Piston rod sleeve snap spring processing equipment and method

A technology for processing equipment and piston rods, applied in the processing equipment and processing fields of piston rod sleeve circlips, can solve the problems of poor quality and low efficiency of manual installation, and achieve the effects of improving production efficiency and quality, saving operating costs and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

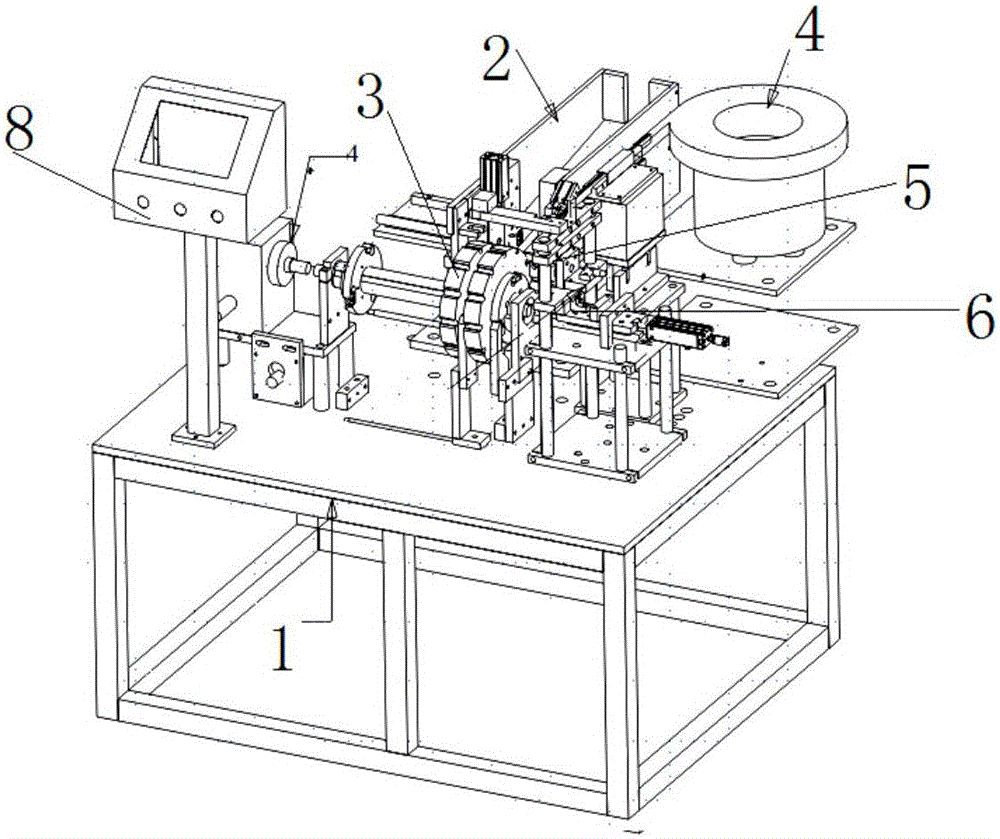

[0042] combine figure 1, a piston rod sleeve circlip processing equipment, including a frame 1, and also includes a piston rod automatic feeding mechanism 2, a piston rod automatic sorting and placement mechanism 3, a snap ring automatic feeding mechanism 4, and a snap ring automatic grasping and placement Mechanism 5, piston rod snap ring automatic assembly mechanism 6, product output mechanism 7 and electrical control system 8, piston rod automatic feeding mechanism 2 sends the piston rod to piston rod automatic sorting and placement mechanism 3, snap ring automatic feeding mechanism 4 Send the snap ring to the snap ring automatic grabbing and placement mechanism 5, the snap ring automatic grabbing and placement mechanism 5 will transport the snap ring to the piston rod snap ring automatic assembly mechanism 6, and the piston rod automatic sorting and placement mechanism 3 will The piston rod is transported to the piston rod snap ring automatic assembly mechanism 6, the pist...

Embodiment 2

[0044] A kind of piston rod sleeve circlip processing equipment of this embodiment is similar to Embodiment 1, the difference is that the piston rod automatic feeding mechanism 2 includes a chute, and the piston rod automatic sorting and placement mechanism 3 includes a rotating wheel, which rotates The roulette is uniformly provided with grooves matched with the piston rod, and the rotating roulette faces the chute, and the rotation is controlled by the electric control system 8 .

[0045] Piston rod enters in the chute of piston rod automatic feeding mechanism 2, and the rotating roulette rotates, and the piston rod in the chute enters automatically on the groove of rotating roulette.

Embodiment 3

[0047] A kind of processing equipment for piston rod sleeve and circlip of this embodiment is similar to that of Embodiment 1, the difference is that the snap ring automatic feeding mechanism 4 includes a vibrating plate, a slide rail and a straight track, and the inner surface of the vibrating plate is provided with a slide rail , the slide rail is connected with the straight rail.

[0048] The snap ring is placed in the vibrating plate, and the vibrating plate rotates. The snap ring moves along the slide rail on the inner side of the vibrating plate, and is placed on the straight track in sequence, moving forward continuously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com