Lens module assembled apparatus and method

A technology for lens modules and assembly equipment, applied in installation, optics, instruments, etc., can solve the problems of time-consuming positioning, lower assembly yield, and inaccuracy, and achieve the effect of accurate and efficient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

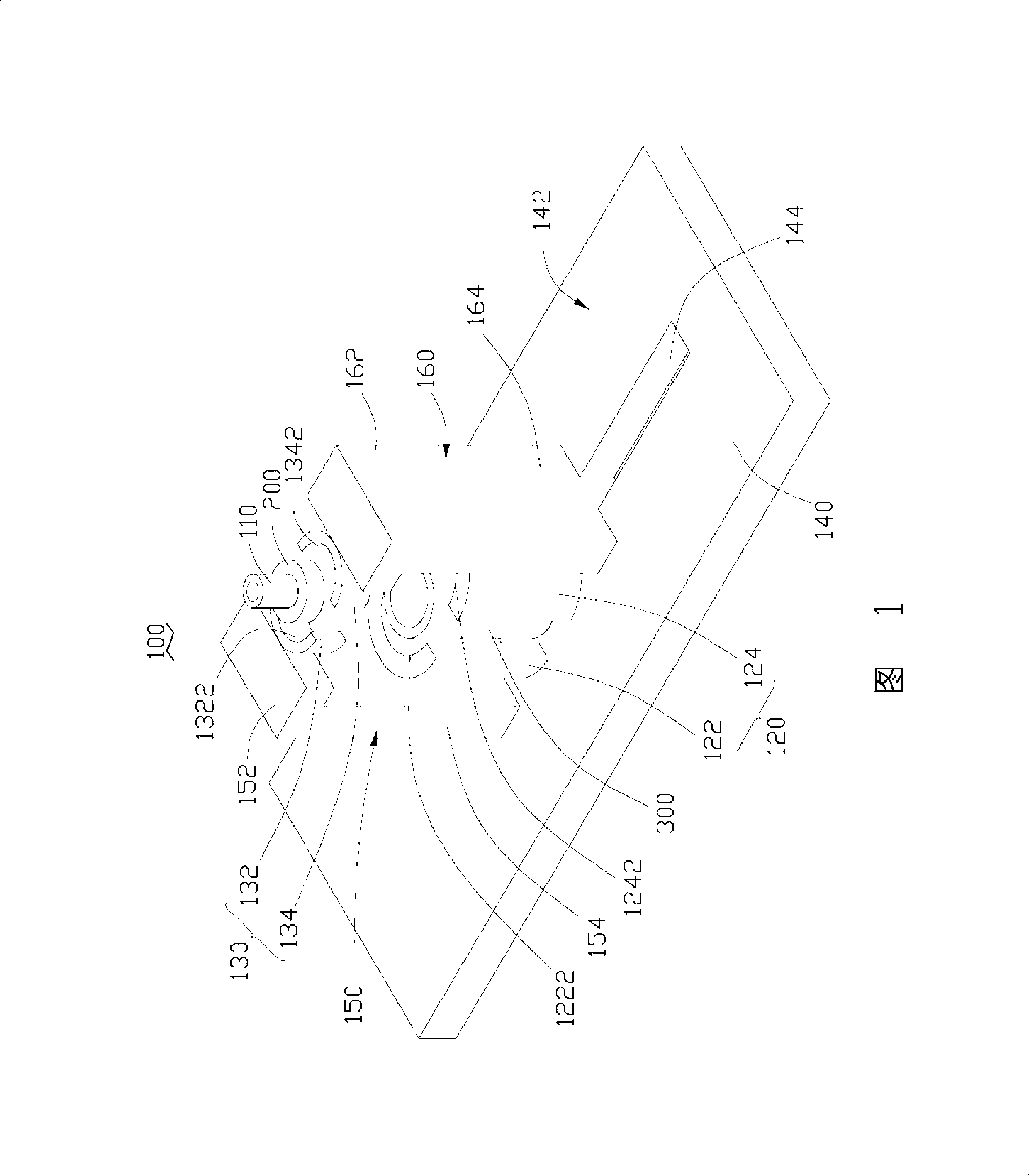

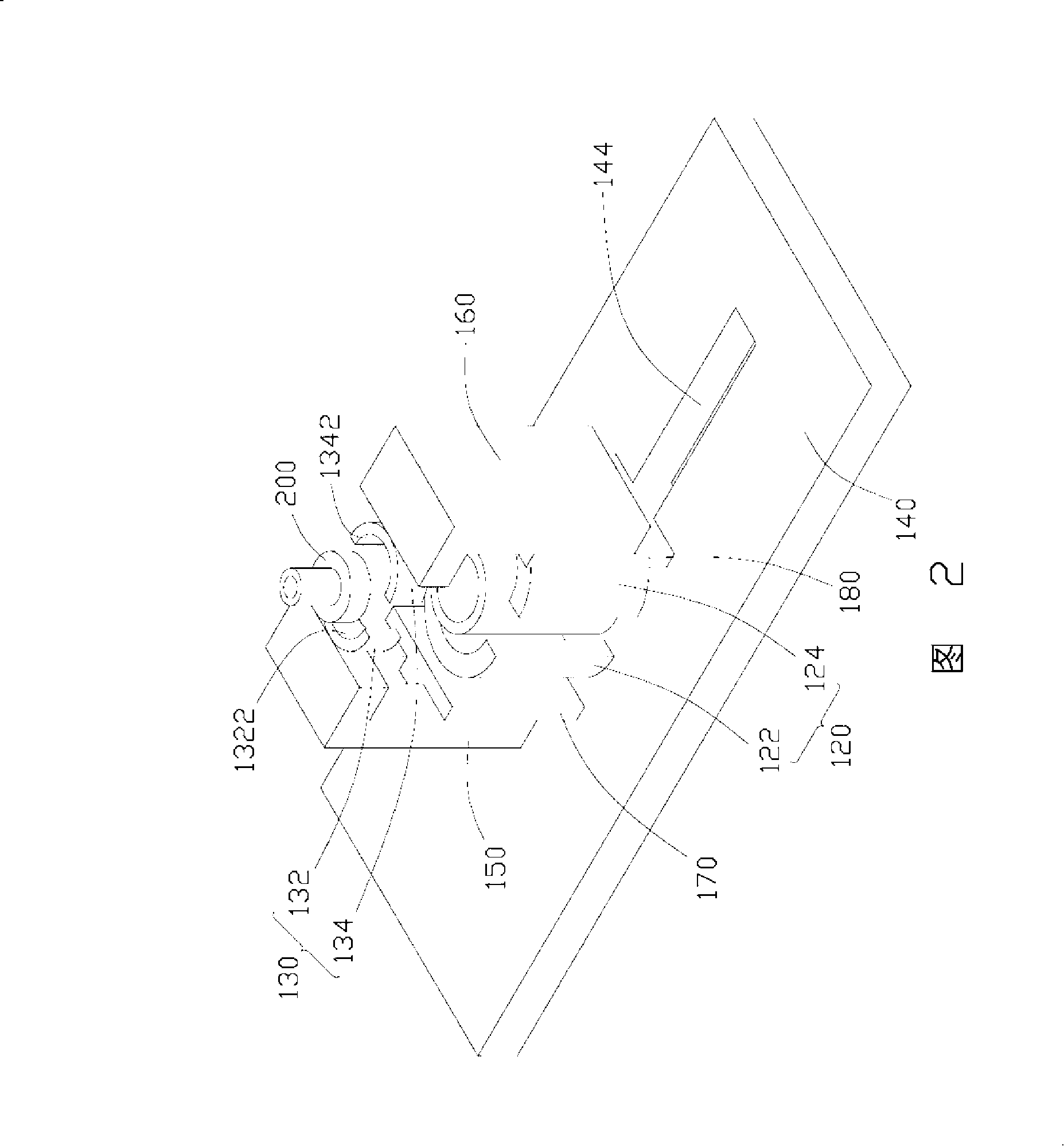

[0011] Please refer to FIG. 1 , a lens module assembling device 100 provided by an embodiment of the present invention includes a pick-up device 110 , a holder 120 and a guide 130 .

[0012] The pick-up device 110 is used to take out the optical components 200 such as lenses and infrared filters from the tray (not shown) carrying the optical components 200 , and assemble the taken-out optical components 200 into the lens barrel 300 . In this embodiment, the pick-up device 110 is a vacuum suction nozzle, which can be connected with an air cylinder (not shown) to absorb the optical element 200 . Of course, it can be understood that the pick-up device 110 may also be other devices capable of taking and placing the optical element 200, such as a robot arm.

[0013] The holding member 120 is used to hold the lens barrel 300 , and includes a first holding portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com