formed in the placing blocks, a rotating motor which drives the placing blocks to move on the closed track is arranged on the table in the closed track, an intermediate assembling mechanism, a needle assembling mechanism, a spring assembling mechanism, a housing assembling mechanism and a product take-out mechanism are separately arrangedon the circumferential table of the closed track along the moving direction of the placing blocks. Circular uninterrupted assembling is achieved by matching the closed track with each assembling station. The automatic blood taking needle assembling equipment aims to improve the problem that blood taking needles assembled by an existing blood taking needle assembling mode are uneven in quality, the quality is hardly ensured and the production efficiency is low.

Owner:福建凯博尔智能装备有限公司

Laser receiving debugging method and debugging device

ActiveCN105301578BResolve offsetPrecise adjustmentWave based measurement systemsLaser rangingOptical axis

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

A kind of processing equipment and processing method of piston rod sleeve circlip

ActiveCN106217016BIncrease productivityImprove product qualityMetal working apparatusElectrical controlEngineering

The invention discloses a piston rod sleeve snap spring processing equipment and method, belonging to the technical field of piston rod assembly. The equipment comprises a rack, a piston rod automatic feeding mechanism, a piston rod automatic sequencing and putting mechanism, a snap ring automatic feeding mechanism, a snap ring automatic grabbing and putting mechanism, a piston rod and snap ring automatic assembly mechanism, a product discharging mechanism and an electrical control system, wherein the piston rod automatic feeding mechanism feeds piston rods to the piston rod automatic sequencing and putting mechanism; the snap ring automatic feeding mechanism feeds snap rings to the snap ring automatic grabbing and putting mechanism; the snap ring automatic grabbing and putting mechanism conveys the snap rings to the piston rod and snap ring automatic assembly mechanism; the piston rod automatic sequencing and putting mechanism conveys the piston rods to the piston rod and snap ring automatic assembly mechanism; the piston rod and snap ring automatic assembly mechanism assemblies the snap rings and the piston rods; and the product discharging mechanism conveys out the assembled piston rods sleeved with the snap rings. The equipment and the method have the effects of improving the production efficiency and ensuring the product quality after installation.

Owner:ANHUI LAITE GAS SPRING CO LTD

Protective cap mounting device and optical fiber device testing equipment

ActiveCN109186948AEfficient and precise assembly processReduce error rateMetal working apparatusTesting fibre optics/optical waveguide devicesProtective relayTesting equipment

The invention relates to the technical field of the communication. A protective cap mounting device comprises a protective cap feeding module, a protective cap sorting module, a tenth mounting plate,a third tool clamp and a rotary module; the optical fiber device performance detection module has the advantages that the optical fiber device is high in positioning and processing precision, and highin product yield.

Owner:温州锐翔装饰工程有限公司

Install protective cover device and optical fiber device test equipment

ActiveCN109186948BAccurate and efficient assemblyReduce error rateMetal working apparatusTesting fibre optics/optical waveguide devicesTest equipmentMaterials science

The invention relates to the technical field of the communication. A protective cap mounting device comprises a protective cap feeding module, a protective cap sorting module, a tenth mounting plate,a third tool clamp and a rotary module; the optical fiber device performance detection module has the advantages that the optical fiber device is high in positioning and processing precision, and highin product yield.

