Automatic assembling process and device for motor plate shell assembly

An automatic assembly device and automatic assembly technology, applied in the direction of electromechanical devices, electric components, electric vehicles, etc., can solve the problems of many processes, high labor costs, increased space, labor occupation and waste, etc., to achieve simple process and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

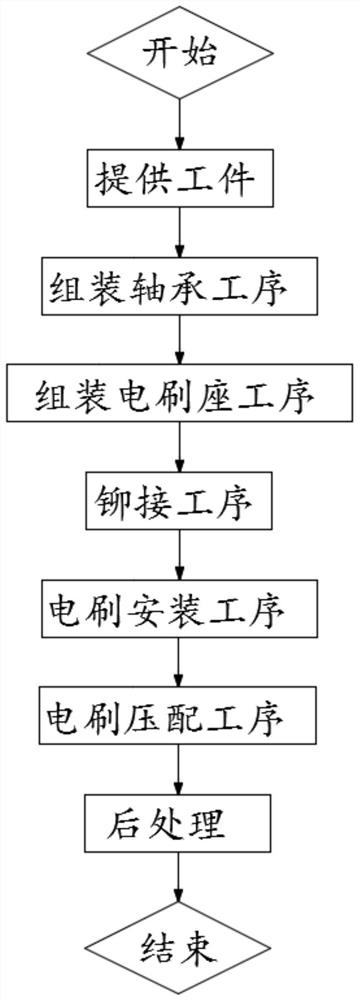

[0048] Such as Figure 1-4 As shown, the present embodiment provides an automatic assembly process of the motor board and housing assembly, including the following steps:

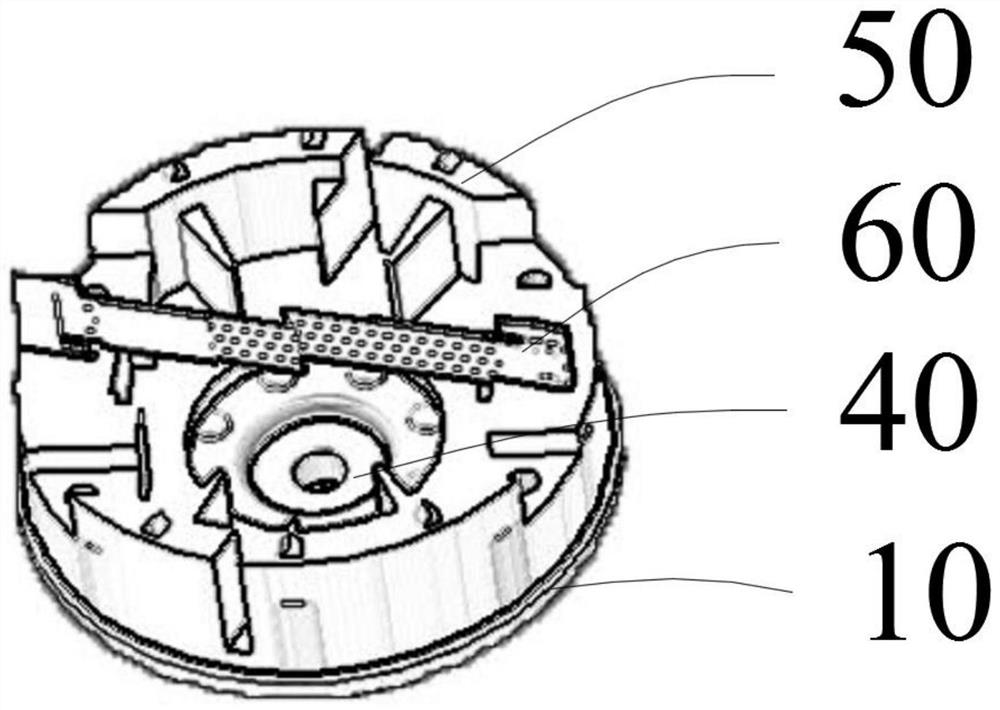

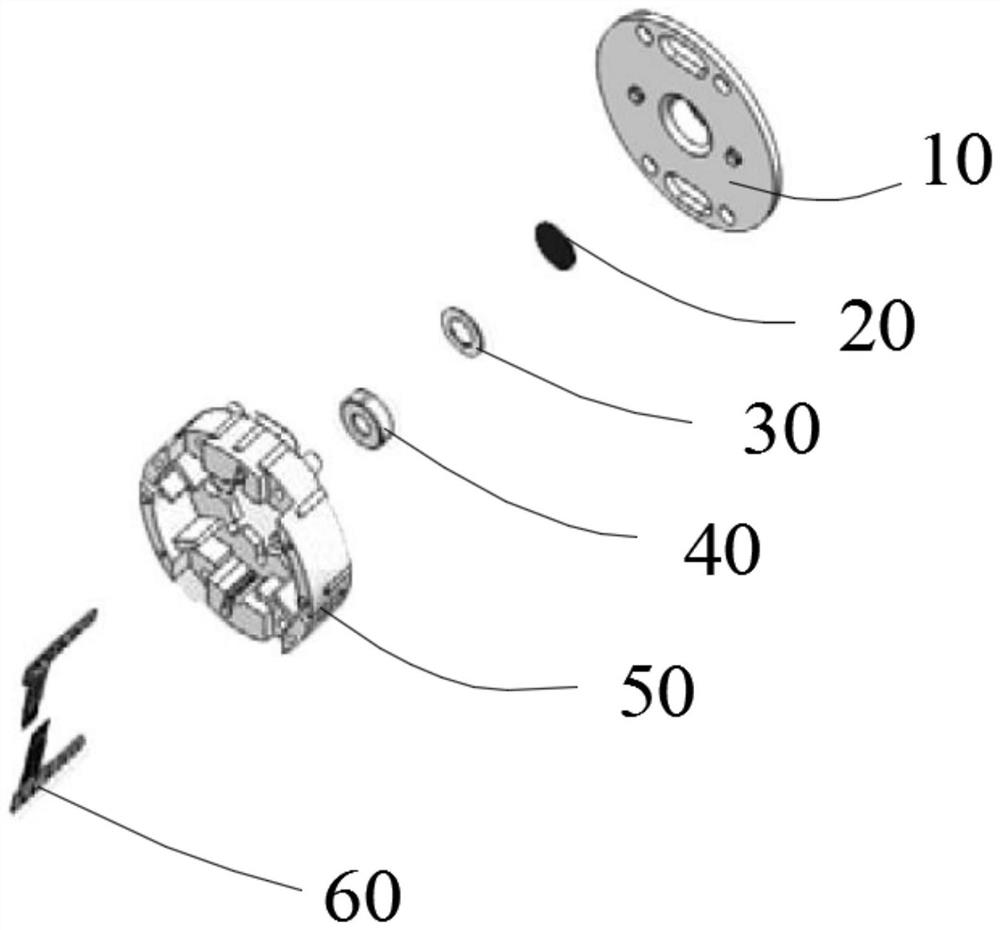

[0049] S1: provide the workpiece, the workpiece includes a shell plate 10, a bearing 40, a brush holder 50, a shaft receiving plate 20, a shaping washer 30 and a film brush 60, and the center of the shell plate 10 is provided with a bearing 40 groove for installing the bearing 40, And the shell plate 10 is provided with four through holes 101, and the through holes 101 are symmetrical about the center of the circle, the brush holder 50 is provided with a plurality of bumps correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com