Ink jet position regulator for making display screen

A technology of position adjustment device and inkjet head, applied in printing, optics, instruments, etc., can solve the problems of use, uneven coating thickness and width, expensive equipment, etc., to achieve simple production process, improve product quality, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

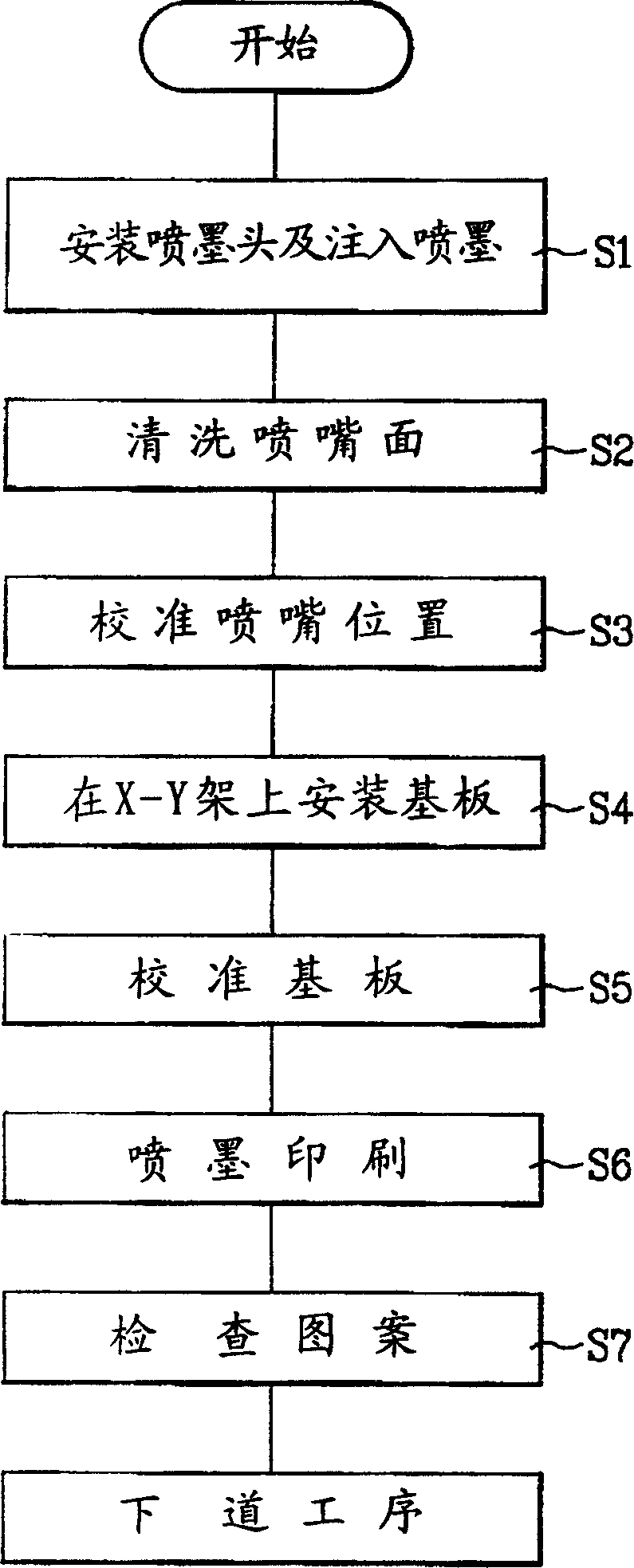

[0016] according to Figure 1-3 The specific structure and working process of the present invention are described in detail with the embodiment.

