Quick loading and unloading construct for heavy construct and manufacturing method thereof

A structure, heavy-duty technology, applied in construction, hoisting device, building structure, etc., can solve problems such as hidden safety hazards, low construction efficiency, manual assistance, etc., to achieve reliable force, reduce equipment and construction costs, and reduce occupation time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

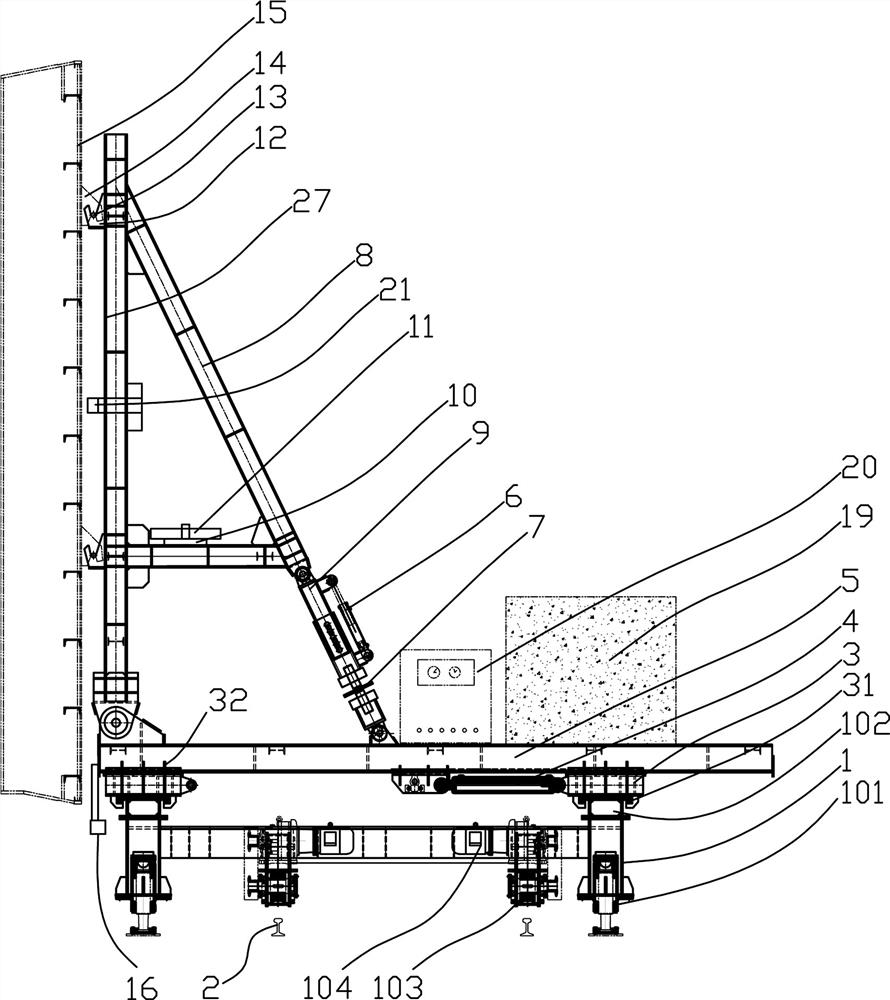

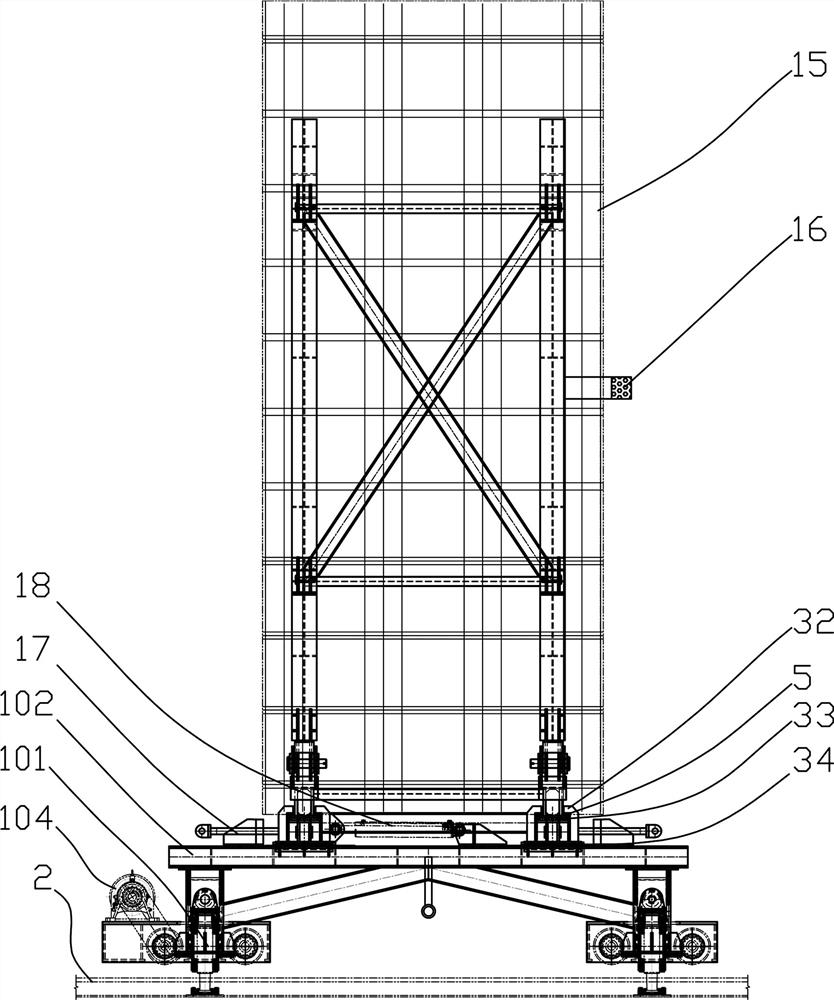

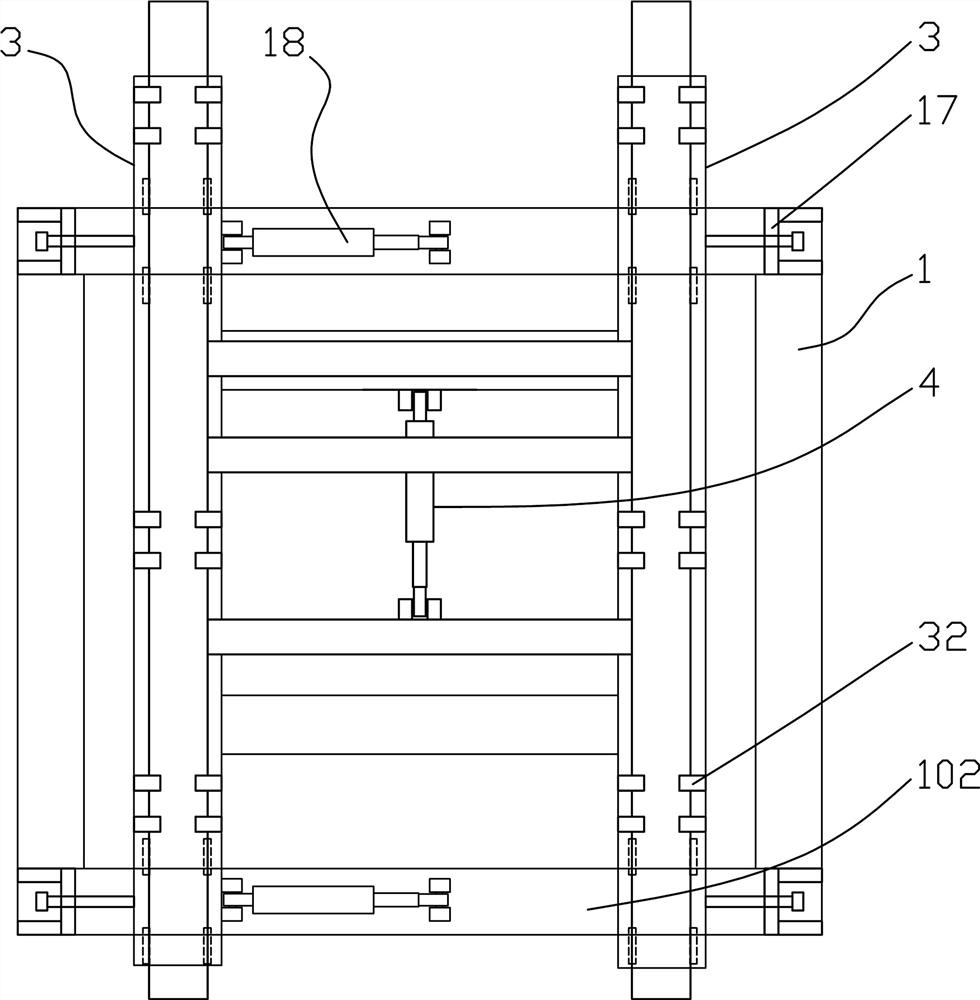

[0052] Such as figure 1 , 2 , 11~15, a fast loading and unloading structure for a heavy-duty structure, which includes a plurality of load-bearing devices fixed on the heavy-duty structure 15, the distance between the multiple load-bearing devices is a fixed value; the heavy-duty structure described in this example The structure 15 includes underground immersed pipes or steel end seal doors of corridors; fabricated shear walls, fabricated beams, fabricated columns or other fabricated components; the number of bearing devices can be 2 to 4. For example, on the prefabricated column, two load-bearing devices are arranged vertically, while on the prefabricated beam, two load-bearing devices are arranged horizontally, and four rectangular ones are set on the prefabricated shear wall. The distance between the carrying devices can also be set in multiple groups according to the size of the heavy-duty structure 15, such as 50cm, 100cm or 200cm apart.

[0053] The bearing device is u...

Embodiment 2

[0079] A method for manufacturing the above-mentioned quick loading and unloading structure for heavy-duty structures, comprising the following steps:

[0080] S1, fixing the relative positions of a plurality of backing plate nuts 23 with a mould, and connecting the connection frame 144 with the backing plate nuts 23;

[0081] S2. Determine the centroid position of the heavy-duty structure 15; obtain the centroid position of the heavy-duty structure 15 through design software or check calculation.

[0082] S3, arrange the reinforcement structure of the heavy-duty structure 15, place the connection frame 144 near the centroid of the heavy-duty structure 15, and connect the connection frame 144 to the reinforcement structure directly or through the connection rib welding;

[0083] S4, fill the backing plate nut 23 with foam sealing plug 29, and form the hole 26 for receiving the connecting bolt 25 by the foam sealing plug, the top of the foam sealing plug 29 is flush with the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com