Continuous feeder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

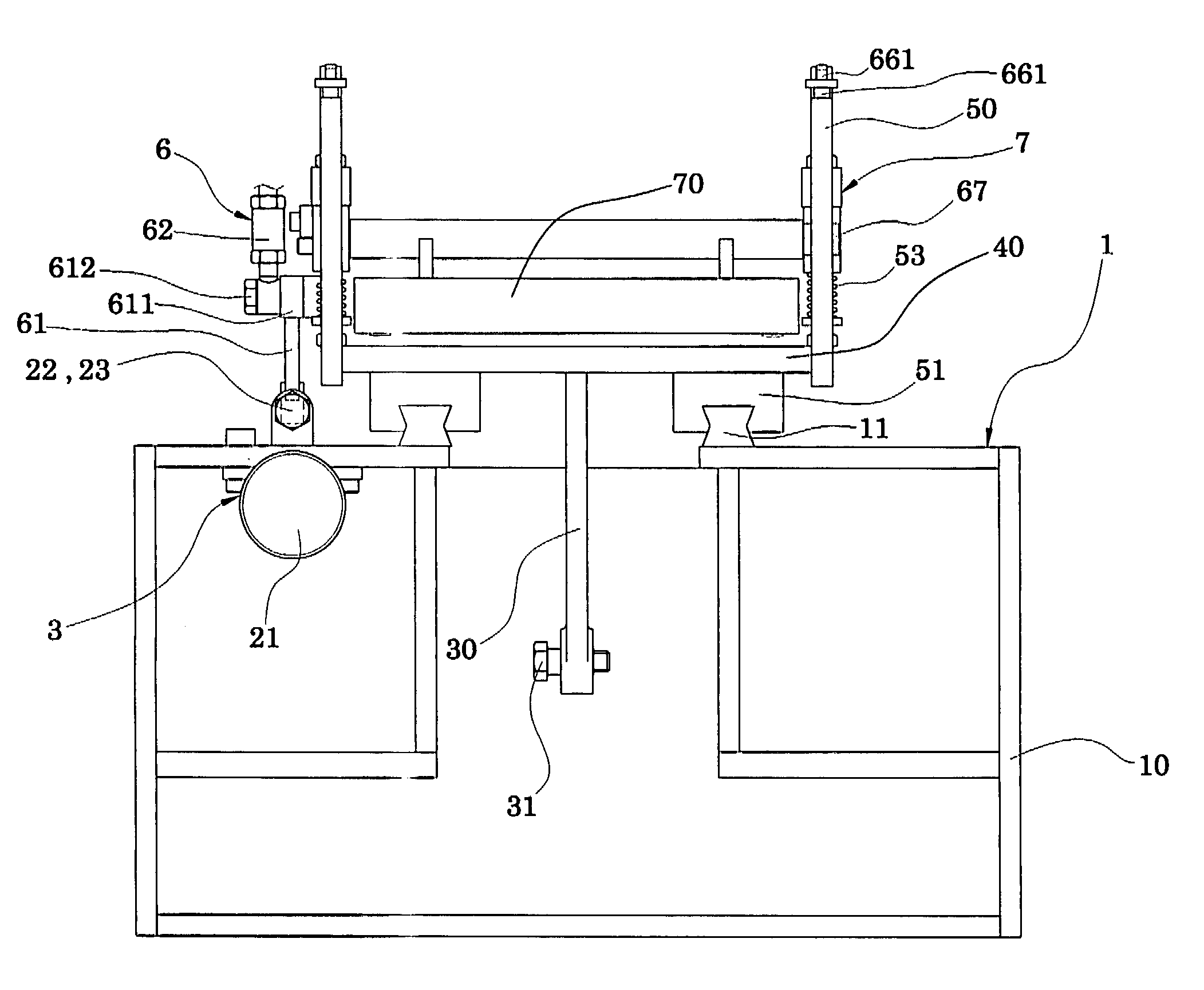

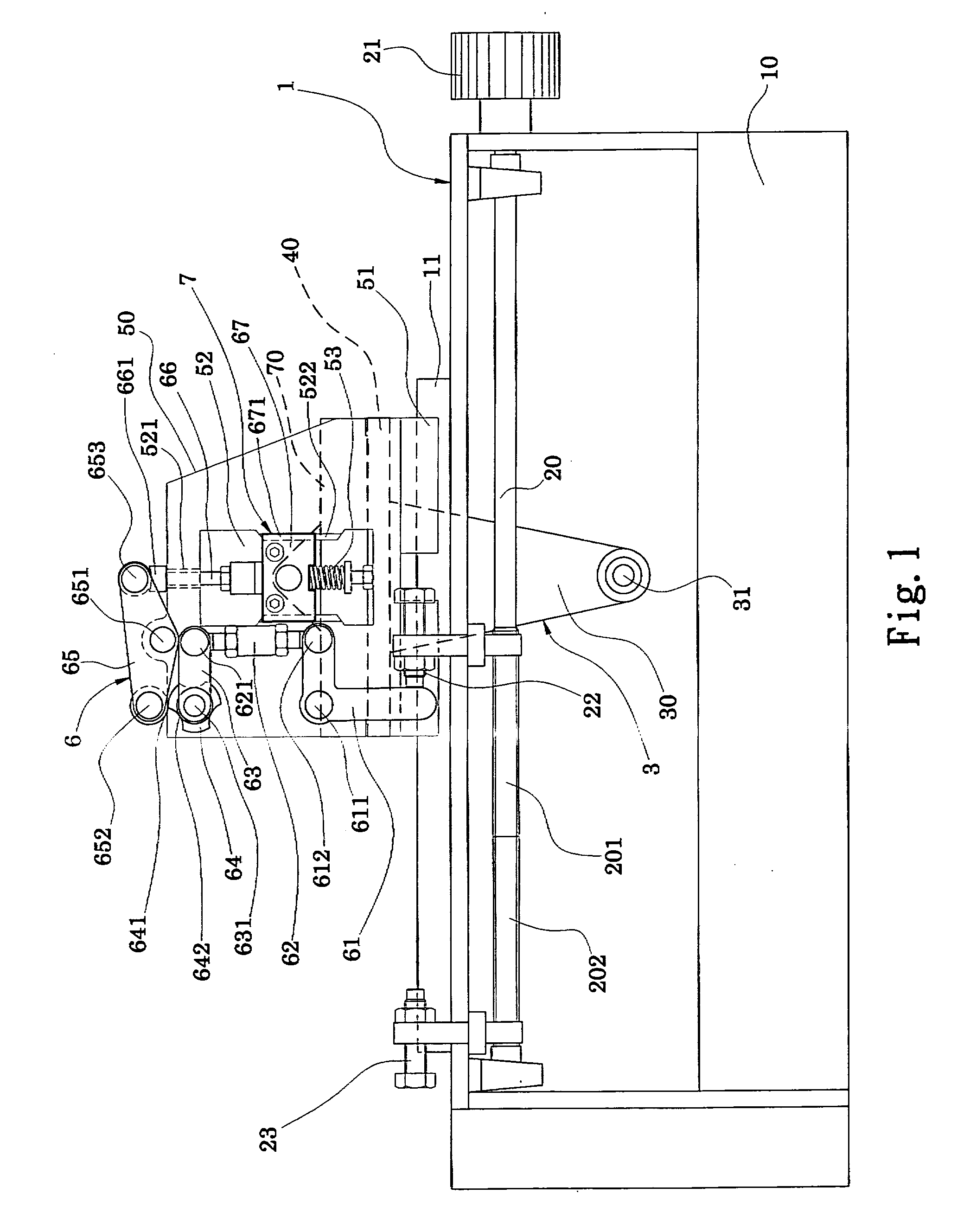

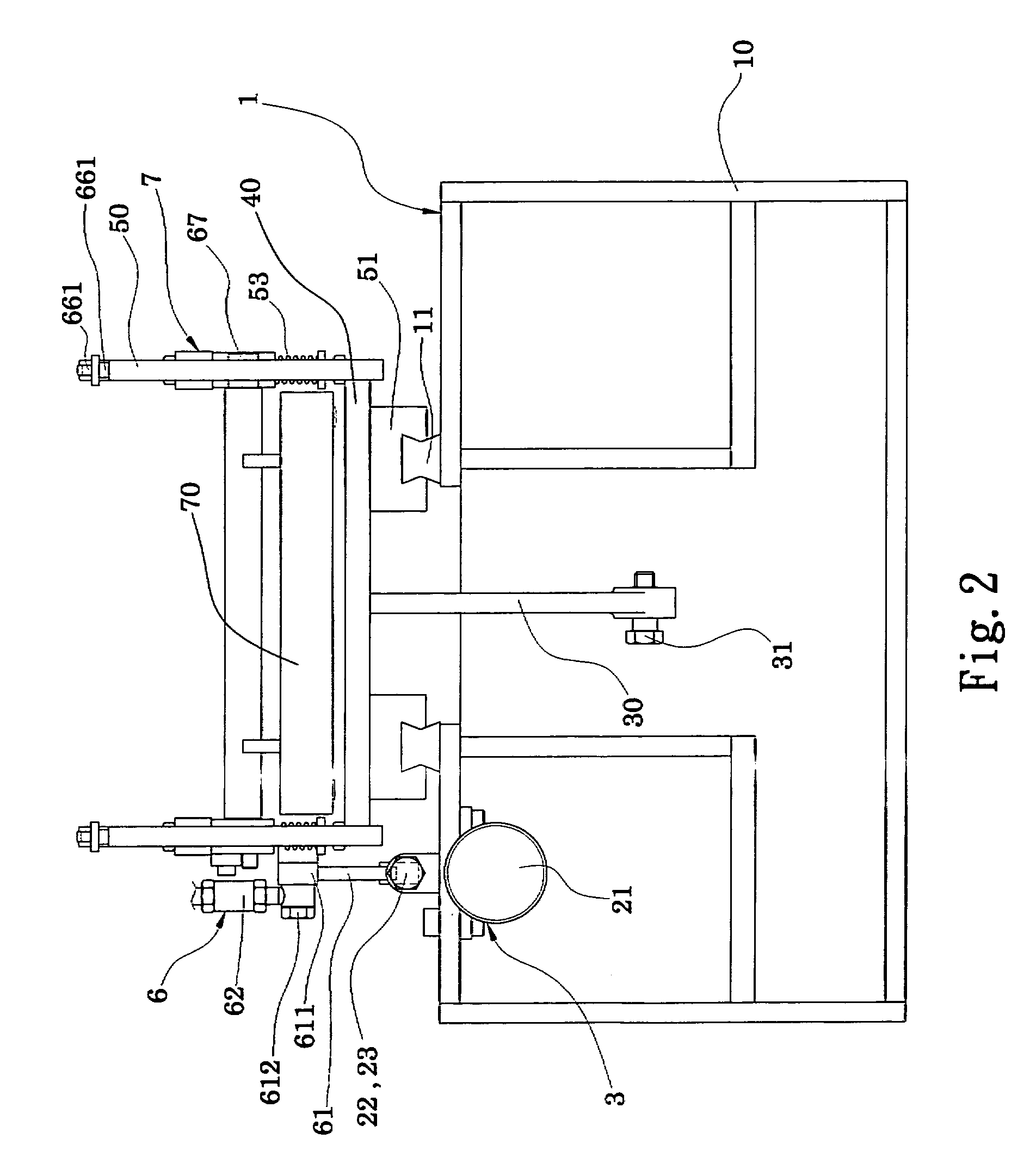

[0015]Please refer to FIGS. 1˜2, which are respectively a lateral view and a partial front view showing a continuous feeder according to the present invention, and FIGS. 3A˜3D, which are lateral views showing a first kind of operations of the continuous feeder in a first embodiment according to the present invention. As shown, the continuous feeder of the present invention includes a base 1, which has a seat 10 having an adjusting shaft 20 thereon with a sliding track 11 at the top of the shaft, wherein the adjusting shaft 20 has a reverse thread region 201 and an obverse thread region 202 which respectively have, mounted thereon, a push-forward rejecting element 22 and a push-backward rejecting element 23 overhead the seat 10, so that through turning an adjusting knob 21 at the front end of the adjusting shaft 20, the push-forward rejecting element 22 and the push-backward rejecting element 23 can reversely move synchronously; a moving unit 3, which has a driving seat 30 having a p...

second embodiment

[0020]Please refer to FIG. 6, which is a lateral view showing the continuous feeder in a second embodiment according to the present invention. As shown, the difference between FIG. 6 and the previous figures is that, between the cam disc 80 and the motor 90, a belt 803 can be used for connection and driving.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com