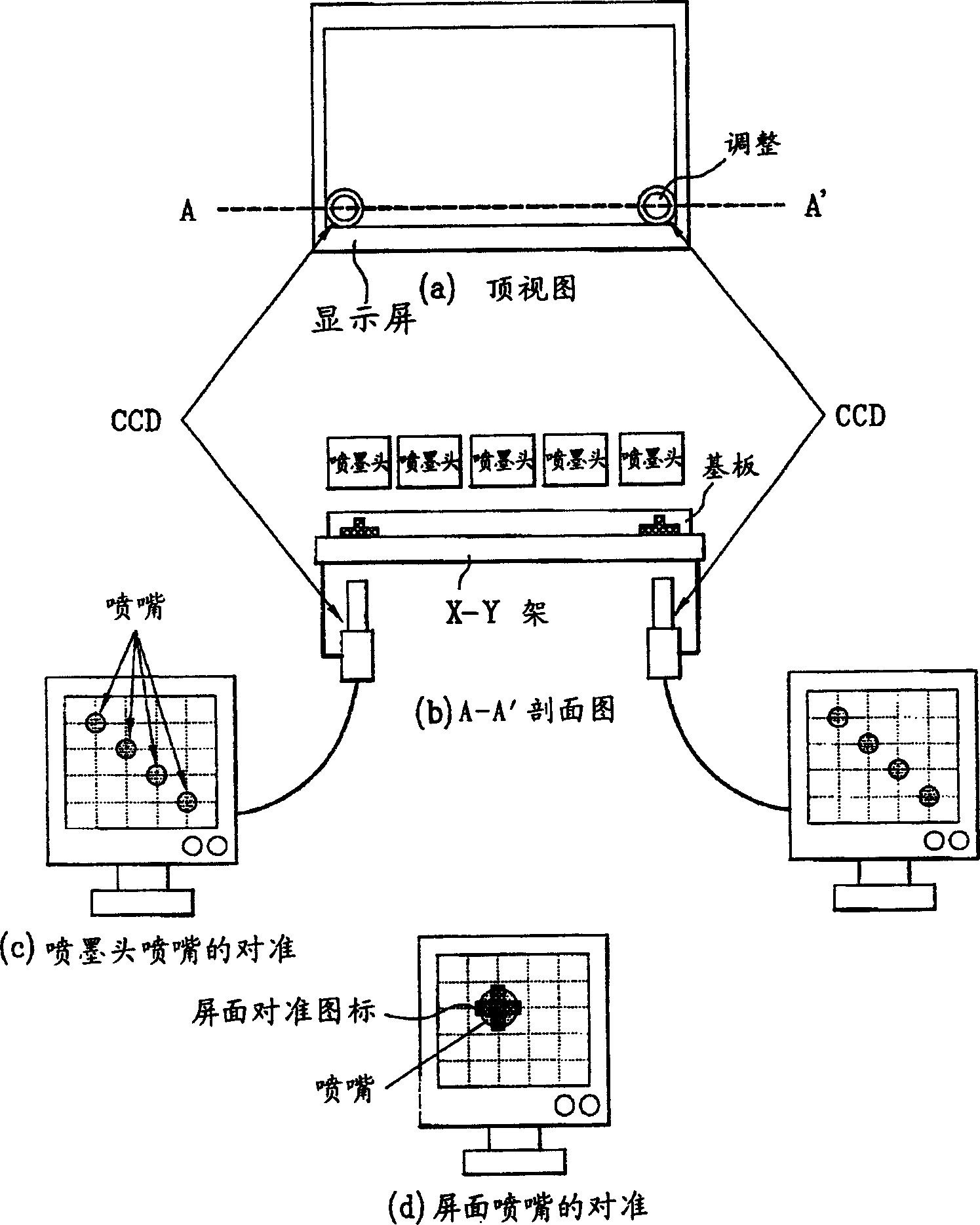

[0017] figure 1 It is a structural schematic diagram of an inkjet head position adjustment device for making display screens according to the present invention.

[0018] as in figure 1 As shown, because the nozzles of the inkjet head are facing downward, two CCD (charge coupled devices) cameras are installed on the X-Y frame from bottom to top.

[0019] Of the two CCD cameras, one or both can do image processing.

[0020] As shown in figure (a), two through holes are arranged on the X-Y frame, and two CCD cameras are respectively arranged below them.

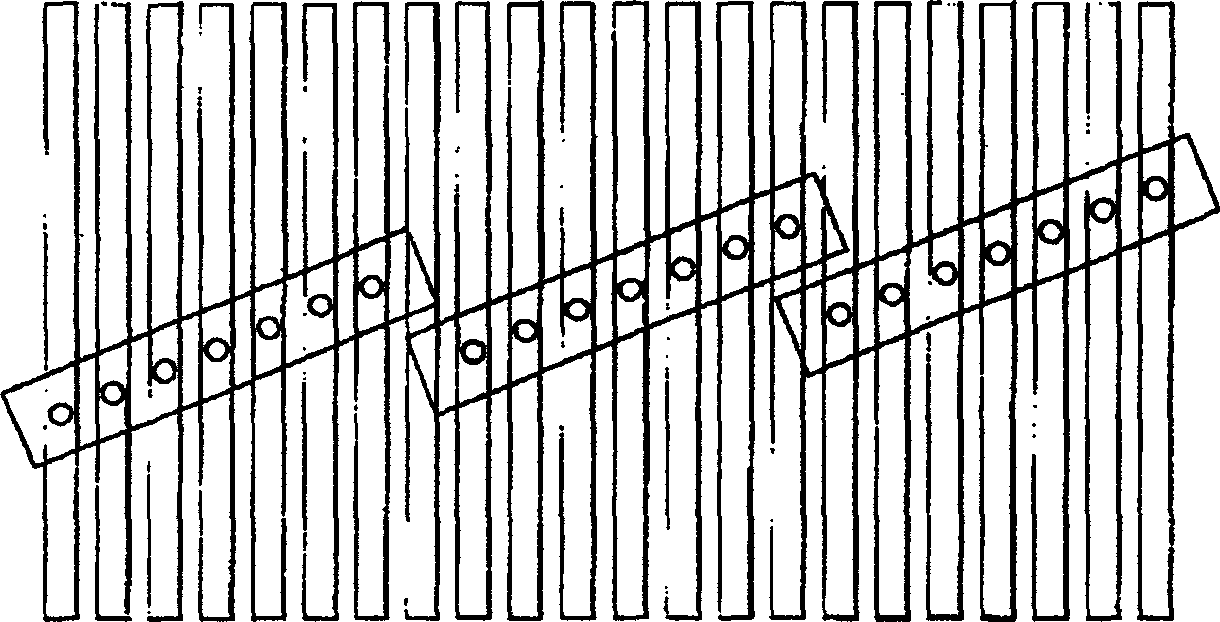

[0021] The sectional view of A-A' of figure (a) is figure (b). like image 3 As shown, in the inclined inkjet head, put the nozzle of the first inkjet head that needs to be aligned on the through hole, so as to align the grid formed by the image pixel pitch that needs to be inkj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com