Owner:温州锐翔装饰工程有限公司

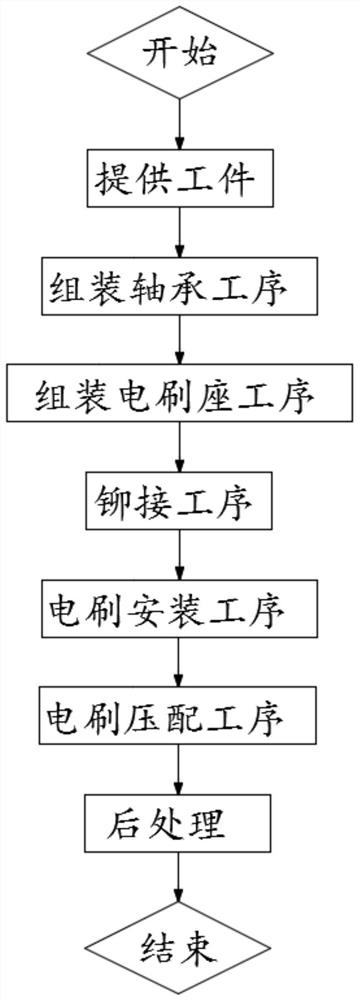

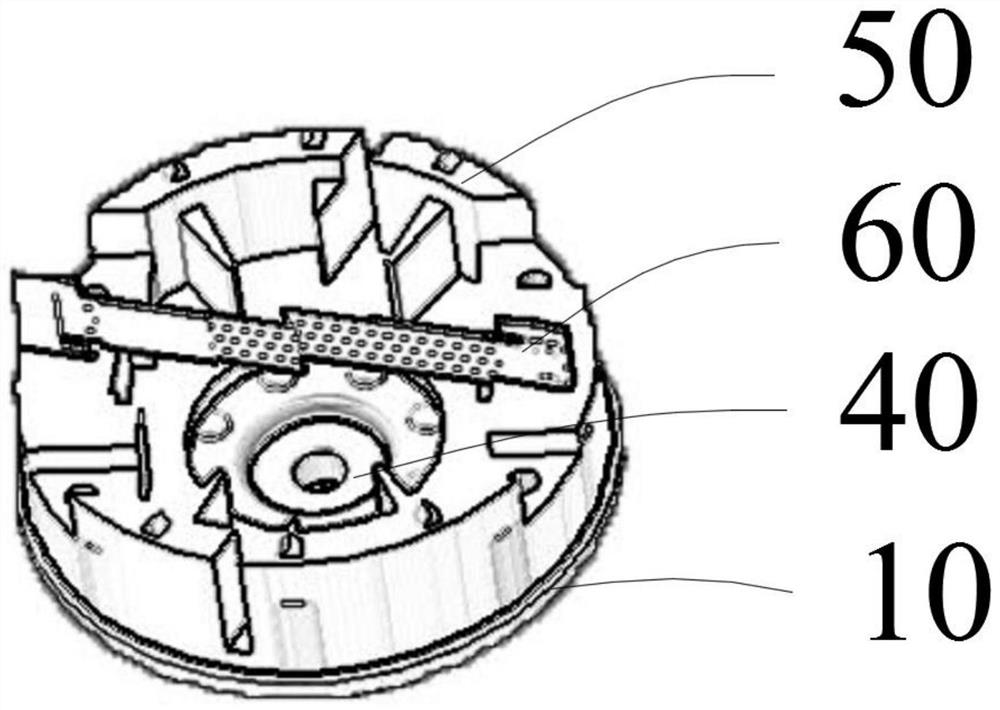

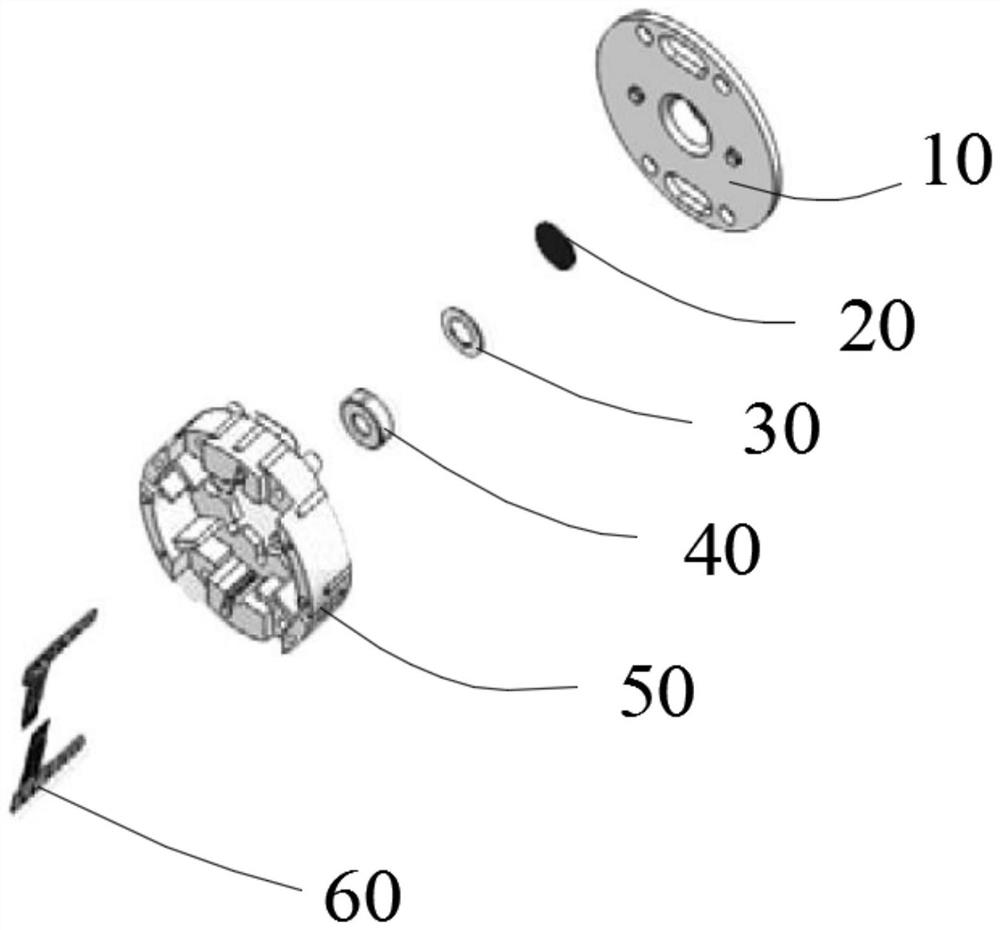

Automatic assembling process and device for motor plate shell assembly

ActiveCN111669018AQuick and accurate installationSimple processElectric machinesManufacturing dynamo-electric machinesBrushWorking space

The invention relates to the field of motor assembling, particularly to an automatic assembling process and device for a motor plate shell assembly. The process comprises: S1, work-piece providing; S2, a bearing assembling procedure: conveying a shell plate and a bearing to a bearing mounting mechanism to assemble the shell plate and the bearing; S3, an electric brush seat assembling process: conveying the shell plate assembled with the bearing into an electric brush seat assembling mechanism to assemble an electric brush seat and the shell plate; S4, a riveting process: conveying the electricbrush seat shell plate assembly after the electric brush seat assembling process S3 into a riveting mechanism to rivet the electric brush seat and the shell plate; S5, an electric brush installationprocess: inserting the electric brush part of a film into an electric brush groove to form a plate shell assembly; S6, an electric brush press-fit process: pressing the film electric brush into the electric brush groove; and S7, post-treatment: detecting the plate shell assembly. According to the invention, rapid assembly of the motor plate shell assembly is achieved, the device space occupation ratio is small, accurate and efficient assembly of the motor plate shell assembly is achieved, the labor cost is reduced, and the working space is saved.

Owner:SHIXING STANDARD MOTOR CO LTD

An automatic hole-aligning assembly equipment for split brake discs

Owner:江苏惠博汽车部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com