Novel duct piece steel structural framework and welding method thereof

A technology of steel structure and segment, applied in welding equipment, welding/welding/cutting items, earthwork drilling, etc., can solve the problems of difficult manual clamping, low welding efficiency, long welding time, etc., and reduce labor costs. The effect of increased labor, welding efficiency, and shortened welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

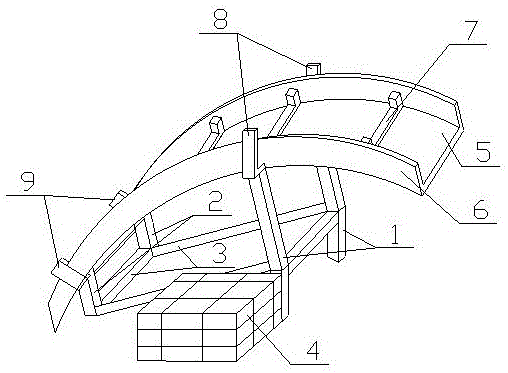

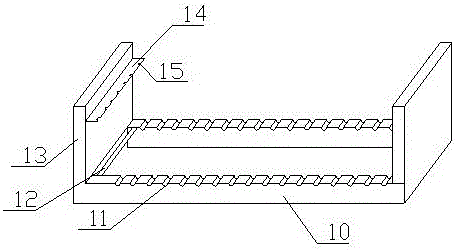

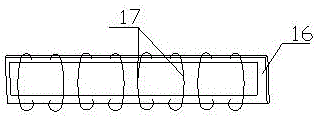

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 Shown: a new segment steel structure skeleton, including: transverse main ribs 22, longitudinal main ribs 23, welding points 24, grouting hole embedded parts 25, fixing hole embedded parts 26, characterized in that: the transverse The main ribs 22 are longitudinally arranged with longitudinal main ribs 23, and there are welding spots 24 at the intersections between each longitudinal main rib 23 and each transverse main rib 22. The skeleton network formed by the plurality of longitudinal main ribs 23 and the plurality of transverse main ribs 22 is There is a grouting hole embedded part 25 at the site, three sets of fixed hole embedded parts 26 are arranged symmetrically in the front and back of the skeleton net, and two sets of fixed hole embedded parts 26 are arranged symmetrically in the left and right sides. The longitudinal main reinforcement 23 includes square main reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com