Counter-flow flame test table capable of accurately adjusting burner nozzles

A flame test and burner technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of difficulty in ensuring accuracy, flame asymmetry, and time-consuming, and achieves high accuracy, easy operation, and simple adjustment methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

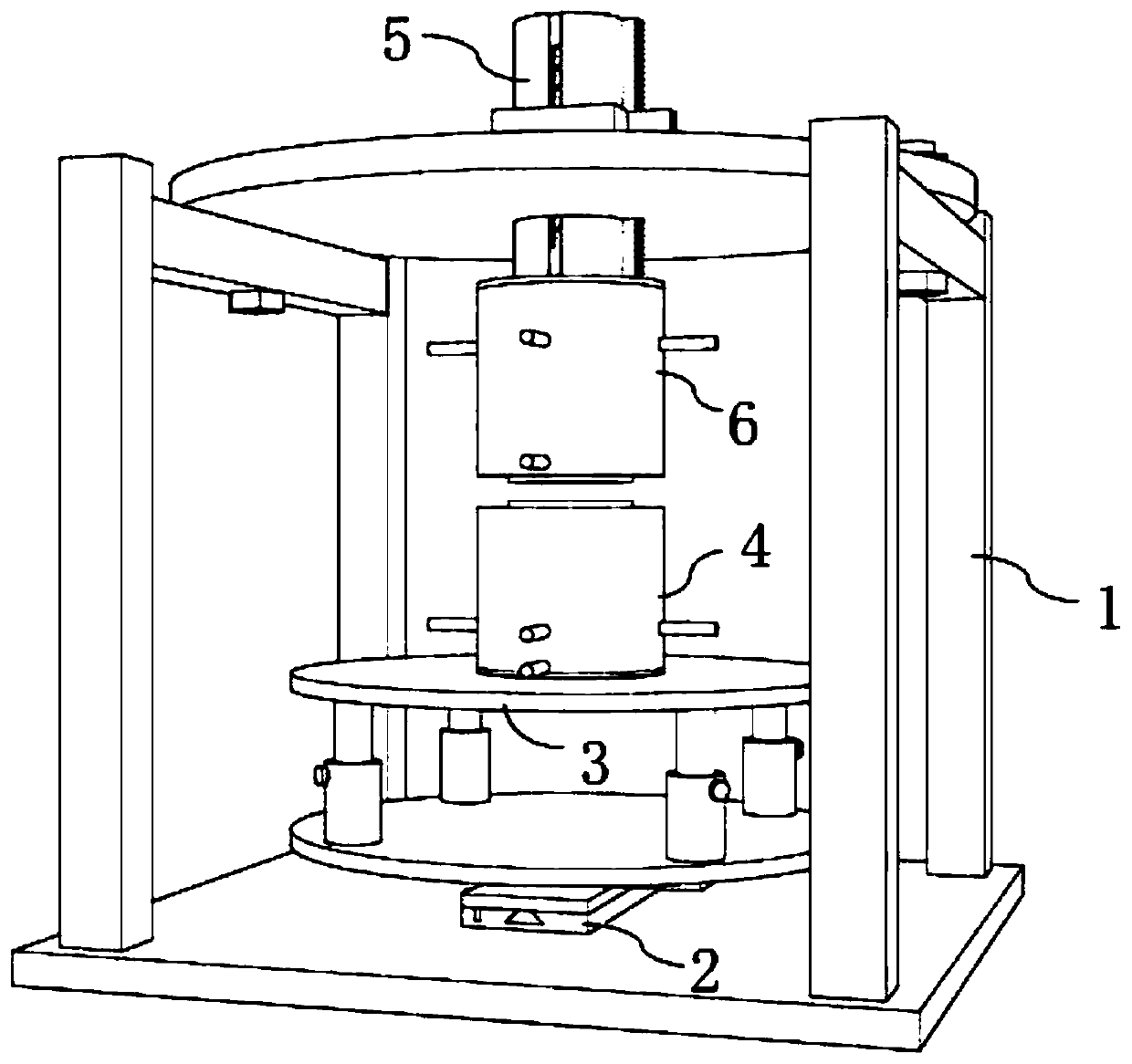

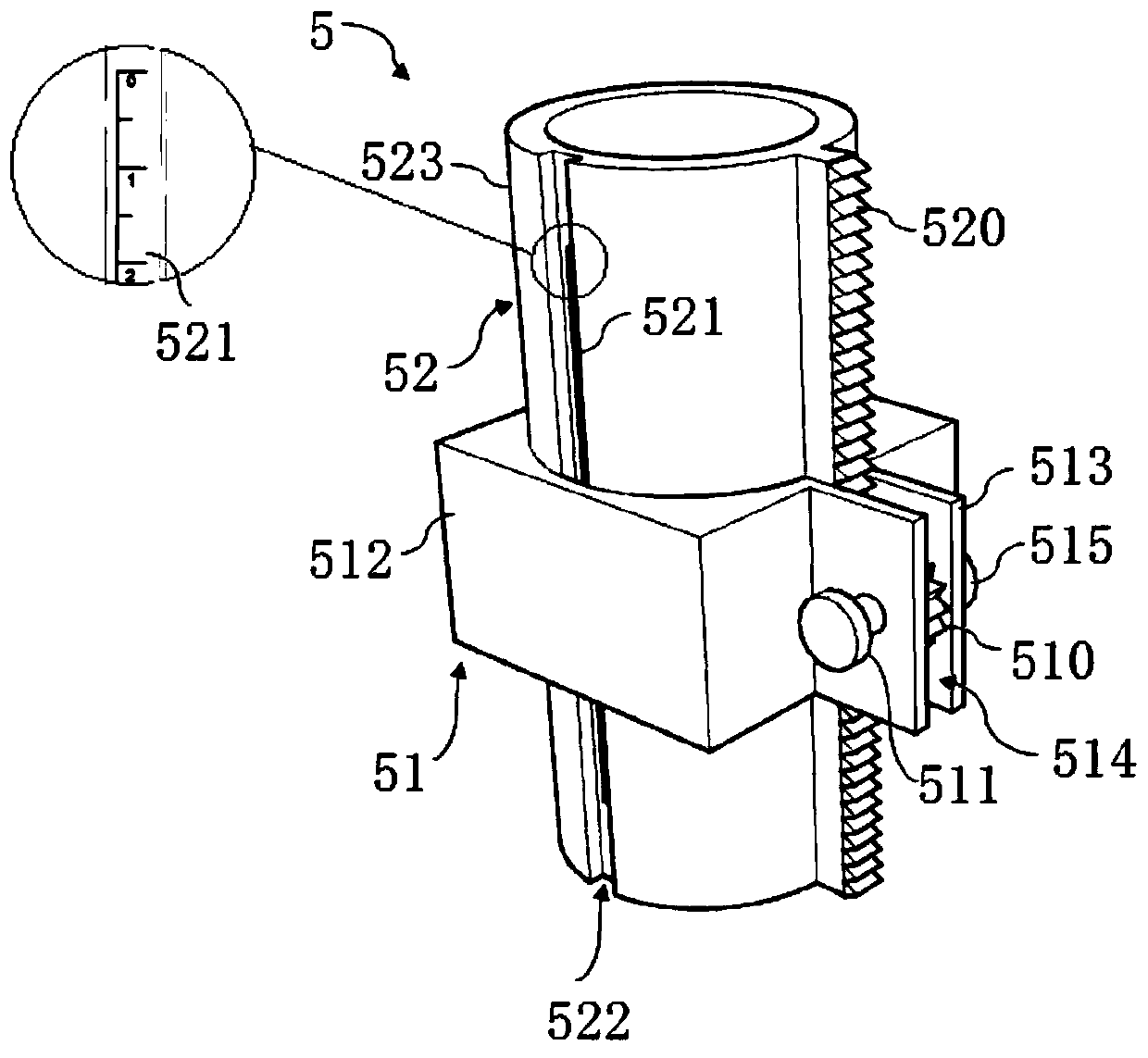

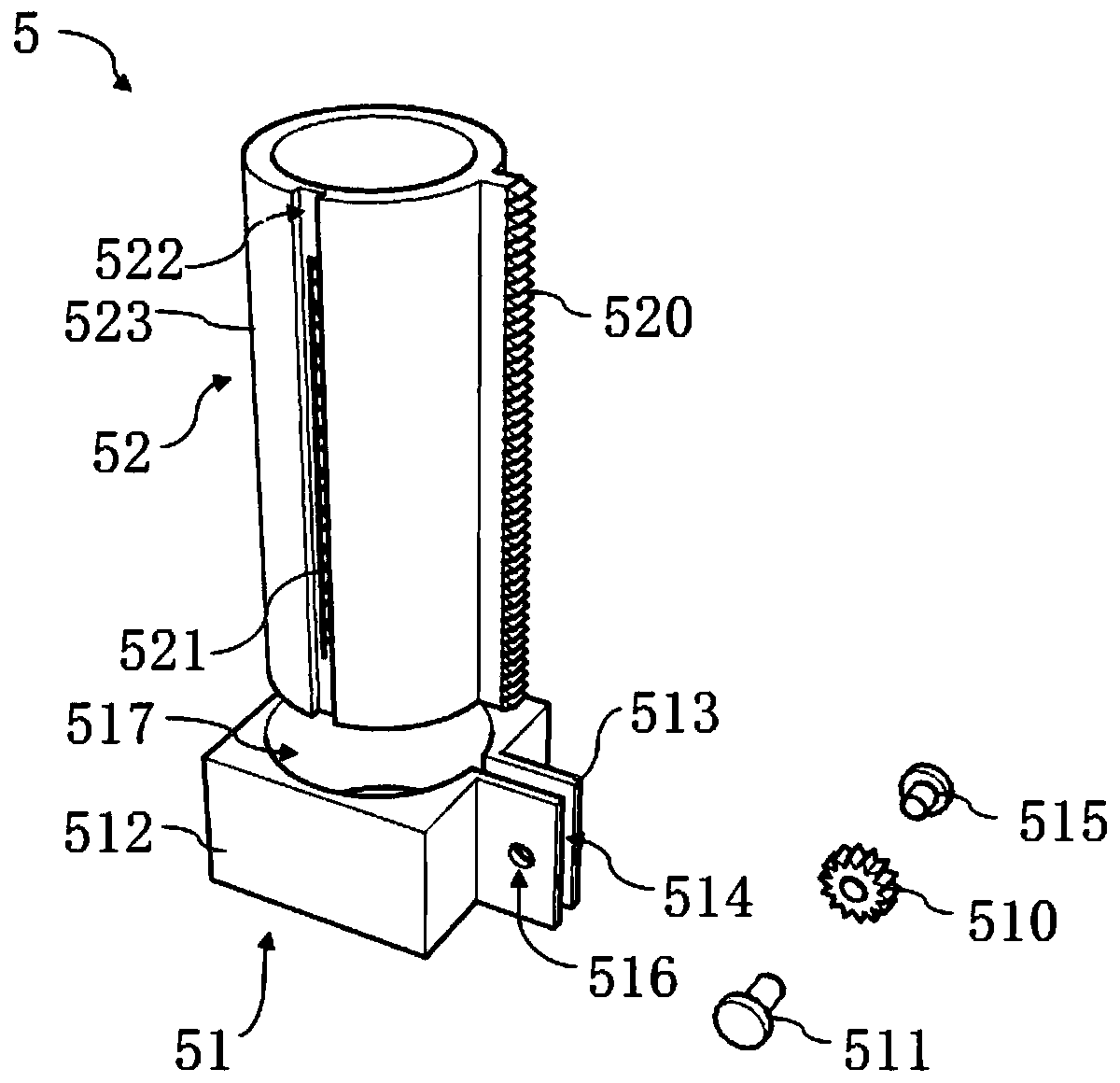

[0040] Such as figure 1 As shown, the flame test bench of the present invention includes an installation stand 1, a horizontal adjustment platform 2 arranged on the bottom plate of the installation stand 1, a lower burner support device 3 arranged on the horizontal adjustment platform 2, a set The lower opposite burner 4 on the lower burner supporting device 3, the upper burner adjustment device 5 passing through the top plate of the installation stand 1, and the upper opposite burner arranged at the lower end of the upper burner adjustment device 5 6. The nozzle of the lower counter burner 4 is opposite to the nozzle of the upper counter burner 6 .

[0041] Mounting stand 1 is mainly used for installing and fixing other components. Mounting stand 1 includes a base plate, a column arranged on the base plate, and a top plate arranged on the top of the column,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com