Force sensing lifting equipment and control method

A technology of equipment and controllers, applied in hoisting devices, clockwork mechanisms, etc., can solve problems such as the limited range of up and down operations, affecting the lifting movement of lifting equipment, and inconvenient operation of the handle, so as to improve battery life and improve operation Convenience, the effect of improving the convenience of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

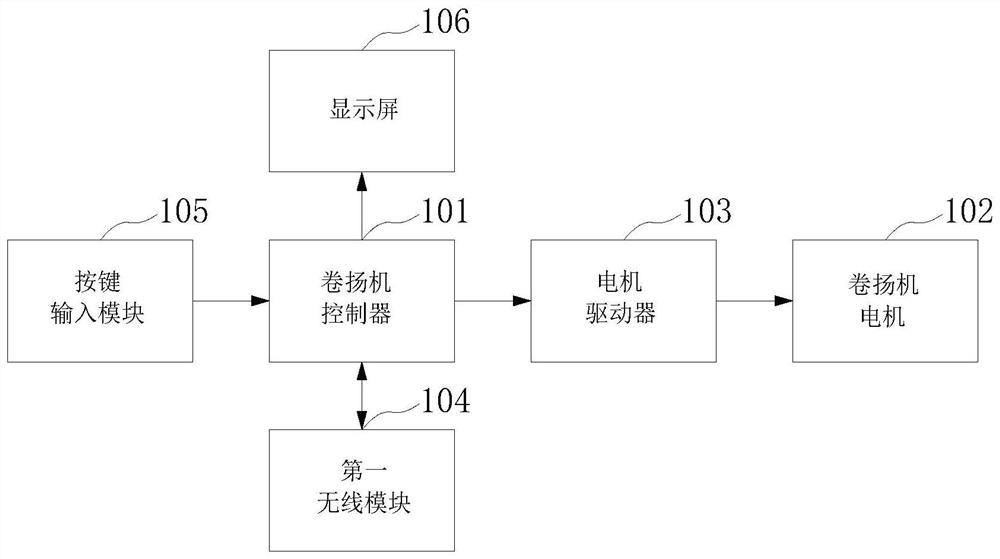

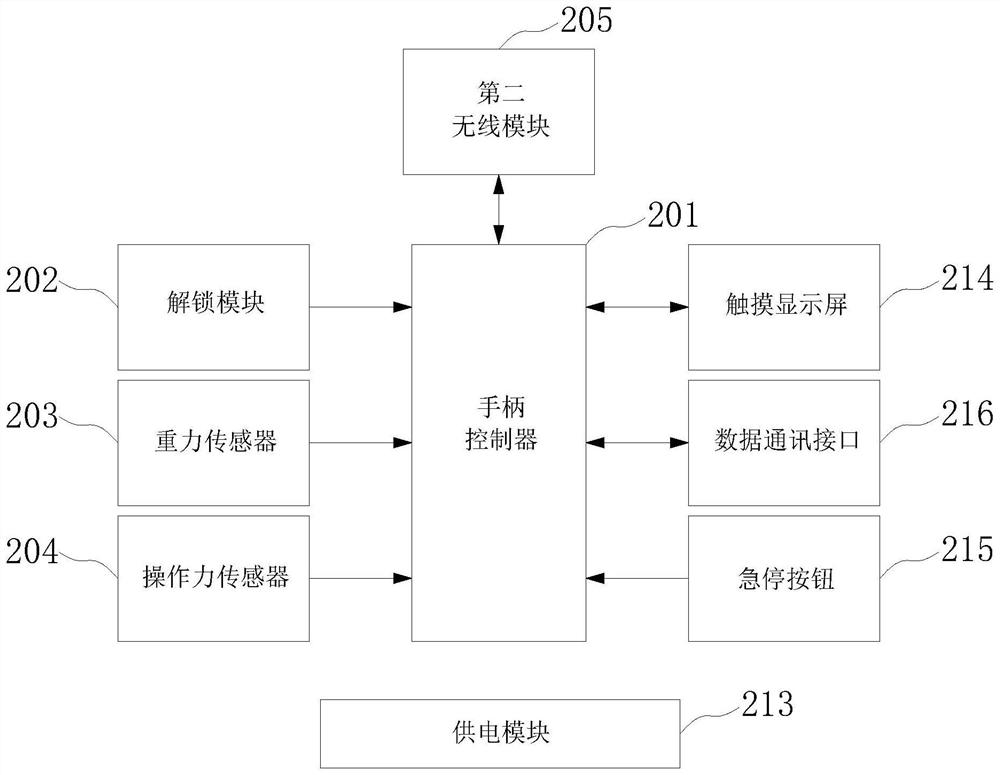

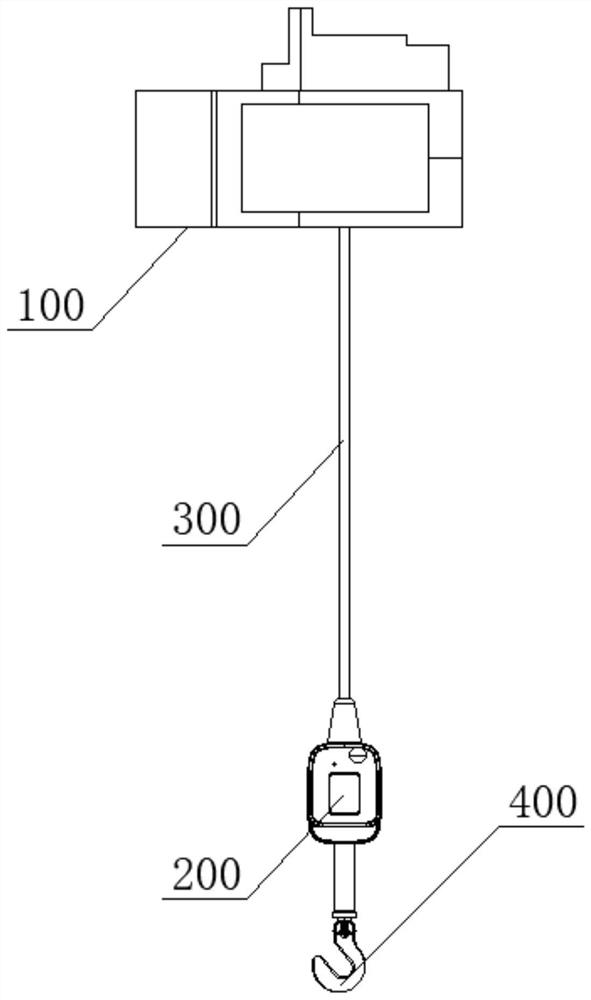

[0040] combined with figure 1 to the attached Figure 7 The technical solution of the present invention is a force-sensing hoisting device, comprising a hoist assembly 100, a force-sensing handle assembly 200 and a cable 300, one end of the cable 300 is connected to the hoist assembly 100, and the other end of the cable 300 is connected to the The force-sensing handle assembly 200 is connected, the force-sensing handle assembly 200 is connected with a suspending assembly 400, and the hoist assembly 100 includes a hoist controller 101, a hoist motor 102, a motor driver 103 and a first wireless module 104. The hoist controller 101 is electrically connected to the motor driver 103 and the first wireless module 104, respectively, the motor driver 103 is electrically connected to the hoist motor 102, and the force-sensing handle assembly 200 includes a handle controller 201, an unlocking module 202, gravity sensor 203, operation force sensor 204 and second wireless module 205, th...

Embodiment 2

[0055] combined with Figure 8 to the attached Figure 10 , the technical solution of the present invention is a control method of a force-sensing lifting device, using the force-sensing lifting device described in the above-mentioned embodiment 1, including:

[0056] The handle controller is powered on for initialization and enters a low-power working state;

[0057] The handle controller obtains and responds to the hand-held unlock signal, interrupts the low-power working state, jumps to the normal working state, and receives the target data;

[0058] Within the preset time, if the handle controller obtains the hand grip operating force signal, the handle controller calculates the operating force direction signal and the operating force magnitude signal according to the hand grip operating force signal, and the handle controller sends the operating force direction signal and the operating force magnitude signal. The signal is sent to the driving device controller, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com