Automatic deviation-adjustment device and deviation-adjustment method for rubber belt at circle forming section of tubular belt conveyor

A tubular belt conveyor technology, which is applied in the field of automatic belt deviation adjustment device in the circular section of the tubular belt conveyor, can solve the problems of time-consuming and labor-intensive effects, waste of manpower and material resources, and low precision, so as to achieve low cost and ensure alignment The effect of high efficiency in operation and deviation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

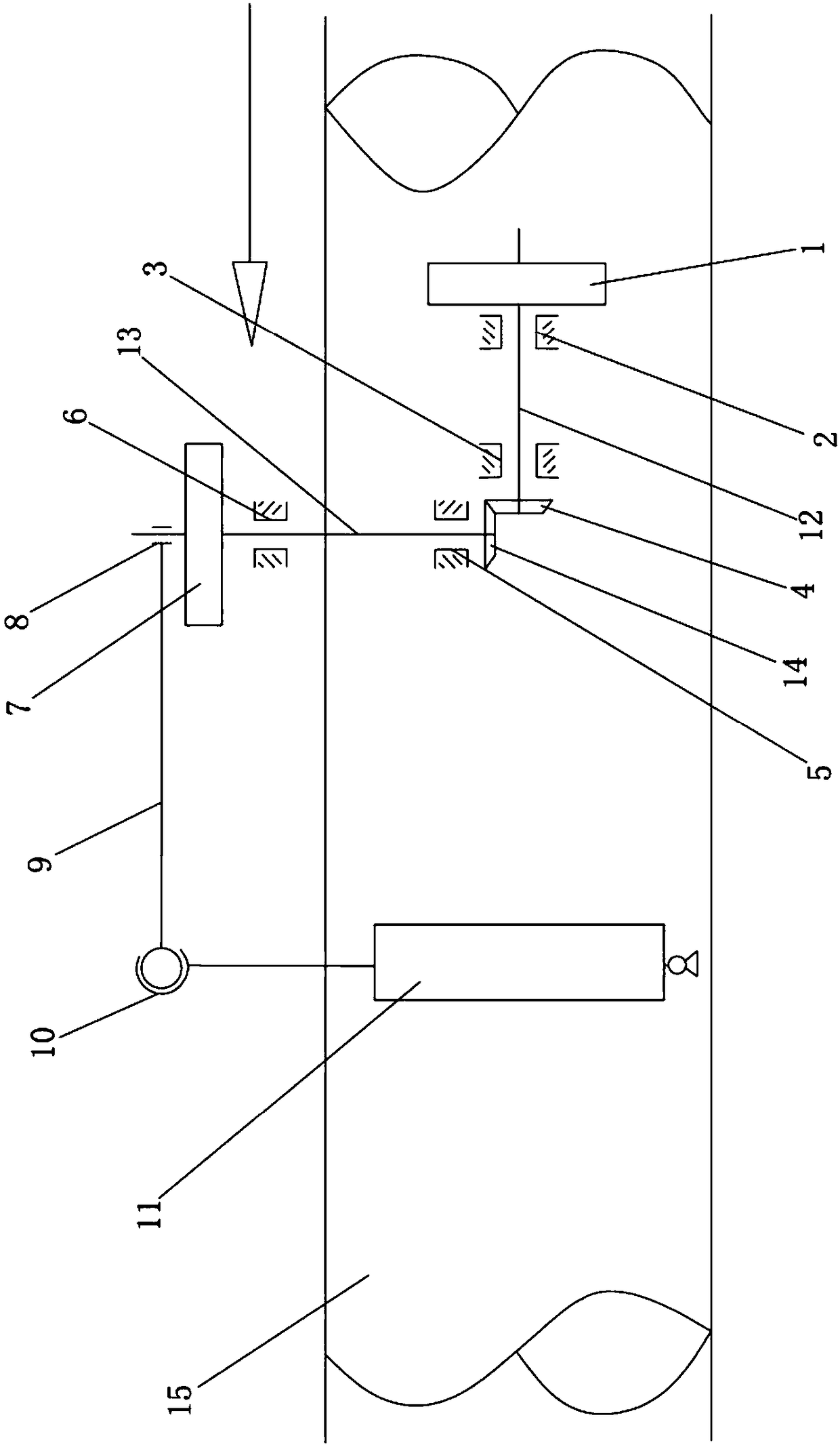

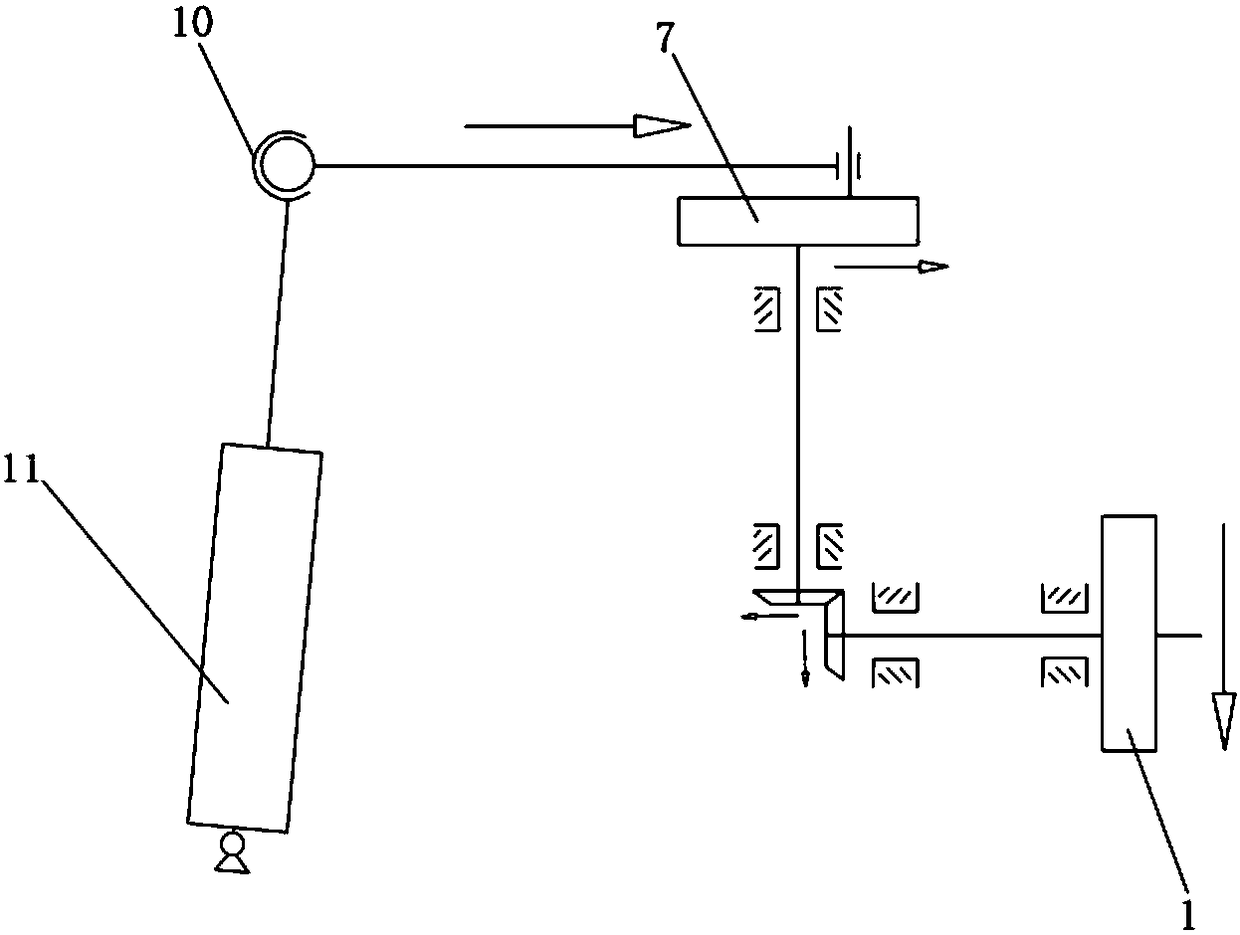

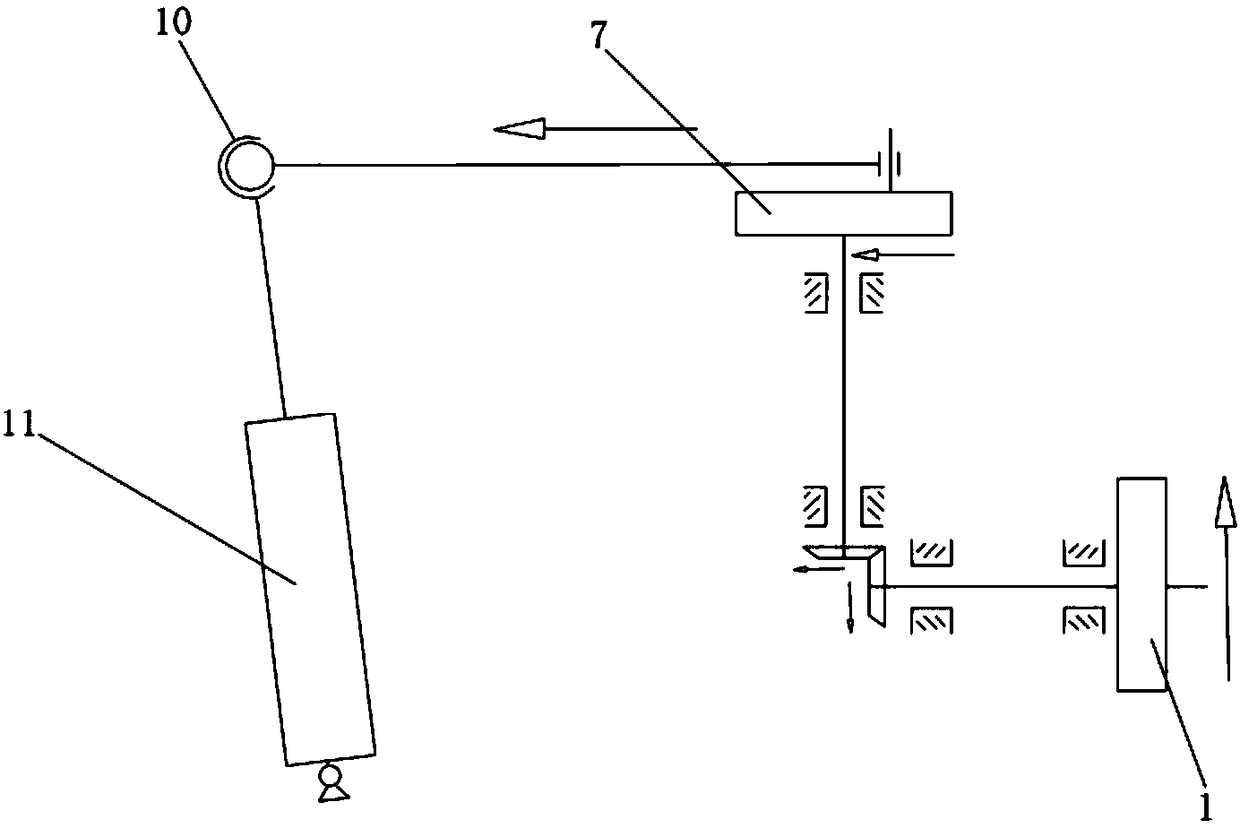

[0019] The automatic deviation adjustment device for the round section of the tubular belt conveyor, such as figure 1 As shown, it includes a transverse transmission mechanism, a longitudinal transmission mechanism, and an idler roller 11. The transverse transmission mechanism includes a first transverse bearing 2 and a second transverse bearing 3 arranged at intervals, and the longitudinal transmission mechanism includes first and second transverse bearings arranged at intervals. Longitudinal bearing 5, second longitudinal bearing 6, described first transverse bearing 2, second transverse bearing 3, first longitudinal bearing 5, second longitudinal bearing 6 are all connected with frame by bearing block; A horizontal rotating shaft 12 is connected between the bearing 2 and the second lateral bearing 3, and the left and right ends of the horizontal rotating shaft 12 extend to the outside of the first lateral bearing 2 and the second lateral bearing 3; the left end of the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com