Rubber-tyred gantry crane walking positioning, correcting and container truck alignment anti-lifting method

A technology of tire cranes and trucks, which is applied in the direction of load hanging components, safety devices, transportation and packaging, and can solve problems such as safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

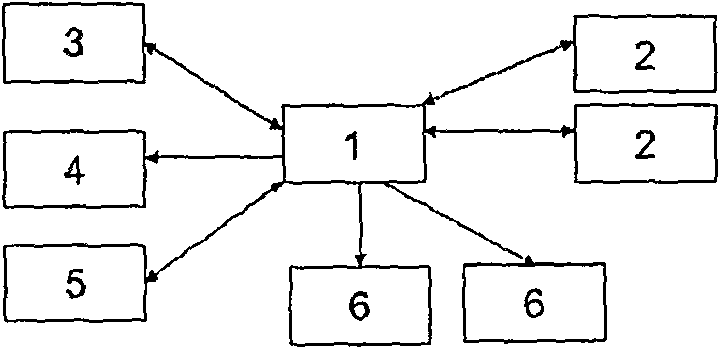

[0023] Such as figure 1 As shown, the laser scanner (2), the container position management display (3), the siren (4), the crane PLC (5), and the display screen (6) are all connected to the computer (1). Siren (4) can warn tire crane driver by sound or combination of sound and light or other methods.

