RRU product assembling device and assembling method based on modular design

A technology of modular design and assembling equipment, applied in metal processing equipment, cooperating devices, and devices that apply liquid to surfaces, etc. It can solve the problems of difficult assembly site management, many manual interventions, and low assembly yield. , to achieve the effect of reducing operational complexity, high assembly yield and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention and the accompanying drawings. Apparently, the described embodiments do not limit the present invention.

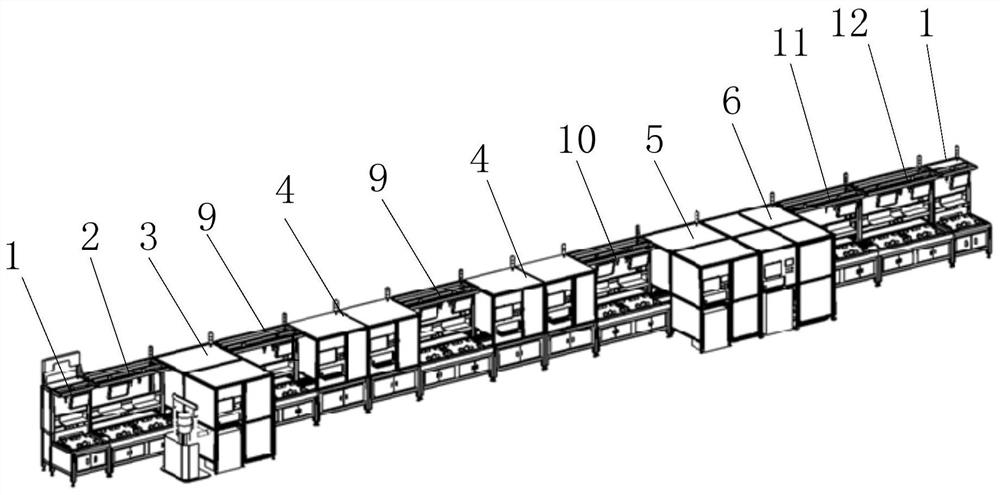

[0078] Such as figure 1 , the present invention provides a RRU product assembly equipment based on modular design, including a first conveyor 8, a second conveyor 7 and two lifting units 1, and a first assembly unit 2 and a glue dispensing unit 3 arranged in sequence , the second assembly unit 9 , the screwing unit 4 , the third assembly unit 10 , the detection unit 5 , the jumper installation unit 6 , the fourth assembly unit 11 and the fifth assembly unit 12 . The two lifting units 1 are arranged adjacent to each other before the first assembly unit 2 and behind the fifth assembly unit 12 . The setting quantity of the second assembly unit 9 and the screwing unit 4 is the same, and at least two can be set, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com