Reactor core measurement sensor based on self-powered detector and thermocouple

A technology of self-sufficient energy detectors and measurement sensors, applied in nuclear power generation, reactors, nuclear reactor monitoring, etc., can solve problems such as difficulty in checking the internal state of nuclear reactor vessels, errors in neutron flux and temperature measurement, difficulty in establishing accident handling decisions, etc. , to achieve the effect of solving the slow response and low precision of on-line measurement, increasing the efficiency of heat conduction, and realizing the effect of on-line accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

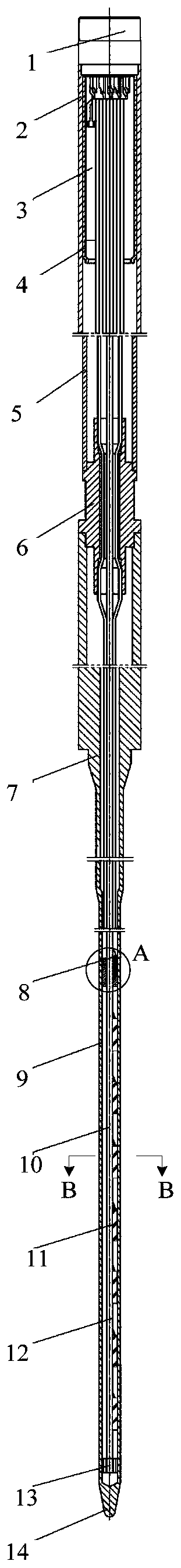

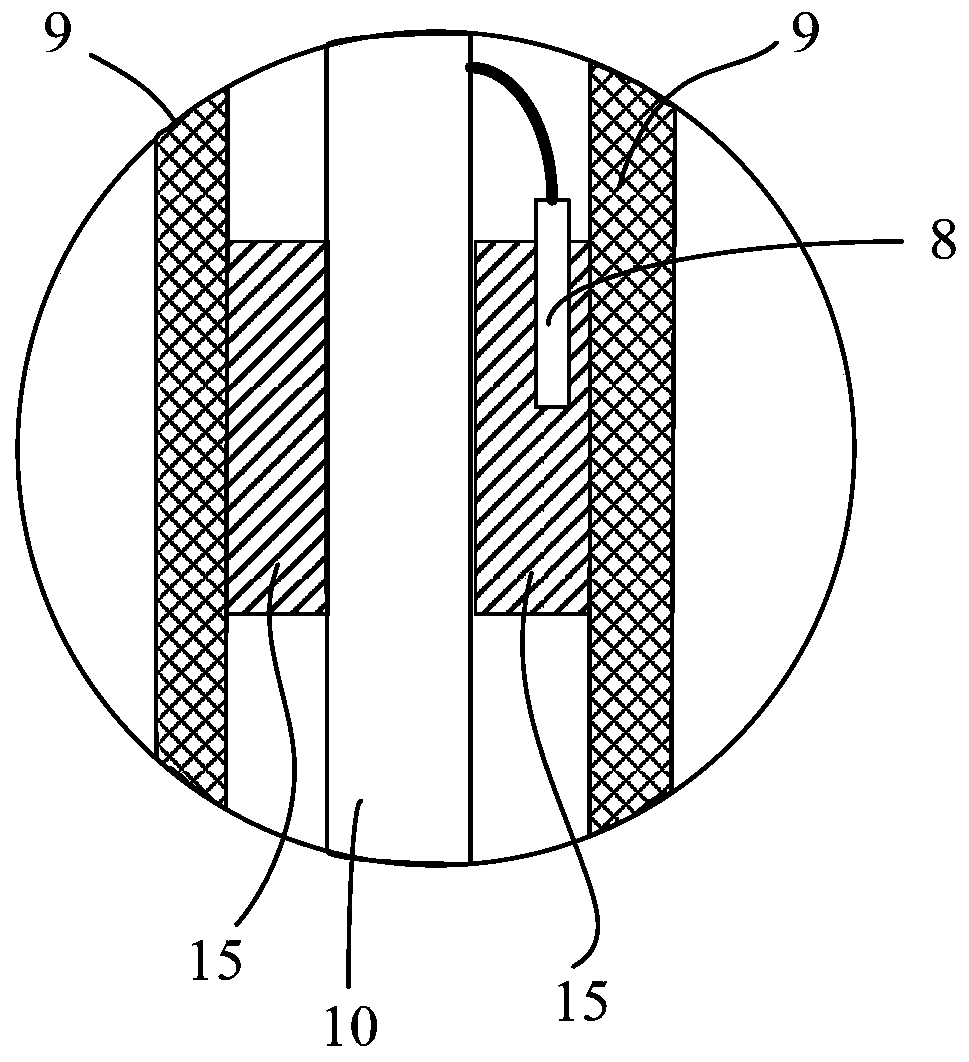

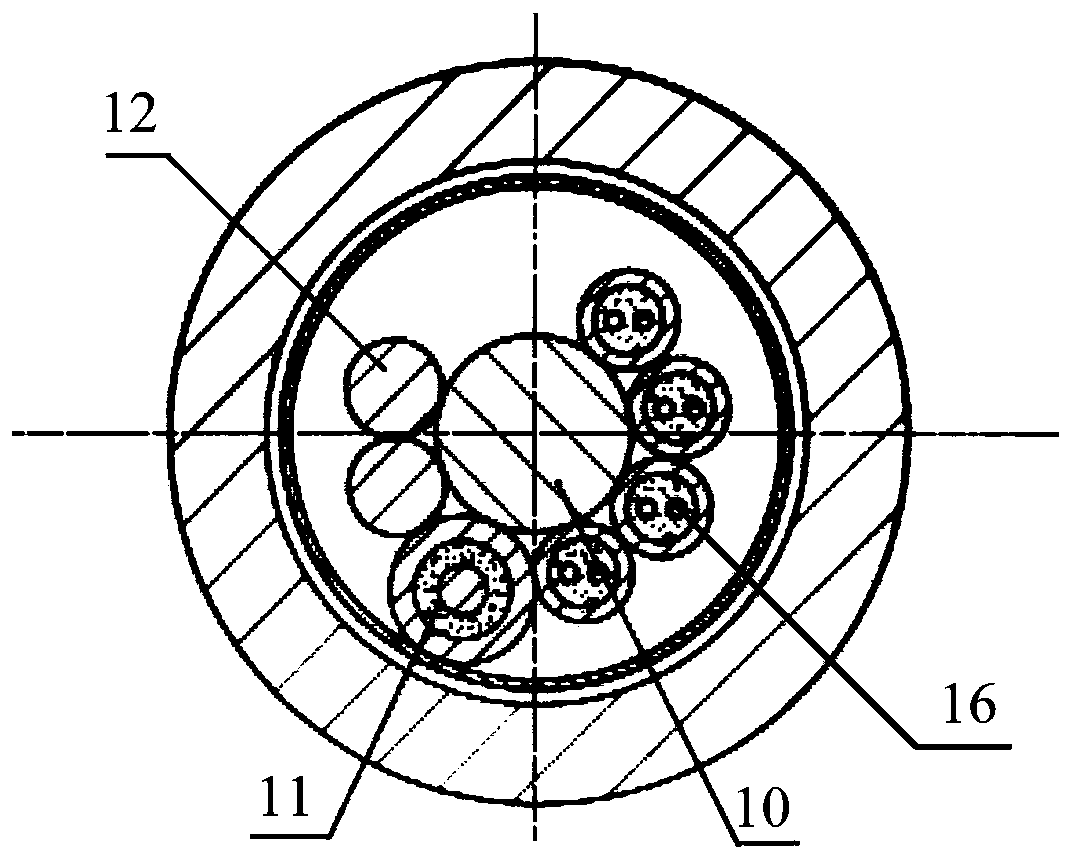

[0029] Attached below figure 1 as well as figure 2 The structure and principle of the present invention will be further described.

[0030] Such as figure 1 As shown, a schematic structural view of a core measurement sensor based on self-powered detectors and thermocouples provided by the present invention is shown; figure 2 shown. In this embodiment, the present invention provides a core measurement sensor based on self-powered detectors and thermocouples, which at least includes sequentially arranged connectors 1, transfer socket tube welding 2, transfer packaging tube 5, internal Sealing joint 6, component sealing shell 7, pressure-bearing shell 9, bottom fixing sleeve 13 and plug 14, wherein:

[0031] The pressure-bearing shell 9 is a tubular structure, one end of which is welded and fixed to the plug 14, and the other end is fixed to one end of the component sealing shell 7; and the internal sealing joint 6 is welded between the component sealing shell 7 and the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com