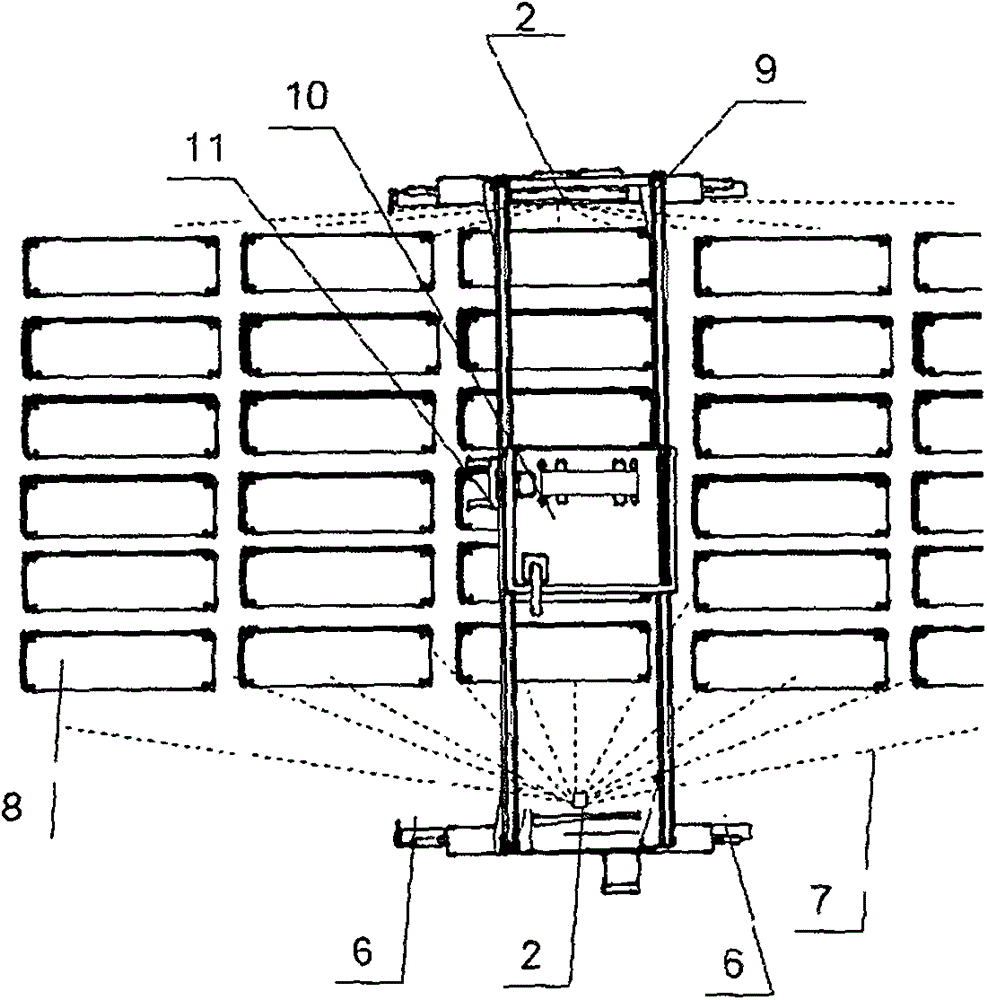

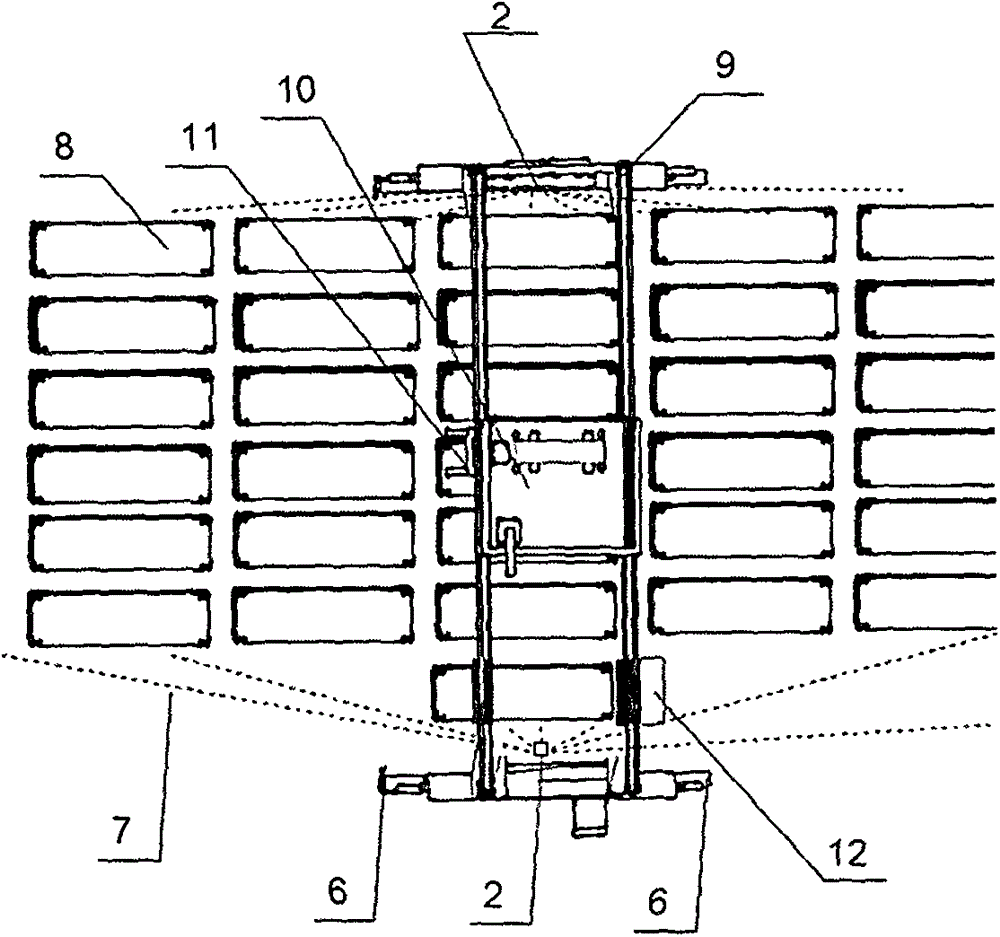

[0024] Such as figure 2 As shown, during the travel of the tire crane (9), two laser scanners (2) simultaneously scan and measure the side of the container (8) on the container yard and the gap between the container (8) and the container (8), so as to The container (8) positions and gaps stacked on the yard are used as reference. If the tire crane (9) deviates from the driving lane, the distance from the side of the container (8) on the container yard measured by the laser scanner (2) to the laser scanner (2) will become larger or smaller, and the computer (1) analyzes the data , it is possible to predict the deviation distance of the tire crane (9) if the deviation is not c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com