Device and method for centering assembling adjustment of large-calibre aspheric-surface reflector

A technology of plane mirrors and mirrors, which is applied in installation, optics, instruments, etc., can solve the problems of spot receiving angle, limited dial indicator measurement accuracy, and difficulty in erection, so as to improve the accuracy of measurement and installation and reduce the Adjustment and technical risk, and the effect of expanding the applicable scope of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Describe the present invention below in conjunction with specific embodiment:

[0040] In view of the problems existing in the existing centering and adjusting technology of large-diameter aspheric mirrors, in order to realize the centering and adjusting of aspheric mirrors, this embodiment provides a device with reasonable structure and easy operation, and a high-speed Accurate, efficient method.

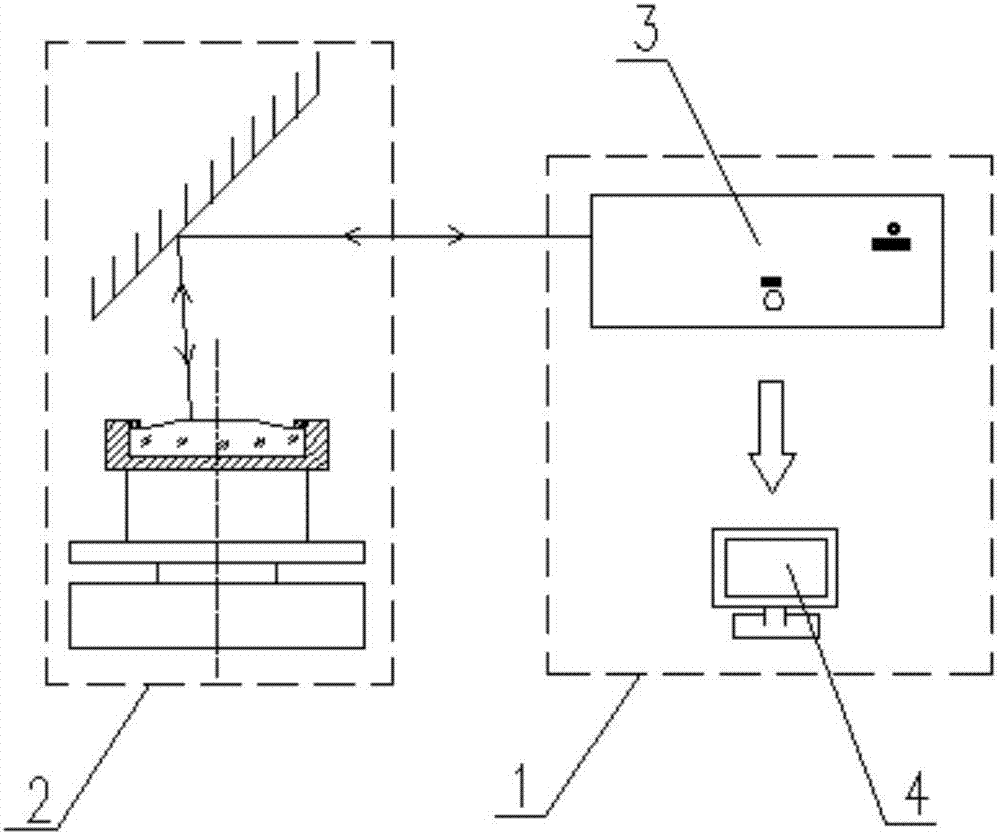

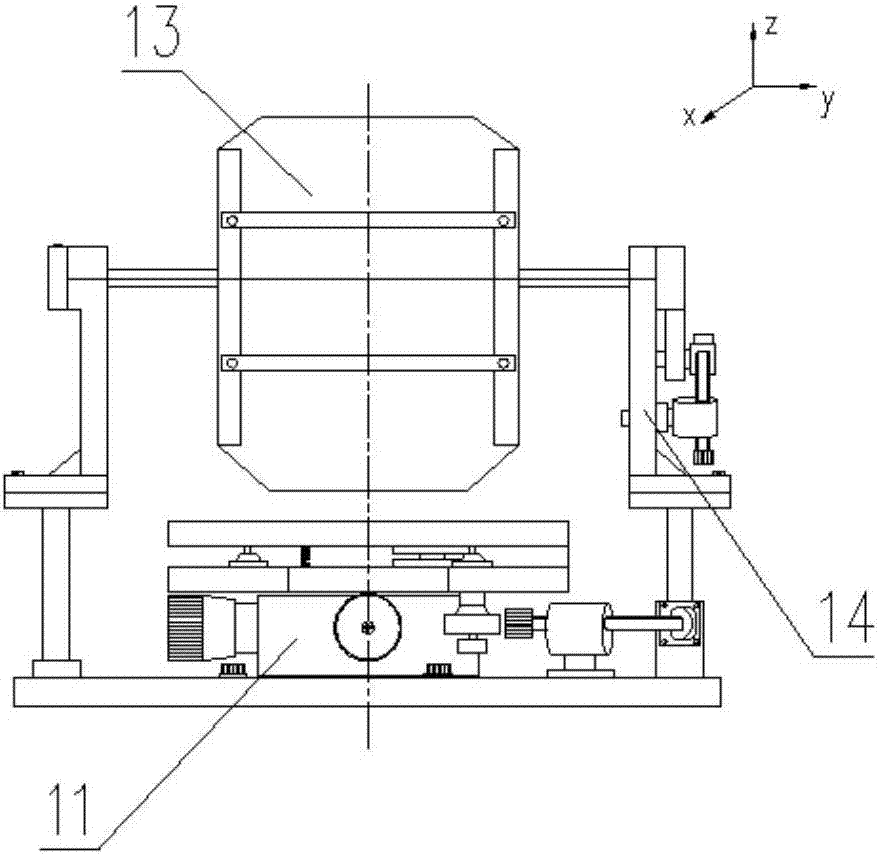

[0041] Such as figure 1 As shown, the aspheric mirror centering and adjusting device is composed of an eccentricity measurement system 1 and a rotary adjustment mechanism 2 .

[0042]The eccentricity measurement system 1 includes a laser emitting and receiving subsystem 3, an image display and processing subsystem 4;

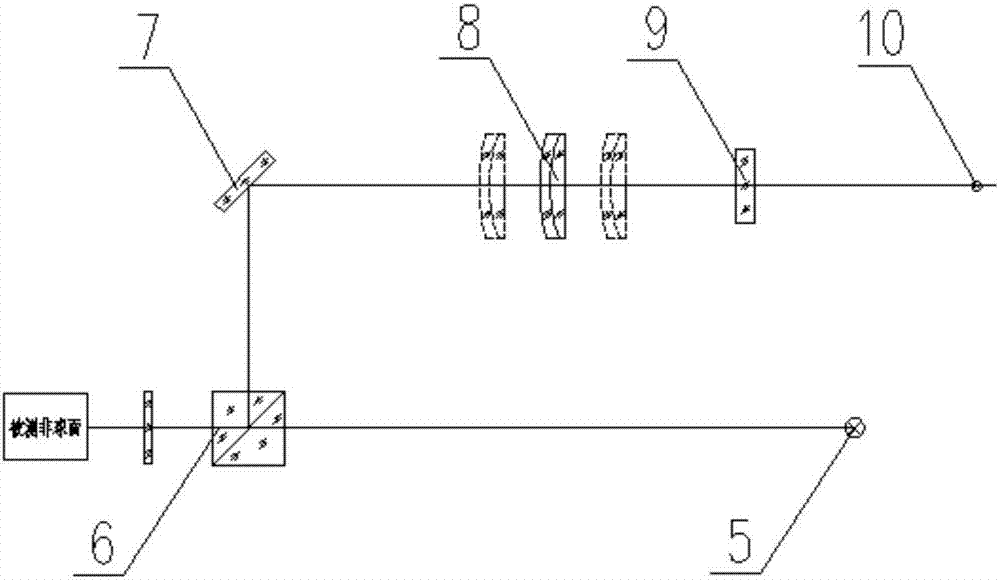

[0043] The laser emitting and receiving sub-system 3 includes a red light semiconductor laser 5, a beam splitting cube 6, a reflector 7, an adjustable laser receiving objective lens 8, an attenuation sheet 9 and a CCD10; Optical axis parallel difference is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com