Deviation rectifying method, device and system for tire crane

A technology of tire lifting and offset value, applied in image data processing, instrumentation, calculation, etc., can solve the problems of high cost, low investment cost, limited application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail.

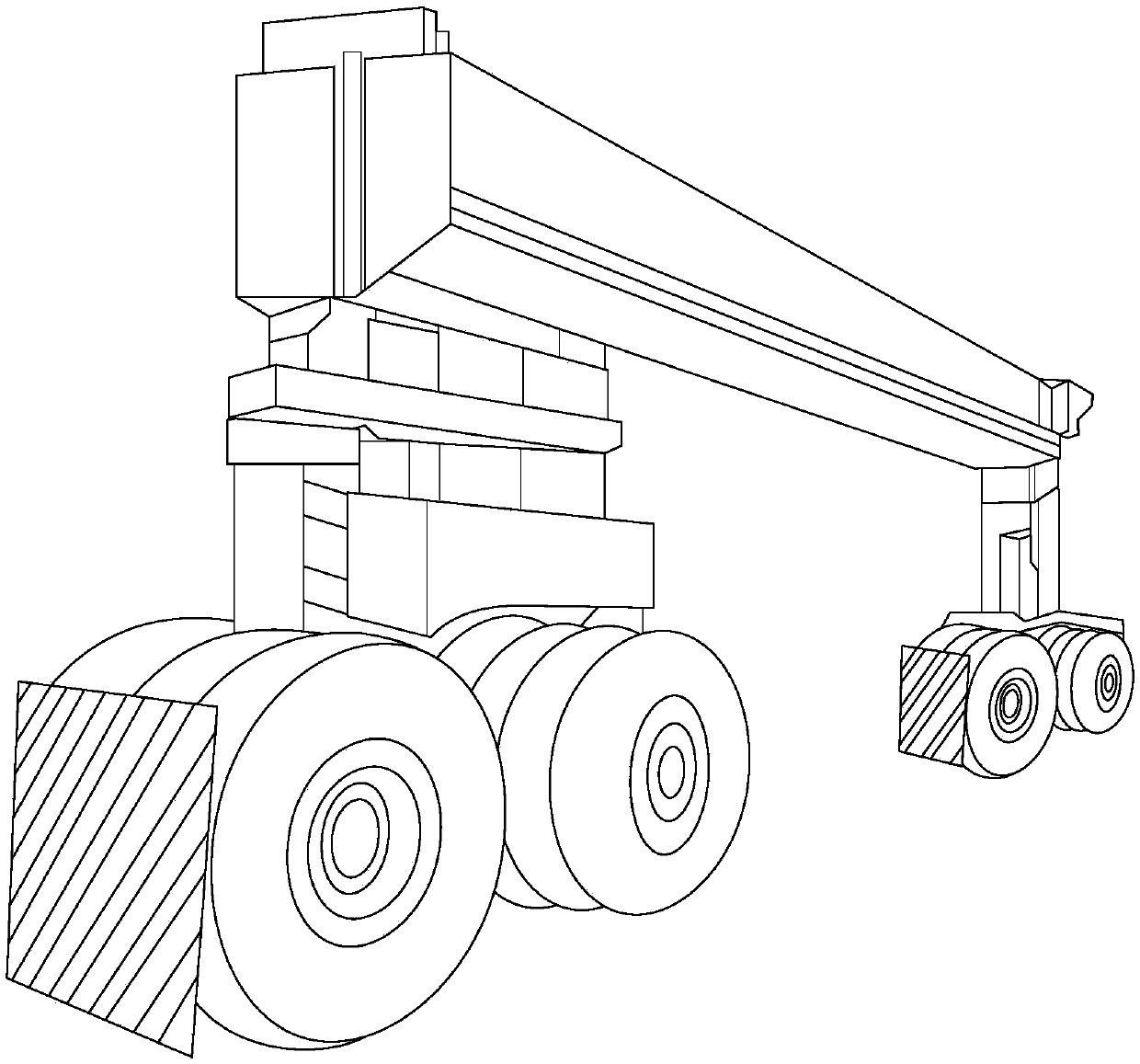

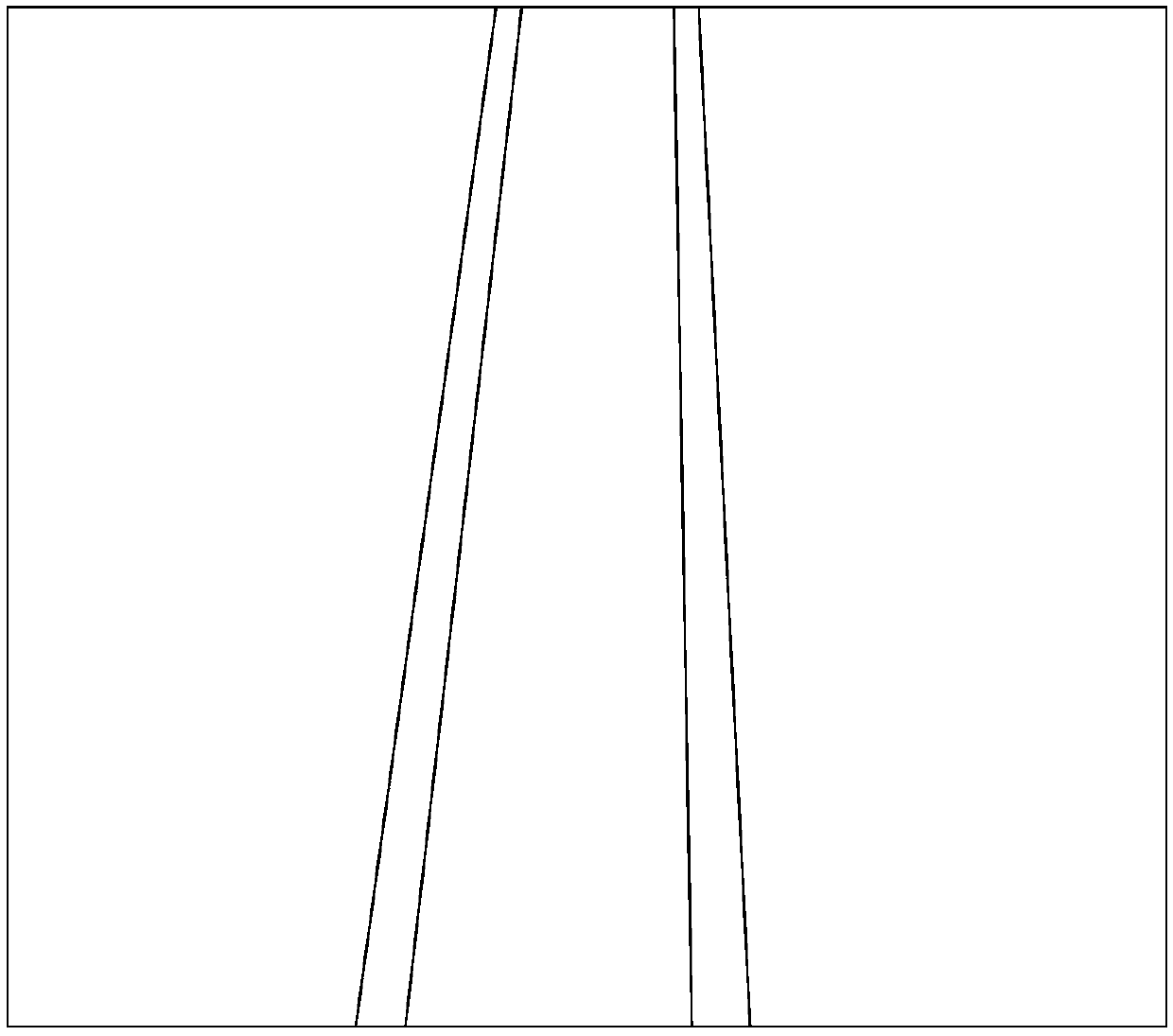

[0068] In order to realize the automatic deviation correction of the tire crane under the premise of reducing the cost, the present invention adopts a video image captured by a camera, and the video image is: when the tire crane travels along a traveling route with a guide ribbon, The image of the guide ribbon in the traveling area of the tire crane taken by the camera in the preset reference frame; image processing is performed on the video image to obtain the guide ribbon in the video image in the reference frame. Current position information in the viewfinder frame; compare the current position information with the reference position information of a reference guide ribbon in the reference viewfinder frame, and when the current position information is different from the reference pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com