Fast assembly fixture

A fixture and clamping technology, which is applied in the field of quick-fit fixtures, can solve problems such as limited application range, many components, and large tank volume, and achieve the effects of wide applicability, simple structure, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

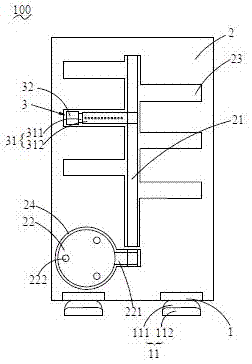

[0018] see figure 1 As shown, the present invention discloses a quick-release clamp 100 , including a base 1 , a support plate 2 fixedly mounted on the base 1 , and a clamp 3 connected and mounted on the support plate 2 .

[0019] The bottom of the base 1 is provided with a supporting foot 11 , and the supporting foot 11 includes a casing 111 and a supporting extension 112 accommodated in the casing 111 . The support extension 112 can be stretched out from the outer casing 111 to enhance the stability of the quick-installation clamp 100 and prevent the quick-installation clamp 100 from toppling after clamping the assembly.

[0020] The support plate 2 is fixedly installed on the base 1, and the support plate 2 is arranged in a plate shape. The m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com