X-ray focus lens vertical installation and adjustment system and method

A focusing mirror and X-ray technology, applied in the field of X-ray optics, can solve the problems of surface error, low installation and adjustment accuracy, and failure to meet X-ray optics, etc., to achieve the effect of reducing installation and adjustment errors and improving installation and adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

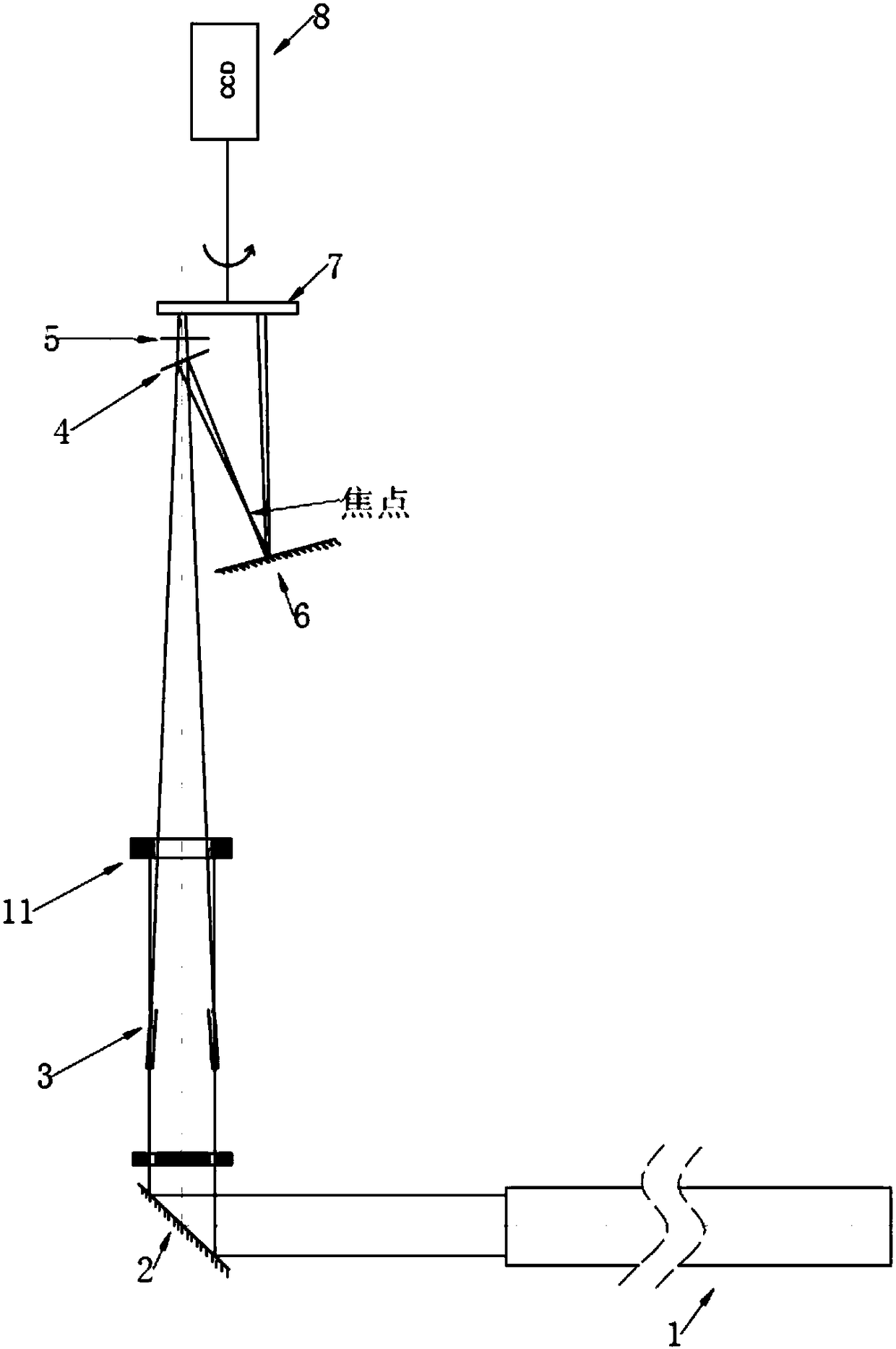

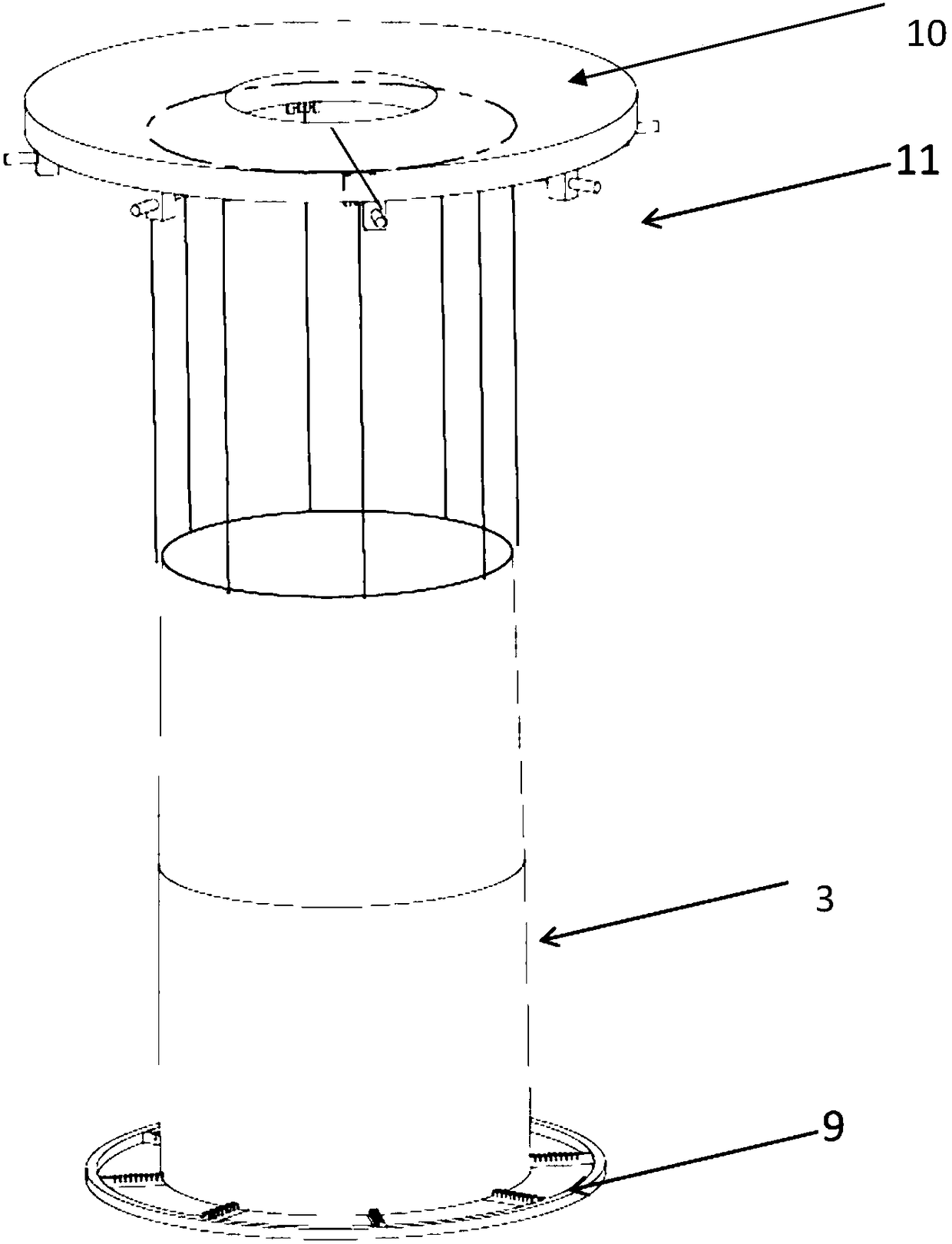

[0029] Such as figure 1 As shown, the X-ray focusing mirror vertical adjustment system of the present invention includes a collimator 1, a plane mirror 2, a fixing seat 9, a focusing mirror adjustment system 11, a half mirror 4, a corrector 5, a mirror 6, Receiving screen 7, CCD camera 8 and computer; collimator 1 is placed horizontally on the operating table, the horizontal parallel light emitted by collimator 1 is converted into vertical parallel light by plane reflector 2, collimator 1 is the whole installation and adjustment system Provide a vertical light source for adjustment; the high-precision flat reflector 2 is placed on the left side of the collimator 1 and below the focusing mirror adjustment system 11, and its surface accuracy has a significant impact on the adjustment result, so its surface shape must be guaranteed accuracy to obtain better adjustment results, while meeting the requirements of the vertical adjustment system; the half-transparent mirror 4 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com